Phase adjuster concentricity air inflation adjusting clamp and device

A phase adjuster and adjusting device technology, which is applied to workpiece clamping devices, assembling machines, manufacturing tools, etc., can solve the problem that the adjustment method cannot meet the requirements, and achieve the effects of low cost, strong economic applicability, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

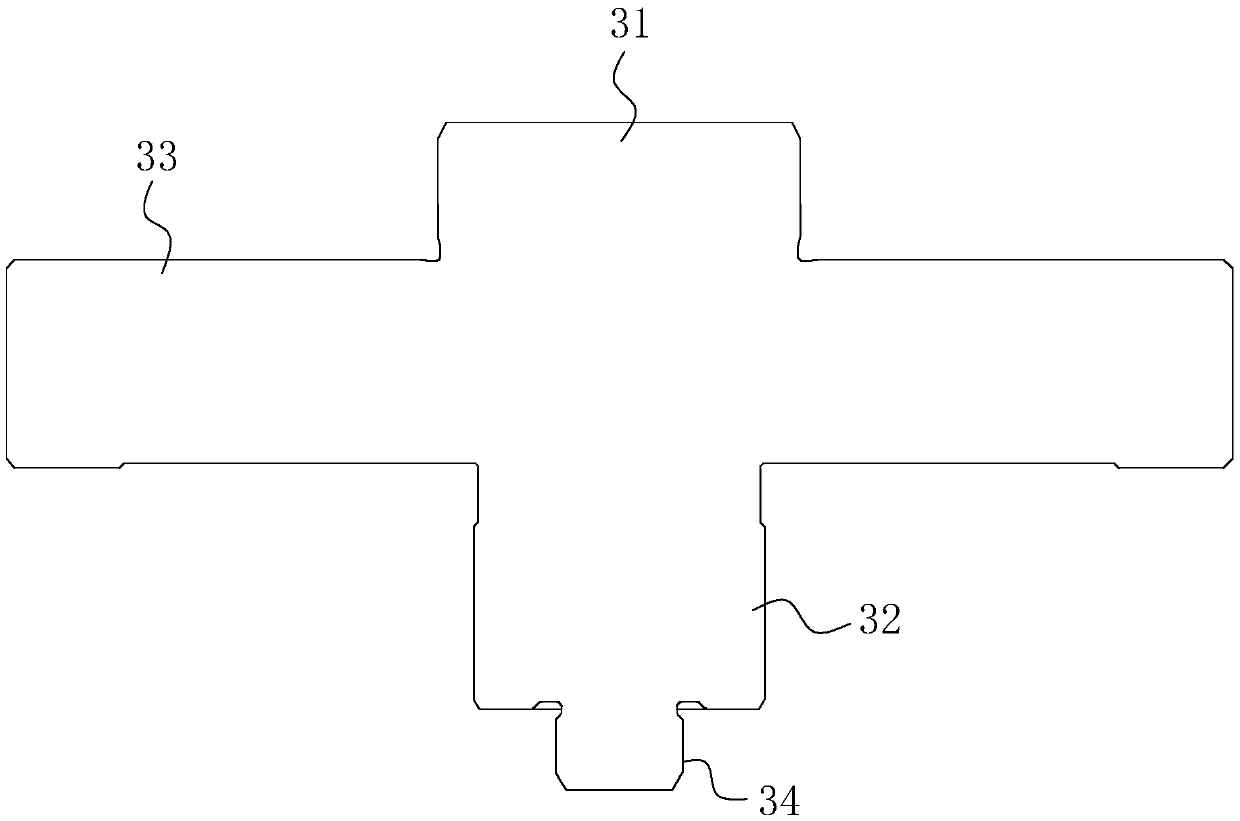

[0034] A phase adjuster concentricity inflatable adjusting fixture, refer to Figure 4 , which includes an adjusting plate 33. In this embodiment, the adjusting plate 33 is disc-shaped; the two ends of the adjusting plate 33 are respectively provided with a first pillar 31 and a second pillar 32, and the end face of the second pillar 32 away from the adjusting plate 33 is provided with a positioning Column 34 ; in this embodiment, the first column 31 , the adjusting plate 33 , the second column 32 and the positioning column 34 are arranged coaxially.

[0035] refer to image 3 , the end face of the first strut 31 is provided with an inflation channel extending to the end face of the second strut 32. In this embodiment, the inflation channel includes a first air channel 35 and a second air channel 36; the first air channel 35 is opened on the end face of the first strut 31 In the middle, it extends inward into the second pillar 32; the second air passage 36 is opened on the en...

Embodiment 2

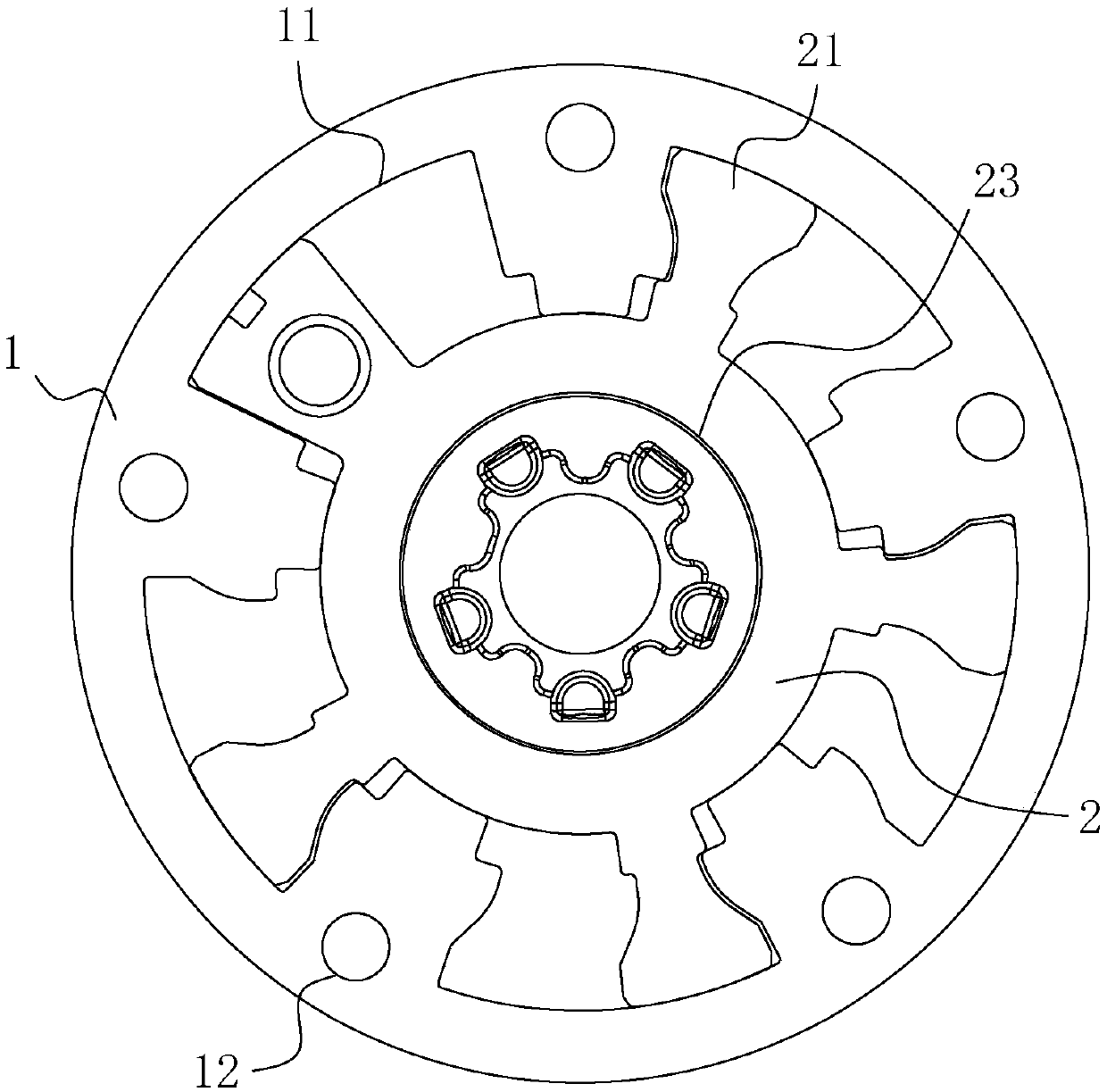

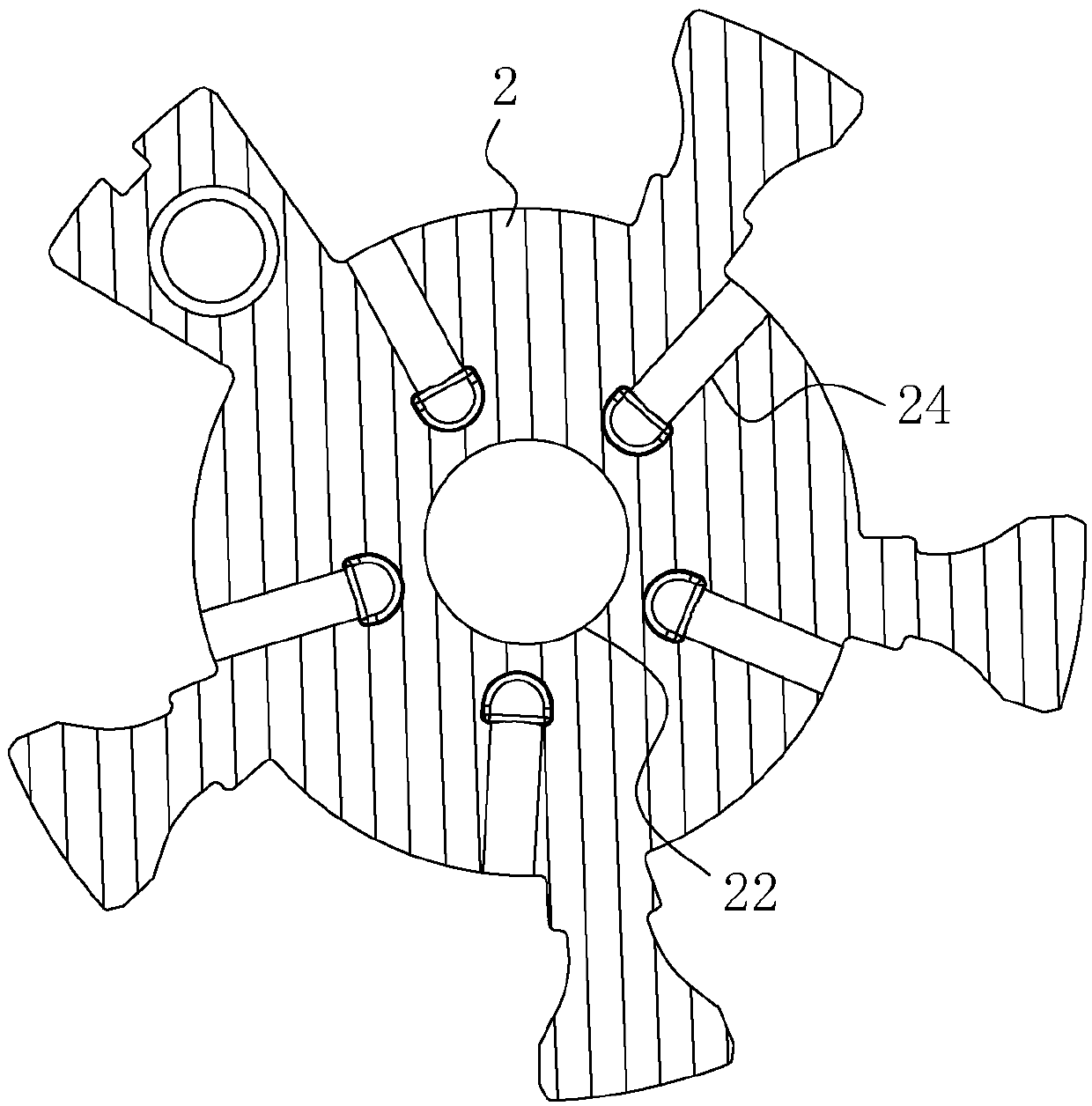

[0039] A phase adjuster concentricity inflatable adjusting device, refer to Figure 5 , which includes a fixed bottom frame for carrying the clamp in Embodiment 1, the fixed bottom frame includes a fixed bottom plate 41, and the bottom wall of the fixed bottom plate 41 is provided with four fixed bottom columns 42 evenly distributed; the fixed bottom frame is provided with a fixed top frame, The fixed top frame includes a fixed top plate 43, and the bottom wall of the fixed top plate 43 is evenly provided with four fixed top columns 44 connected with the top wall of the fixed bottom plate 41; figure 1 ) on the five bolt holes 12 (refer to figure 1 )Corresponding.

[0040] refer to Image 6 , the adjusting plate 33 is connected with the bottom wall of the fixed bottom plate 41, and the bottom wall of the fixed bottom plate 41 is provided with a positioning slot 412 for inserting the first pillar 31; 411, an inflatable tube connected to an inflatable device is inserted in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com