Method of producing ceramic green sheet and electronic component

A manufacturing method and technology of ceramic green sheets, which are applied in coil manufacturing, manufacturing tools, ceramic molding machines, etc., can solve problems such as uneven electrical characteristics, differences in substrate height, formation accuracy and formation position of concave parts, and achieve basic Improved sheet thickness controllability, reduced unevenness in electrical properties, and excellent thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

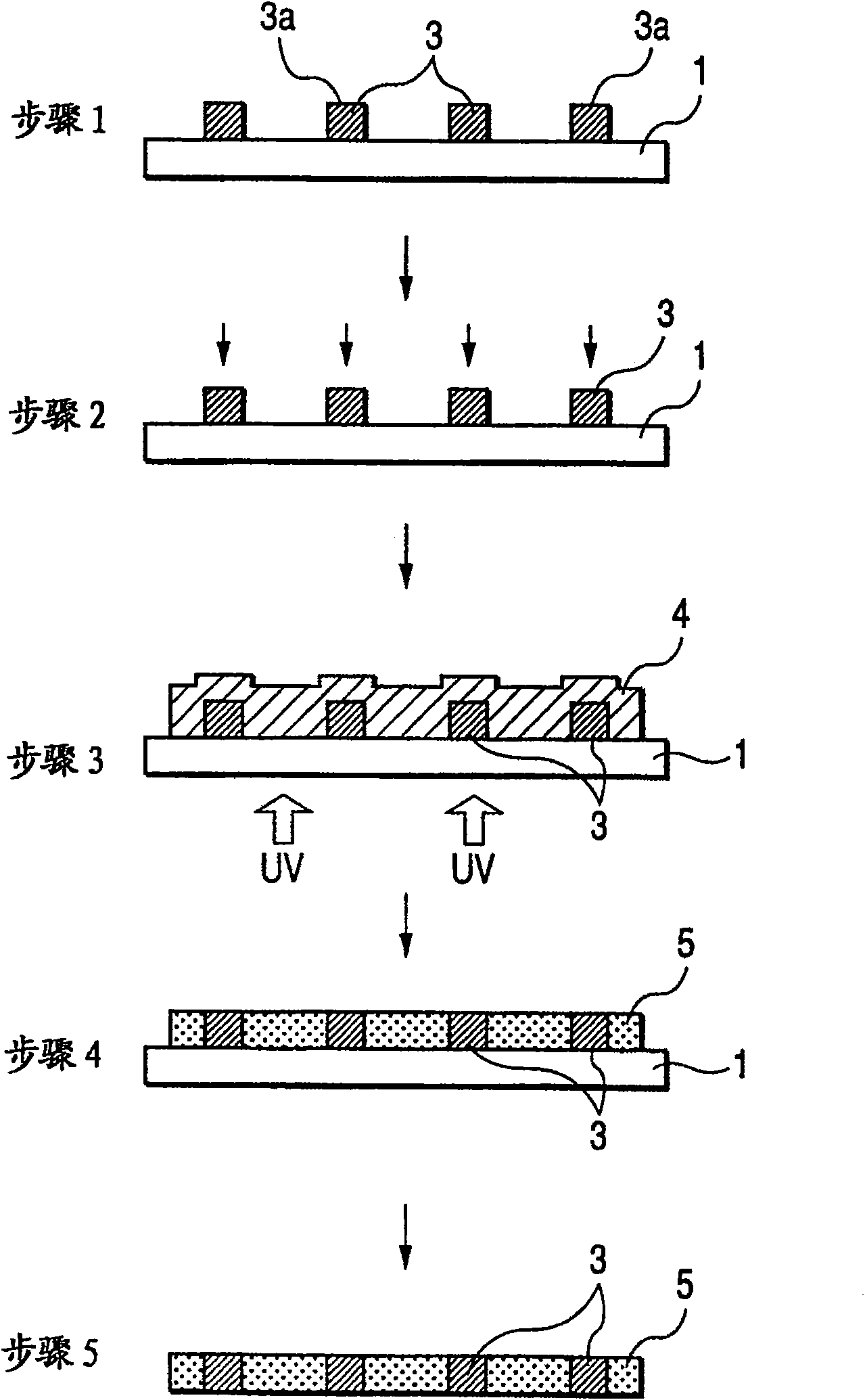

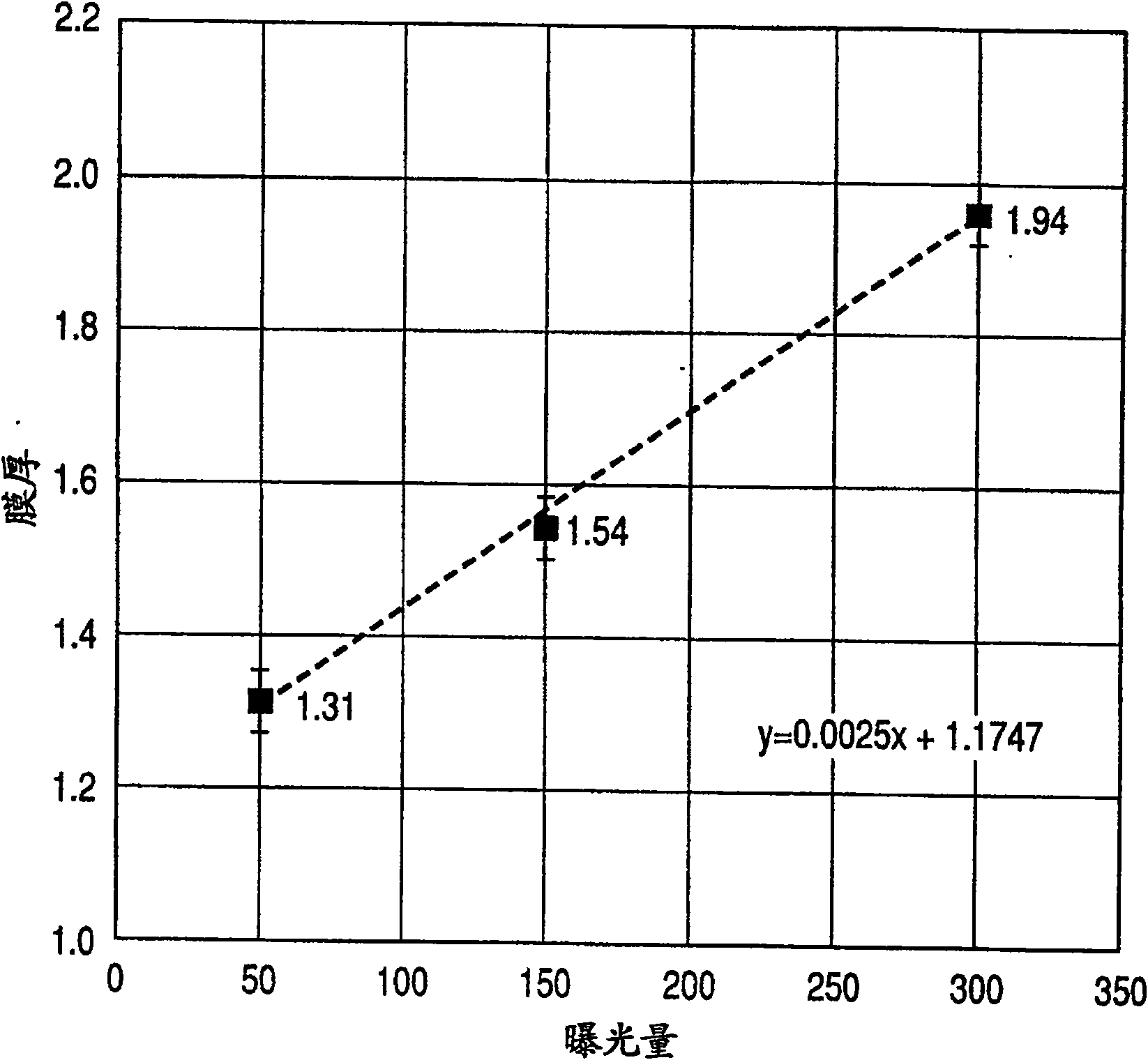

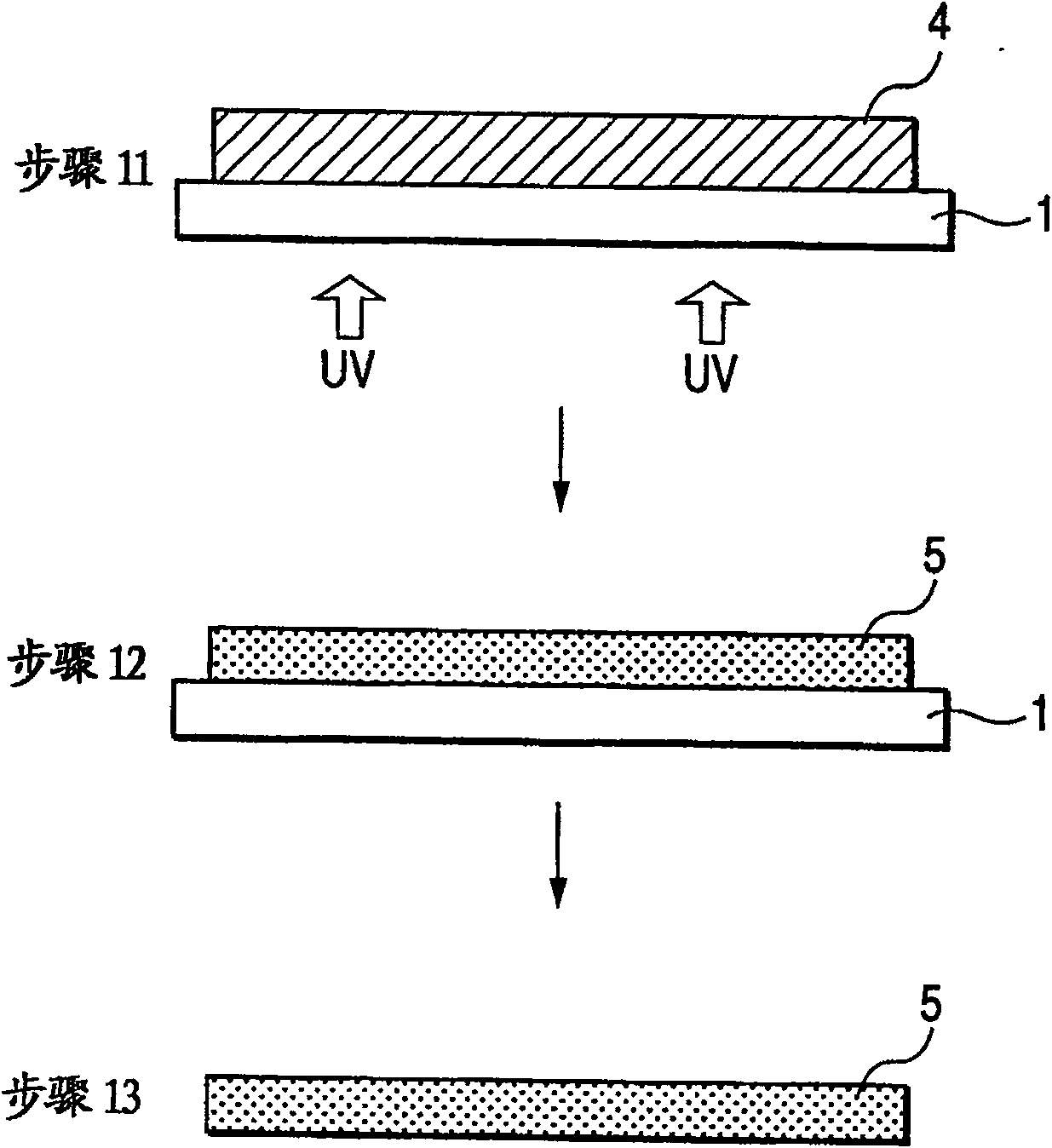

[0047] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 Regarding the method of manufacturing an electronic component according to the embodiment of the present invention, a method of forming a single layer of a ceramic green sheet including an electrode portion is shown. In the drawings, the cross-sections of the substrates in the respective steps are shown, and the steps are carried out according to the arrows. In the accompanying drawings, the substrate 1 is, for example, a PET film whose surface has undergone appropriate mold release treatment using transparent silicone resin or the like. Furthermore, for example, by screen printing, in step 1, the electrode portion 3 is formed on the surface of the substrate 1 subjected to the release treatment using a conductive paste conventionally used for forming electrodes. The electrode portion is formed of a light-shielding portion made of a material that does n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com