A variable step size monitoring AGC automatic control method for rolling piece thickness control

A technology of thickness control and variable step length, used in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as overshoot or insufficient adjustment, and achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

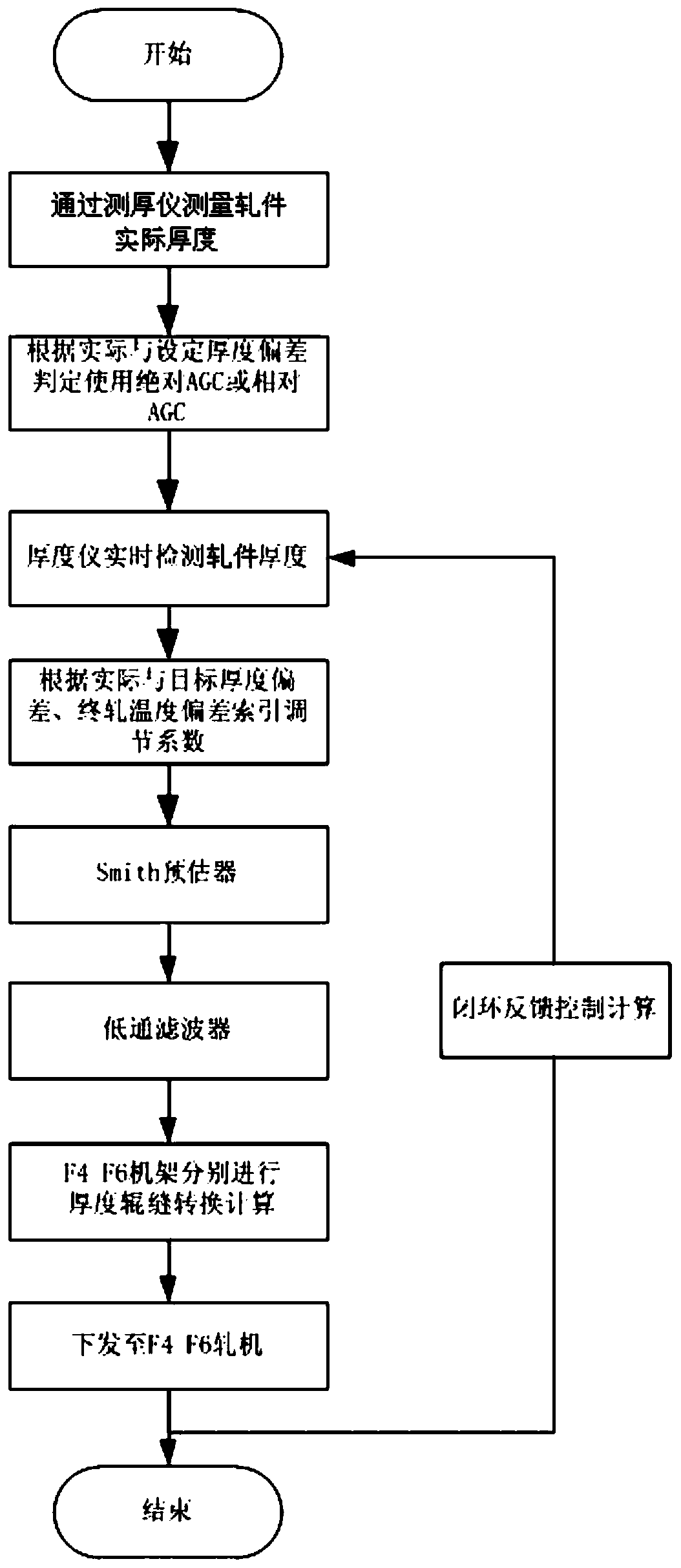

[0036] In the embodiment of the present invention, taking the 2250mm hot rolling production line of a certain iron and steel enterprise as an example, the finishing rolling unit of the hot rolling production line has 6 stands, which are used for hot rolling to produce automobile plates, and its thickness control system adopts the rolling mill of the present invention. For the variable step size monitoring AGC automatic control method of piece thickness control, see figure 1 , the specific control steps are as follows:

[0037] (1) The thickness of the rolled piece is measured by the thickness gauge. After the thickness gauge is loaded for a few seconds, it is judged whether to use absolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com