High-hardness steel belt for home appliances and manufacturing method

A manufacturing method and high-hardness technology, applied in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of poor surface treatment, insufficient hardness of ordinary cold-rolled steel strips, and inability to meet the quality requirements for producing steel for household appliances, etc. A promising, promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

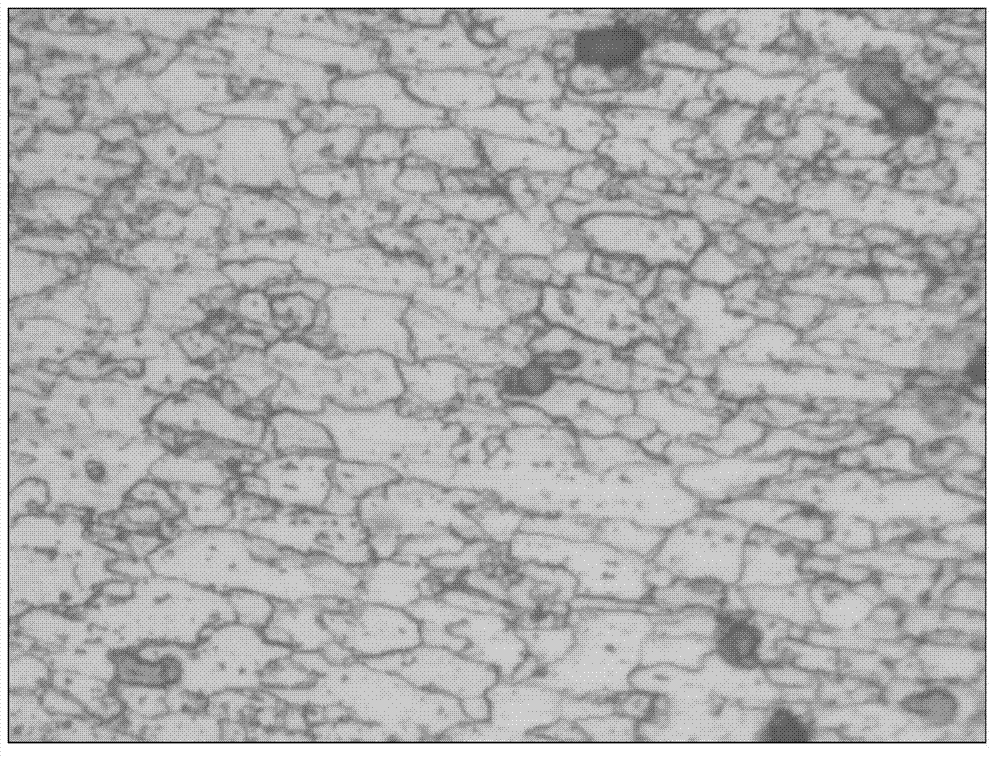

Image

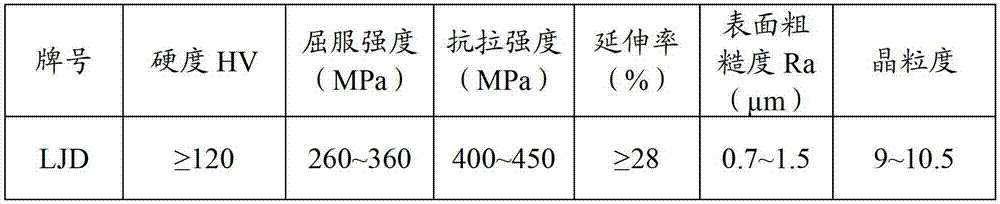

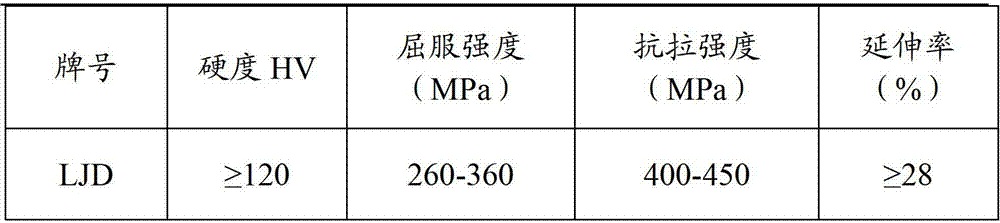

Examples

Embodiment 1

[0053] (1) Hot rolling:

[0054] The composition of hot-rolled raw materials is shown in the table below:

[0055] serial number

C

Si

mn

P

S

Al

1

0.07

0.12

0.28

0.018

0.015

0.015

2

0.1

0.09

0.25

0.019

0.014

0.02

3

0.07

0.13

0.27

0.016

0.015

0.023

[0056] The balance is Fe and trace unavoidable impurities;

[0057] The finishing temperature of hot rolling is 870±20℃, and the coiling temperature of finishing rolling is 650±20℃;

[0058] (2) pickling

[0059] The hot-rolled steel coil is pickled by a push-pull shallow tank turbulent pickling unit, and pickled with hydrochloric acid. The concentration of hydrochloric acid is controlled between 7% and 17% (w / w) to remove the surface oxide scale.

[0060] (3) cold rolling

[0061] After pickling, the steel coil is rolled by a double-stand reversible rolling mill;

[0062] (4) Degreasing of the ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com