Processing method of titanium alloy TA15 thin-wall long boss

A technology of titanium alloy and boss, which is applied in the direction of metal processing equipment, metal processing machinery parts, workpieces, etc., to achieve the effect of reducing control, reducing part deformation, and meeting processing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the accompanying drawings.

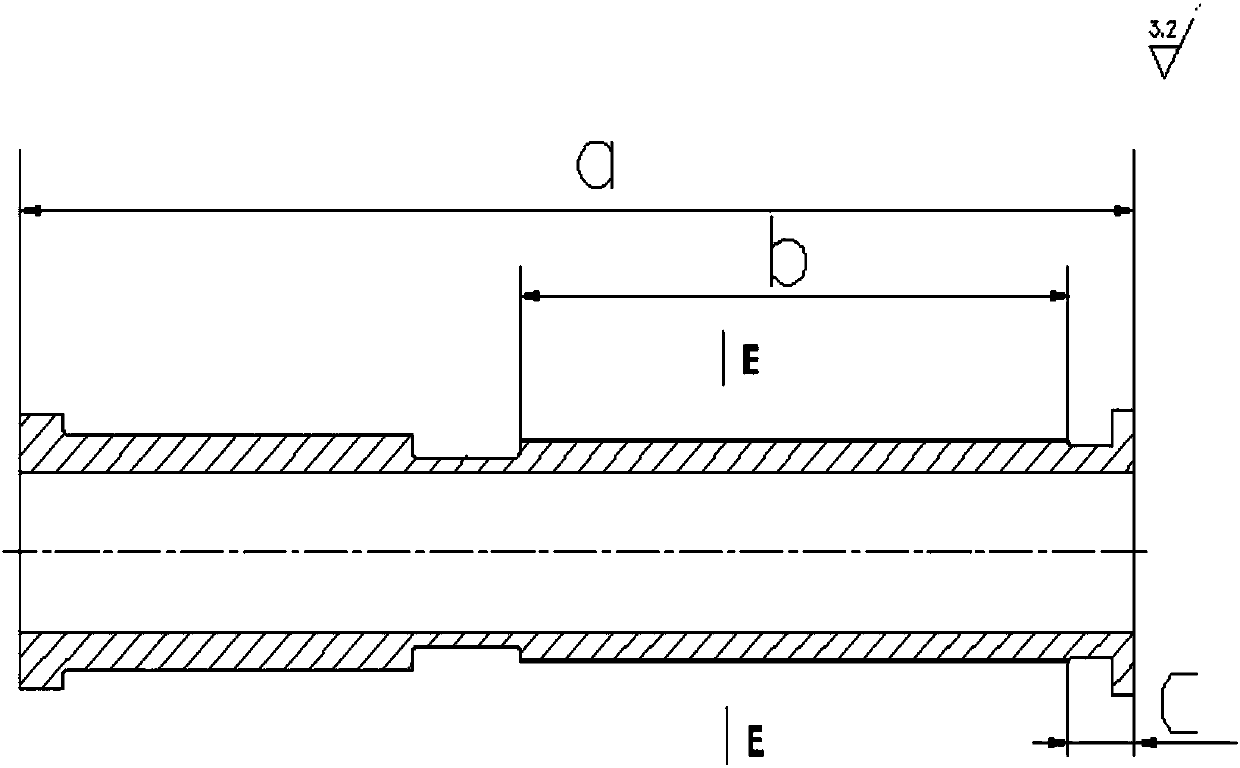

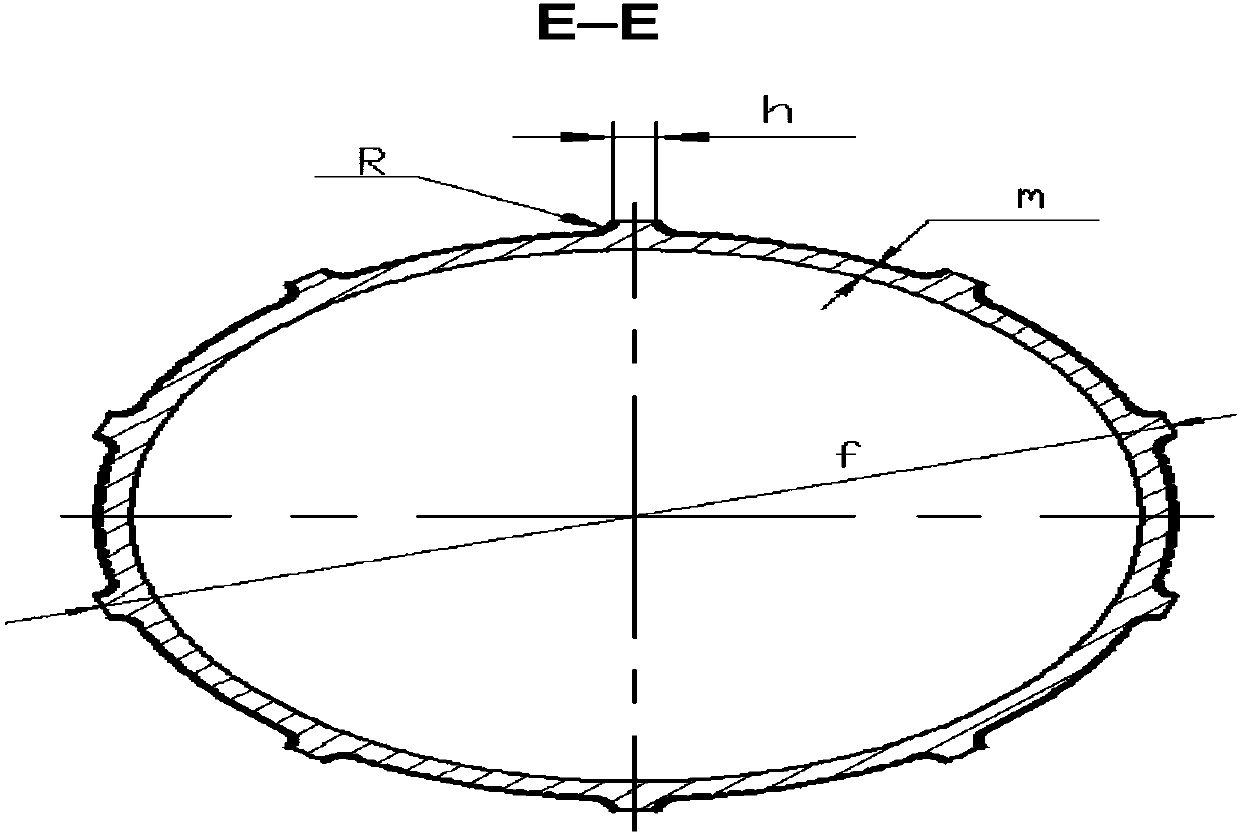

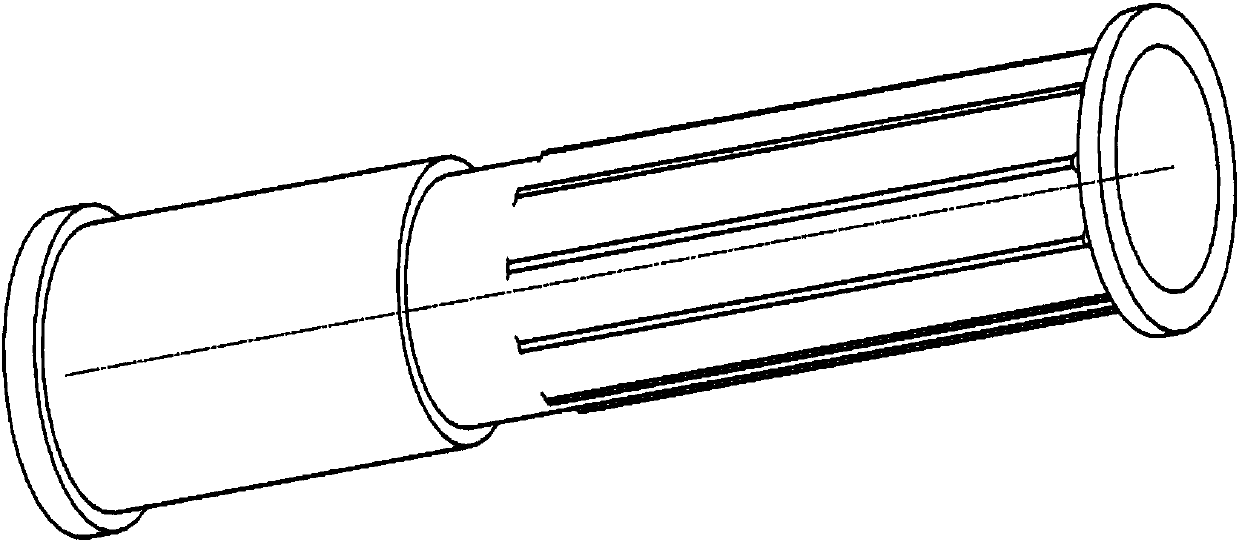

[0038] figure 1 It is a schematic diagram of the structure of a thin-walled long boss part, figure 2 is a schematic cross-sectional view of a thin-walled long boss part, image 3 is a three-dimensional schematic diagram of a thin-walled long boss part, Figure 4 It is a schematic diagram of the structure of the thin-walled long boss fixture. As shown in the figure, the catheter part of a new machine is a thin-walled long boss part (a length 838mm, f cylinder wall outer diameter Ф110mm, m wall thickness 1.3mm), the part is made of TA15 titanium alloy, and the outer diameter of the catheter needs to be milled 10mm. There is a long bar-shaped boss, and the length b of the boss is 432mm. Thin-walled long boss parts have complex shapes, are prone to vibration and deformatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com