Equal-diameter dust cover mould machining method

A mold processing and dust cover technology, which is applied in the field of auto parts processing, can solve the problems of deceleration of contour processing machine tools, unbalanced allowance, and decline in product quality, so as to reduce tool marks, reduce sanding difficulty, The effect of uniform machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

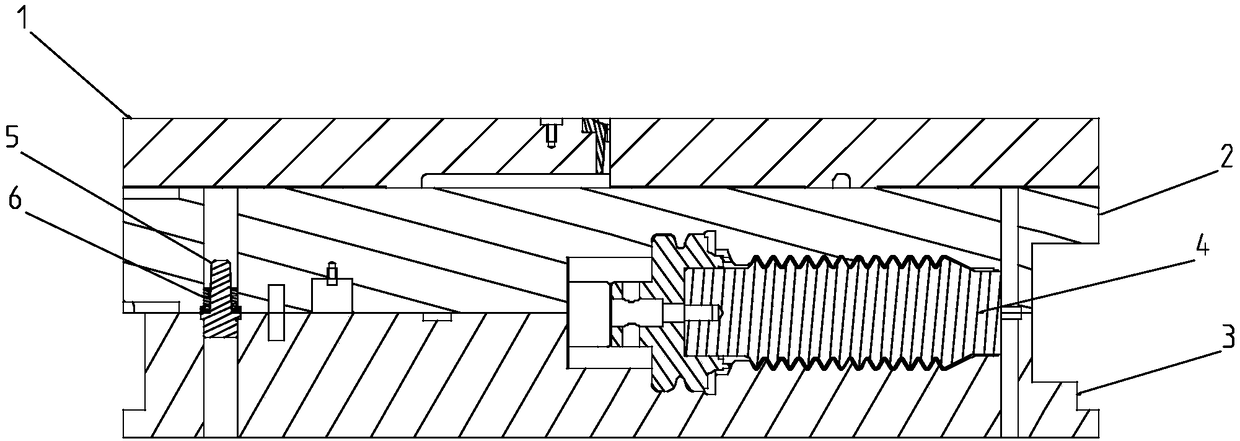

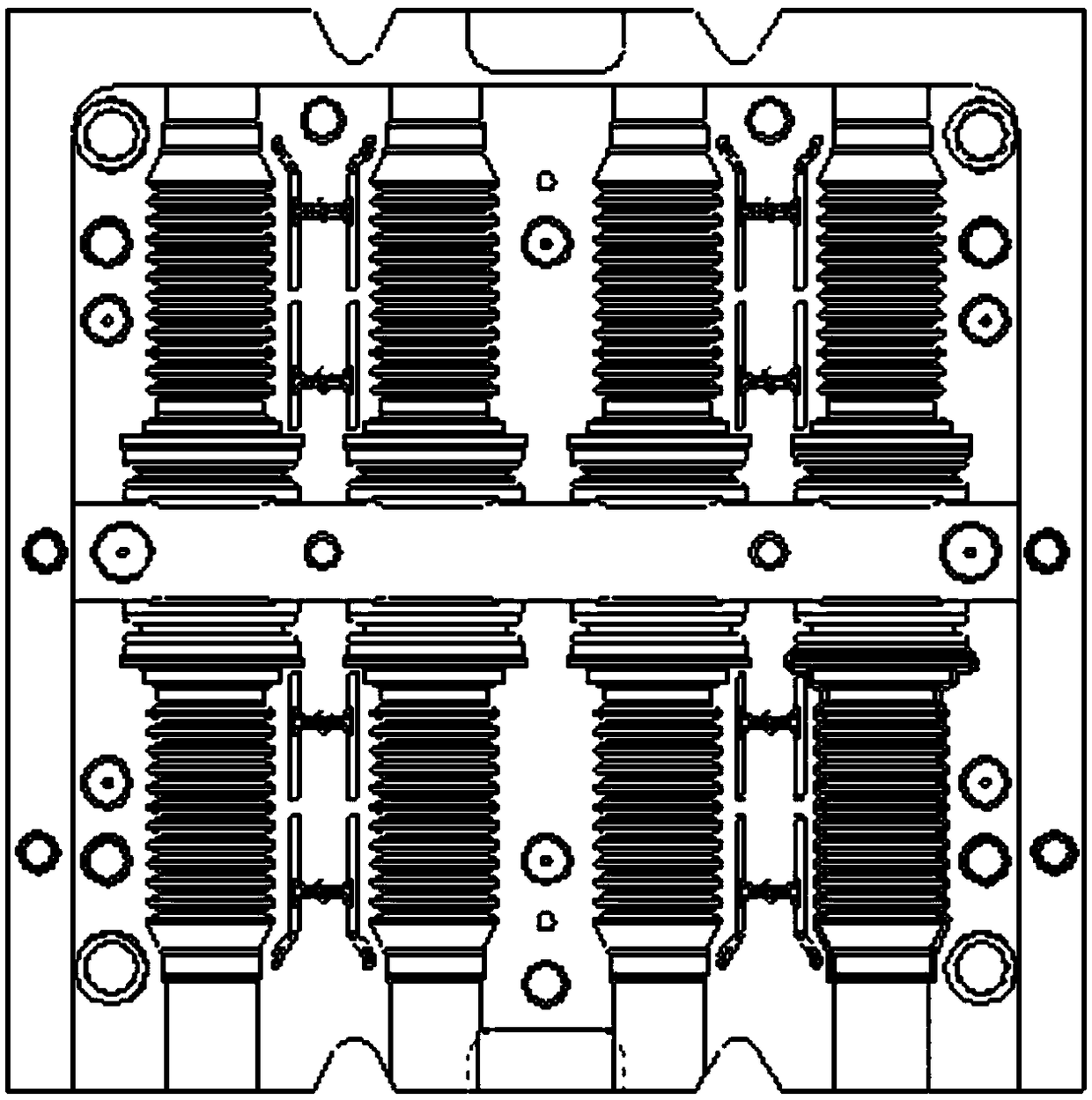

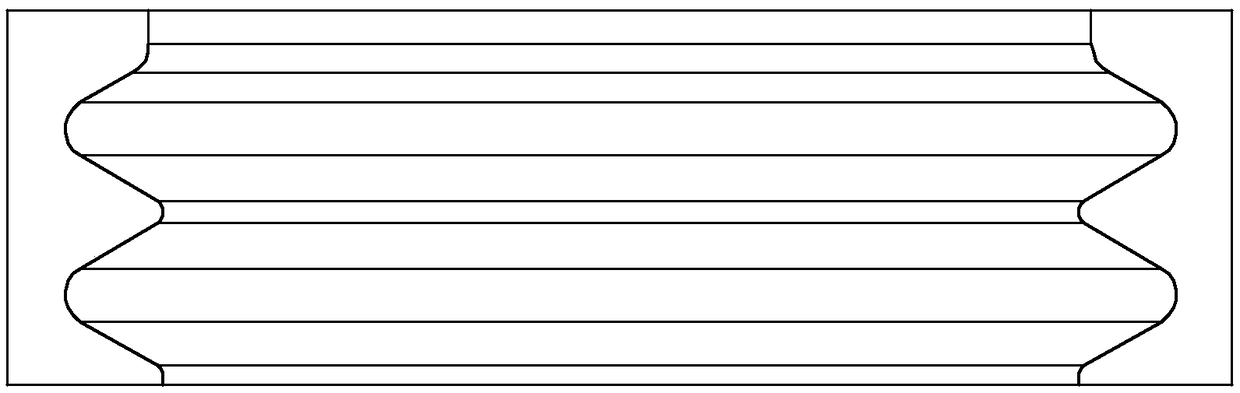

[0022] refer to figure 1 , a kind of equal-diameter dust cover mold processing method proposed by the present invention, the mold includes a runner plate 1, an upper mold 2, a lower mold 3 and a mold core 4. The upper mold 2 and the lower mold 3 are respectively provided with an upper cavity and a lower cavity whose inner wall is a corrugated surface. When the upper mold 2 and the lower mold 3 are closed, the upper cavity and the lower cavity cooperate to form a cavity A0 matching the mold core 4. . The runner plate 1 covers the upper mold 2, and the runner plate 1 is provided with a runner communicating with the cavity A0. Specifically, the outer surface of the mold core 4 is a corrugated surface. During the production process, after the mold core 4 is installed on the lower mold 3, the upper mold 2 and the lower mold 3 are molded together, and then the runner plate 1 is installed, and then the mold core 4 passes through the runner plate. 1 Inject liquid material into the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com