Polishing equipment for head of wrench

A head and wrench technology, applied in the field of wrench head polishing equipment, can solve the problems of increased production cost, low work efficiency, uneven margin, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

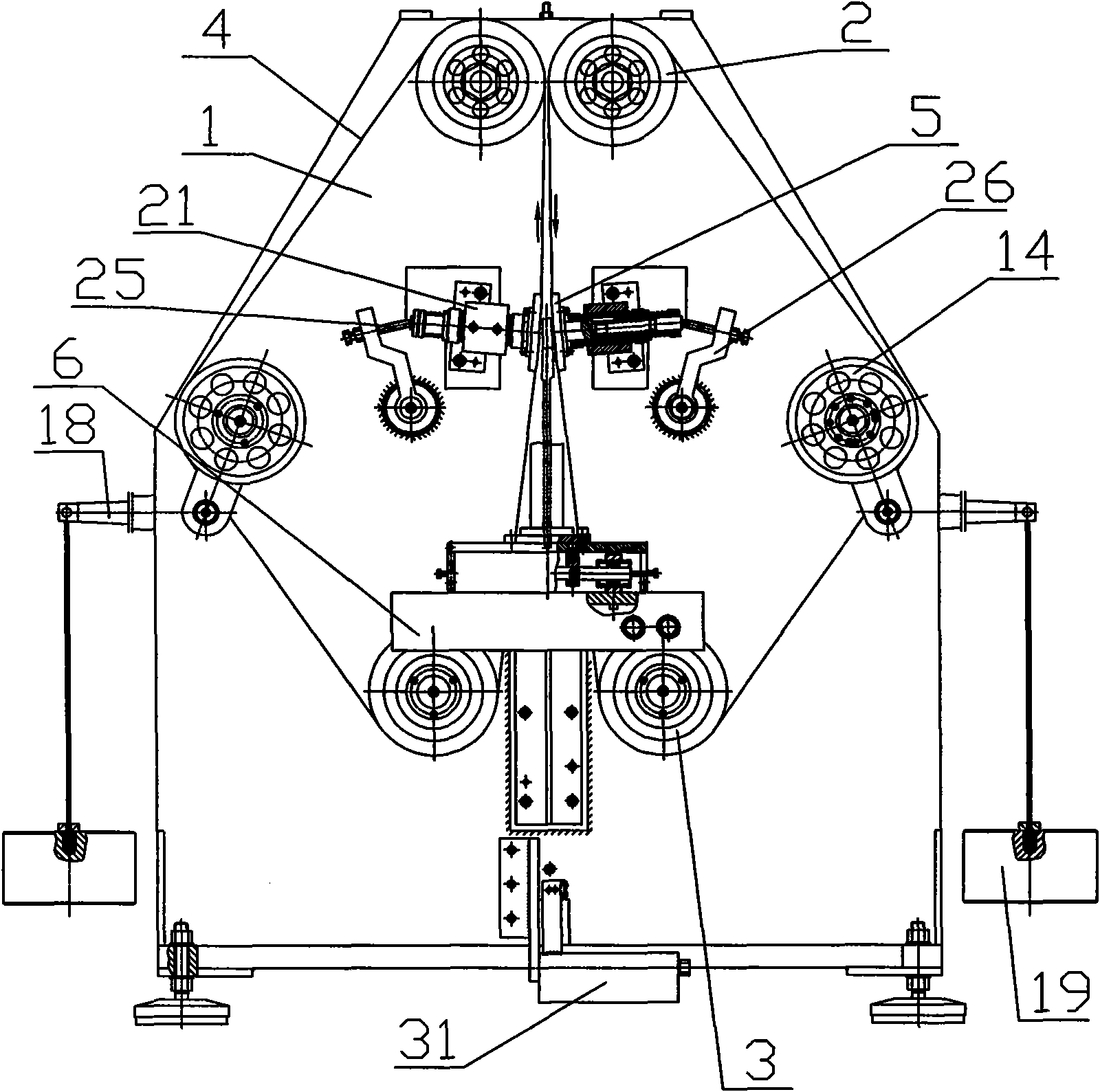

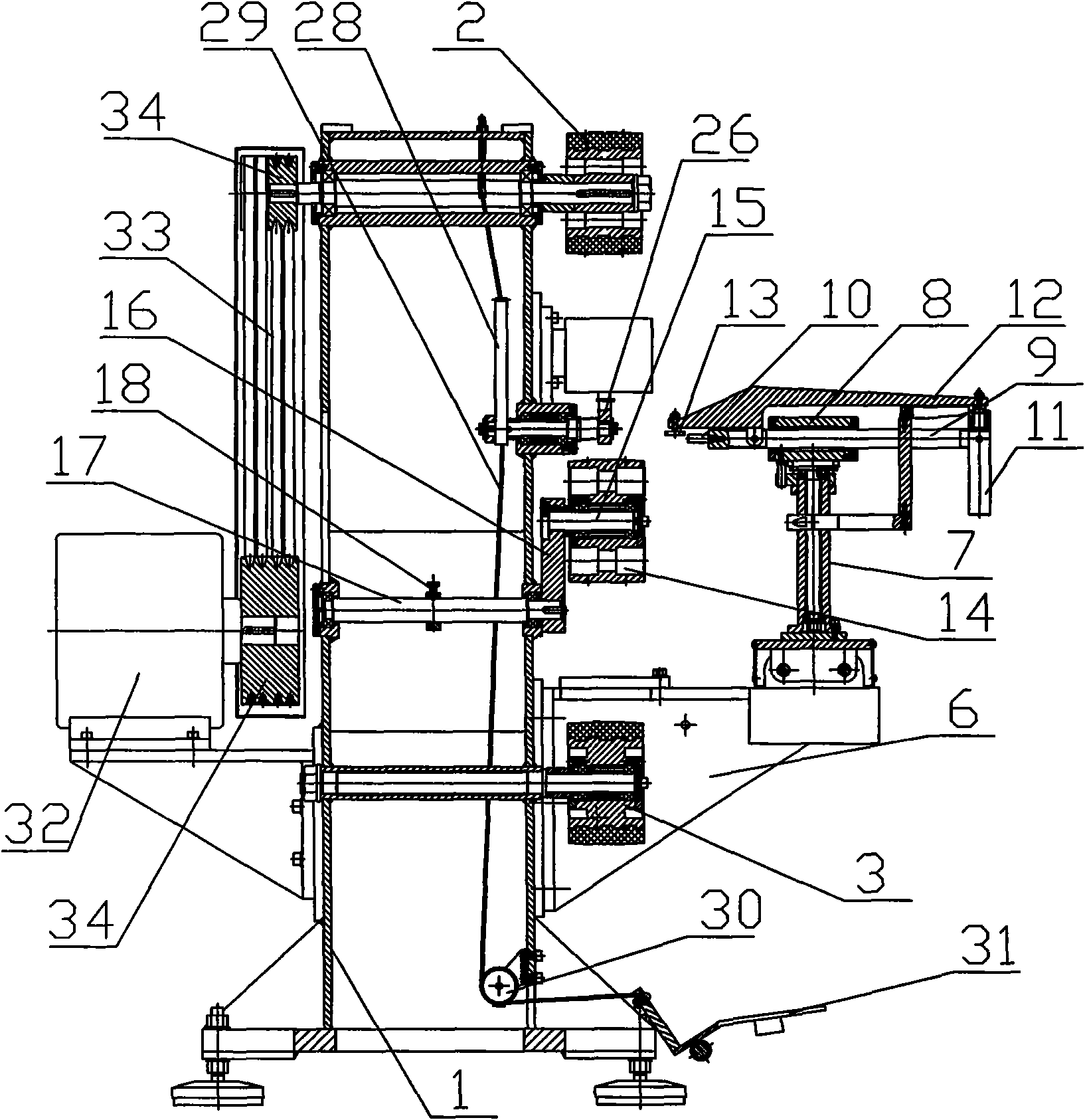

[0031] refer to Figure 1 to Figure 6 , a wrench head polishing equipment, including a frame 1, also includes a transmission device arranged on the frame 1, and a fixing device arranged in front of the transmission device;

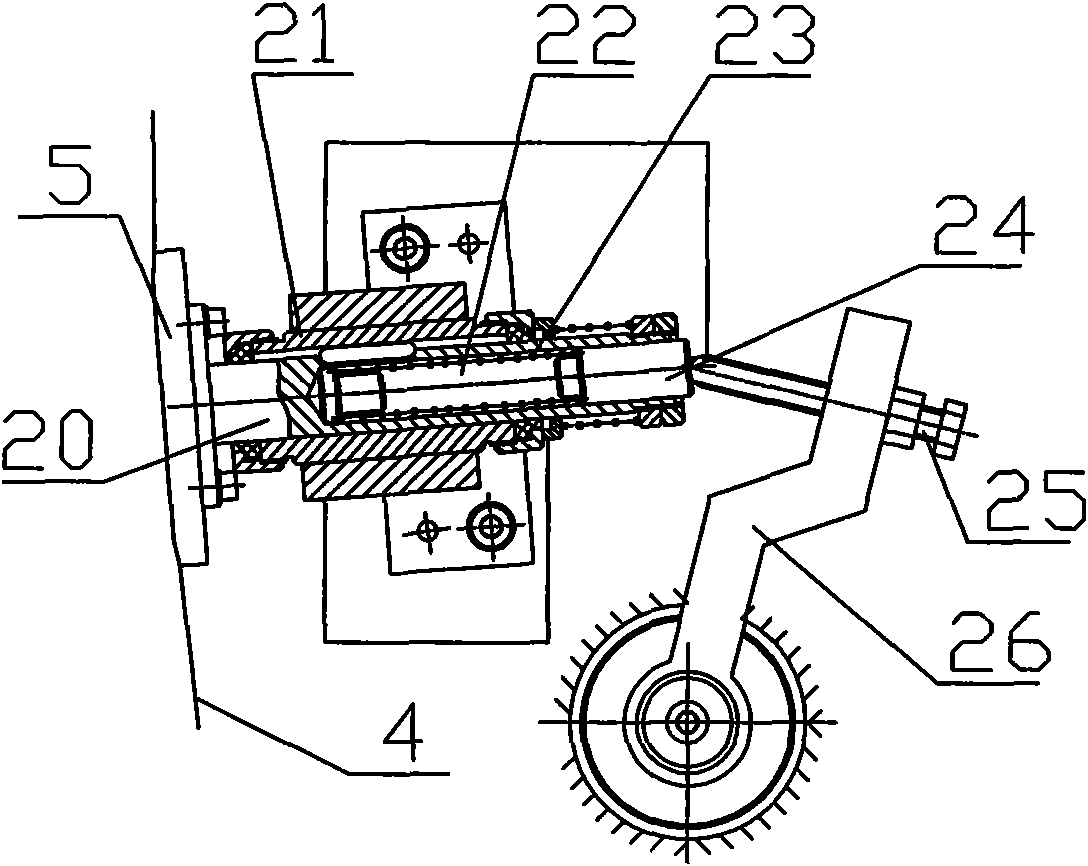

[0032] The transmission device includes two sets of transmission mechanisms and two sets of guide mechanisms symmetrically arranged along the center line of the frame 1, the transmission mechanism includes a drive wheel 2 located on the upper part of the frame 1, a tension pulley located in the middle of the frame 1 Tightening wheel 14, the fixed wheel 3 positioned at the bottom of the frame 1, and the abrasive belt 4 stretched on the outer periphery of the driving wheel 2, the tensioning wheel 14 and the fixed wheel 3, the tensioning wheel 14 positioned at the driving wheel 1 The outer side of the wheel 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com