Deep hole machining process

A processing technology and deep hole technology, applied in metal processing equipment, manufacturing tools, hole reaming devices, etc., can solve the problems of difficult to guarantee processing accuracy, difficult to control actual operation, low processing efficiency, etc., and achieve high processing quality and processing quality. Easy control and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

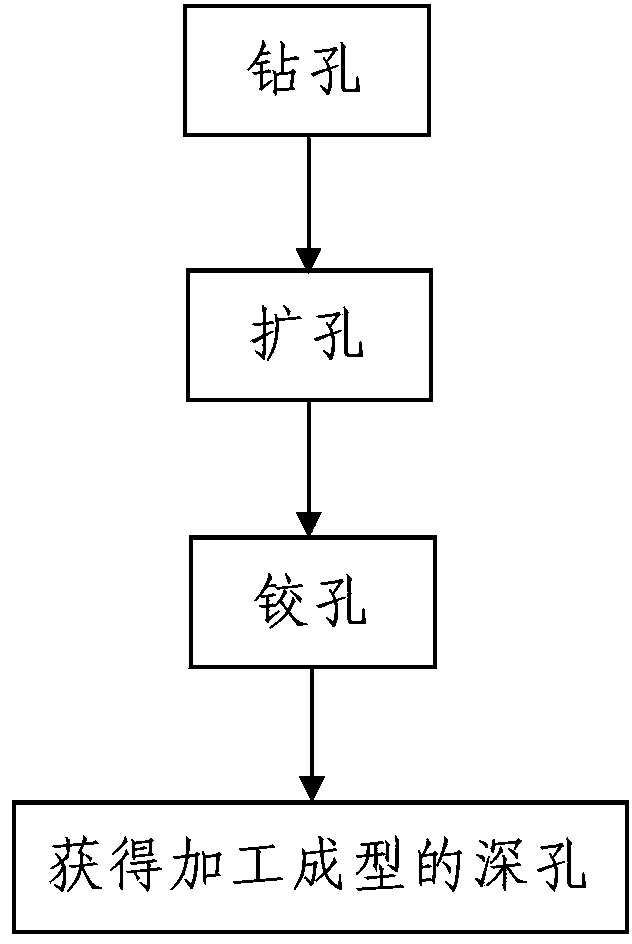

[0042] like figure 1 In the shown deep hole processing technology, the deep hole to be processed is located under one side of the processed part set on the product to be processed, and the distance between the upper end surface of the deep hole to be processed and the upper end surface of the processed part is H1 and the distance between the bottom of the hole and the upper surface of the machined part is H2, the diameter of the deep hole to be processed is Φd, and the processing depth of the deep hole to be processed is ΔH=H2-H1, and the hole to be processed is The distance between the center line and the outer wall of the processed part is H3, wherein H1>500mm, H2>600mm, H3≤50mm, d<2×H3, and the process includes the following steps:

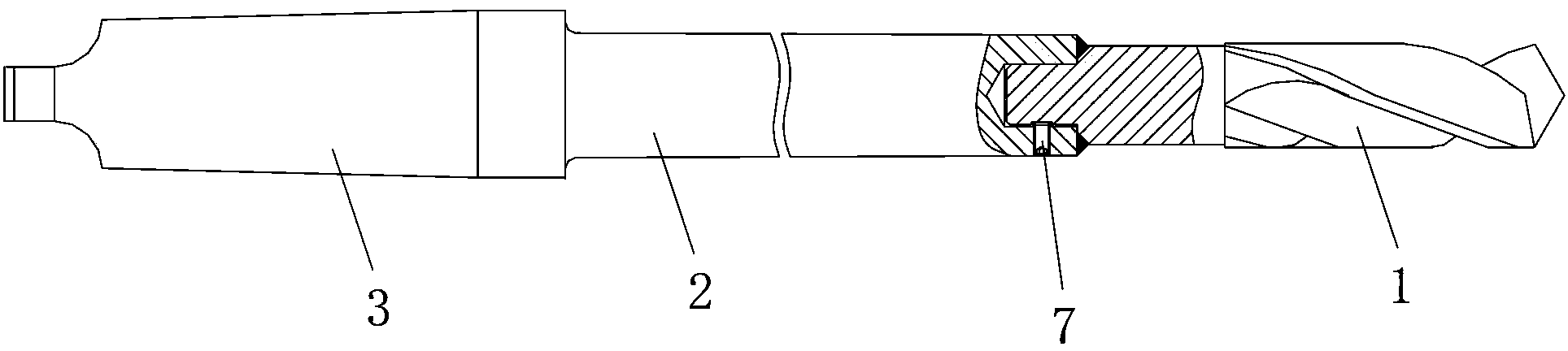

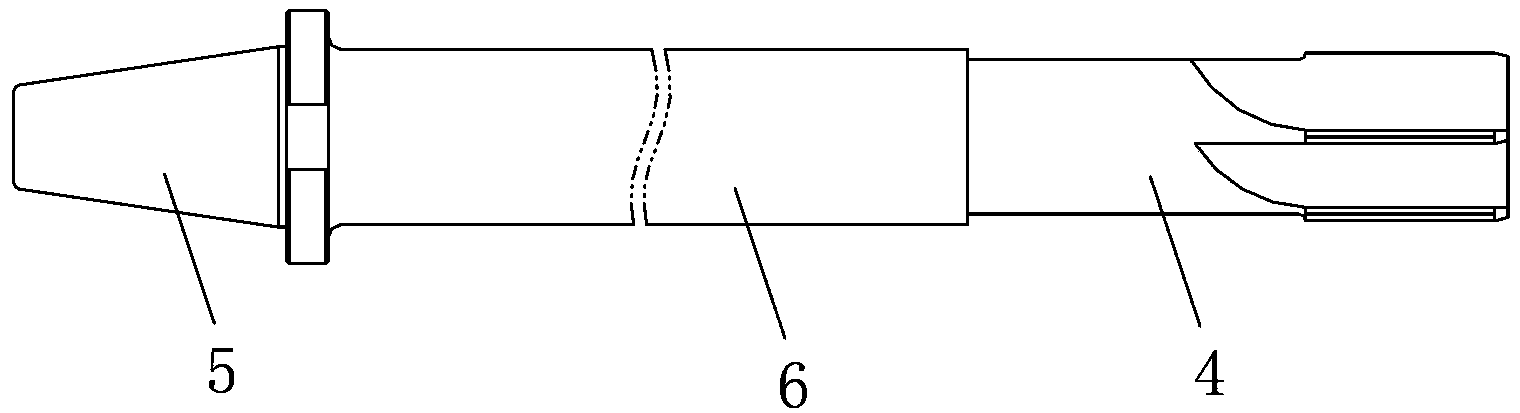

[0043] Step 1. Drilling: The deep hole to be processed is processed on a CNC machine tool with a rod drill bit, and a drilled hole with a diameter of Φd1 is obtained. During actual processing, the cutting depth of the adapter drill bit is ΔH. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com