Coatings for preparing barrier layers, preparation methods of barrier layers and barrier layers

A barrier layer and coating technology, which is applied in the field of barrier layer, coating, and barrier layer preparation, can solve the problems affecting the long-term stability of the battery, and the sintering temperature cannot prevent the electrolyte and barrier layer, etc., so as to reduce the thickness, promote sintering, and reduce sintering The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation method of coating

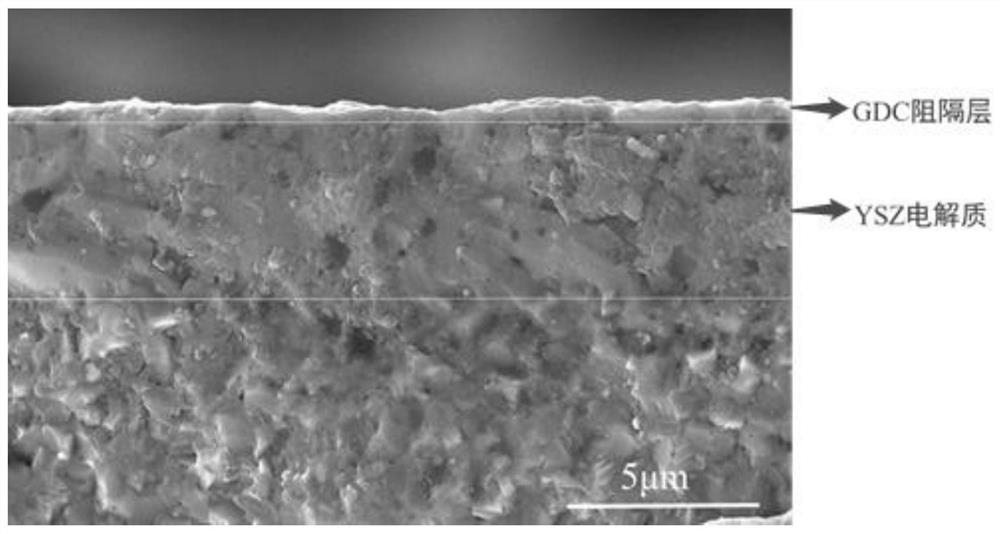

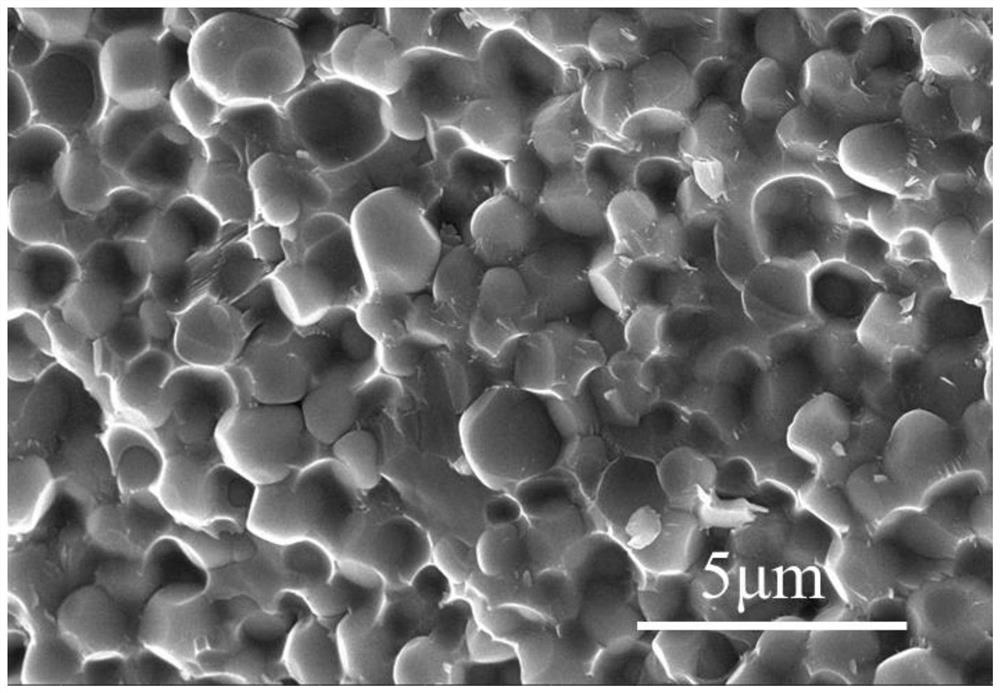

[0045]This embodiment provides a coating for preparing a barrier layer, including nitrate, a combustion enhancer, and an aqueous solution. In this embodiment, as an optional solution, in order to reduce impurities in the coating, the aqueous solution uses distilled water. Wherein, the nitrates include gadolinium nitrate and cerium nitrate, and the molar ratio of gadolinium nitrate and cerium nitrate is 1:9; the combustion enhancer of this embodiment is citric acid, and as an alternative, the coating also includes GDC nanopowder, ethanol and dispersed agent, among which the dispersant is PVP. The preparation steps are as follows:

[0046] (1) ethanol is mixed with distilled water, wherein ethanol accounts for 10wt% of distilled water;

[0047] (2) Take a certain amount of gadolinium nitrate and cerium nitrate respectively according to the molar ratio of 1:9, dissolve them in the mixed solution of ethanol and distilled water, wherein g...

Embodiment 2

[0058] 1. Preparation method of coating:

[0059] This embodiment provides a coating for preparing a barrier layer, including nitrate, a combustion enhancer, and an aqueous solution. In this embodiment, as an optional solution, in order to reduce impurities in the coating, the aqueous solution uses distilled water. Wherein, the nitrates include gadolinium nitrate and cerium nitrate, and the molar ratio of gadolinium nitrate and cerium nitrate is 1:9; the combustion enhancer of this embodiment is citric acid, and as an alternative, the coating also includes GDC nanopowder, ethanol and dispersed agent, among which the dispersant is PVP. The preparation steps are as follows:

[0060] (1) ethanol is mixed with distilled water, wherein ethanol accounts for 20wt% of distilled water;

[0061] (2) Take a certain amount of gadolinium nitrate and cerium nitrate respectively according to the molar ratio of 1:9, dissolve them in the mixed solution of ethanol and distilled water, wherein...

Embodiment 3

[0071] 1. Preparation method of coating:

[0072] This embodiment provides a coating for preparing a barrier layer, including nitrate, a combustion enhancer, and an aqueous solution. In this embodiment, as an optional solution, in order to reduce impurities in the coating, the aqueous solution uses distilled water. Wherein, the nitrates include gadolinium nitrate and cerium nitrate, and the molar ratio of gadolinium nitrate and cerium nitrate is 1:9; the combustion enhancer of this embodiment is citric acid, and as an alternative, the coating also includes GDC nanopowder, ethanol and dispersed agent, among which the dispersant is PVP. The preparation steps are as follows:

[0073] (1) ethanol is mixed with distilled water, wherein ethanol accounts for 30wt% of distilled water;

[0074] (2) Take a certain amount of gadolinium nitrate and cerium nitrate respectively according to the molar ratio of 1:9, dissolve them in the mixed solution of ethanol and distilled water, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com