Machining method for sealing tape of valve seat ring of cylinder cover

A valve seat ring and processing method technology, which is applied in the field of diesel engines, can solve the problems of uneven allowance, difficult control, and influence on the performance of diesel engines, and achieves the effects of uniform processing allowance and satisfactory coaxiality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

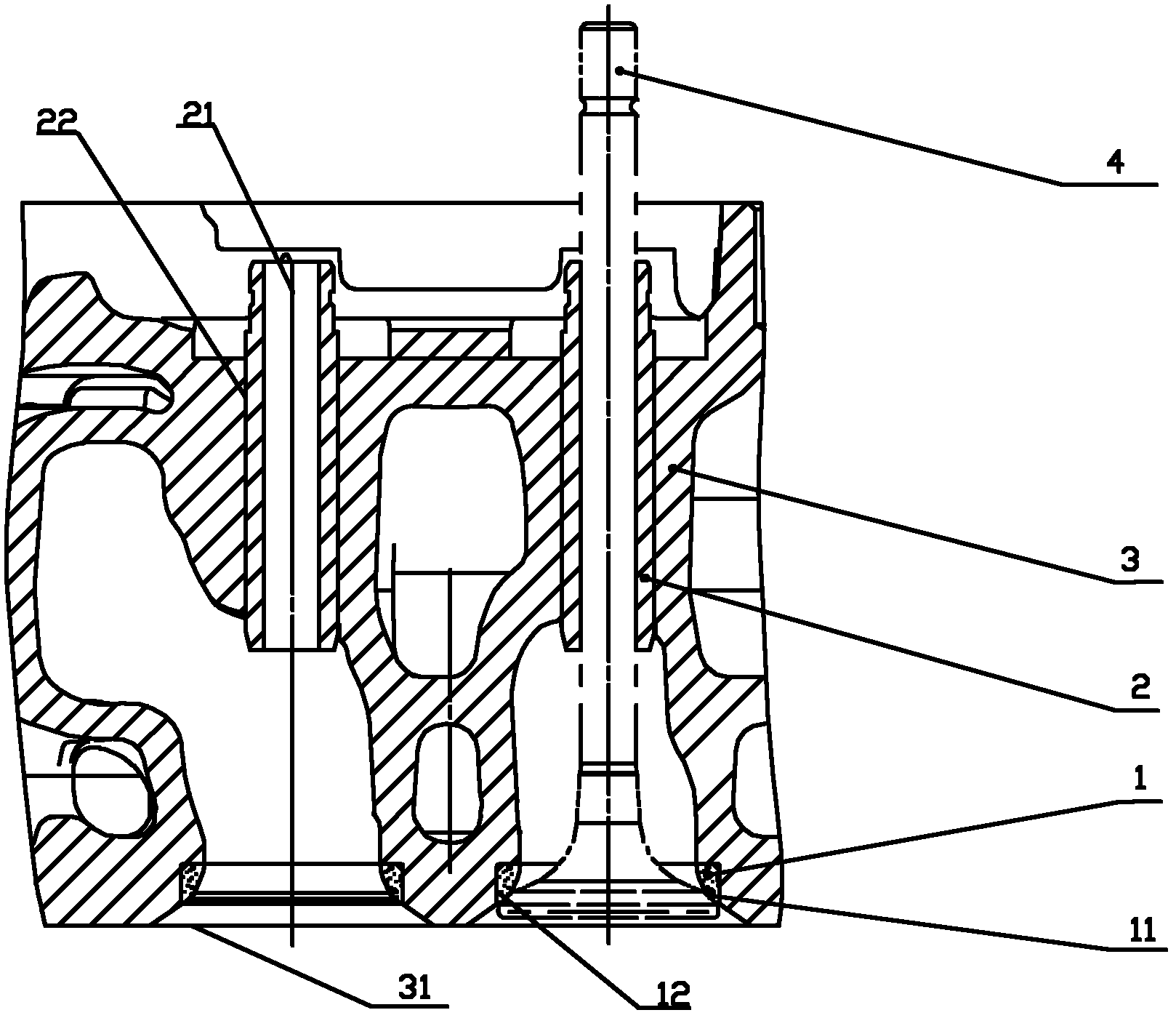

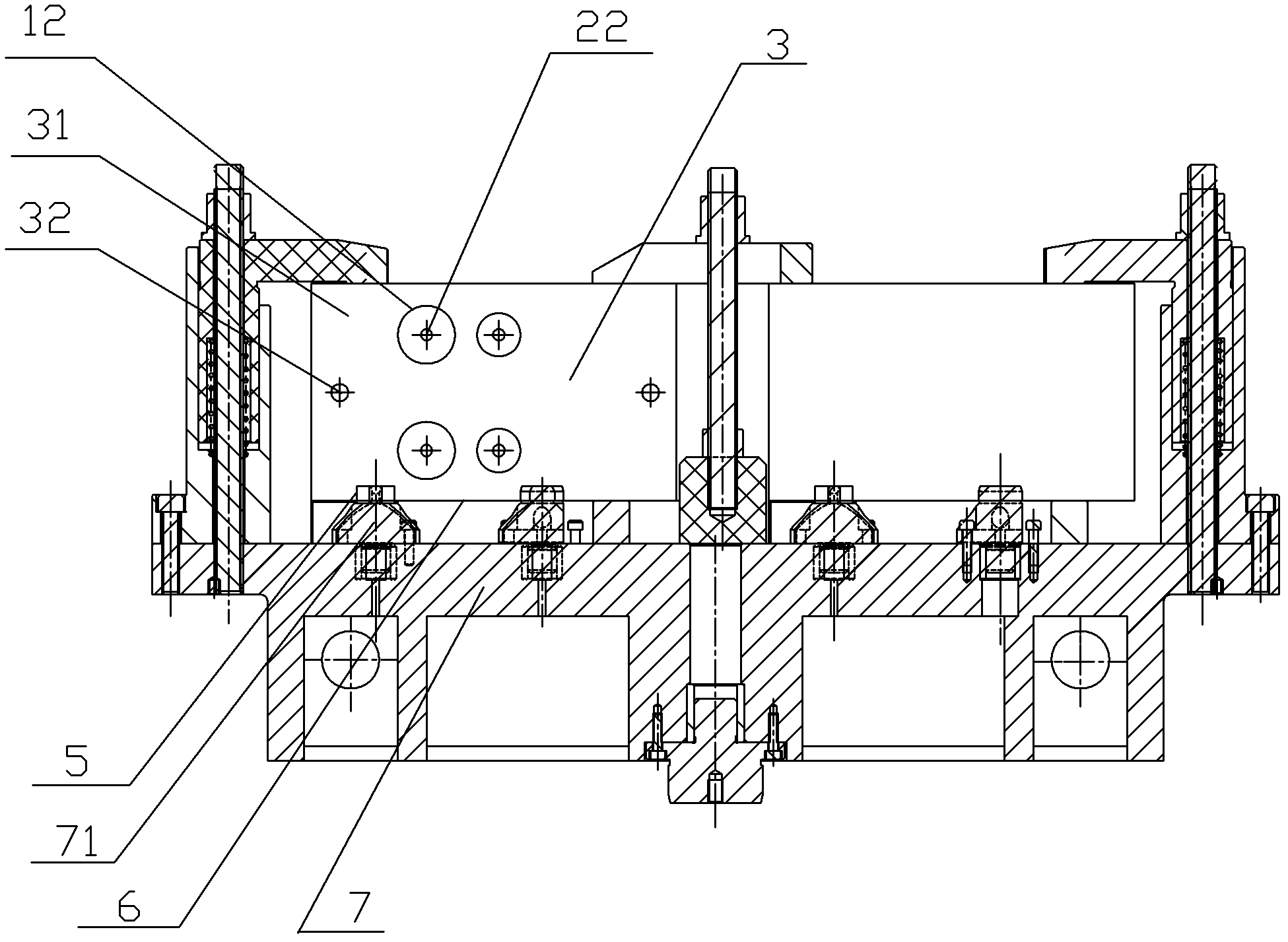

[0019] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

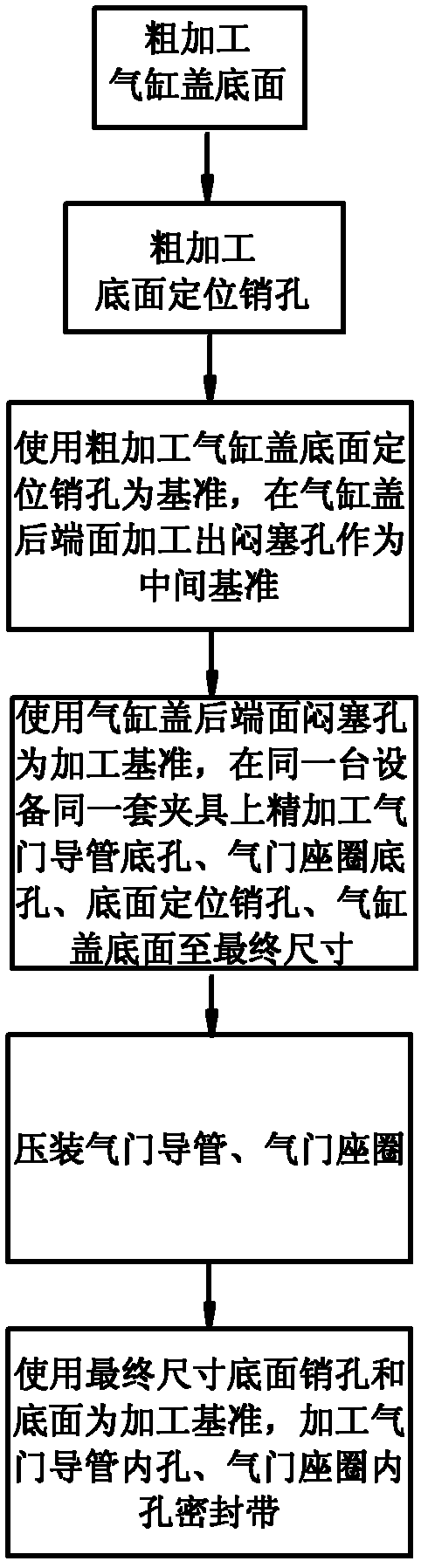

[0020] see figure 2 and image 3 , the steps of the processing method of the cylinder head valve seat ring sealing band are:

[0021] First, the bottom surface 31 of the cylinder head is roughly machined; then, the bottom alignment pin hole 32 of the bottom surface 31 of the cylinder head is roughly machined; after that, using the rough machining bottom surface alignment pin hole 32 as a reference, the plug hole 5 is processed on the rear end surface 6 of the cylinder head ( It can be two) as the intermediate reference; then use the plugged hole 5 on the rear end face of the cylinder head as the processing reference, and finish machining the valve guide bottom hole 22, the valve seat ring bottom hole 12, and the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com