Enhanced flexible substrate surface magnetron sputtering winding coating equipment

A flexible substrate, magnetron sputtering technology, applied in the direction of sputtering coating, vacuum evaporation coating, ion implantation coating, etc. To achieve the effect of speeding up the efficiency of coating forming, preventing instability and accelerating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

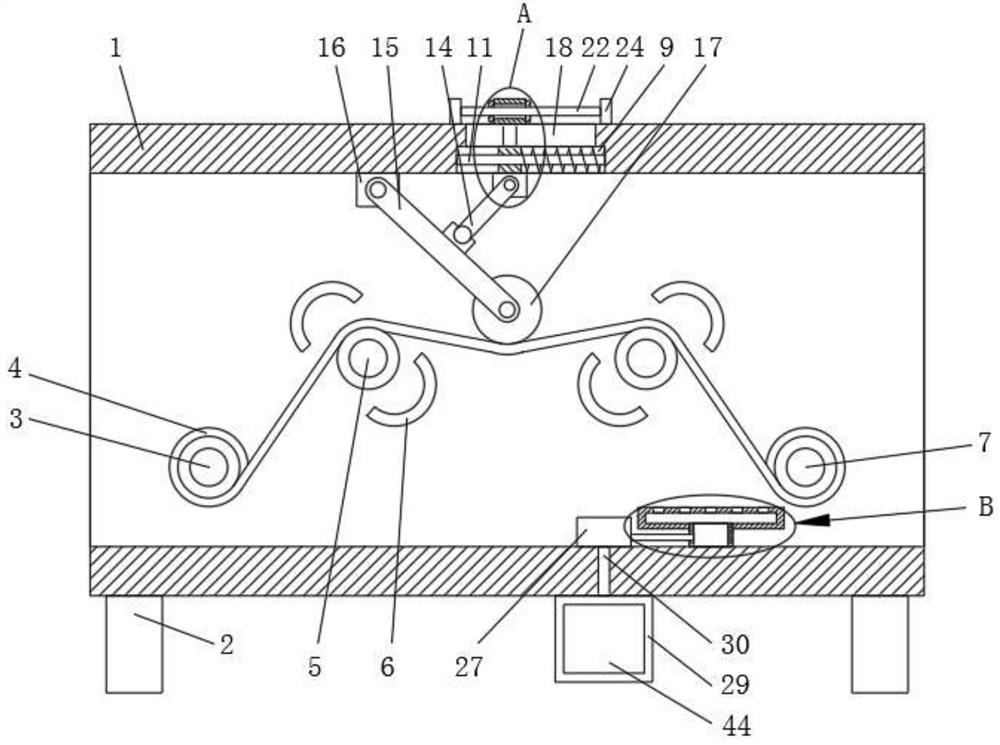

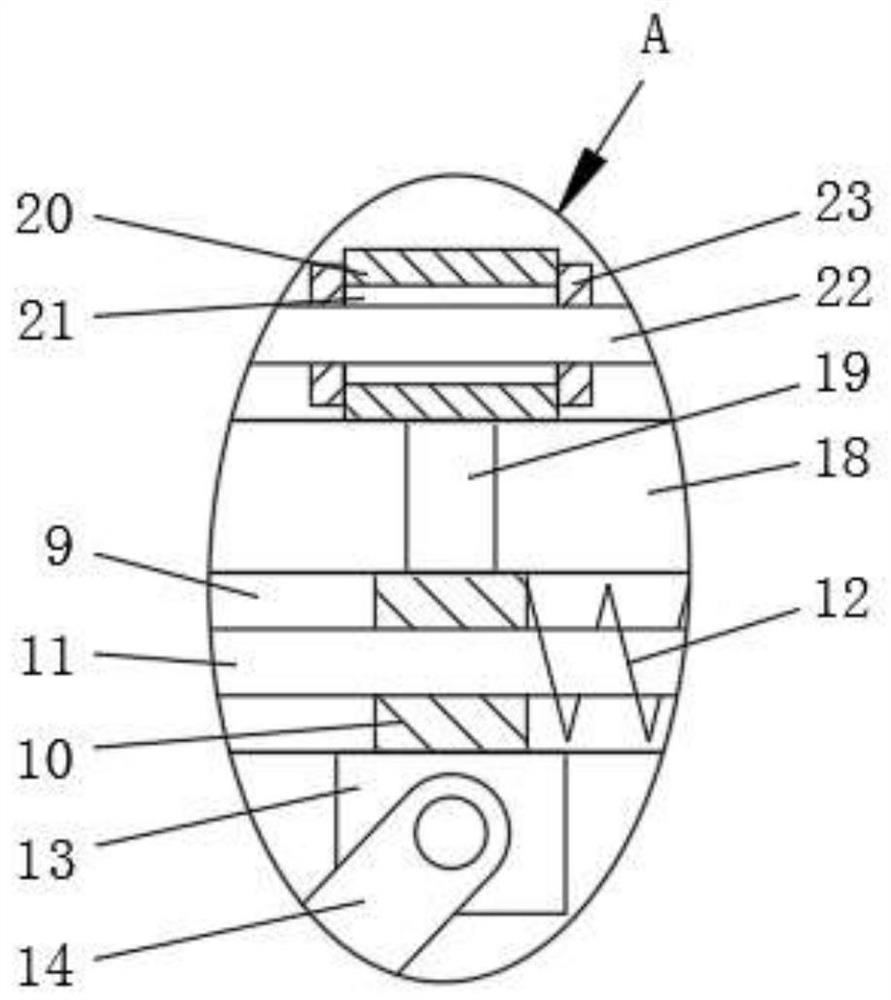

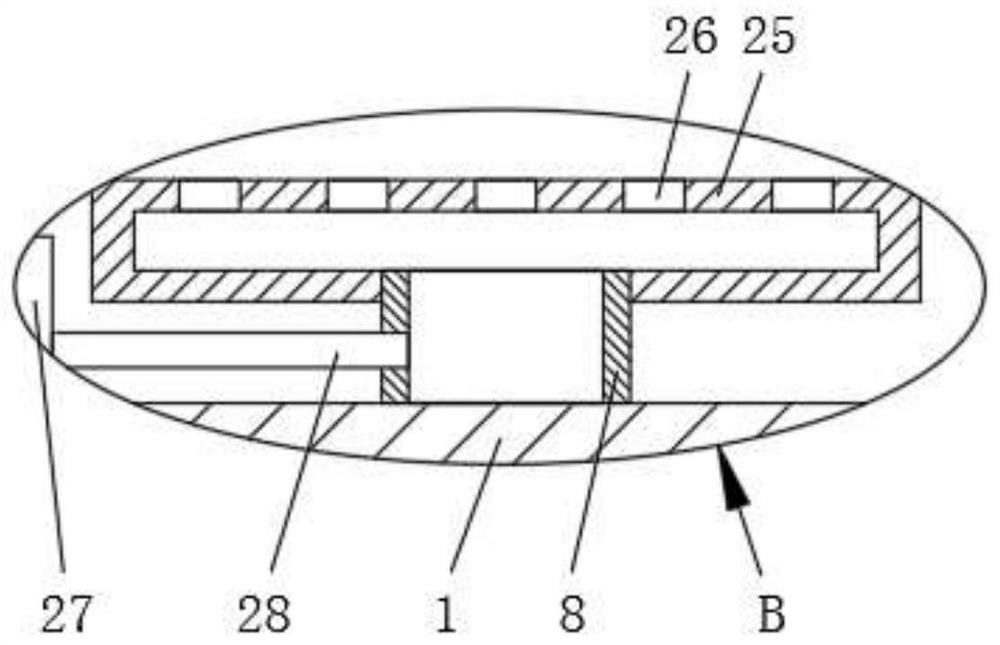

[0026] An enhanced flexible substrate surface magnetron sputtering winding coating equipment, comprising a working room 1 and a connecting seat 20, the lower end of the working room 1 is fixedly connected with a support 2, and the working room 1 is rotatably connected with a stand A flat roller 3, the flattening roller 3 is wound with a substrate 4, two symmetrical rotating rollers 5 are rotatably connected to the working room 1, and the substrate 4 is contacted and connected to the rotating roller 5. The working room 1 is fixedly connected with four magnetron targets 6, and the magnetron target 6 is arranged on the outside of the rotating roller 5, and the working room 1 is rotatably connected with a winding roller 7, and the winding roller 7 is connected to the base material 4 contact, the inside of the working chamber 1 is provided with a chute 9, the inside of the chute 9 is slidably connected with a slider 10, the inside of the slider 10 is slidably connected with a fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com