Lithium ion battery negative plate and preparation method thereof

A technology for lithium ion batteries and negative electrode sheets, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of complex manufacturing process, poor consistency of fast charging performance, and low energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

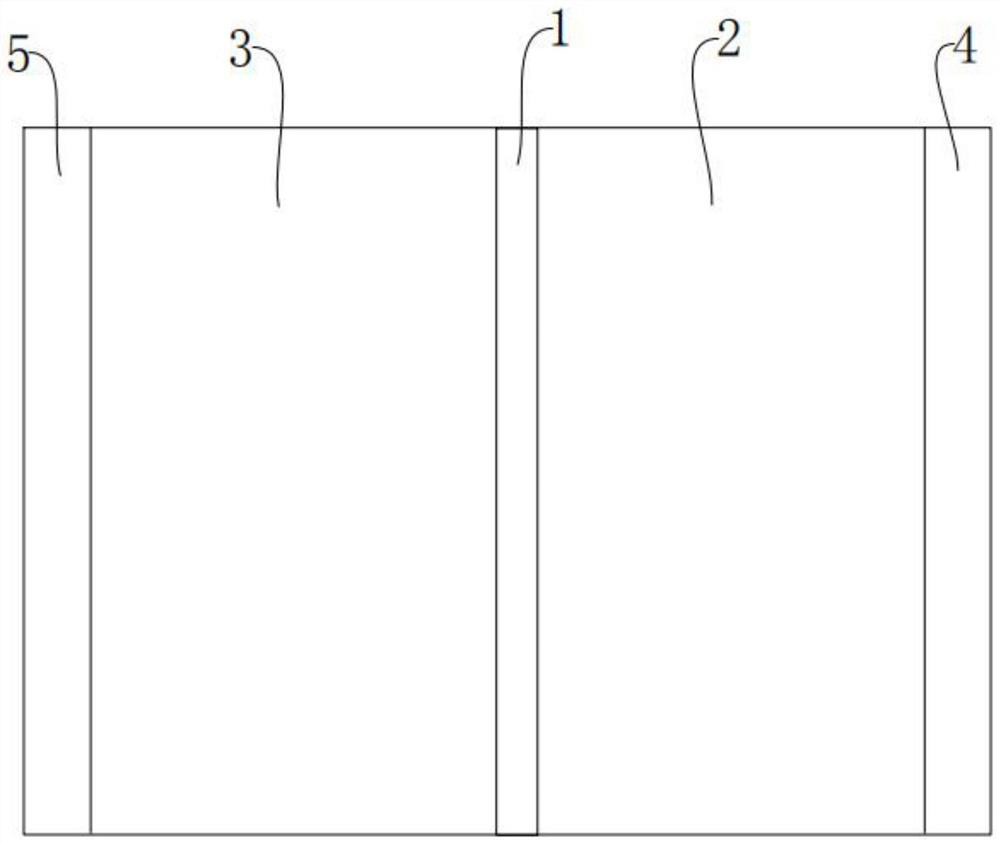

[0022] like figure 1 As shown, the present invention provides a lithium ion battery negative electrode sheet, which includes a copper foil 1, a first graphite layer 2 coated on one side of the copper foil 1, a second graphite layer 3 coated on the other side of the copper foil 1, The first fast-charging material layer 4 is coated on the side of the first graphite layer 2 facing away from the copper foil 1 , and the second fast-charging material layer 5 is coated on the side of the second graphite layer 3 facing away from the copper foil 1 .

[0023] The manufacturing process of the negative electrode sheet designed with this structure is relatively simple, it does not need to coat a layer of fast charging material on the outside of the tiny particles, and does not need to be produced separately, just coat the graphite layer and the fast charging material on the copper foil 1 respectively Therefore, the negative electrode sheet designed with this structure has the advantage of ...

Embodiment 2

[0027] Please refer to figure 1 , the present invention also provides a kind of preparation method of lithium-ion battery negative plate, comprises the following steps:

[0028] S1, coating a high-capacity negative electrode graphite material on one side of the copper foil 1 to form a first graphite layer 2;

[0029] S2, coating a high-capacity negative electrode graphite material on the other side of the copper foil 1 to form a second graphite layer 3;

[0030] S3, coating the fast charging material on the side of the first graphite layer 2 facing away from the copper foil 1 to form the first fast charging material layer 4;

[0031] S4, coating the fast charging material on the side of the second graphite layer 3 facing away from the copper foil 1 to form the second fast charging material layer 5 and form the negative electrode sheet.

[0032] This preparation method is relatively simple, and it does not need to coat a layer of fast-charging material on the outside of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com