Cold-rolled steel strip for saw-chain cutter teeth and preparation method thereof

A technology of cold-rolled steel strip and manufacturing method, which is applied in the field of cold-rolled steel strip for saw chain cutter teeth and its preparation, can solve the problems of long delivery period and high price of imported cold-rolled steel strip, and achieve low price and convenient Cold rolling and spheroidizing annealing, the effect of broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

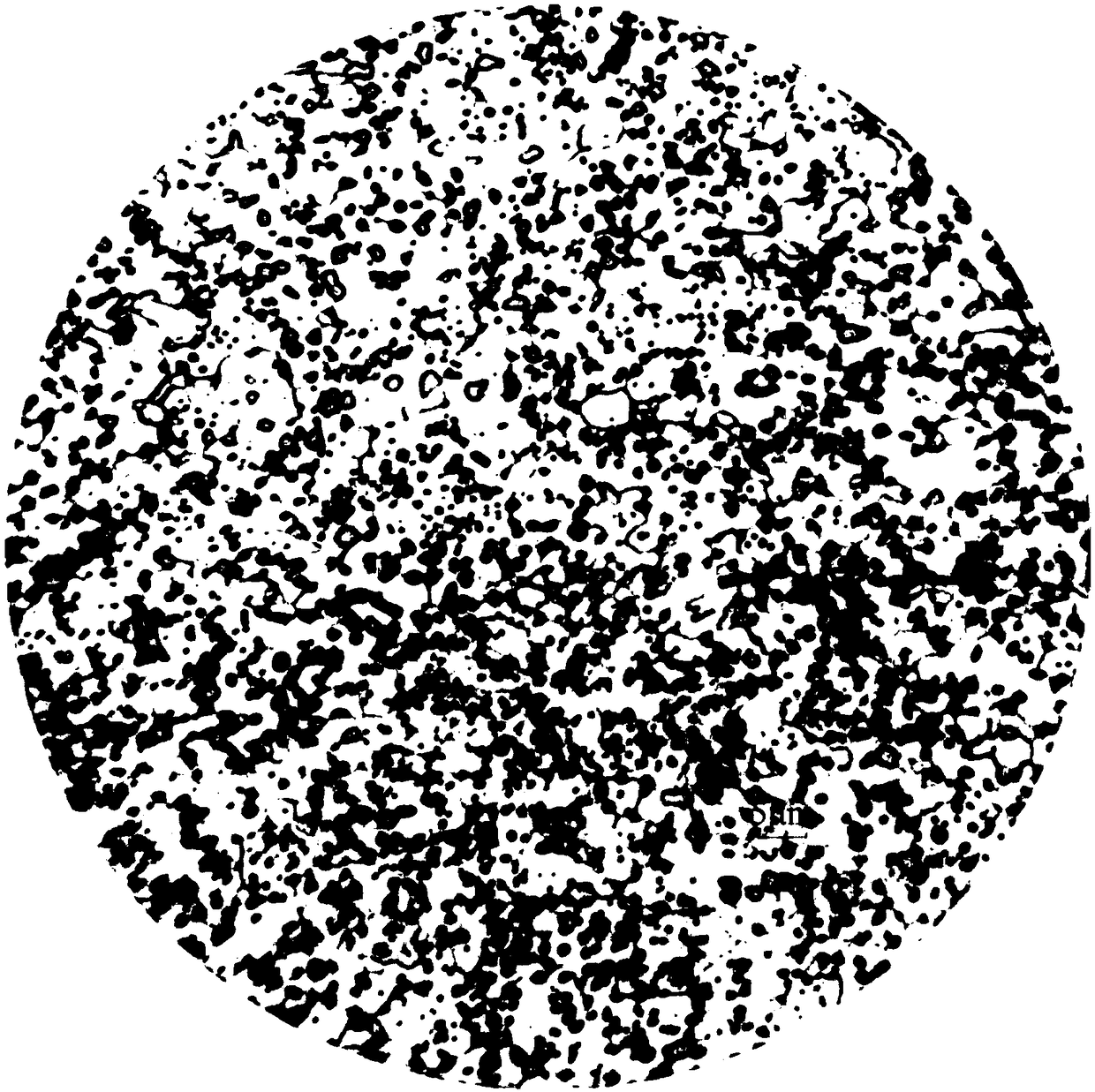

Image

Examples

Embodiment 1

[0057] (1) Hot rolling

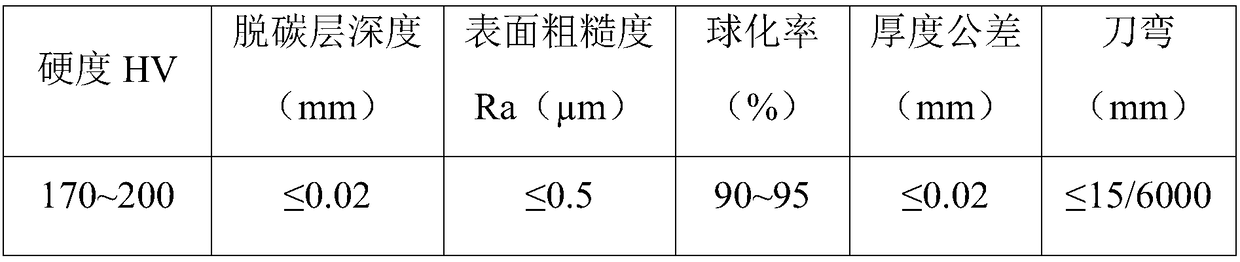

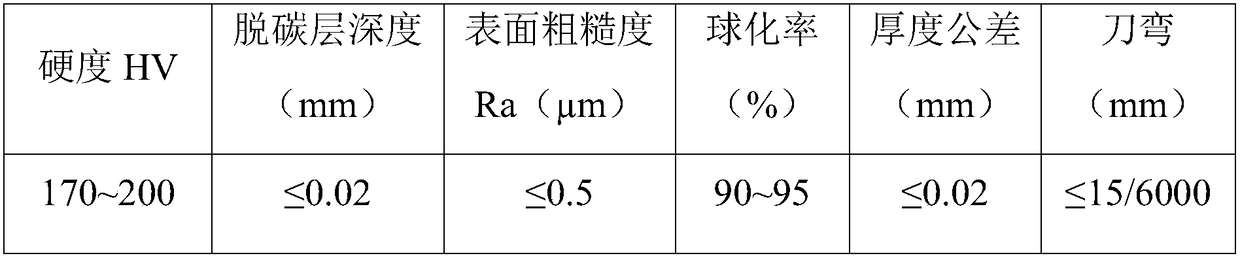

[0058] The composition and content (%) of hot-rolled raw materials are shown in Table 2:

[0059] Table 2 hot rolling raw material composition and content (%)

[0060] serial number

C

Si

mn

Ni

Cr

Al

Nb

P

S

1

0.621

0.200

0.340

0.911

0.100

0.006

0.037

0.008

0.001

2

0.619

0.200

0.340

0.911

0.099

0.006

0.034

0.008

0.003

3

0.620

0.248

0.340

0.936

0.095

0.007

0.039

0.008

0.001

[0061] The balance is Fe and trace unavoidable impurities;

[0062] The heating temperature is 1200±20°C, the rough rolling temperature is 1150±20°C, the finish rolling temperature is 1000±20°C, and the final rolling coiling temperature is 600±20°C;

[0063] (2) cold rolling

[0064] The hot-rolled steel strip is rolled twice through a single-stand reversible rolling mill after being annealed, and the specific process parameters are shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com