Alloy moving conduit for sodium-cooled fast reactor control rod drive mechanism and manufacturing method

A technology of driving mechanism and sodium-cooled fast reactor, which is applied in the field of iron-nickel-chromium alloy seamless pipe, can solve the problems of high alloying degree of GH1059 alloy, difficult smelting and manufacturing technology, and large deformation resistance, so as to improve the anti-radiation swelling Performance, elimination of segregation of elements, and effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

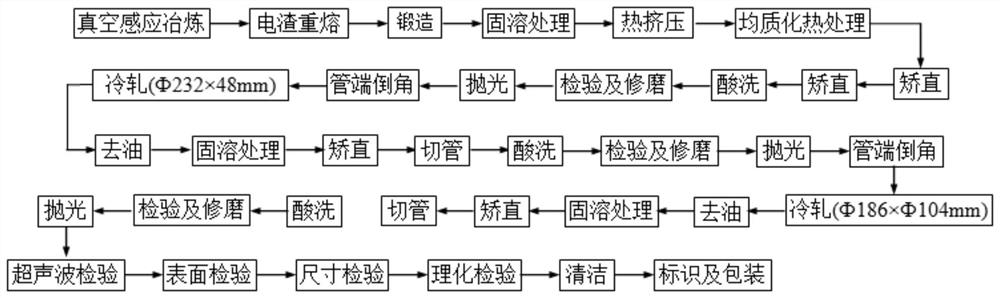

Method used

Image

Examples

Embodiment 1

[0054] A soda-cooled fast heap control rod drive mechanism provided by this embodiment with a alloy movement tube, and its chemical composition and mass of: C: 0.063%, Si: 0.10%, Mn: 1.51%, P: 0.005%, s: 0.005%, Cr: 16.44%, Ni: 36.30%, Cu: 0.03%, MO: 3.40%, W: 0.063%, Al: 0.08%, N: 0.018%, CO: 0.005%, B: 0.0017%, ZR: 0.010%, Y: Y: 0.001%, SN: 0.0002%, AS: 0.0007%, PB: 0.0001%, BI: 0.0001%, margin is Fe and trace elements.

[0055] The manufacturing method includes the following steps:

[0056] (1) Smelting

[0057] The alloy material was subjected to a vacuum induction smelting, the smelting temperature was 1480 ° C, cast into a 1,440 mm alloy ingot, and then using a 6-ton protective atmosphere of the electric slag heavy furnace to smelt into alloy ingots of ф 620 / ф720 mm;

[0058] (2) Forging

[0059] The alloy ingot obtained by step (1) is used in a 2000-ton fast forging unit, and the starting temperature is 1100 ~ 1150 ° C, the final forging temperature is 900 ~ 950 ° C, and ...

Embodiment 2

[0084] In this embodiment, a sodium cold fast heap control rod drive mechanism is used for alloy movement tubes, and the difference from Example 1 is that the chemical composition and mass of mass, such as: C: 0.060%, Si: 0.1%, Mn: 1.53% P: 0.005%, S: 0.005%, Cr: 36.40%, Ni: 36.30%, Cu: 0.02%, MO: 3.25%, W: 0.07%, Al: 0.073%, N: 0.02%, CO: 0.005% B: 0.0019%, Zr: 0.010%, Y: 0.001%, SN: 0.0002%, AS: 0.0008%, PB: 0.0001%, BI: 0.0001%, Sb: 0.001%, margin is Fe and trace elements.

[0085] In the product, the outer surface roughness Ra is ≤1.6 μm; the outer diameter is ± 1.00mm, the inner diameter is ± 1.00mm; 20 ° C Tensile properties: R m = 590MPa, R p0.2 = 264MPa, A 50 = 49.0%, z = 75%, R m Indicates tensile strength, R p0.2 Indicates the yield strength, and A means a broken elongation, Z represents a section shrinkage rate; high temperature tensile performance: 100 ° C, R m = 553MPa, R p0.2 = 233MPa, A 50 = 44.5%, z = 76%, 200 ° C, R m = 525MPa, R p0.2 = 201MPA, A 50 = 45.0%, z = 7...

Embodiment 3

[0087] In this embodiment, a sodium cold fast heap control rod drive mechanism is used with alloy movement tubes, and the difference from Example 1 is that the chemical composition and mass of: 0.060%, Si: 0.10%, Mn: 1.54 %, P: 0.005%, S: 0.001%, Cr: 36.27%, Ni: 36.18%, Cu: 0.03%, MO: 3.26%, W: 0.07%, Al: 0.048%, N: 0.012%, CO: 0.001 %, B: 0.001%, Zr: 0.0010%, Y: 0.001%, SN: 0.001%, AS: 0.0007%, Pb: 0.0001%, BI: 0.0001%, Sb: 0.001%, margin is Fe and trace elements.

[0088] In the product, the outer surface roughness Ra is ≤1.6 μm; the outer diameter is ± 1.00mm, the inner diameter is ± 1.00mm; 20 ° C Tensile properties: R m = 592MPa, R p0.2 = 266MPa, A 50 = 48.5%, z = 75%, R m Indicates tensile strength, R p0.2 Indicates the yield strength, and A means a broken elongation, Z represents a section shrinkage rate; high temperature tensile performance: 100 ° C, R m = 552MPa, R p0.2 = 231MPA, A 50 = 44.0%, z = 75%, 200 ° C, R m = 526MPa, R p0.2 = 203MPa, A 50 = 45.0%, z = 74%, 300 ° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com