Device and method for removing re-melting layers on inner walls of air film holes of blades

A gas film hole and remelting layer technology, which is applied in the electrolysis process, electrolytic components, electrochemical processing equipment, etc., can solve the problems of affecting the safety of the engine, fracture failure, low processing efficiency, etc., to improve the cooling effect of the gas film, The effect of prolonging the service life and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

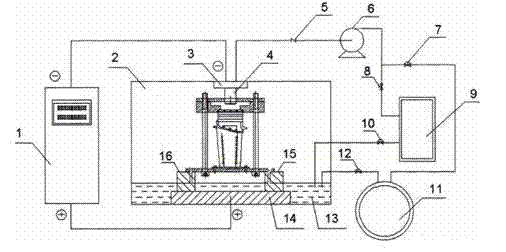

[0020] Such as figure 1 As shown, it is a schematic structural view of the device for removing the remelting layer on the inner wall of the air film hole of the blade according to the present invention, wherein 1 is a power control cabinet, 2 is a working box, 3 is an adapter, 4 is a nozzle, 5 is a check valve, and 6 is a Hydraulic pump, 7 and 8 are cut-off valves, 9 is heat exchanger, 10 is ball valve, 11 is filter, 12 is ball valve, 13 is electrolyte, 14 is workbench, 15 and 16 are pads; improved electrolyte-plasma The processing device includes a machine tool and an electrolyte circulation system. The main part of the machine tool is composed of a power control cabinet 1, a work box 2, an adapter 3 and a worktable 14 to ensure the installation and positioning of the workpiece and provide processing power. The electrolyte circulation system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com