Concentric assembly apparatus and method for linear vibration motor

A linear vibration and assembly equipment technology, applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve problems such as the difficulty of meeting the reference value of linear vibration motors, the influence of manual work characteristics, etc., to improve workability and productivity, Improved workability and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

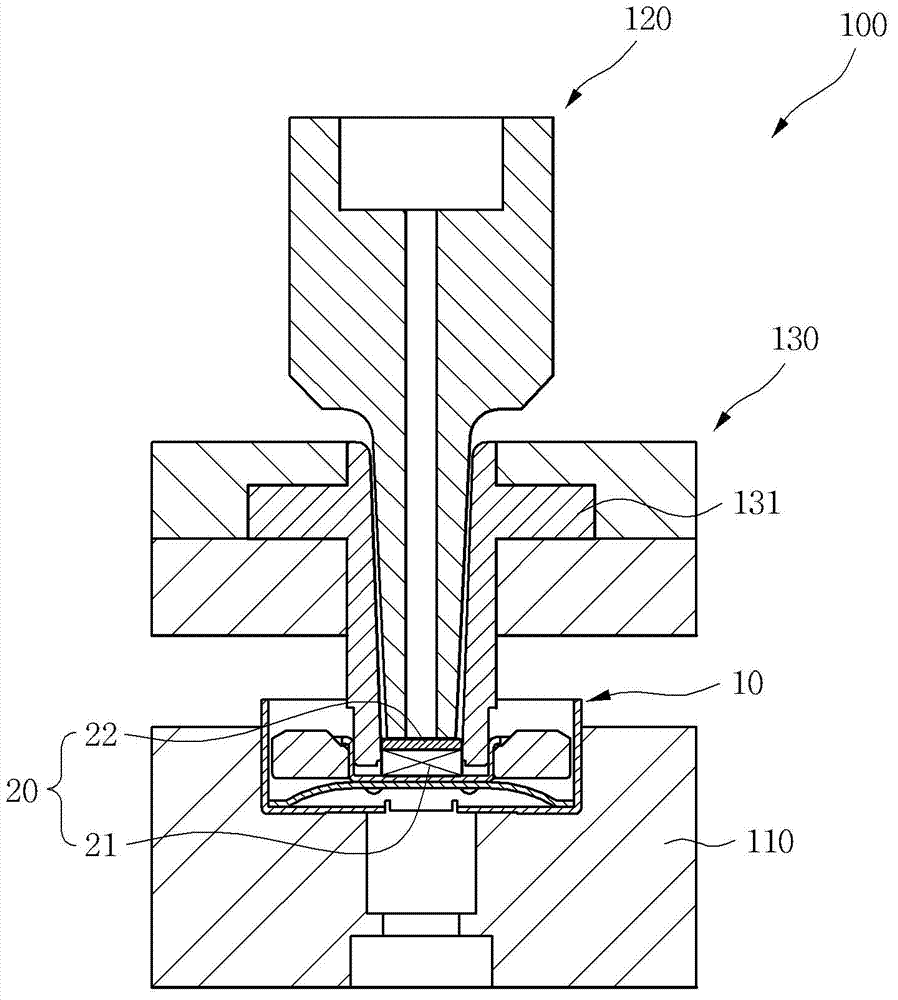

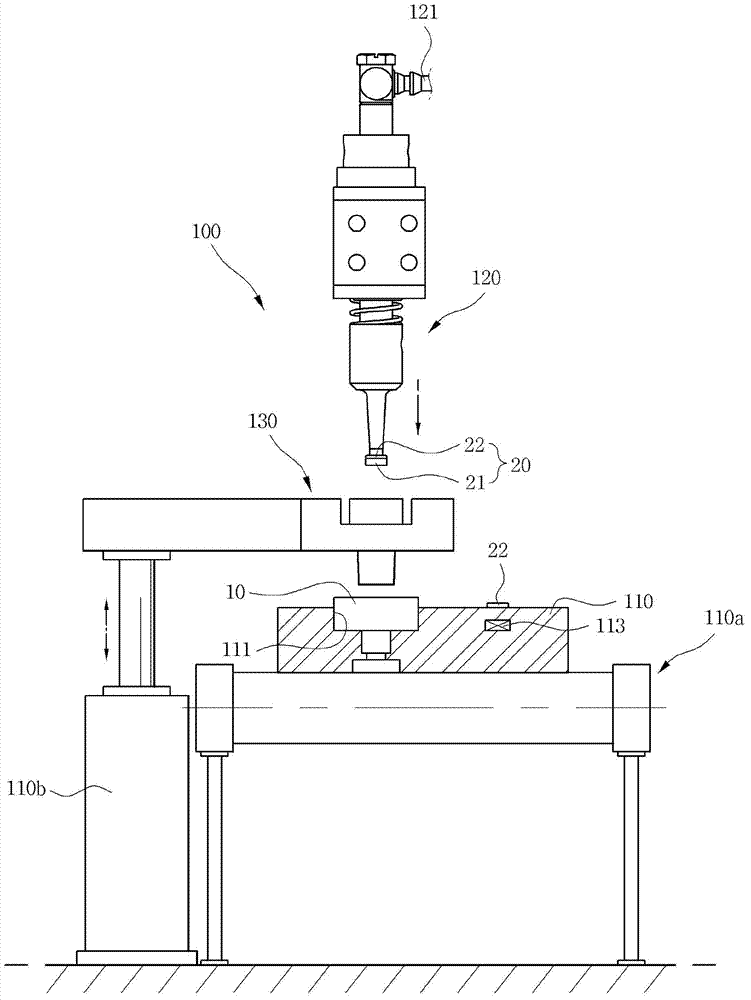

[0045] The concentric assembly equipment 100 involved in the embodiment of the present invention is as Figure 1 to Figure 2 As shown, it includes: a tray fixture (Tray Jig) used to place the weight assembly (Weight Ass'y) of the linear vibration motor; used to pick up (Pick-up) and transfer the assembly to the weight assembly 10 a pick-up device 120 for the armature 20 ; and a work guide for concentrically assembling the armature 20 on the counterweight assembly 10 .

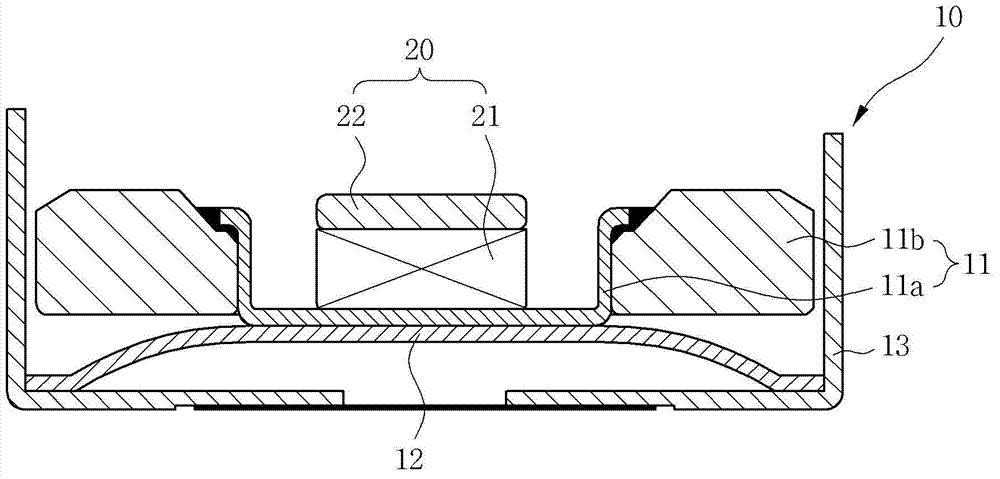

[0046] Here, counterweight assembly 10 such as image 3 As shown, it includes: a vibrator 11 having a yoke 11a for accommodating the armature 20 and a weight body 11b arranged outside the yoke 11a; used to elastically support the vibrator 11 so that it can perform linear a moving spring 12; and an accommodating case 13 for accommodating the vibrator and the spring inside. In addition, the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com