Dry-type cable terminal

A cable termination, dry technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

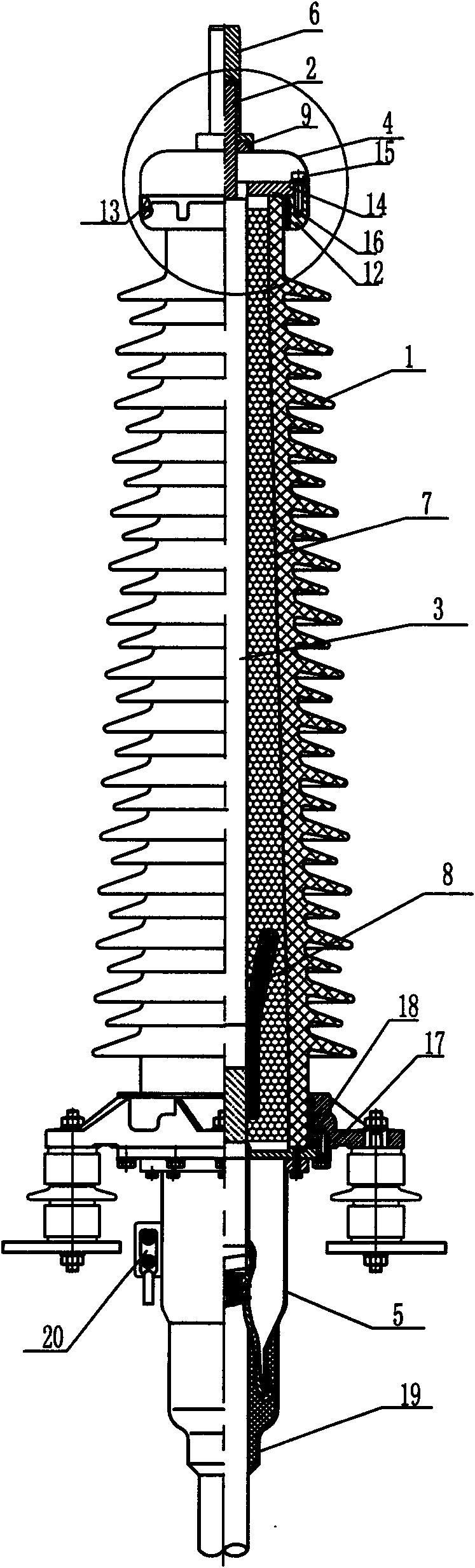

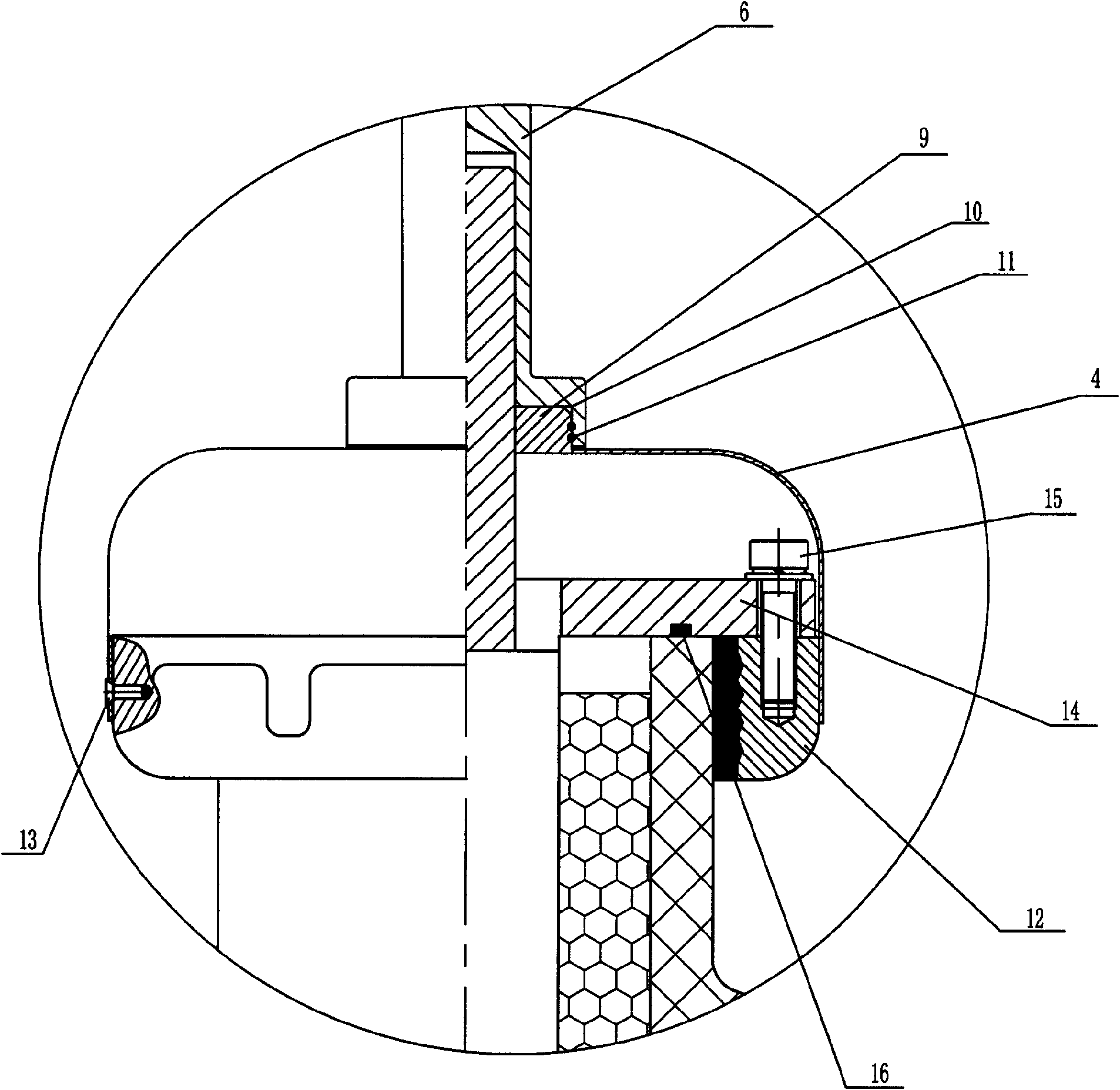

[0026] Such as figure 1 and figure 2As shown, a dry-type cable terminal of this embodiment, a dry-type cable terminal, includes an insulating sleeve 1 having an inner cavity 3 for the core wire 2 to pass through; it is arranged at the bottom of the insulating sleeve 1 The tail pipe 5 at the mouth of the nozzle for the core wire 2 to be inserted, the tail pipe 5 has a lower perforation for the core wire 2 to extend into the inner cavity 3; it is arranged on the top of the insulating sleeve 1 The shielding sealing cover 4 at the mouth of the tube for the core wire 2 to protrude from, the shielding sealing cover 4 is formed with an upper perforation for the core wire 2 to pass through the shielding sealing cover; and is arranged on the shielding sealing cover 4 On the sealing cover 4, the conductive rod 6 electrically connected to the end of the core wire 2 passing through the shielding sealing cover 4 is cylindrically formed on the inner wall of the insulating sleeve 1, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com