Patents

Literature

34results about How to "Won't curl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

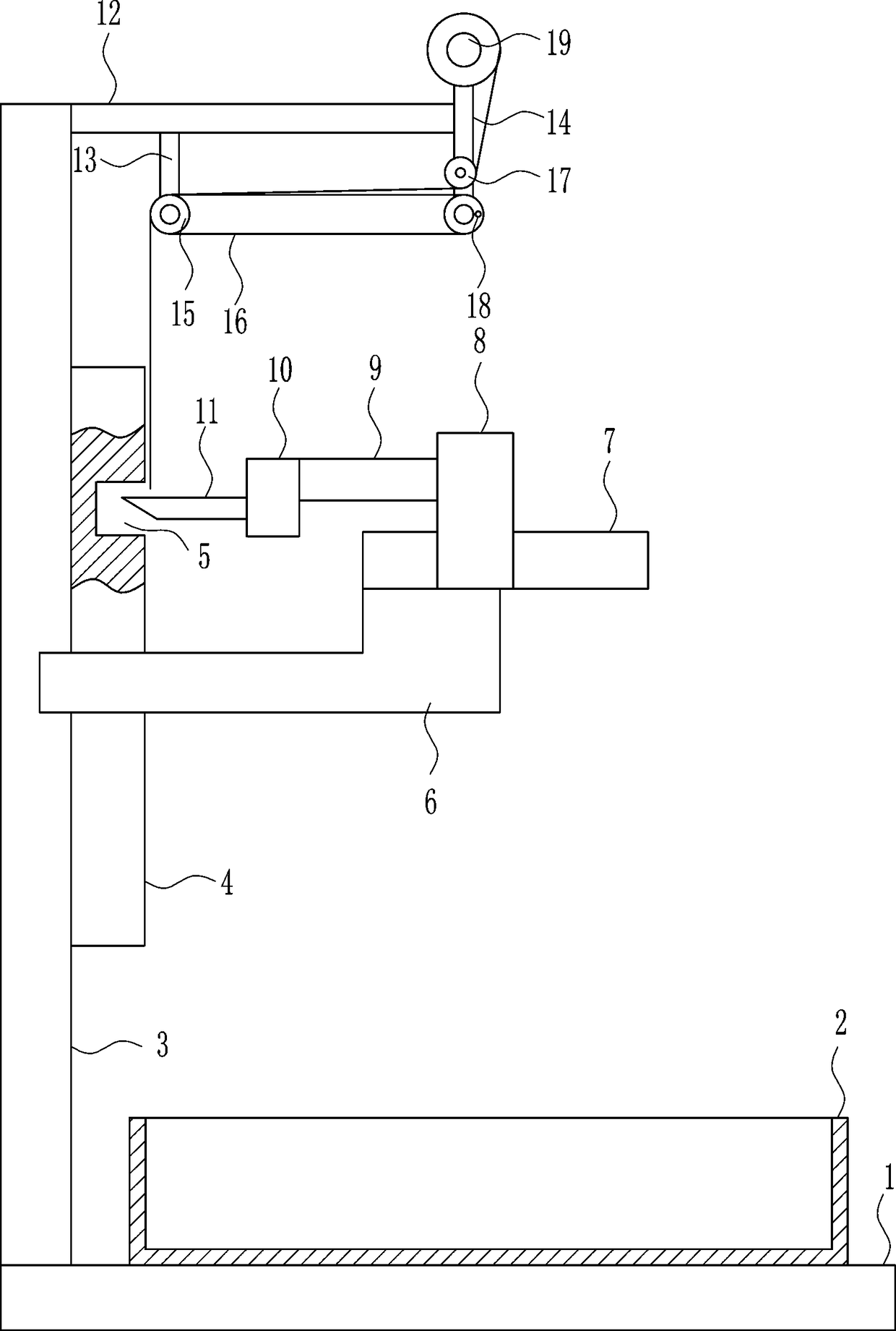

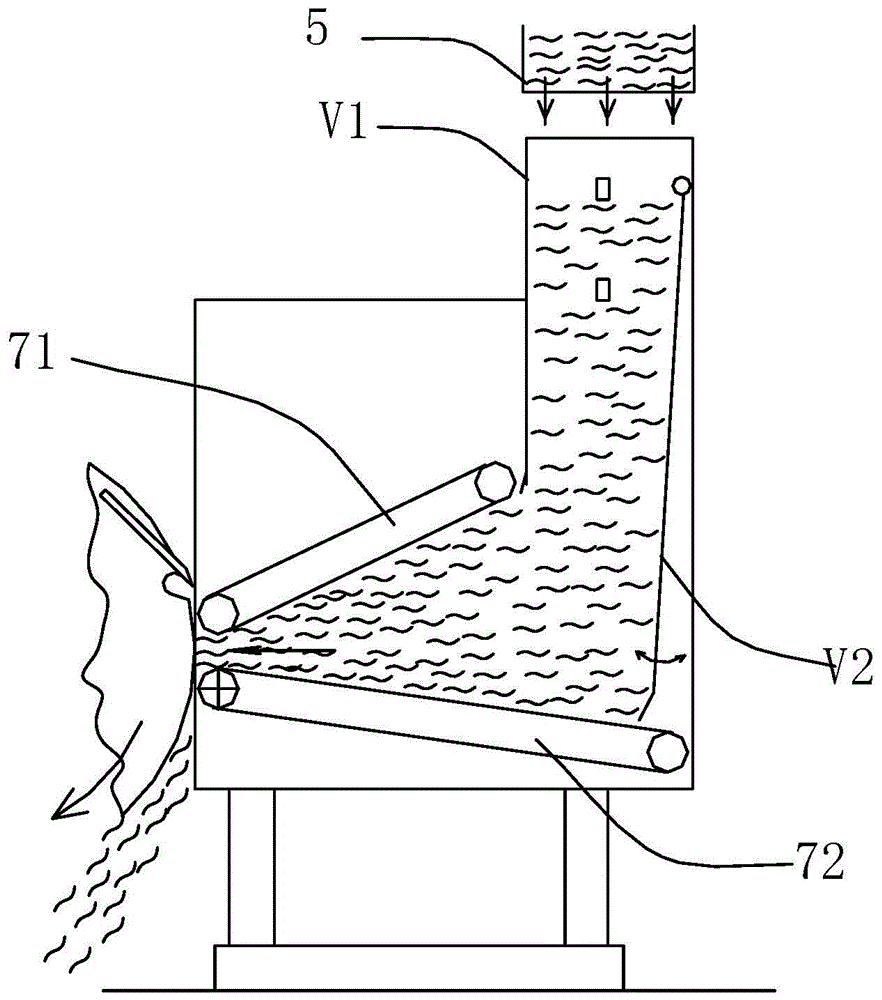

Film slitting machine preventing edge curling

ActiveCN108408455AImprove heating efficiencyExtended service lifeArticle deliveryWebs handlingEngineeringMechanical engineering

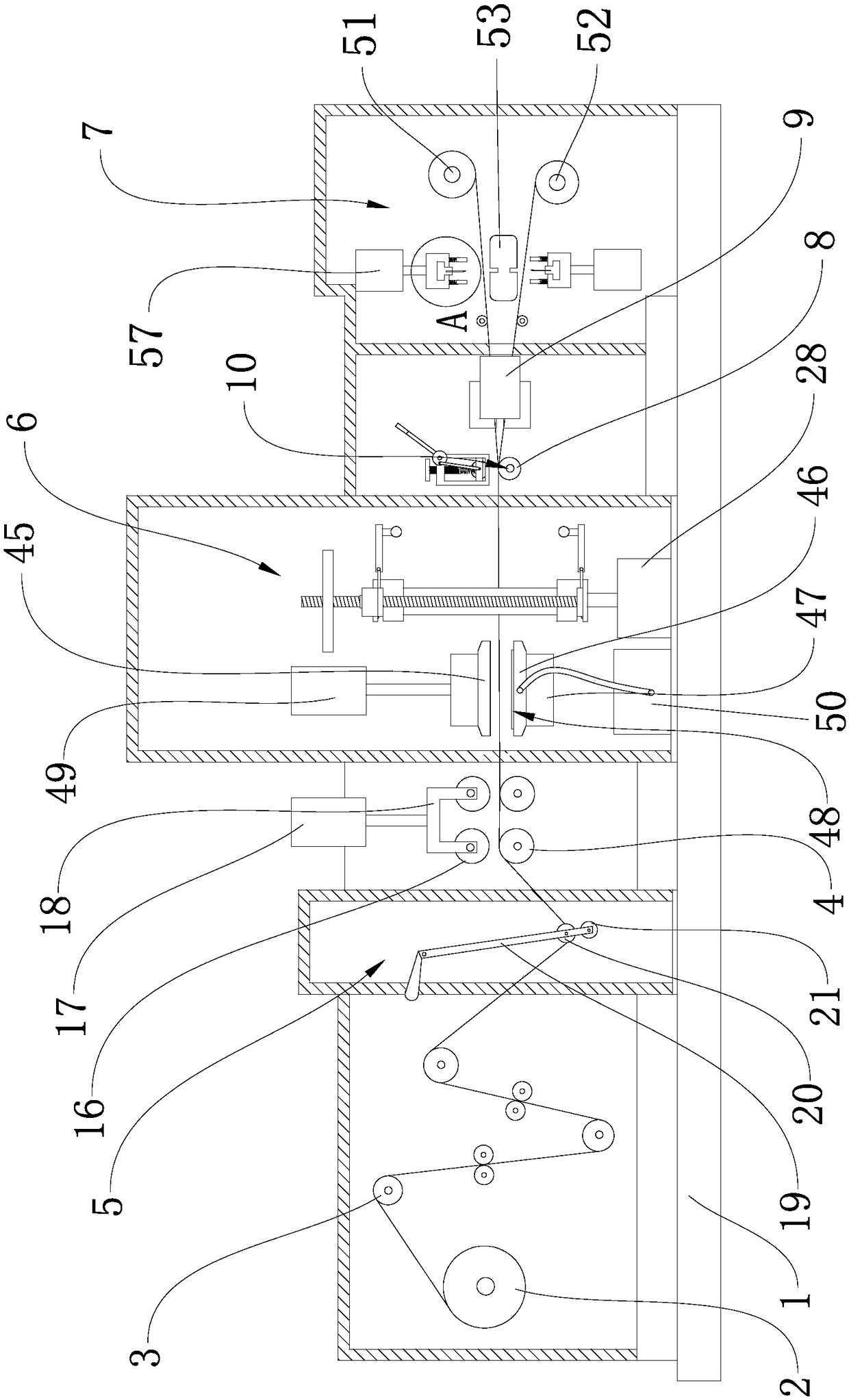

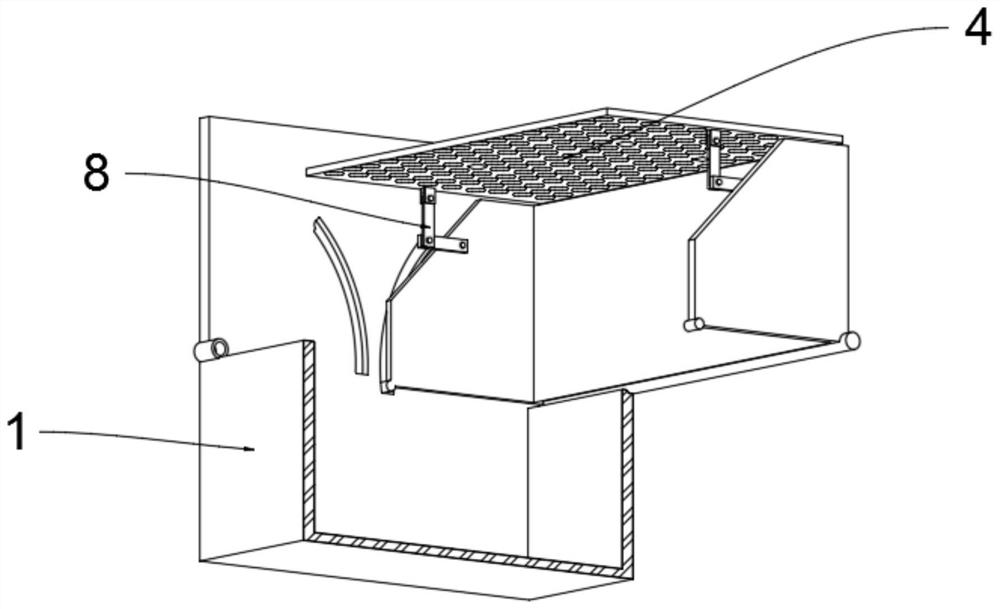

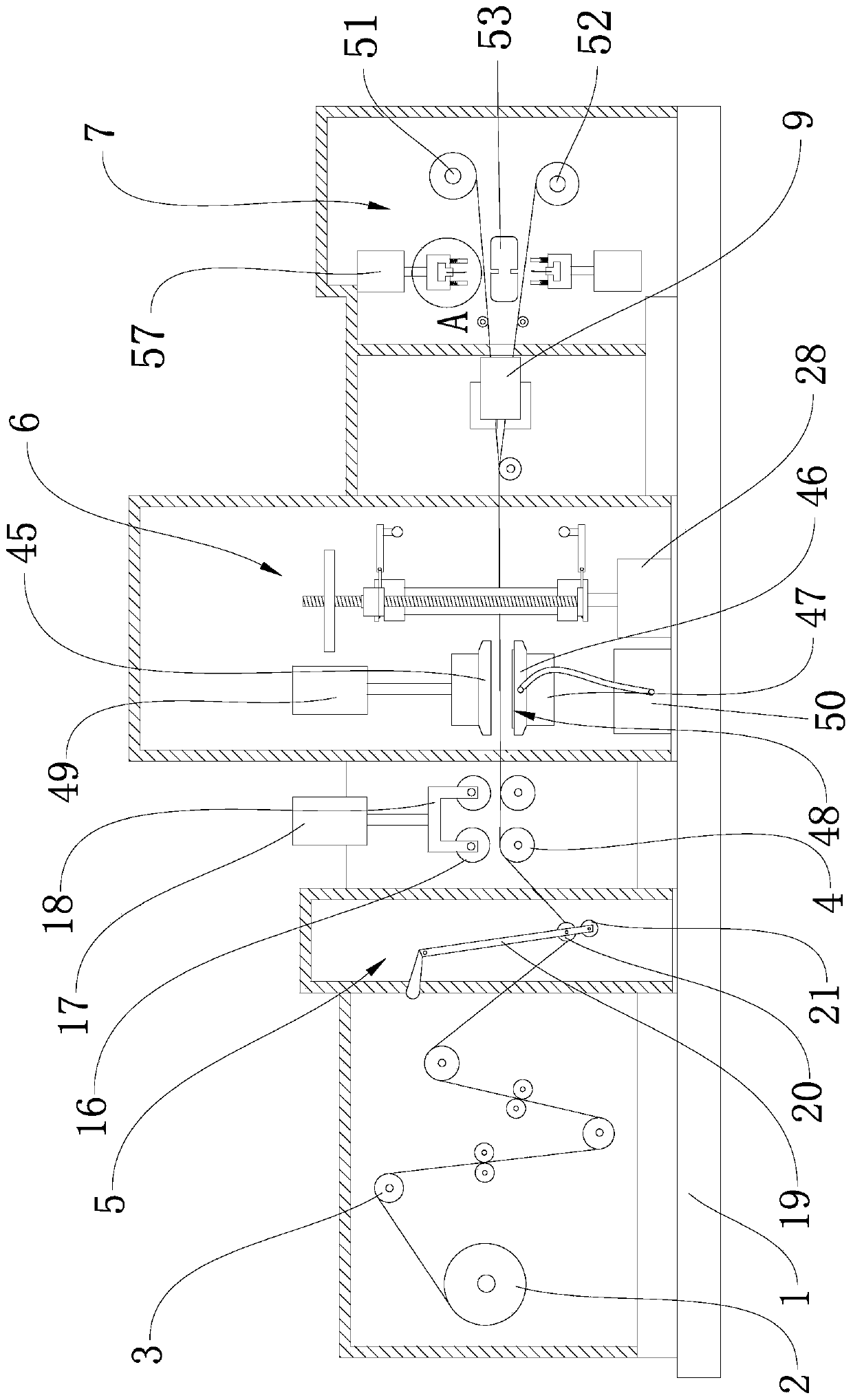

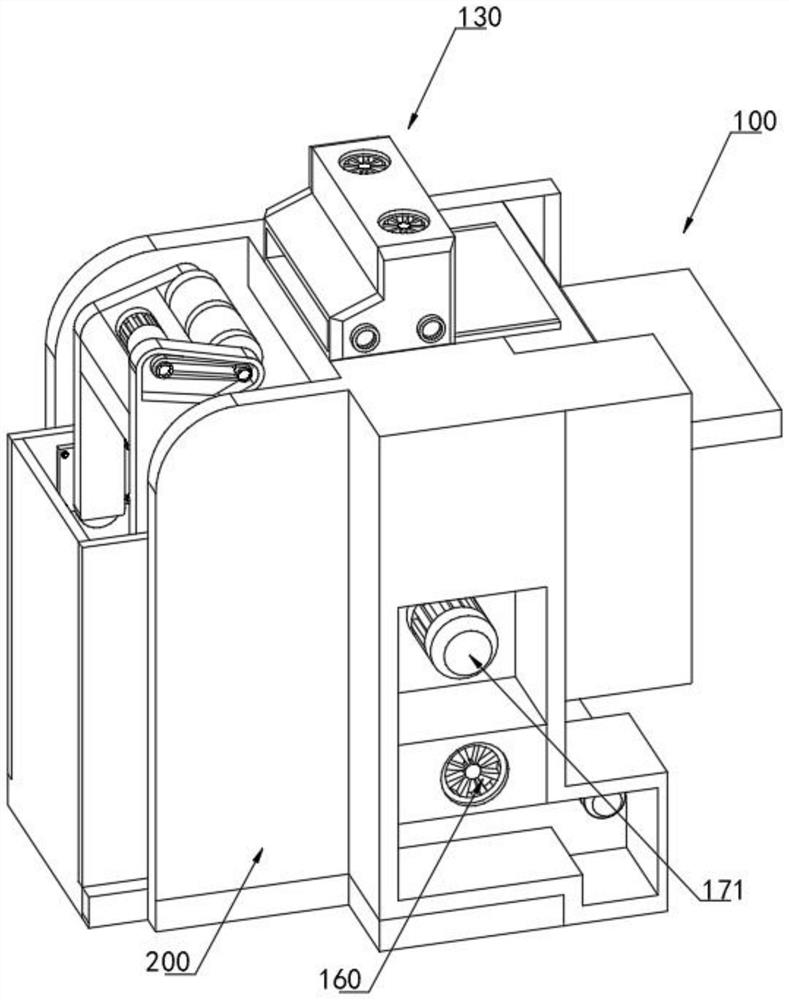

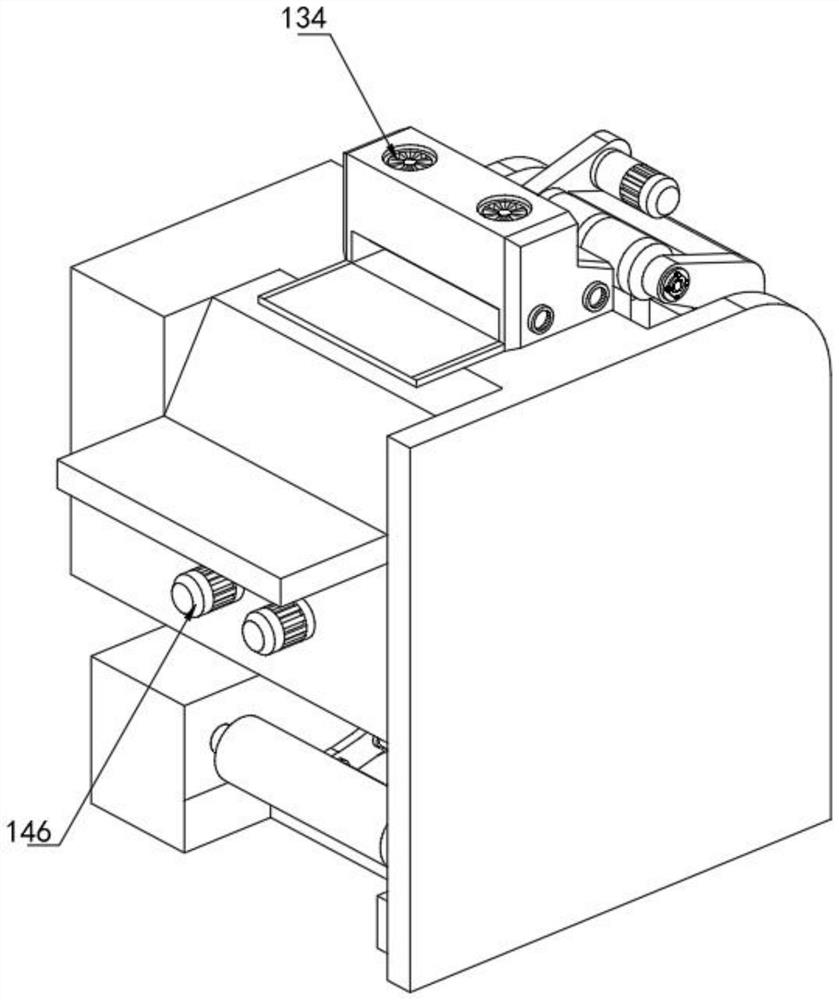

The invention provides a film slitting machining preventing edge curling and belongs to the mechanical technical field. The film slitting machining preventing edge curling solves the technical problemthat an existing film slitting machine is poor in cutting effect. The film slitting machining preventing edge curling comprises a machine frame. A feeding roller is rotationally arranged on the machine frame. A plurality of extension rollers and adhesion rollers are sequentially and rotationally arranged on one side of the feeding roller. The extension rollers and the adhesion rollers are rotationally arranged on the machine frame. A tensioning structure used for tensioning the film is arranged between the extension rollers and the adhesion rollers. The side, far away from the extension rollers, of the adhesion rollers is further sequentially provided with a cutting mechanism used for film slitting and a coiling mechanism for slit film. A heating roller used for preventing the edges of the film strips from curling and a strip separating block capable of separating adjacent cut film strips in a staggered manner are sequentially arranged between the cutting mechanism and the coiling mechanism. The strip separating block and the heating roller are fixedly arranged on the machine frame. The film slitting machine preventing edge curling has the advantage of being good in slitting effect.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

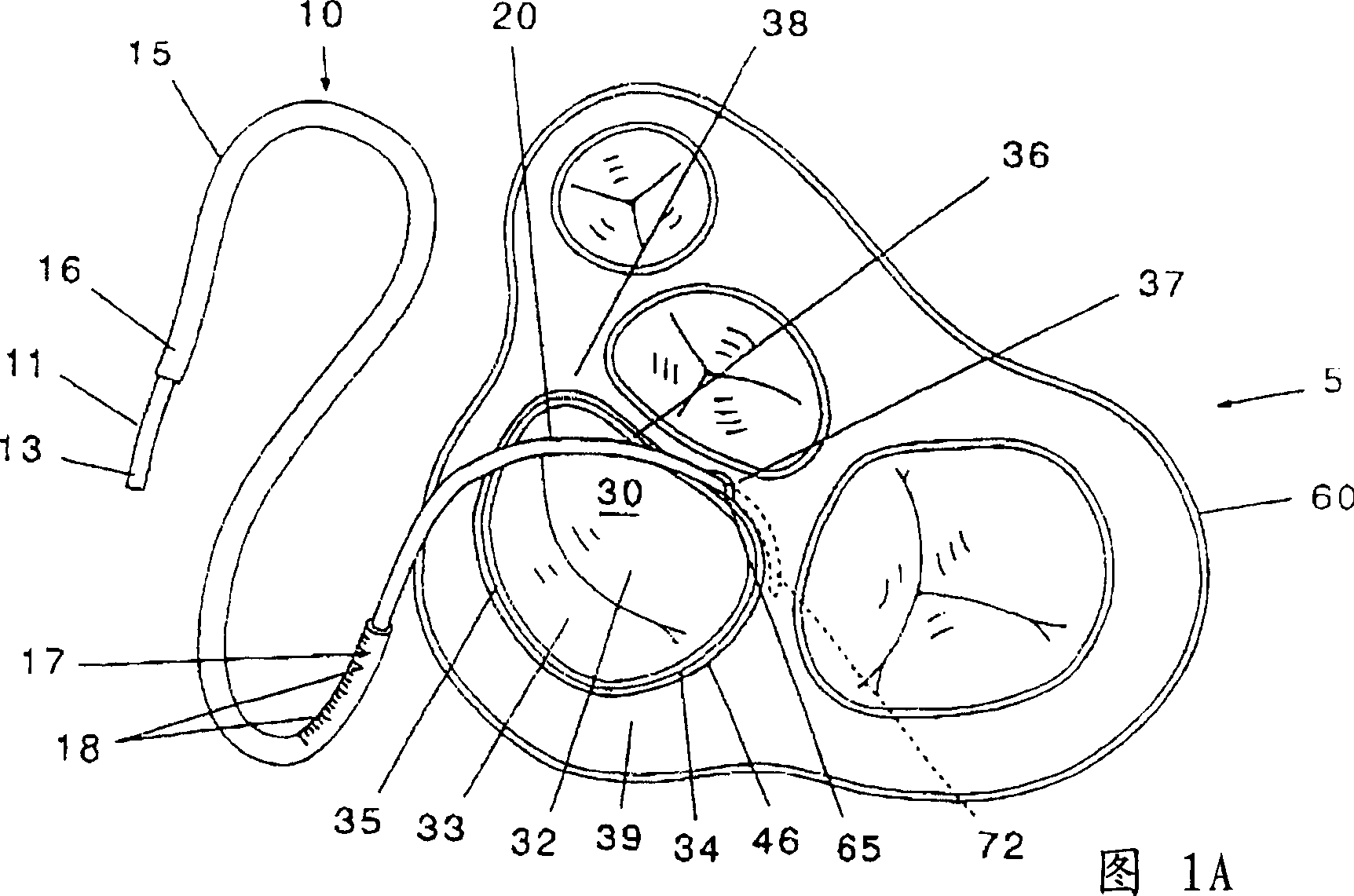

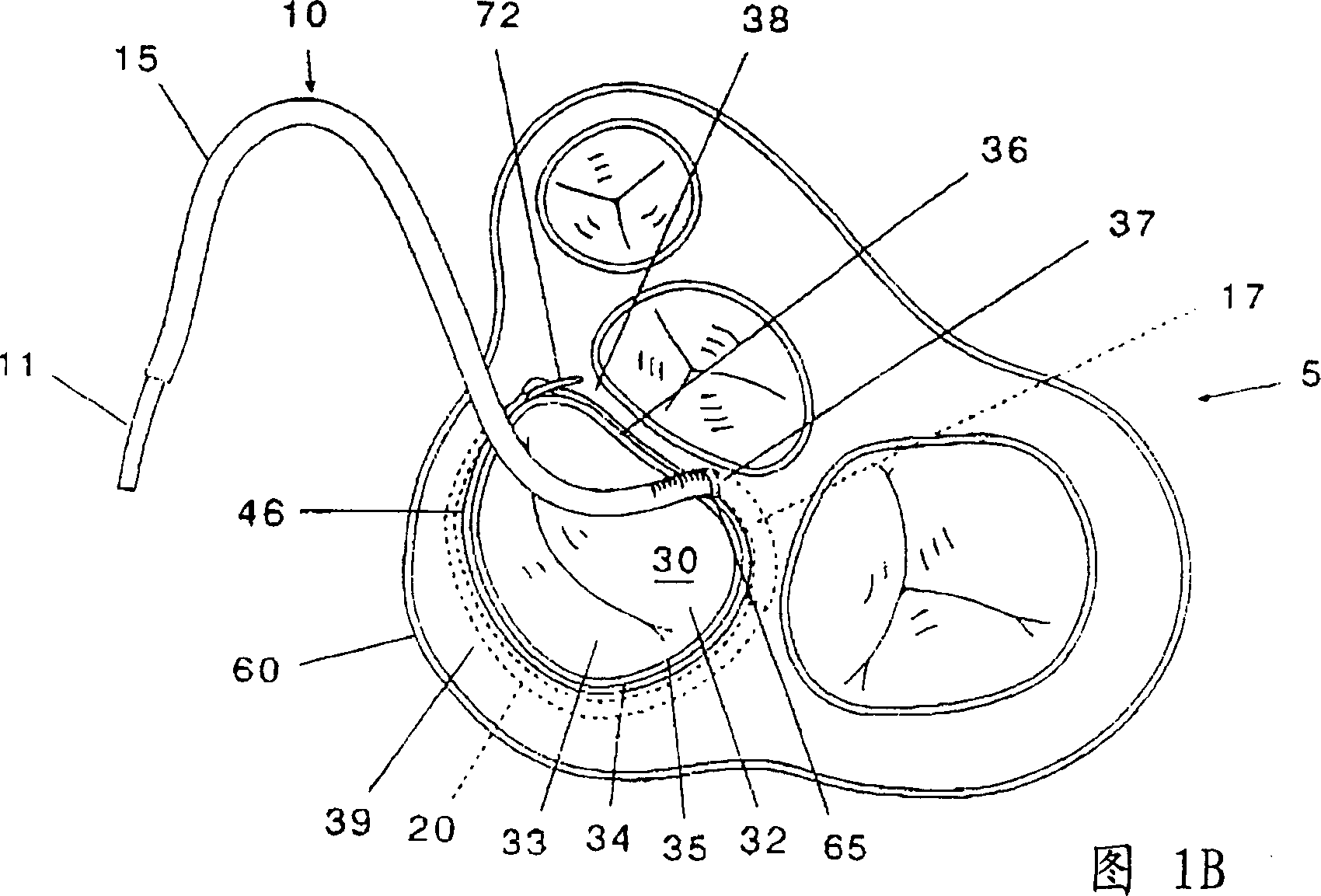

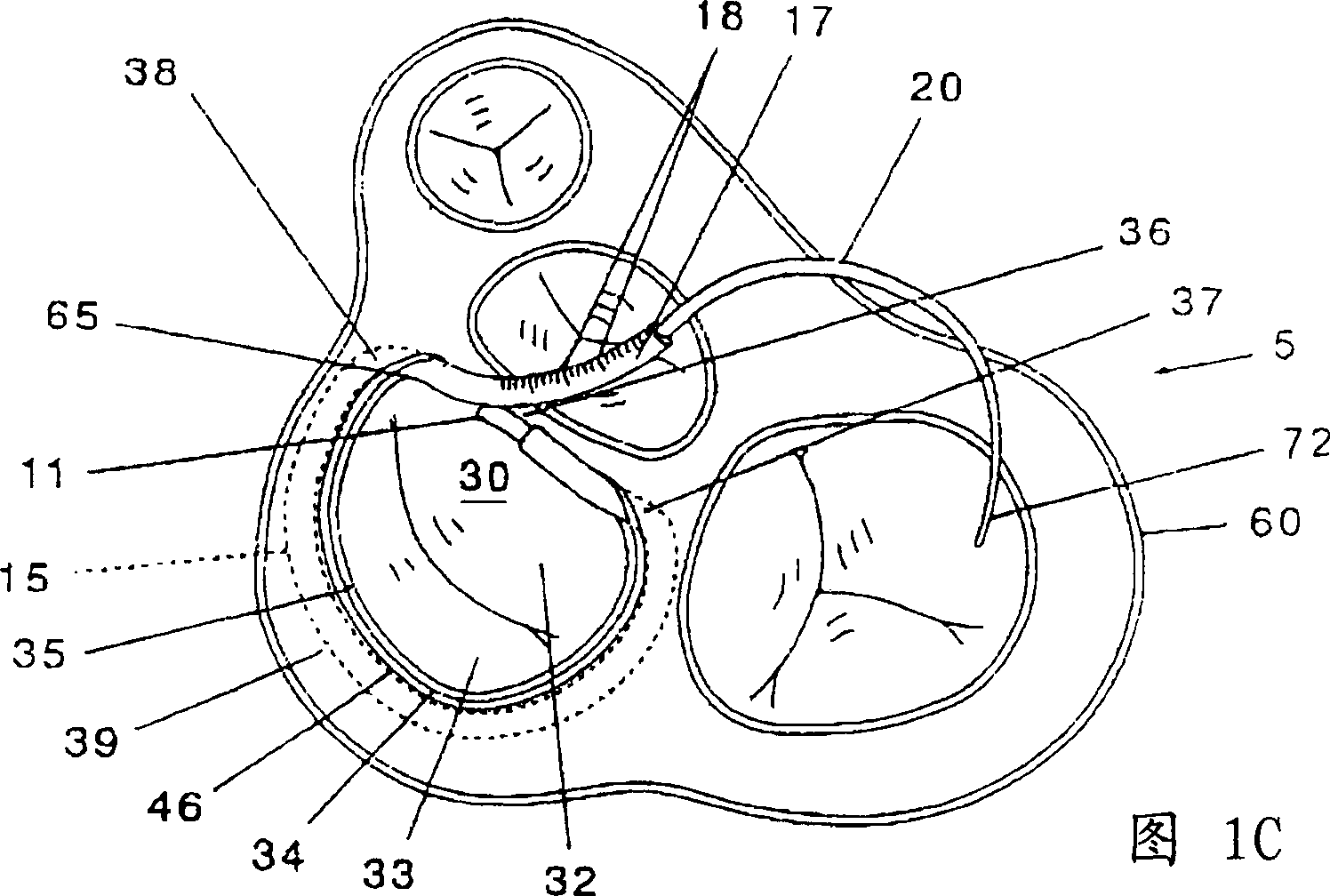

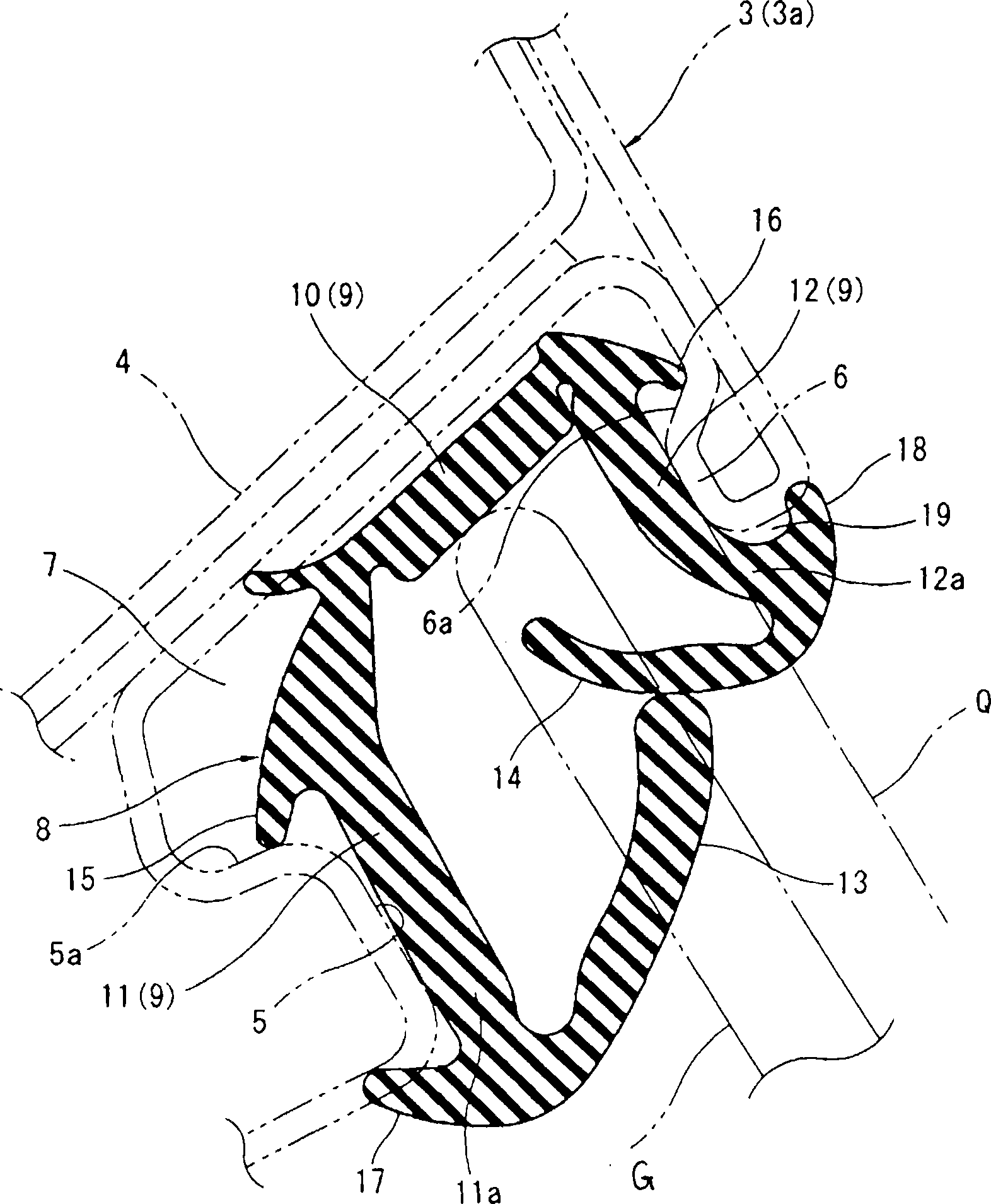

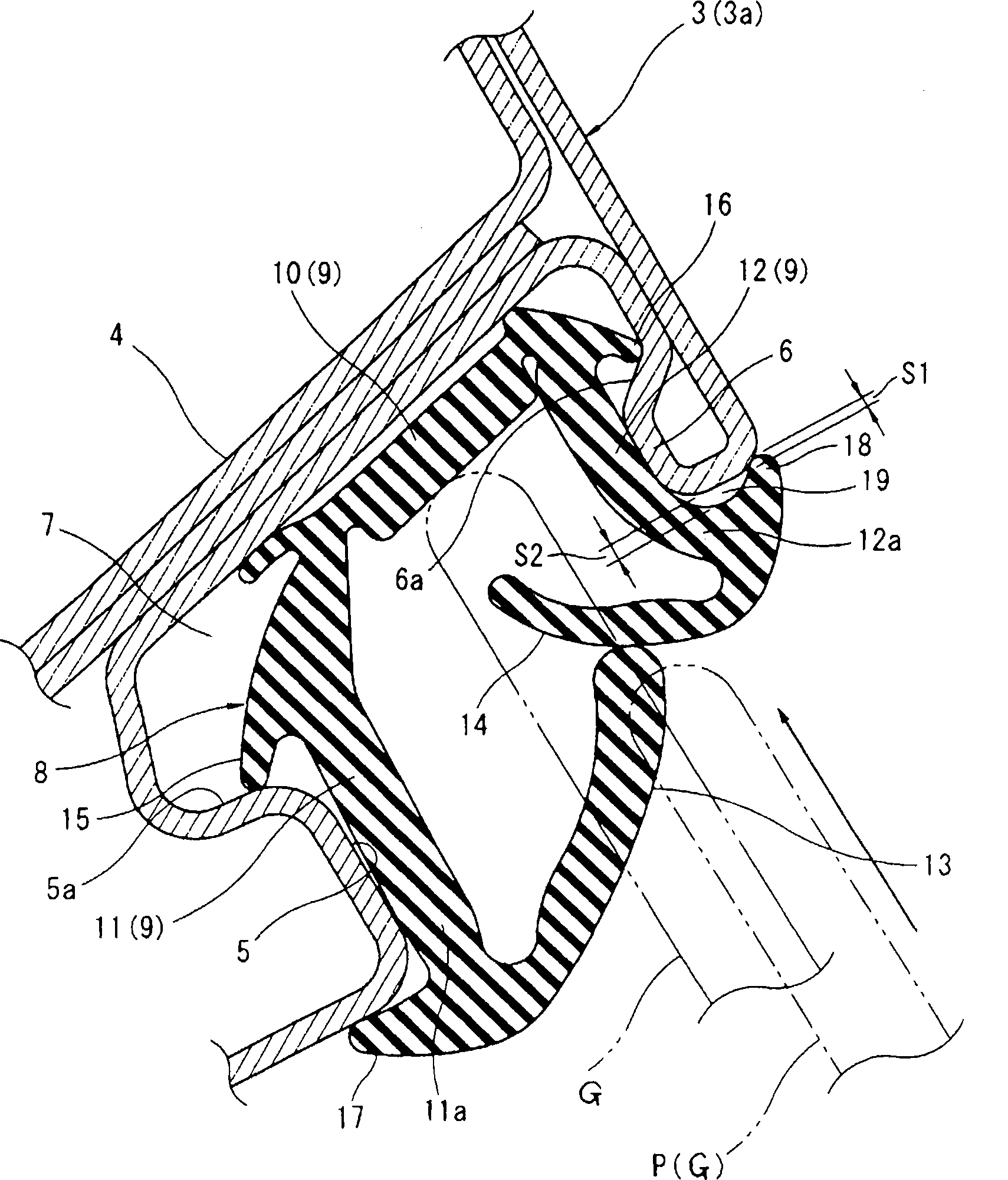

Mitral valve annuloplasty ring and method

InactiveCN1391453APrevent loss of flexibilityGuaranteed flexibilitySurgical needlesAnnuloplasty ringsAnnuloplasty ringsCardiology

A mitral valve annuloplasty ring and method for implanting a mitral valve annuloplasty ring to treat mitral insufficiency by reestablishing the normal shape and contour of the mitral valve annulus. The annuloplasty ring is flexible and can be readily adjusted to different sizes and shapes. The method substantially eliminates scarring subsequent to the annuloplasty procedure to maintain flexibility of the ring and the annulus indefinitely.

Owner:卡迪亚克·康赛普茨公司

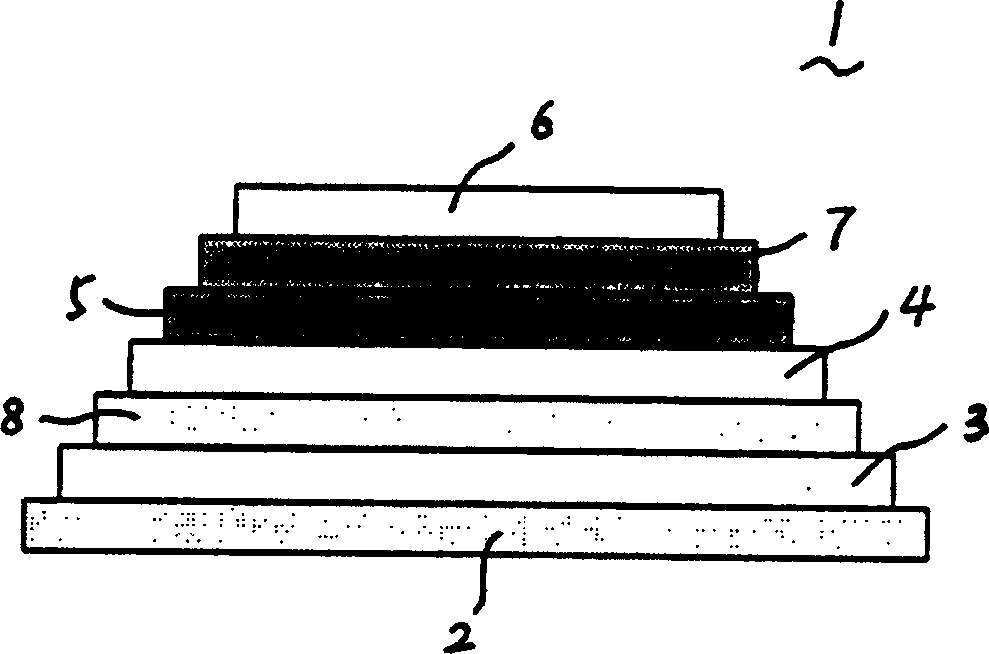

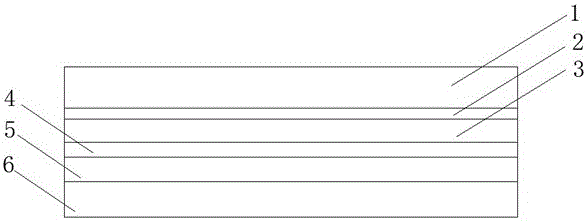

Manufacturing method of transfer paper

A technology for making transfer paper for printing pattern on the external surface of product includes such steps as preparing high-processing performance synthetic resin, adding viscosity-increasing assistant, pressing resin film with the said mixture by extruding method, rolling method or doctor blading method, printing pattern on a substrate paper with a prepared water sol layer, and covering with the said resin film.

Owner:增城市运豪五金塑料有限公司

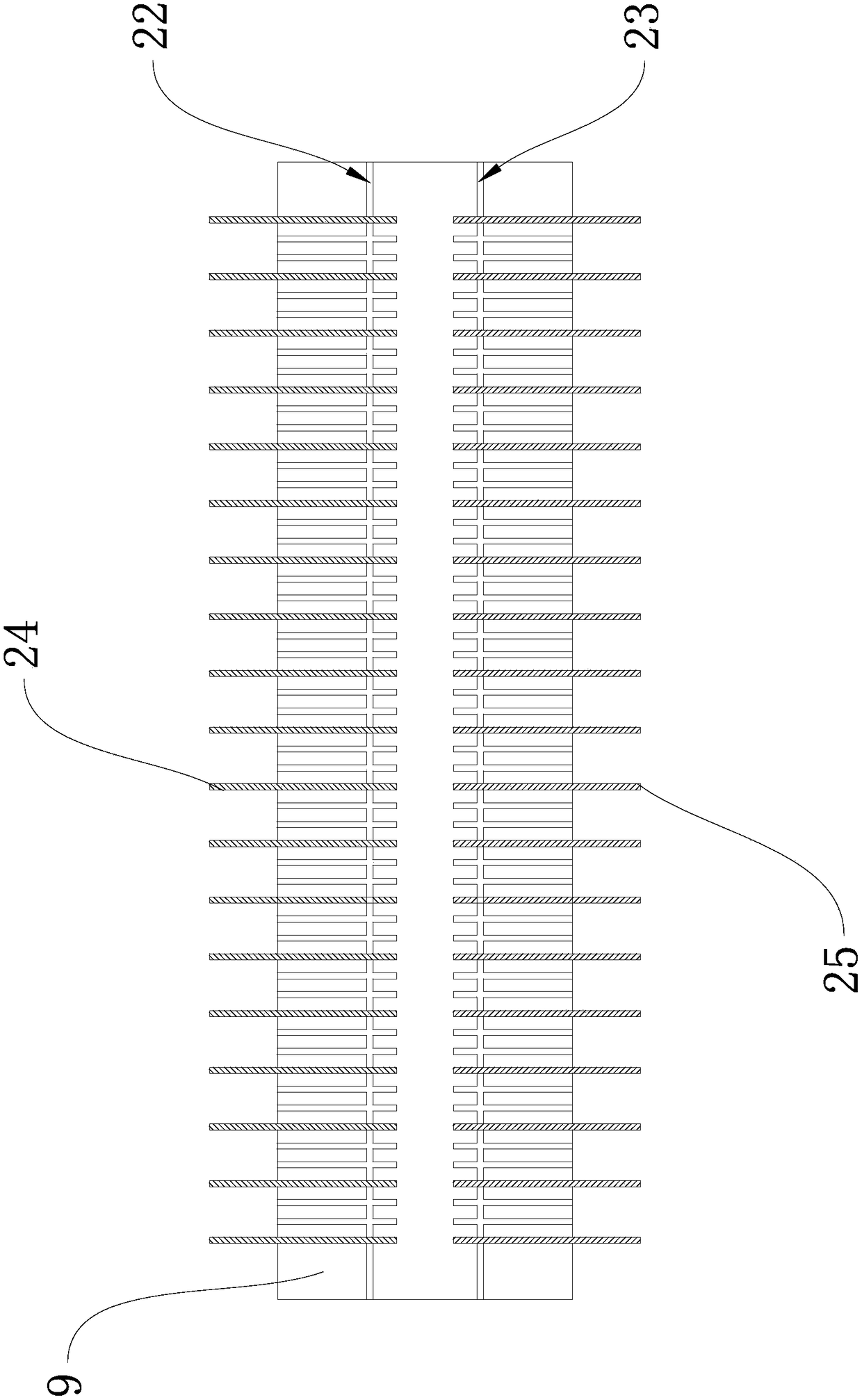

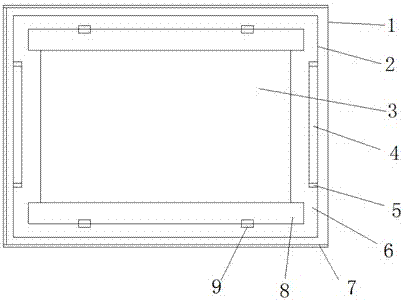

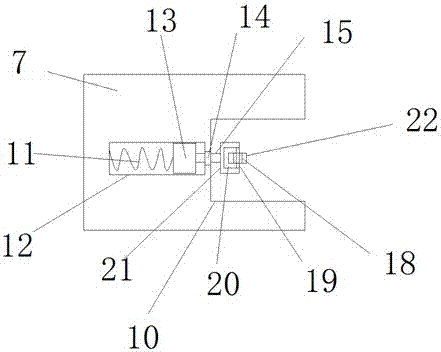

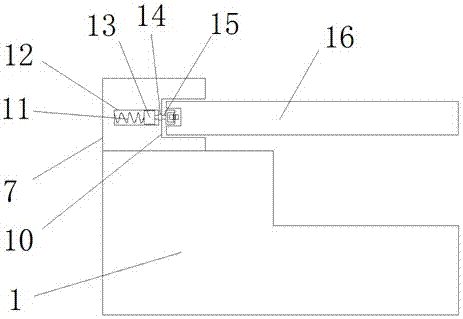

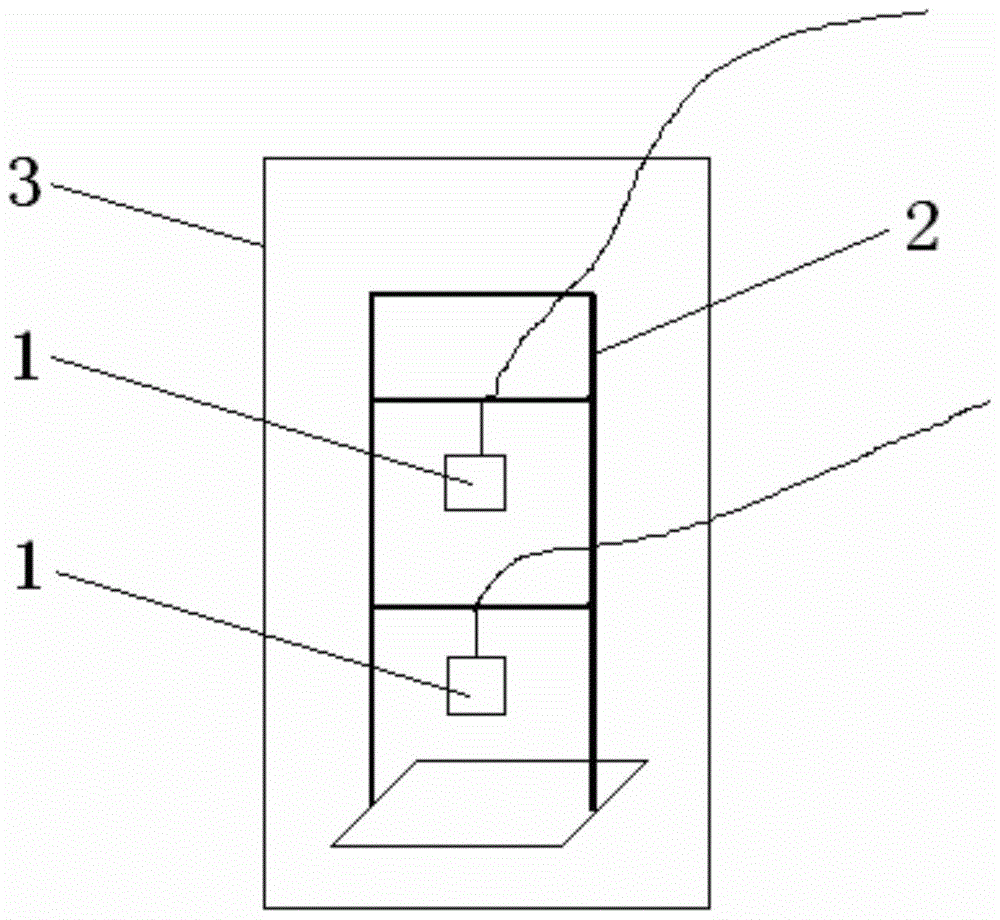

Graph paper display device

The invention discloses a graph paper display device comprising a graph paper frame. A groove is formed in the graph paper frame; lamp holders are arranged on the inner walls of two sides of the groove; a lamp tube is mounted on each lamp holder; a base plate is arranged on the bottom of the groove; a piece of graph paper is arranged on the base plate; the base plate is rotationally connected with a paper pressing plate; one side that the paper pressing plate and the base plate get close to each other and are pressed against each other is provided with a magnet; a glass slide seat is arranged on the top of the edge of the graph paper frame; glass is slideably connected to the glass slide seat; one side that the glass slide seat is close to the graph paper is provided with a second groove; one side that the second groove is far away from a second groove mouth is provided with an accommodating cavity; the inner wall of the accommodating cavity is connected with one end of a spring; the other end of the spring is connected with a slide block disposed in the accommodating cavity. By the use of the graph paper display device, the graph paper can be stored, so the edges of the graph paper cannot be folded and wrinkled; the glass slide seat and the glass can slide conveniently; buffering effect can be achieved during the process of slide, so pause during the slide can be avoided; and meanwhile, the glass can prevent dust and facilitates graph paper preservation.

Owner:佛山标天下信息科技有限公司

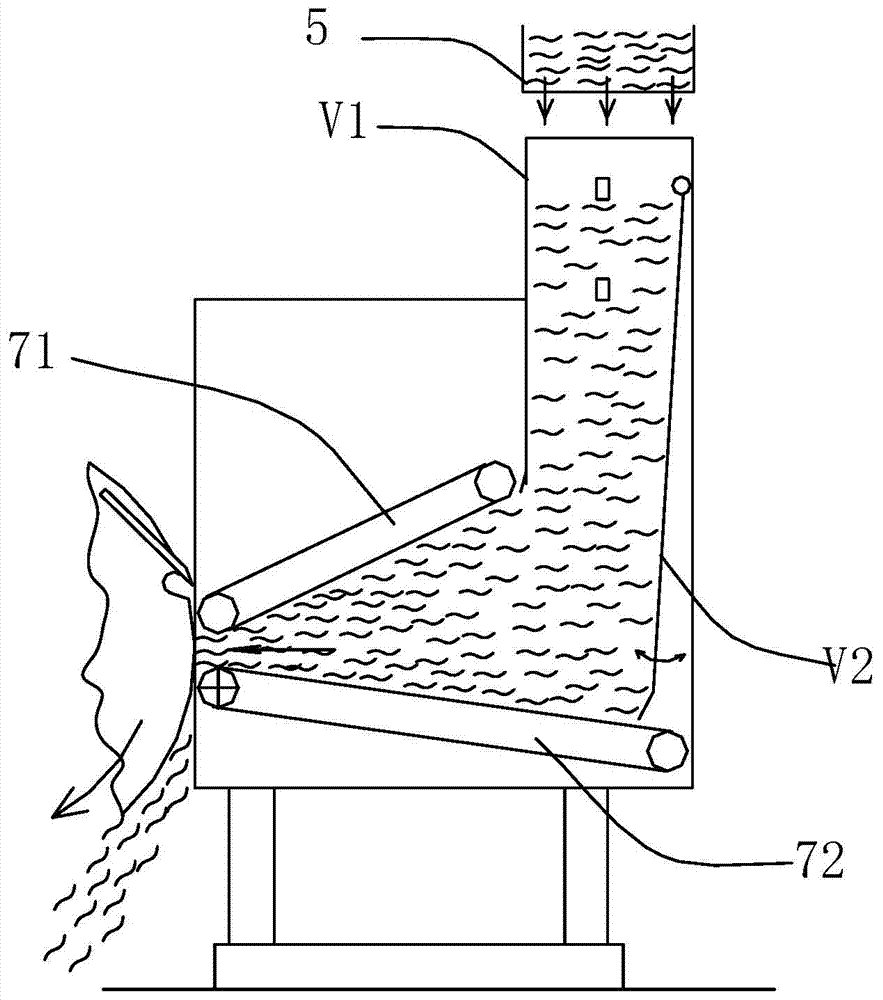

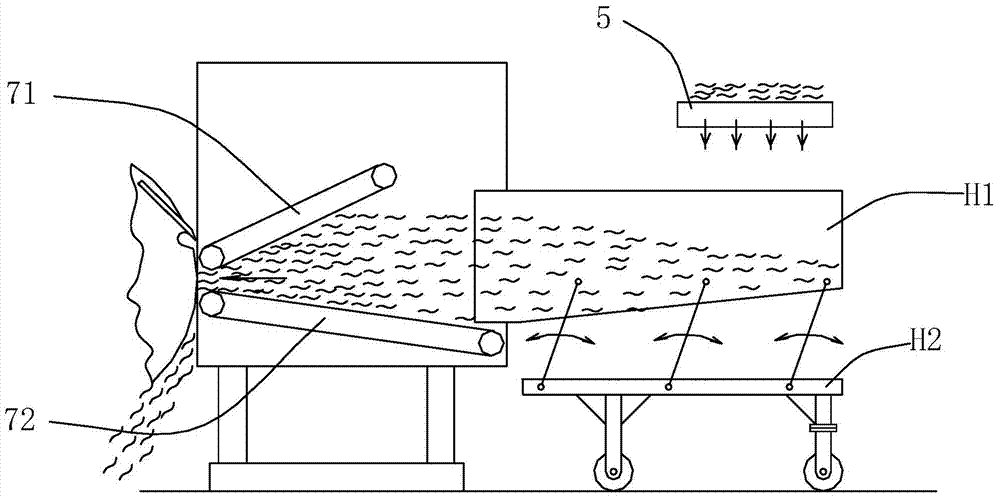

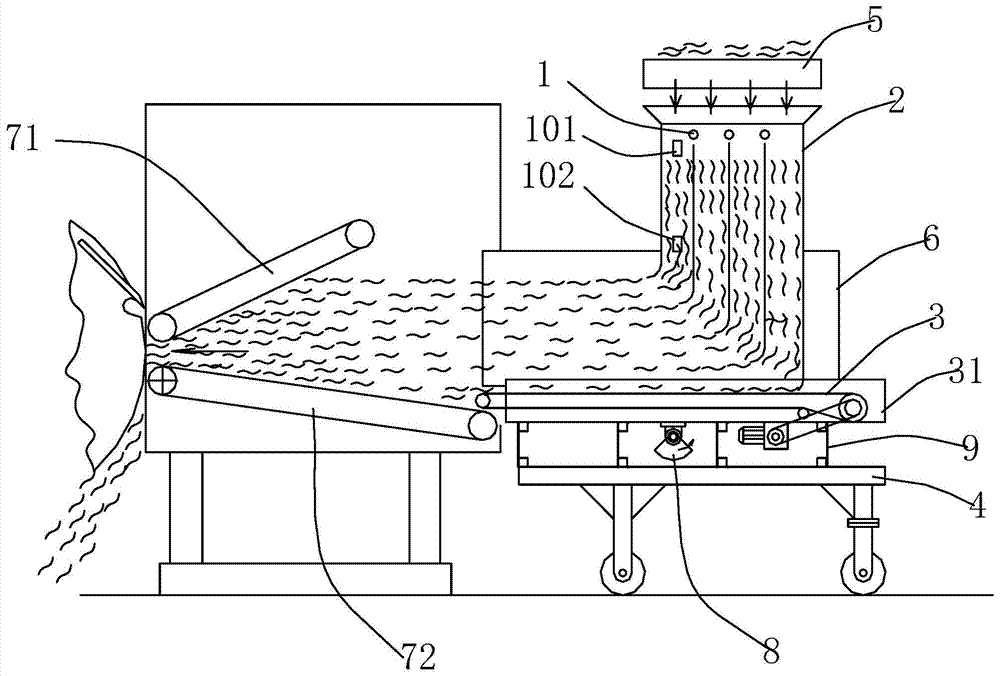

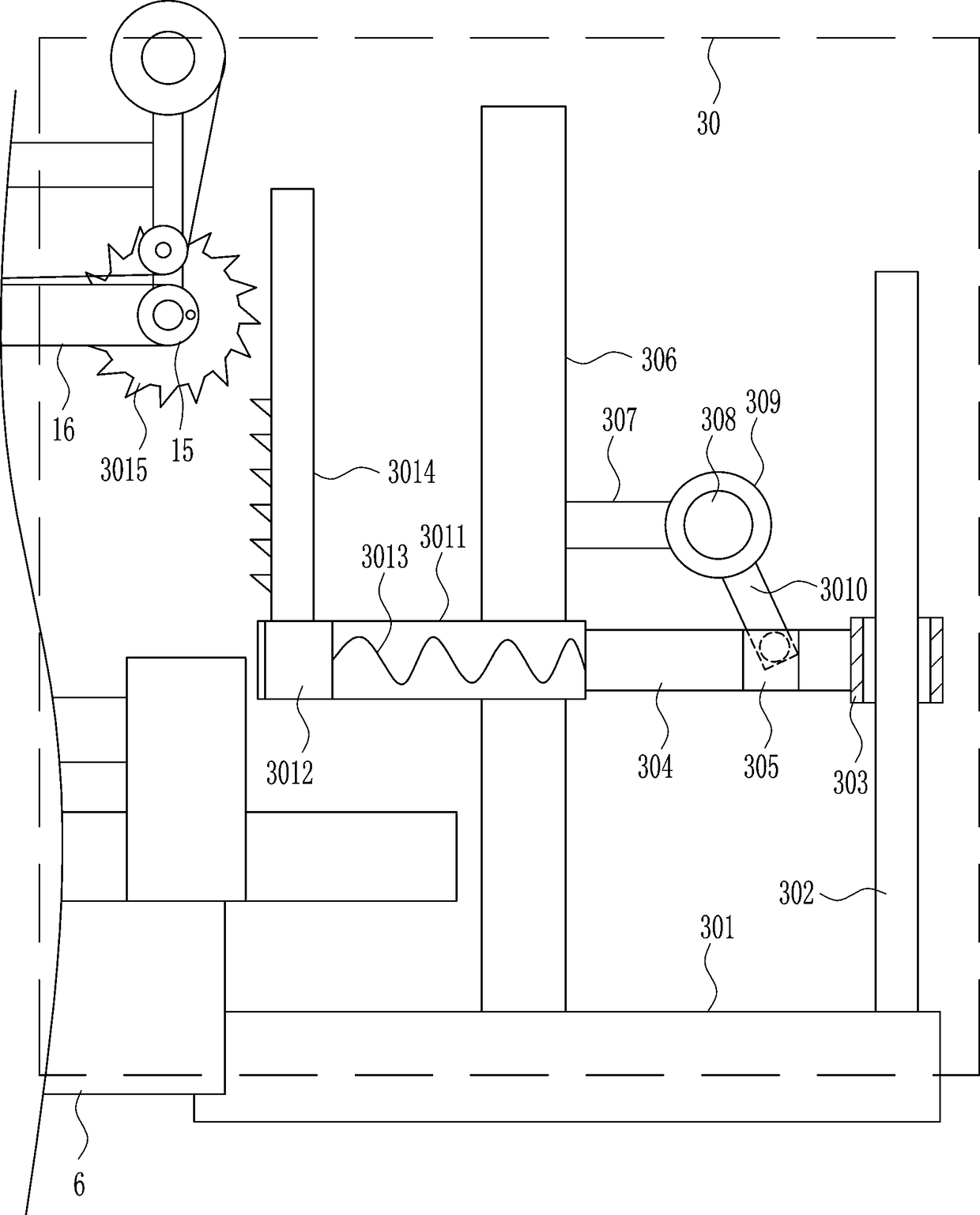

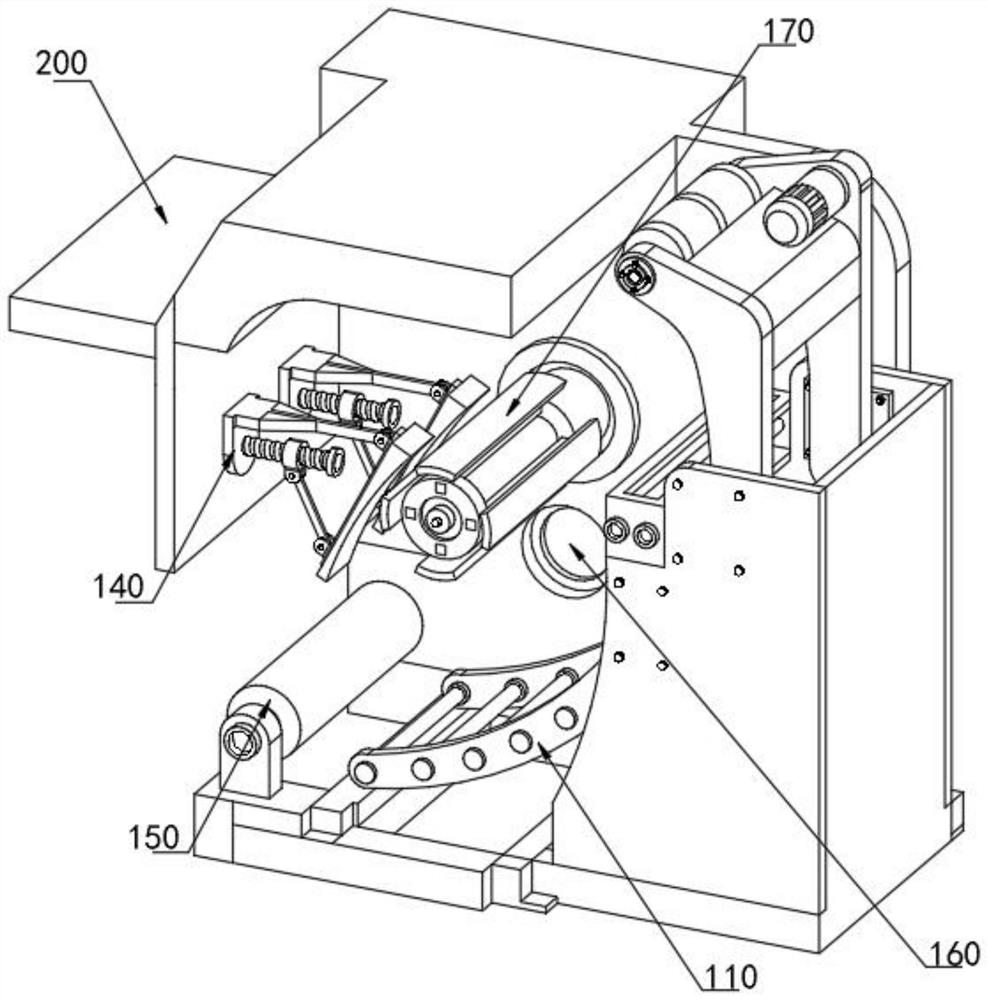

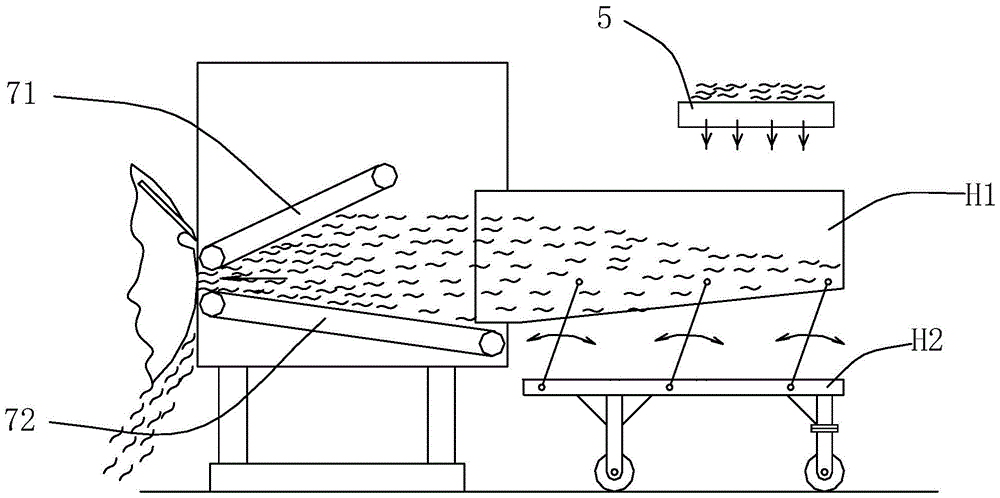

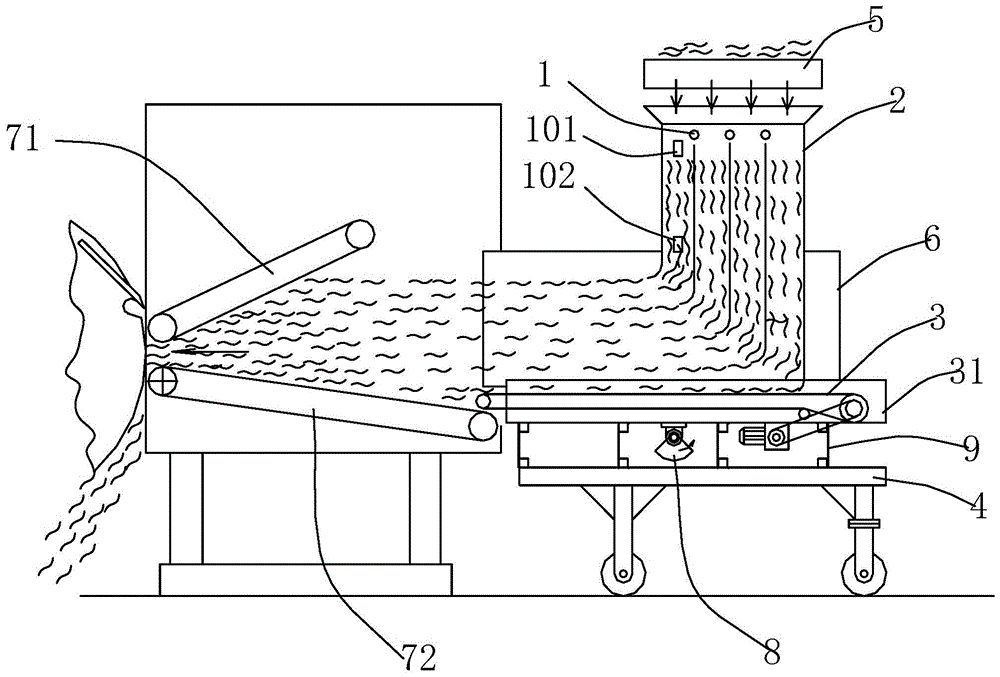

Thin film slitting machine capable of preventing burrs

ActiveCN108393951AIncrease temperatureExtended service lifeMetal working apparatusMechanical engineering

The invention provides a thin film slitting machine capable of preventing burrs, and belongs to the technical field of machinery. The thin film slitting machine solves the technical problems of poor slitting effect and the like which exist in an existing thin film slitting machine. The thin film slitting machine capable of preventing the burrs comprises a machine frame, wherein a material feedingroller is rotationally arranged on the machine frame, and a plurality of extension rollers and adhesion rollers are sequentially and rotationally arranged on one side of the material feeding roller; the extension rollers and the adhesion rollers are all rotationally arranged on the machine frame, and a tensioning structure used for tensioning a thin film is arranged between the extension rollers and the adhesion rollers; the sides, far away from the extension rollers, of the adhesion rollers are also sequentially provided with a cutting mechanism and a winding mechanism, wherein the cutting mechanism is used for slitting the thin film and is adjustable in width, and the winding mechanism is used for winding the thin film after slitting; and a strip separating block capable of separating cut adjacent thin film strips in a staggered mode is arranged between the cutting mechanism and the winding mechanism, and the strip separating block is fixedly arranged on the machine frame. The thin film slitting machine has the advantage of being good in slitting effect.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

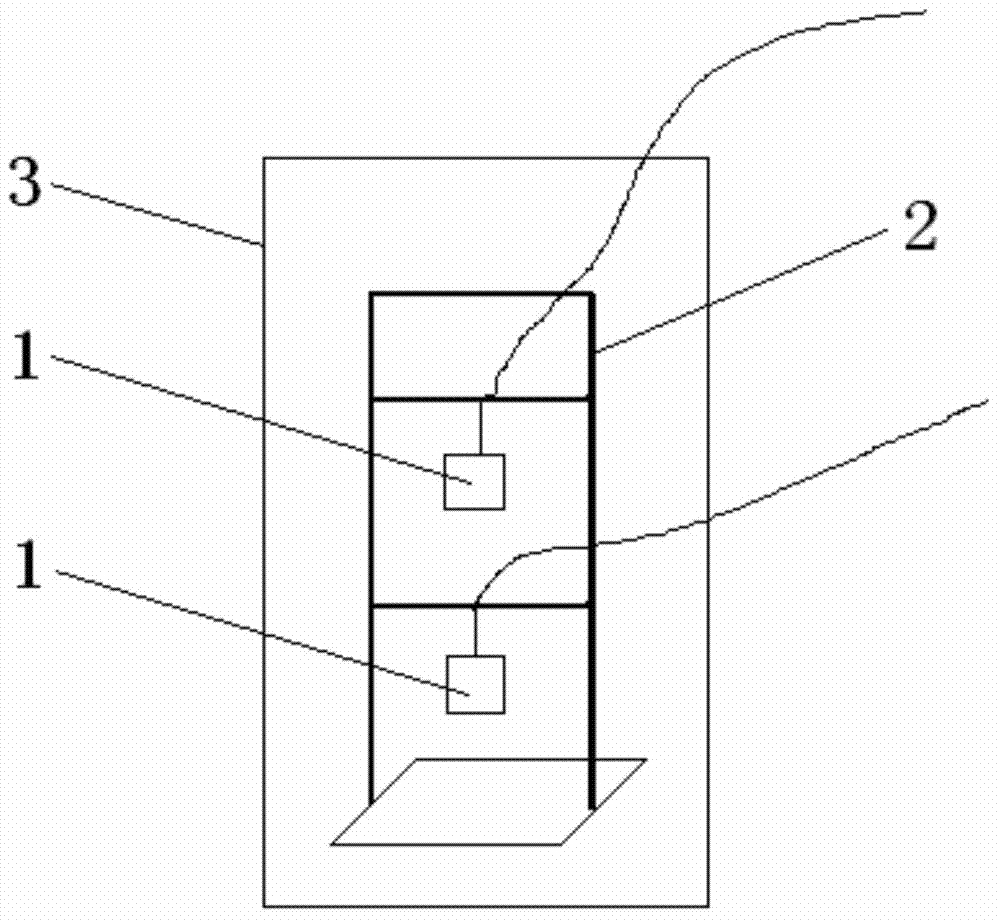

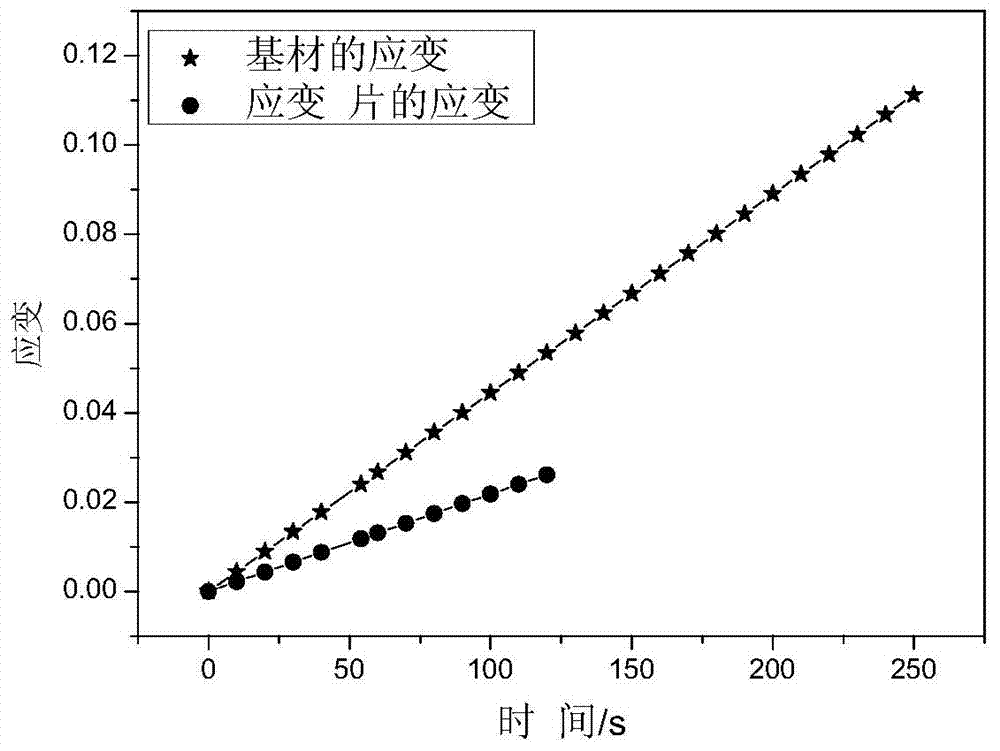

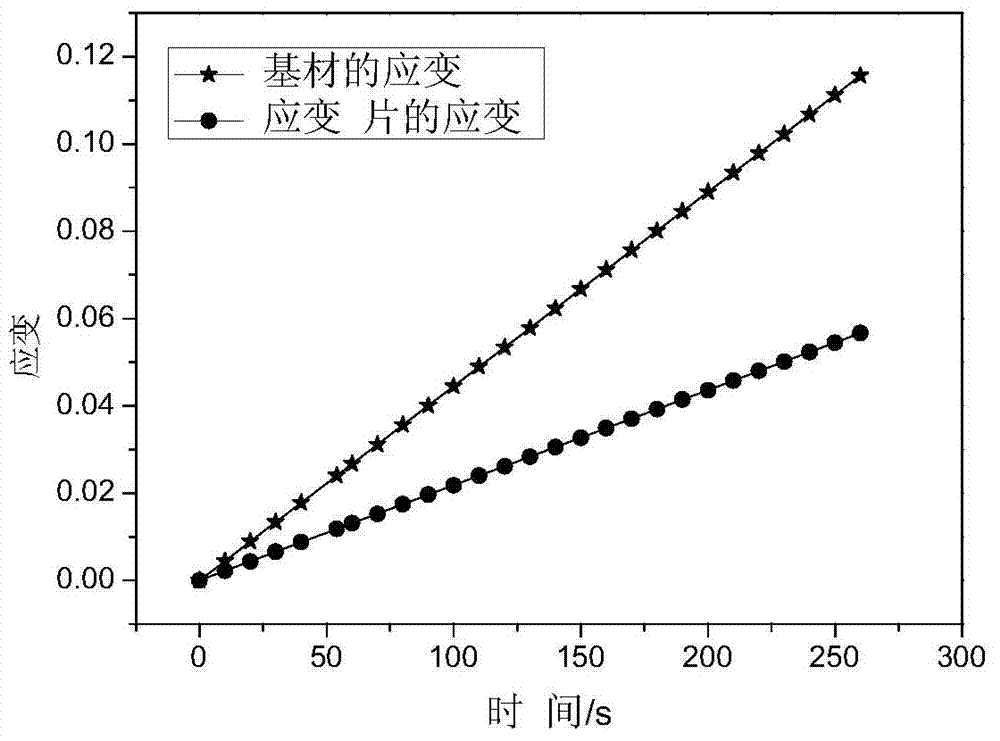

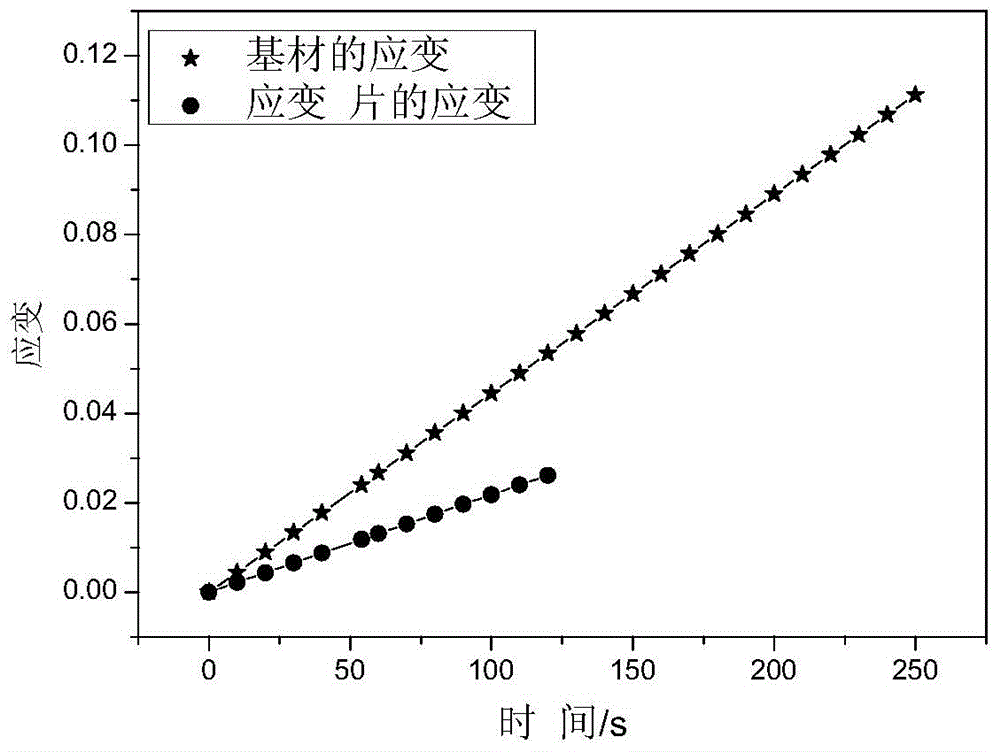

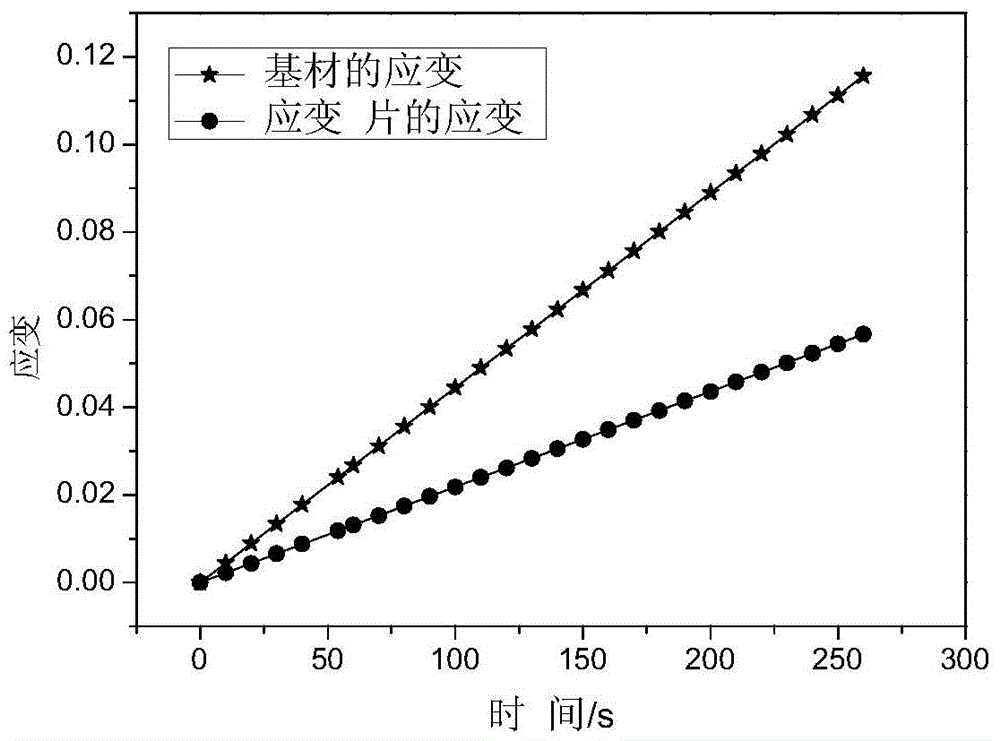

Strain gauge assembly for testing curing stress of thermosetting pouring PBX and testing method thereof

InactiveCN103940534AFixed and accurateNo compatibility issuesForce measurement by permanent gauge deformationForce measurement by elastic gauge deformationSlurryToluene

The invention relates to a strain gauge assembly for testing the curing stress of a thermosetting pouring PBX and a testing method thereof. The strain gauge assembly for testing the curing stress of the thermosetting pouring PBX comprises a base material and a strain gauge which is wrapped in the base material, the strain gauge is in a tiling shape in the base material, and the base material is composed of hydroxyl-terminated polybutadiene, dioctyl adipate, aluminite powder, 2 / 4- toluene diisocynate and triphenylbismuthine. The testing method of the curing stress of the thermosetting pouring PBX comprises the steps of calibrating the strain gauge assembly, arranging the strain gauge assembly, pouring an elastic body, and testing the stress in the curing process. The strain gauge assembly can be randomly placed at different positions in the pouring PBX, in the testing process, the compatibility of the base material and chemical slurry is good, the strain gage can not be curled or corroded by liquid chemical slurry due to the protection of the base material, and the testing effect on the curing stress of the pouring PBX is obvious.

Owner:XIAN MODERN CHEM RES INST

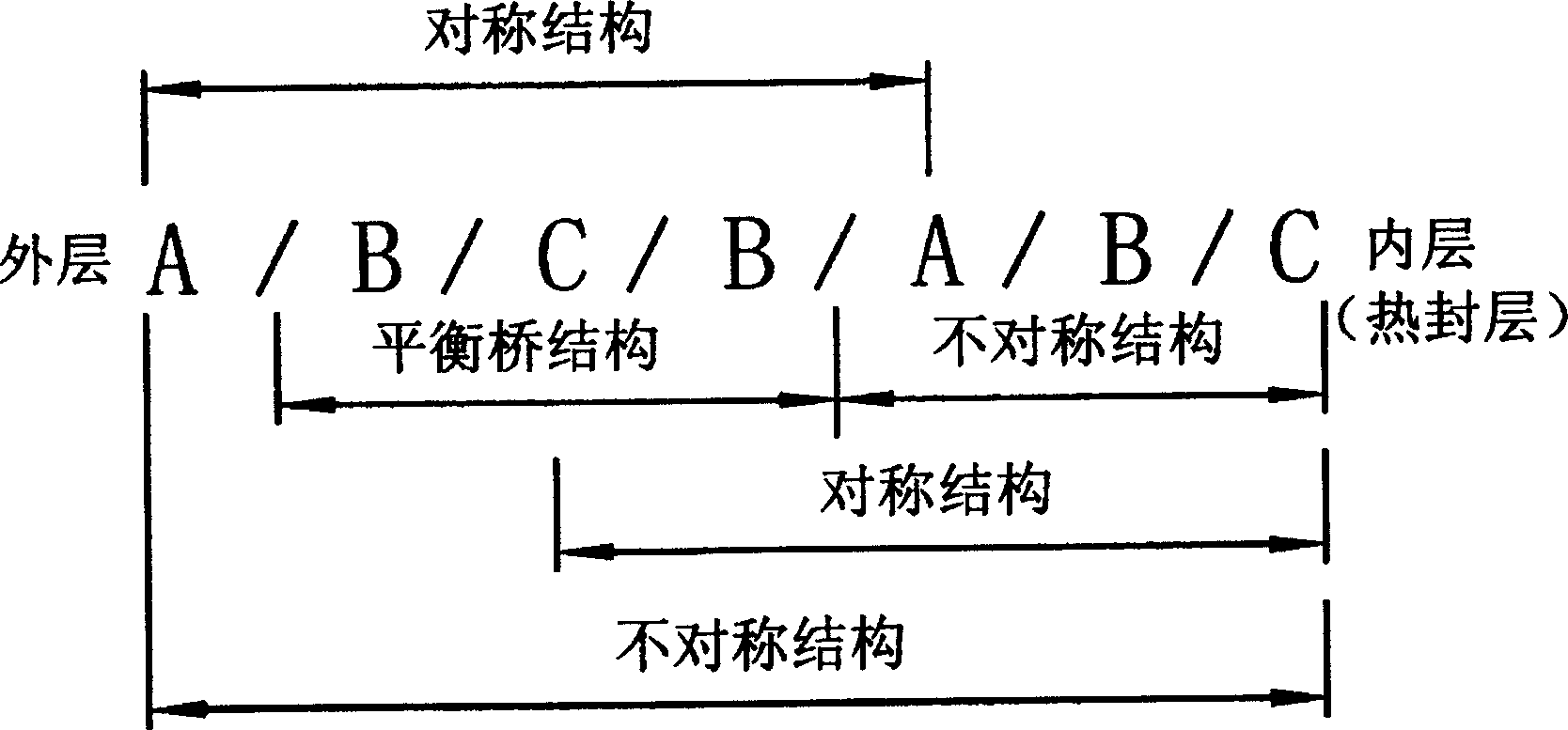

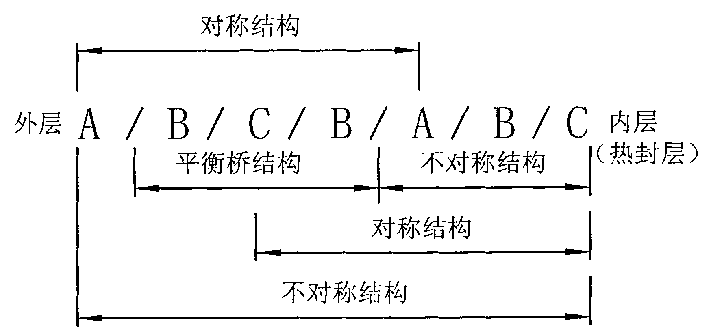

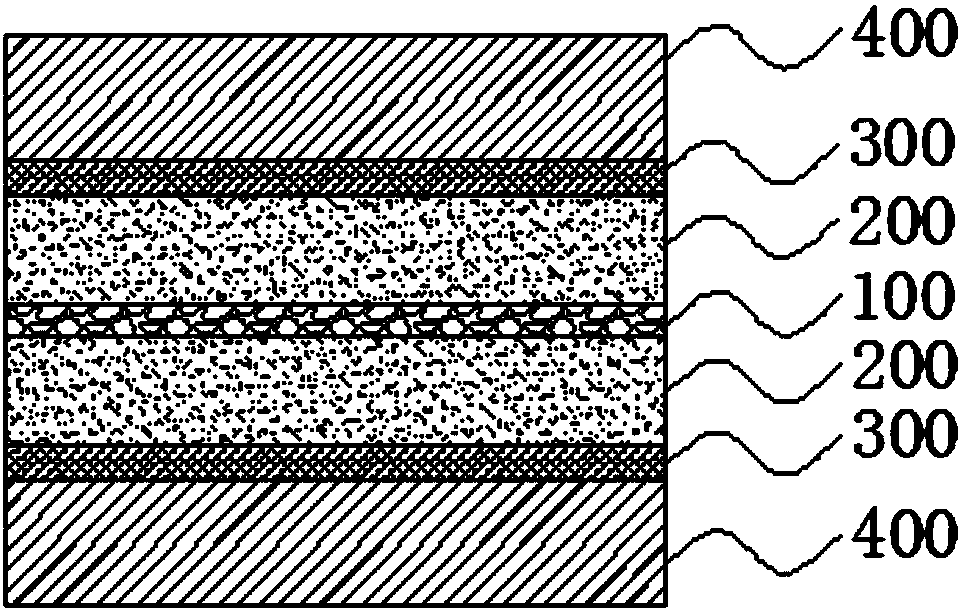

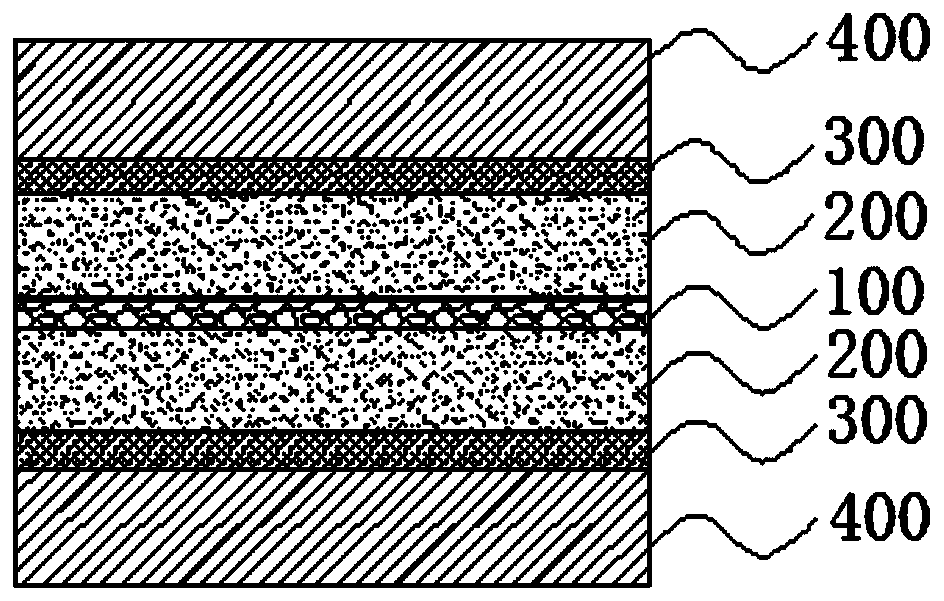

Non-symmetry structure for seven-layer laminated coiling-resistant composite film

Owner:KUSN ZHANGPU COLOR PRINTING FACTORY

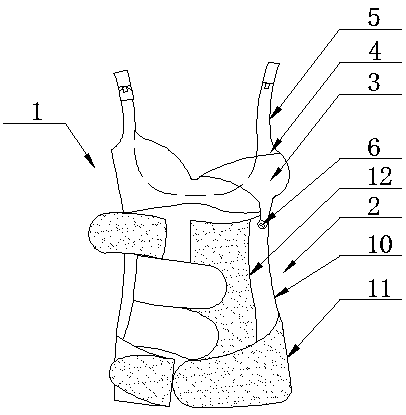

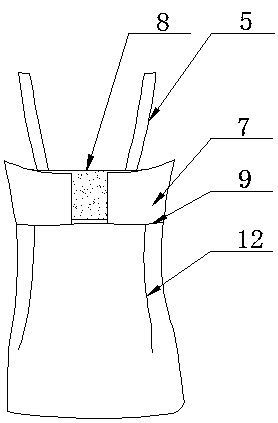

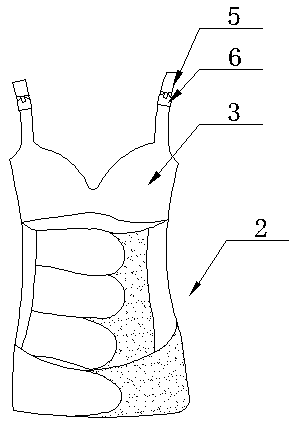

Integrated corset and breast-feeding bra

The invention discloses an integrated corset and breast-feeding bra, and relates to the technical field of underwear. The bra comprises a bra body and a strap, the strap is connected at the bottom ofthe bra body, the bra body comprises outer covers, inner supports, shoulder straps, fixed fasteners, rear pulling sheets and cross belts, the inner supports are arranged in the outer cover, one end ofeach shoulder strap is fixedly connected with the corresponding inner support, the other end of each shoulder strap is fixedly connected with the corresponding cross belt, the outer covers are fixedwith the shoulder straps through the fixed fasteners, the outer covers and the outer sides of the inner supports are connected with the rear pulling sheets, the rear pulling sheets are connected withthe cross belts through hook and loop fasteners, and the back of the strap is fixedly connected with the rear pulling sheets through sewing threads. The integrated corset and lactation bra has corseting and shaping effects and is suitable for use of postpartum women, wide in chest size range and good corseting effect, and crimping is omitted. The bra has the advantages of simple structure, reasonable to set, low in manufacturing cost and the like.

Owner:DANYANG XIAQI UNDERWEAR

Airing rack based on textile printing and dyeing

InactiveCN112160098AReduce drying yellowingReduce yellowingLiquid/gas/vapor removalLiquid/gas/vapor textile treatmentTextile printerThermal radiation

The invention discloses an airing rack based on textile printing and dyeing, relates to the technical field of textile printing and dyeing, and solves the problem that the color of sampled cloth at the upper part of an existing airing rack easily becomes yellow due to overlong drying time since a dryer of the existing airing rack mostly adopts an electric heating wire for heating. The airing rackbased on textile printing and dyeing comprises a main frame; the top of the main frame is rotationally connected with a square fixing frame; the fixing frame comprises a fixing block, a supporting rodand a fixing column, and the top of the fixing frame is rotationally connected with one fixing block; the supporting rod is mounted in the middle of the fixing frame in a sliding manner; the top of the supporting rod is rotationally connected with the tail of the fixing block; and an airing frame is fixedly mounted at the top of the main frame. According to the airing rack, through transition ofwater vapor, the degree of heat radiation is reduced, so that the sampled cloth dried on the airing frame can keep the natural color after being dried for a long time, and the condition that the sampled cloth becomes yellow after being dried for a long time is reduced.

Owner:王智飞

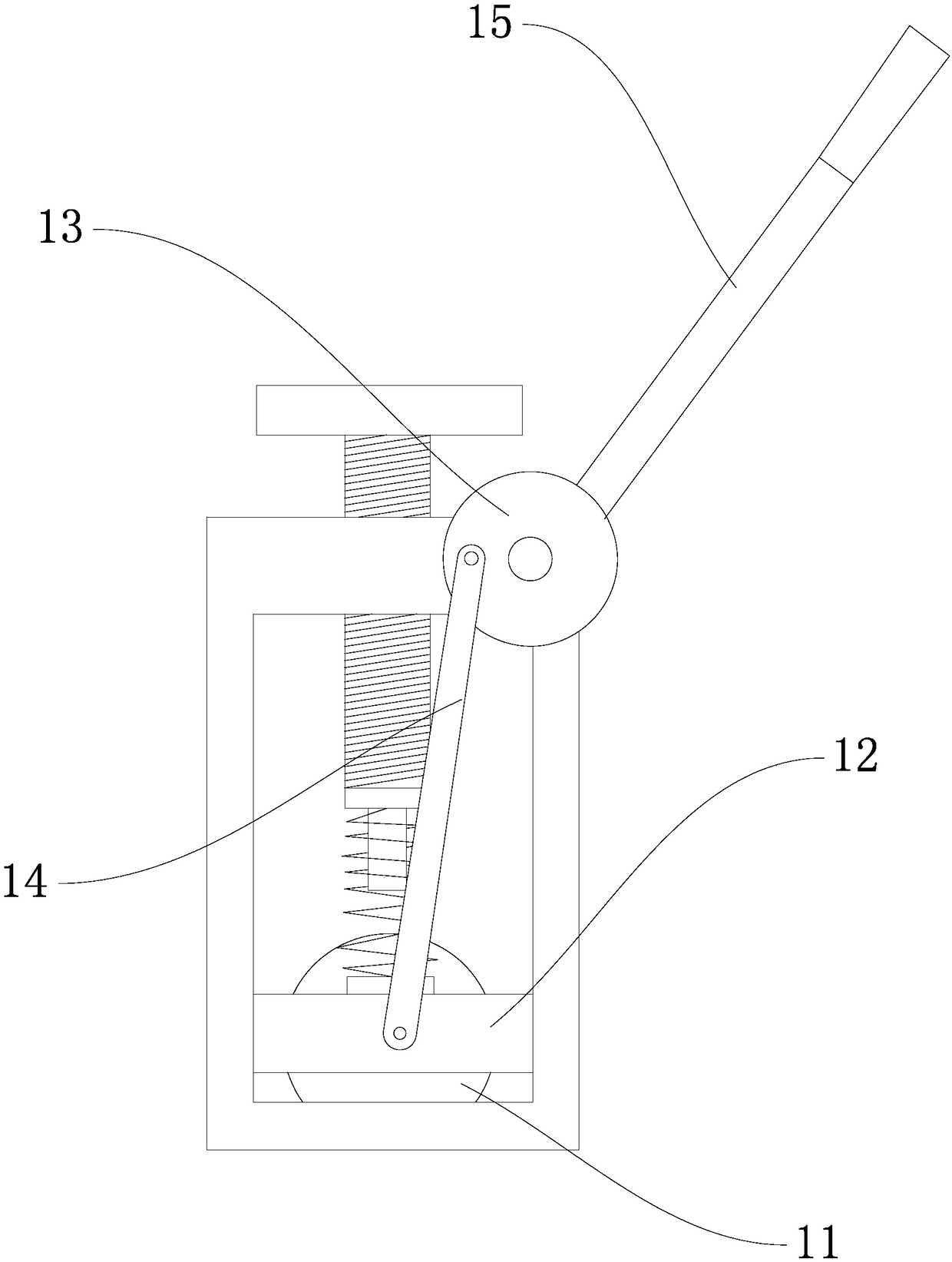

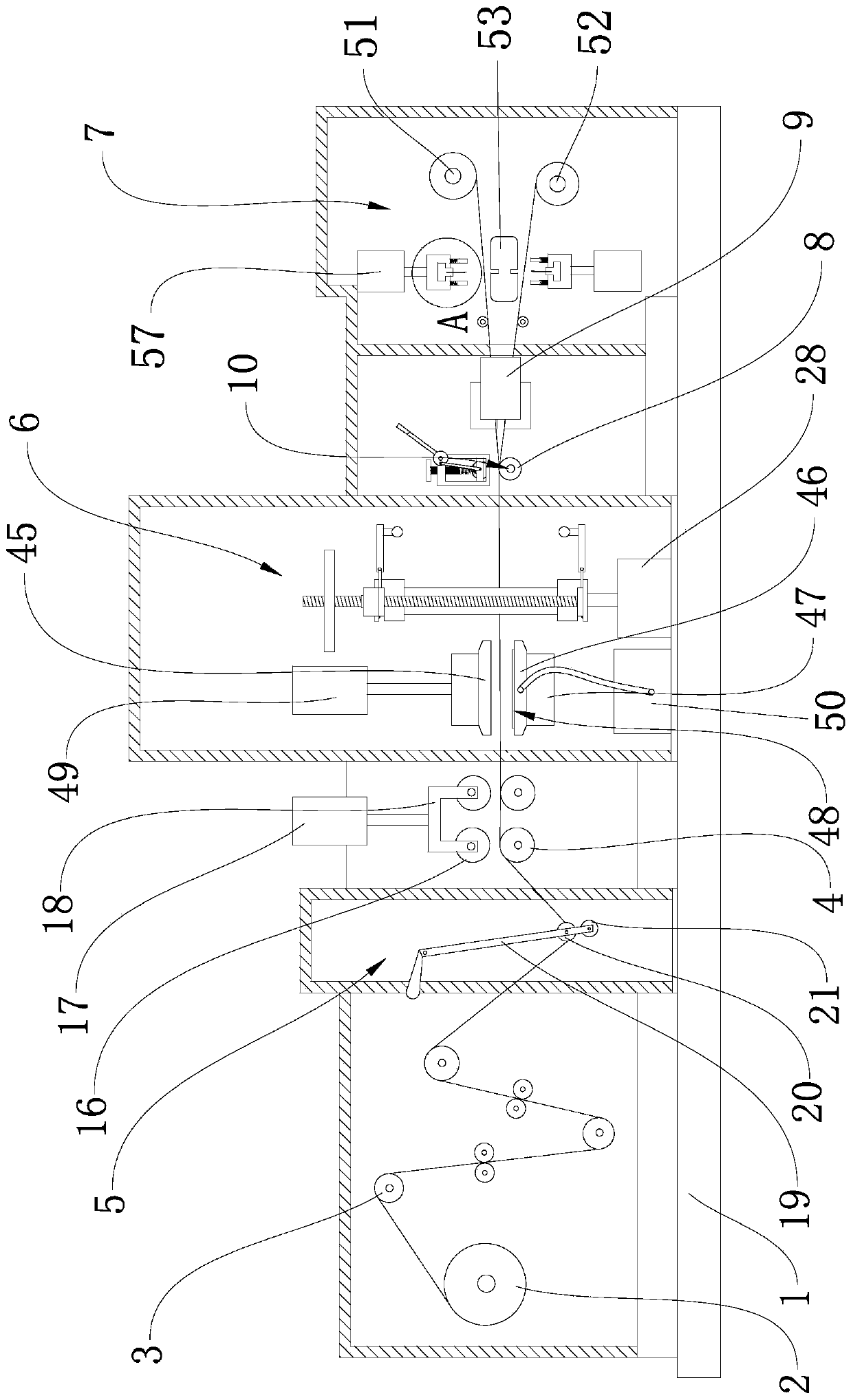

Non-thrust feeding device of tobacco cutter

The invention provides a non-thrust feeding device of a tobacco cutter. The non-thrust feeding device comprises a distributing mechanism, a guide structure, a conveying belt and a feeding underframe. The distributing mechanism is arranged at a feeding port of the guide structure, the guide structure is positioned above the feeding end of the conveying belt, a storage bin is penetratingly arranged at the lower end of the guide structure, the conveying belt is mounted on a belt support and is accommodated in the storage bin, the discharging end of the conveying belt is positioned between an upper copper bar chain and a lower copper bar chain of the tobacco cutter, the lower end of the storage bin is connected with the belt support, and a vibrator is rigidly connected to the lower end of the belt support. A glass plate is connected to the top surface of the feeding underframe elastically, and the upper end of the glass plate is connected with the belt support. The non-thrust feeding device of the tobacco cutter can enable tobacco leaves not to be subjected to any thrust, so that the quantity of netted tobacco (coalesced tobacco) and scraps contained in cut cigarette tobacco is decreased substantially.

Owner:SHANGHAI TOBACCO GRP CO LTD

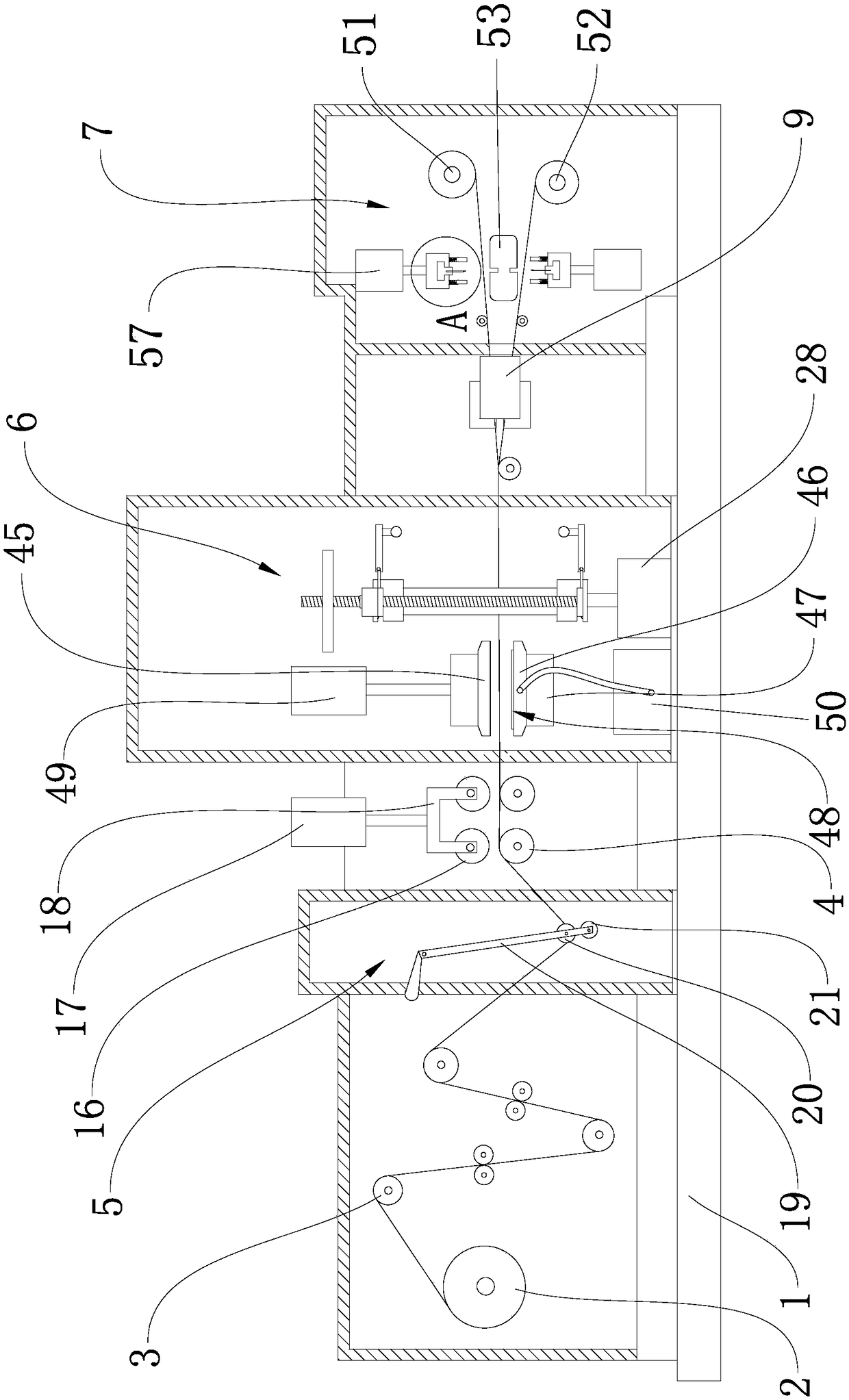

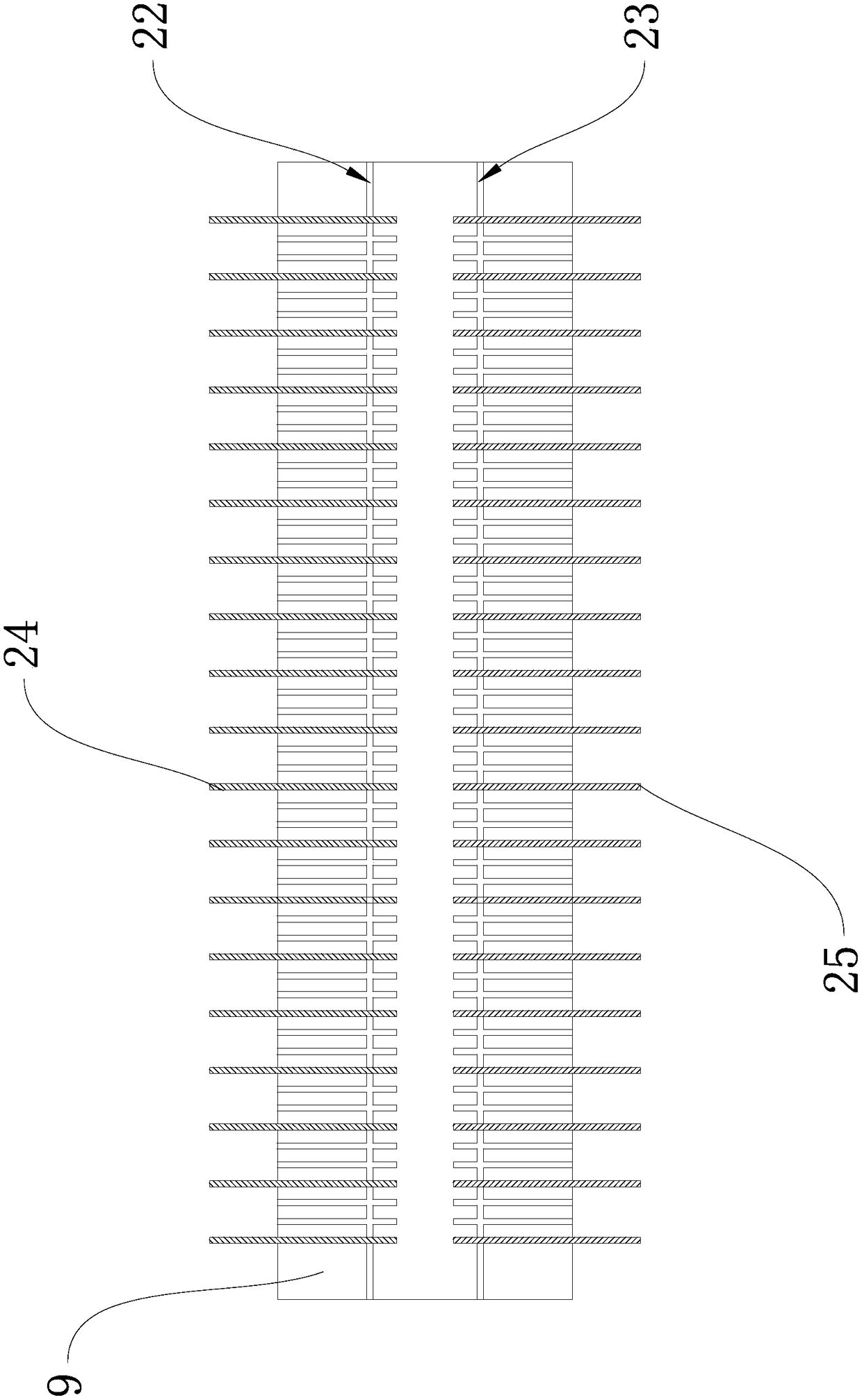

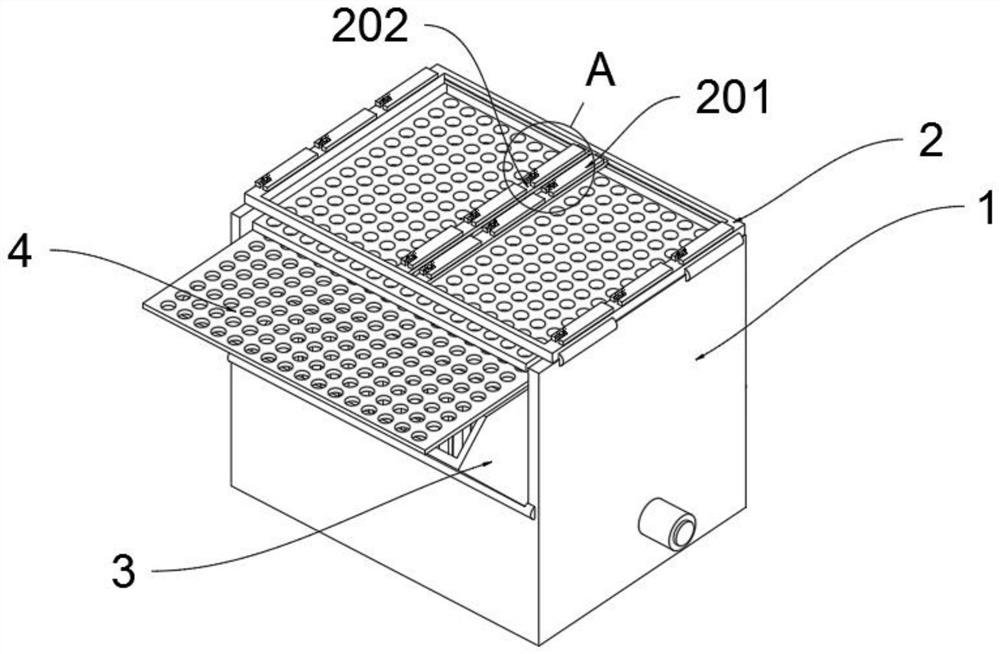

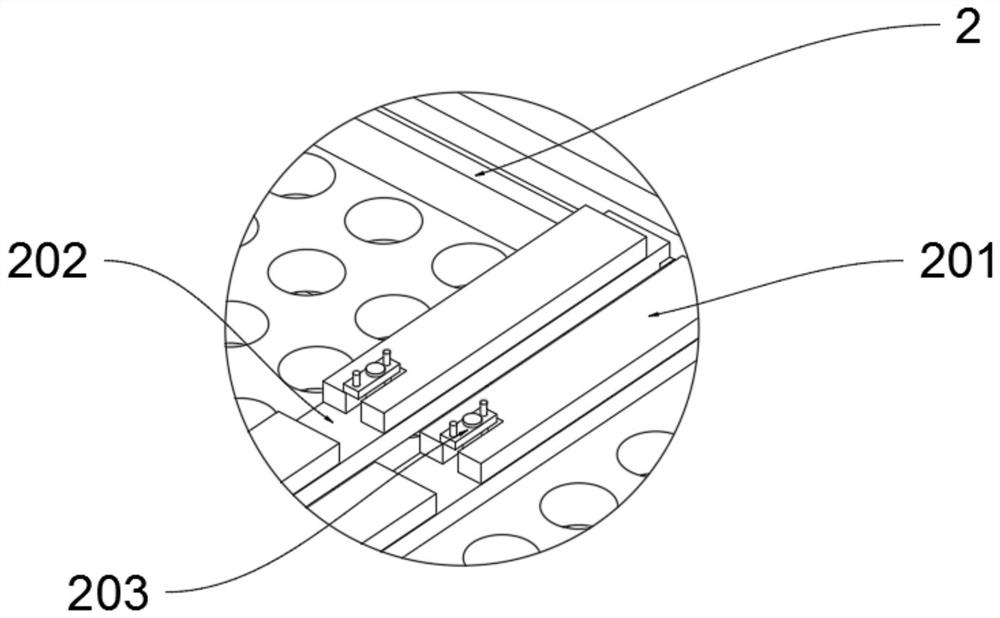

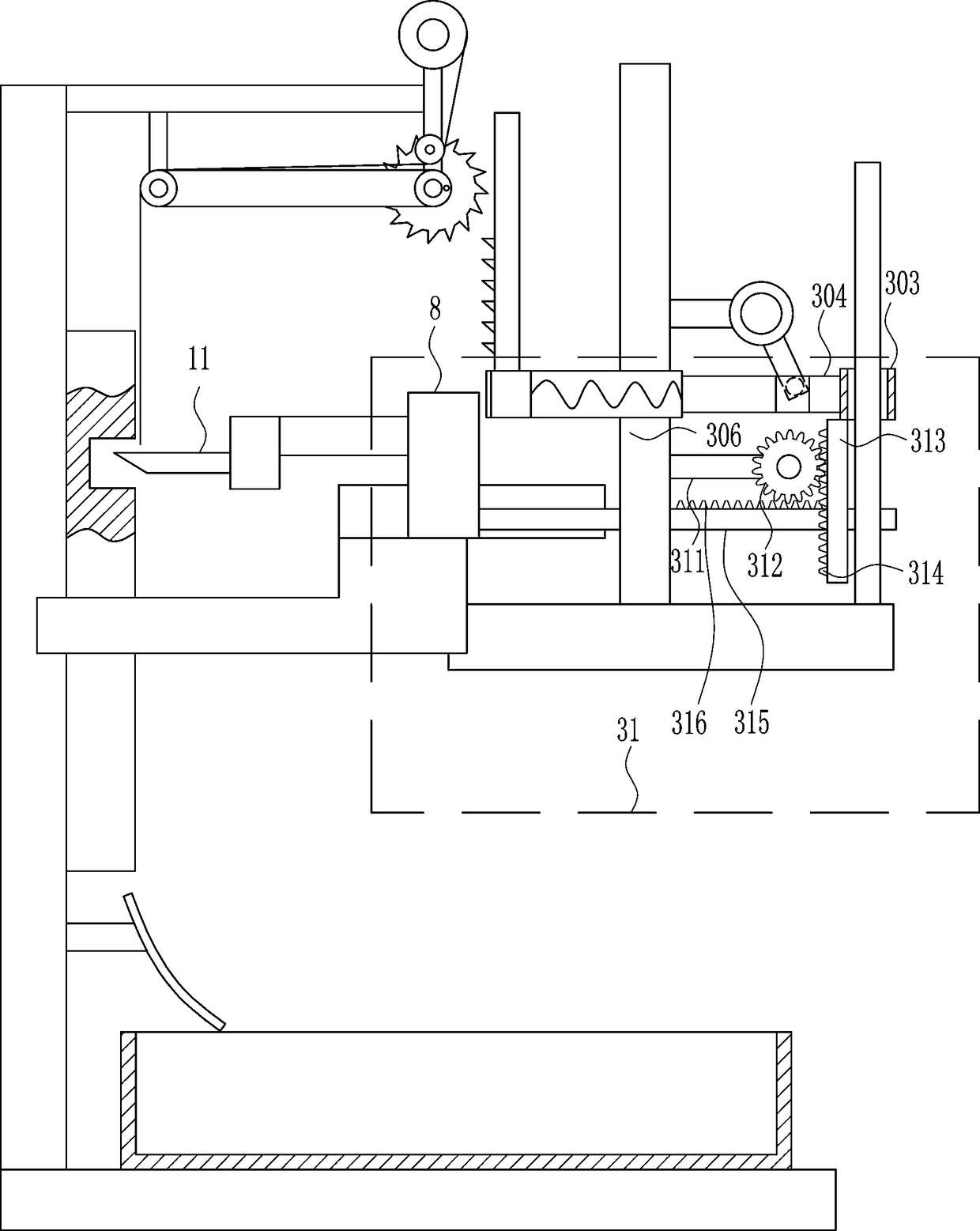

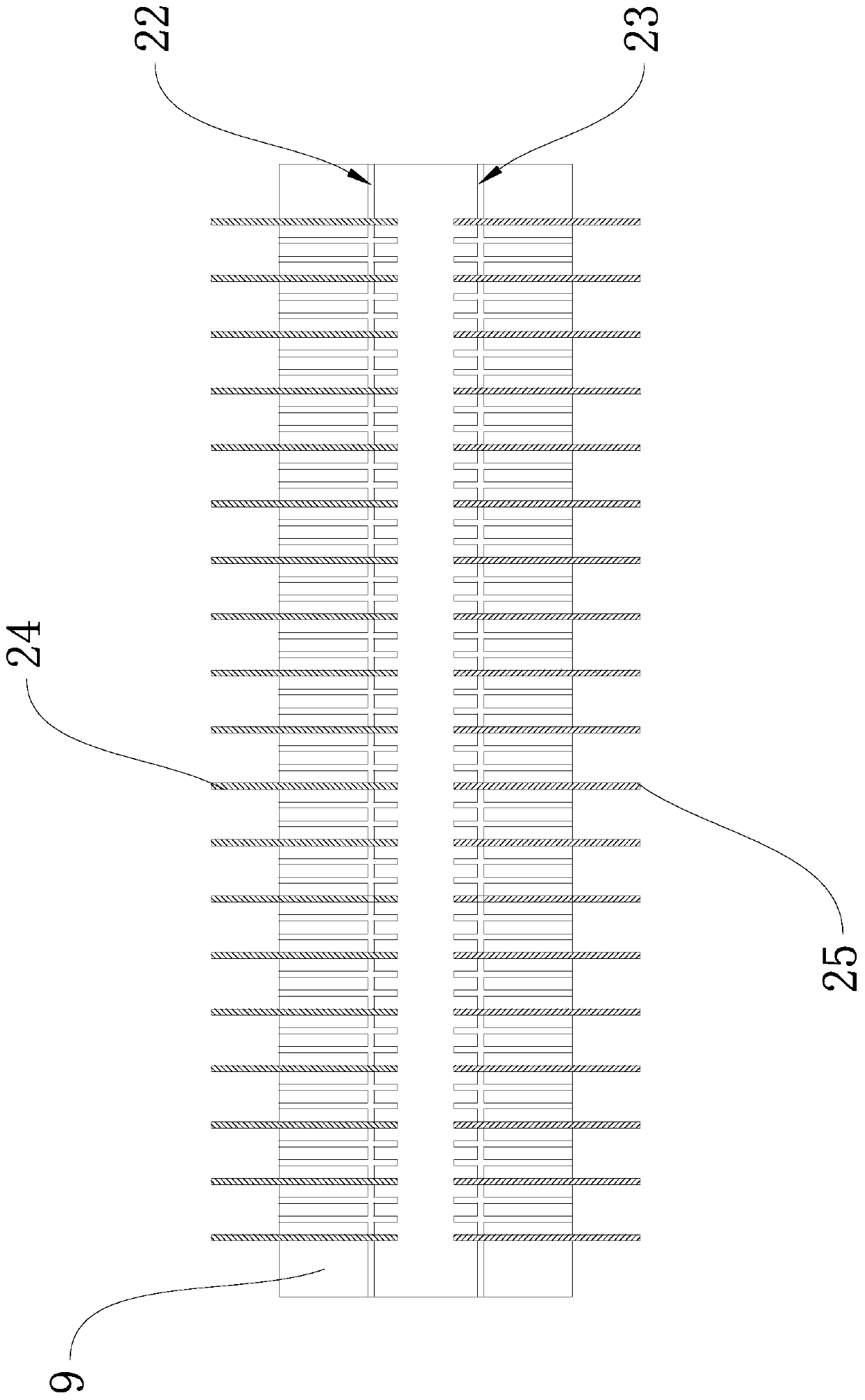

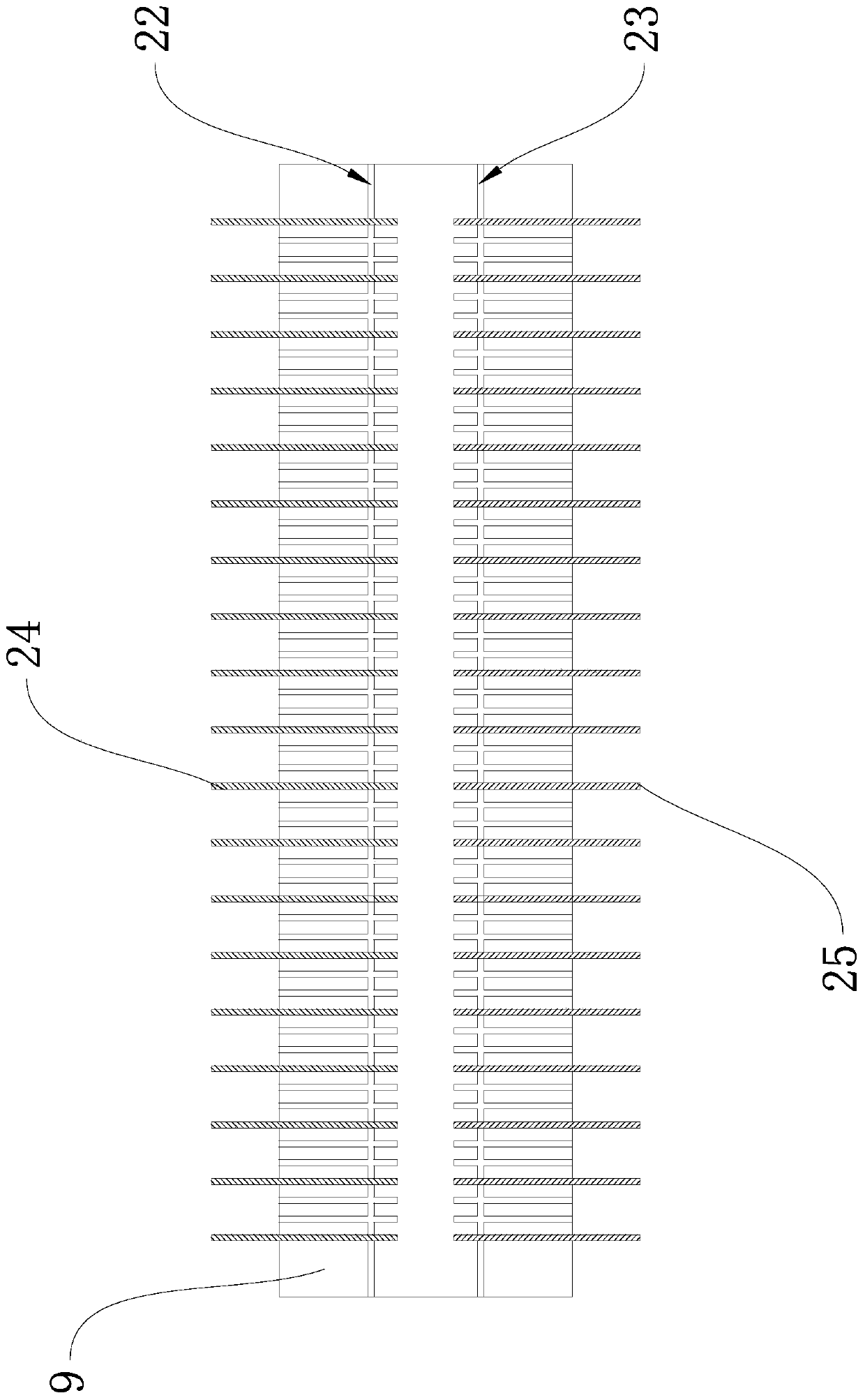

Automatic equal-length large-pole-piece-cutting equipment for pole piece for lithium battery production and processing

InactiveCN108380964AEqual transport distanceWon't curlElectrode manufacturing processesMetal-working feeding devicesProcess equipmentPole piece

The invention relates to processing equipment of lithium battery accessories, in particular to automatic equal-length large-pole-piece-cutting equipment for a pole piece for lithium battery productionand processing and aims to achieve the technical effect of providing the automatic equal-length large-pole-piece-cutting equipment for the pole piece for lithium battery production and processing, wherein automatic equal-length transport error is small, equal-length cutting can be realized, time and labor are saved in the cutting process, and workers cannot be harmed in the cutting process. To achieve the technical effect, the automatic equal-length large-pole-piece-cutting equipment for the pole piece for lithium battery production and processing provided by the invention comprises a bottomplate, a collection box, a supporting plate, a cutting plate, an L-shaped plate, a first sliding rail, a first sliding block, a connection rod, a knife rest, a knife board, a connection plate, a firstinstallation block and the like. The bottom plate is provided with the collection box, and the left side on the bottom plate is connected with the supporting plate. The effects that the automatic equal-length transport error is small, equal-length cutting can be realized, time and labor are saved in the cutting process, and the workers cannot be harmed in the cutting process are achieved.

Owner:季寒飞

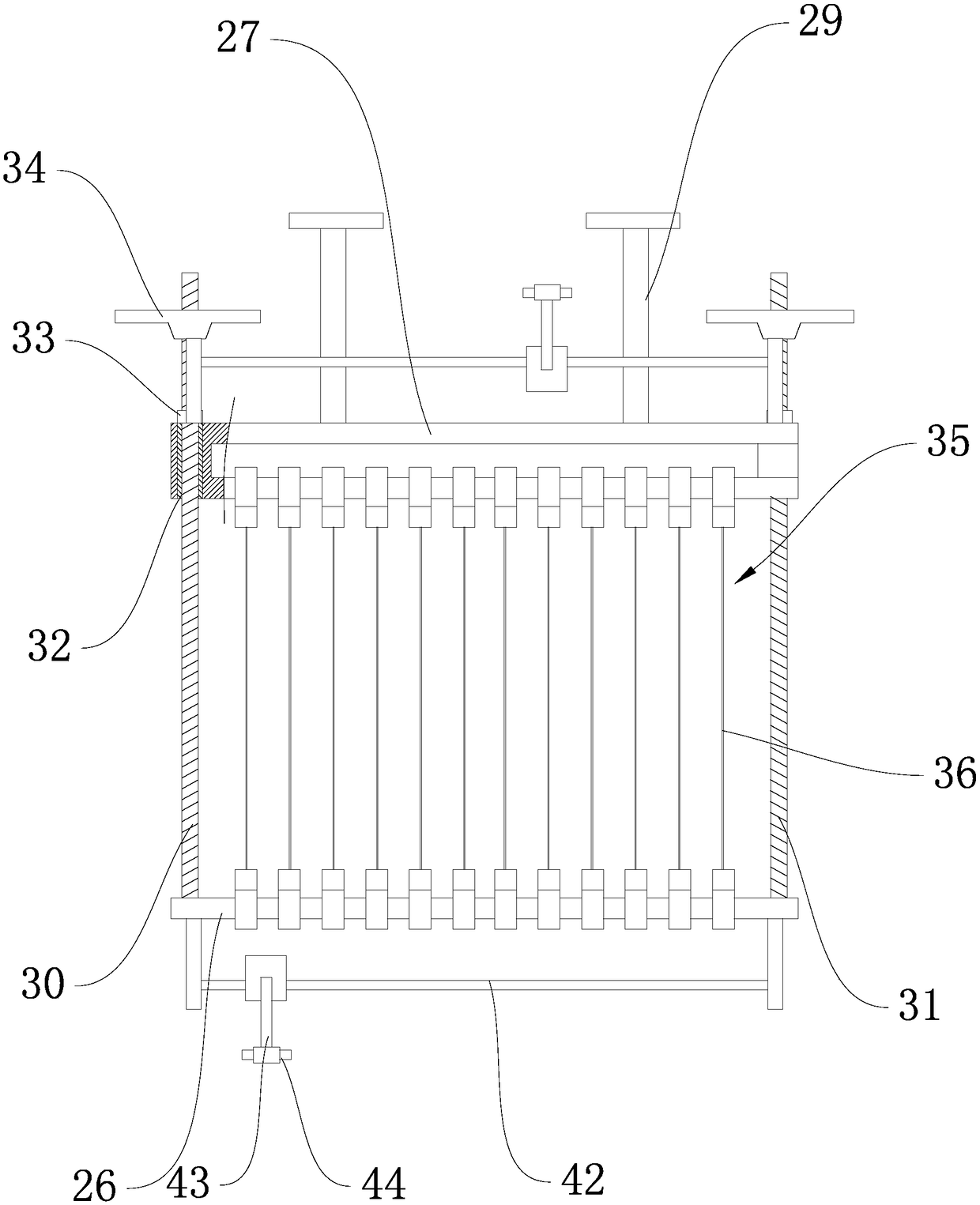

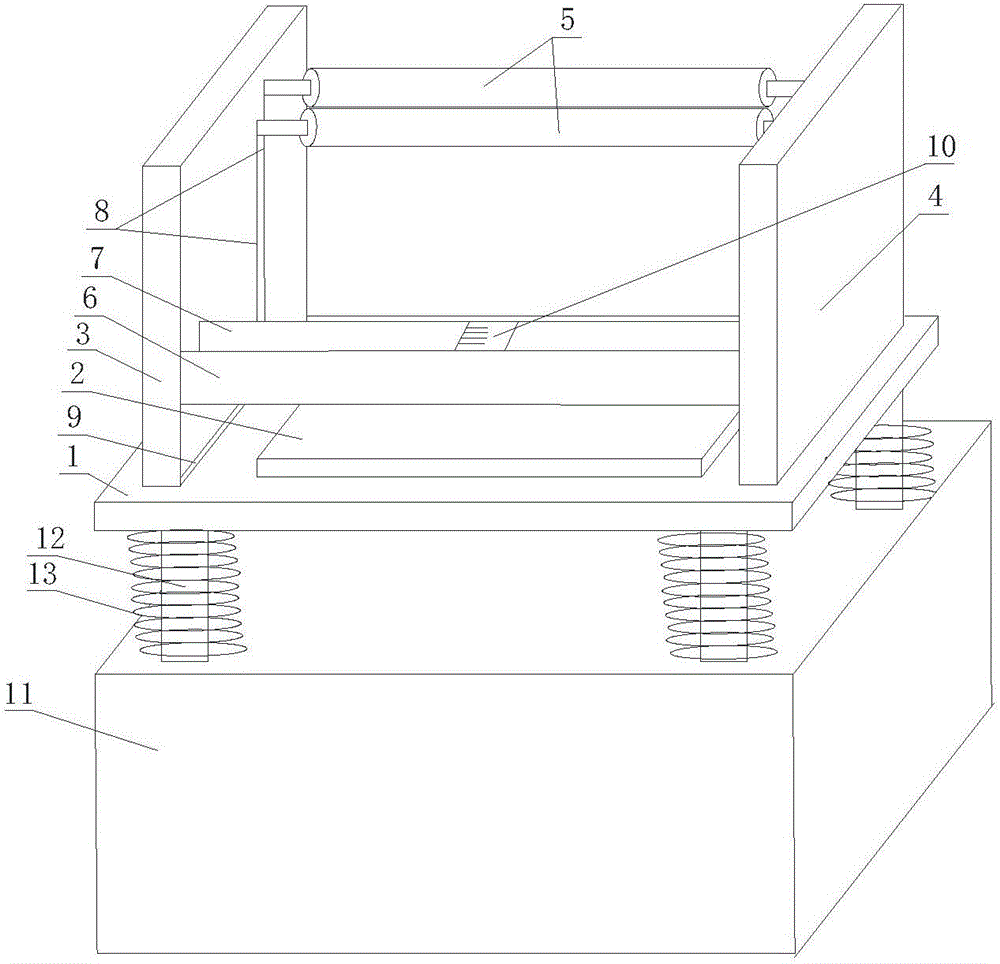

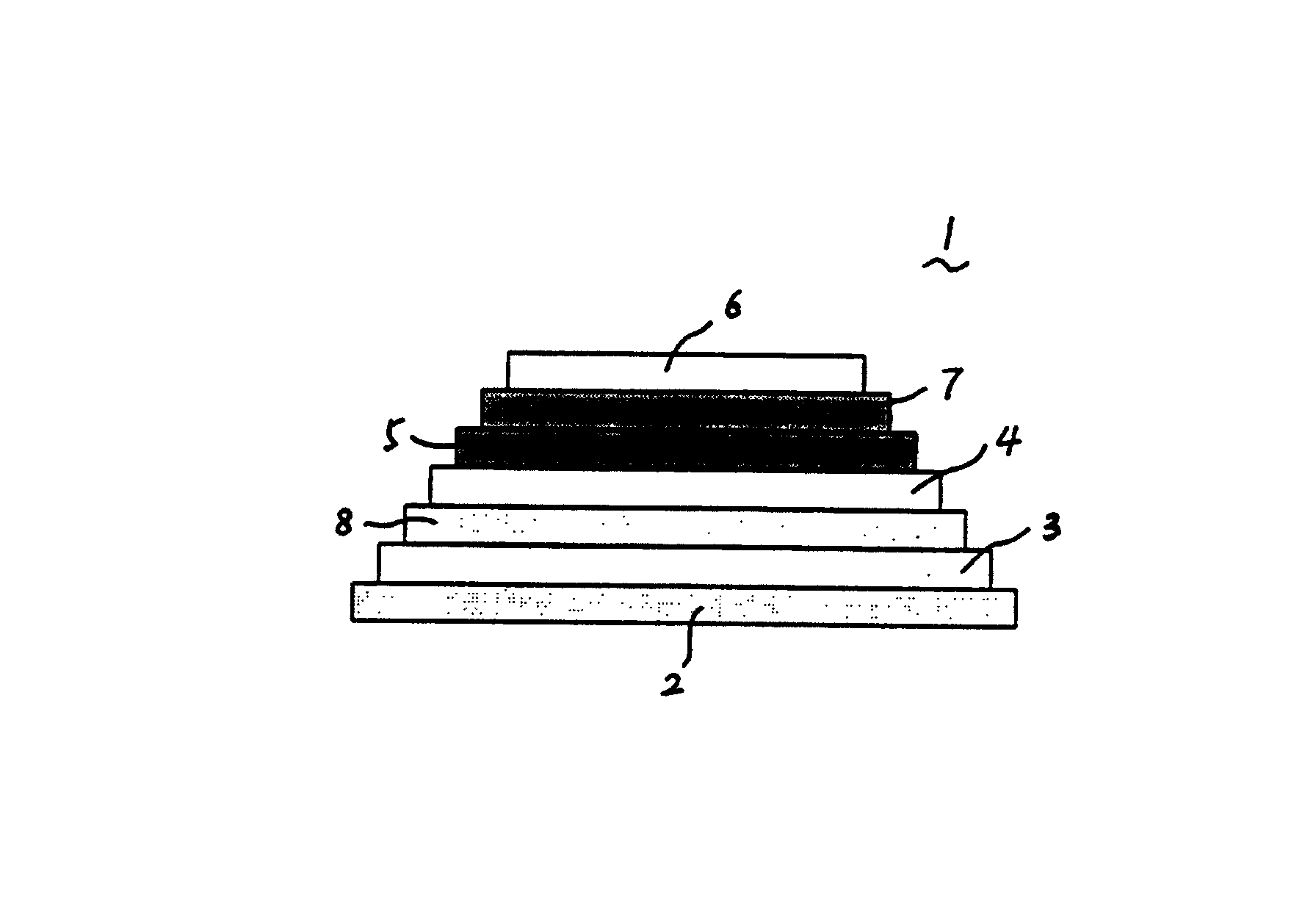

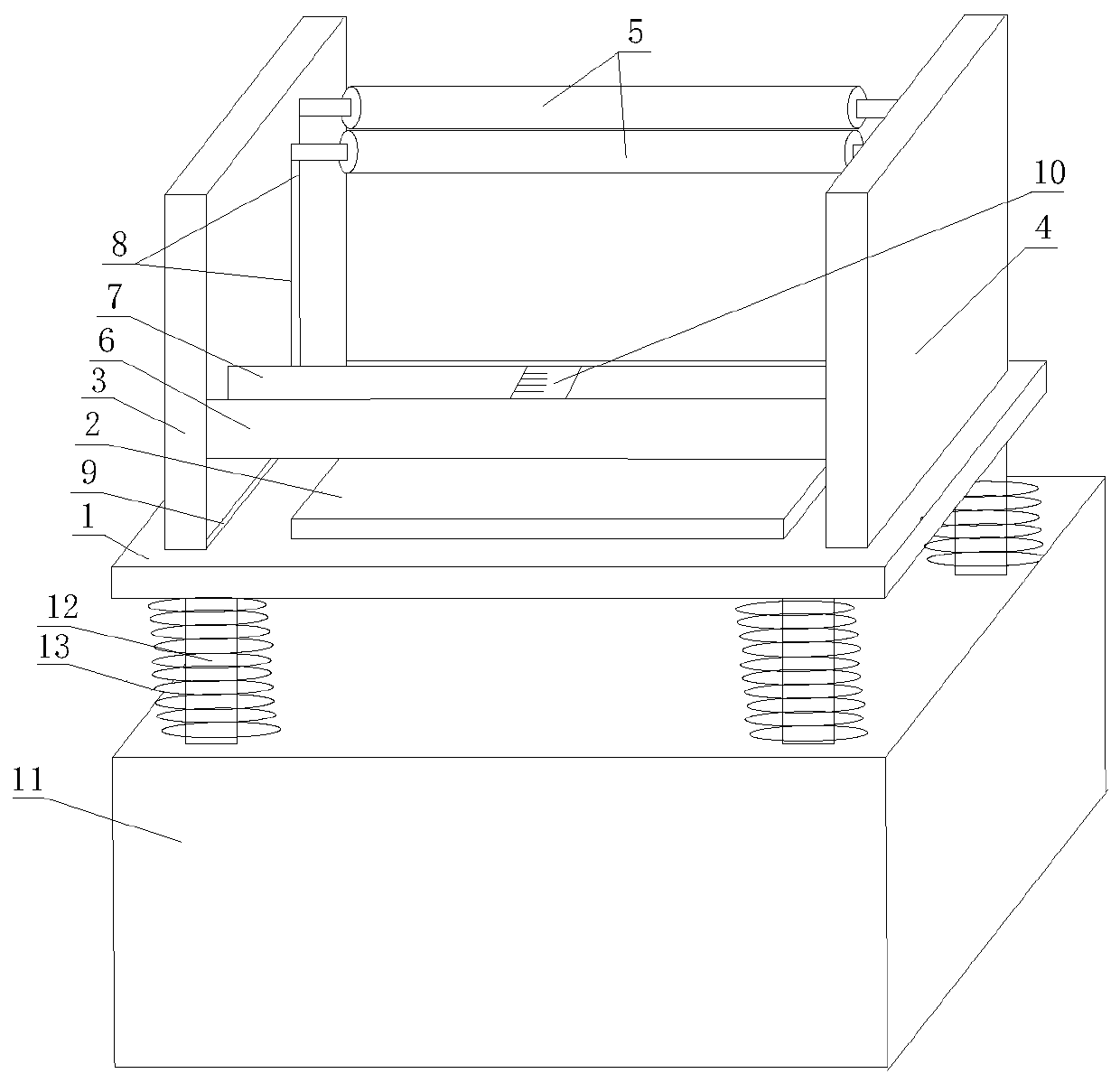

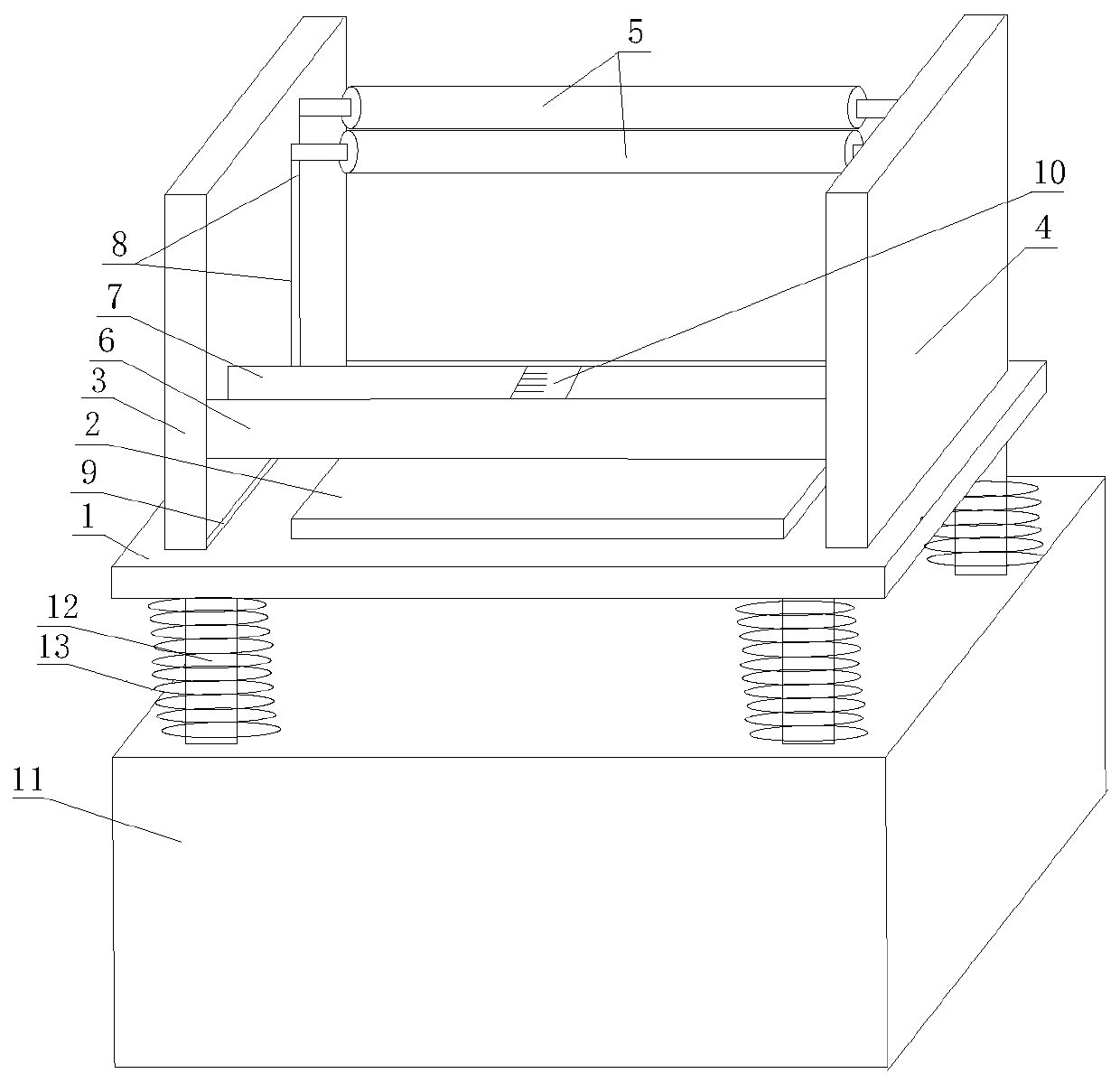

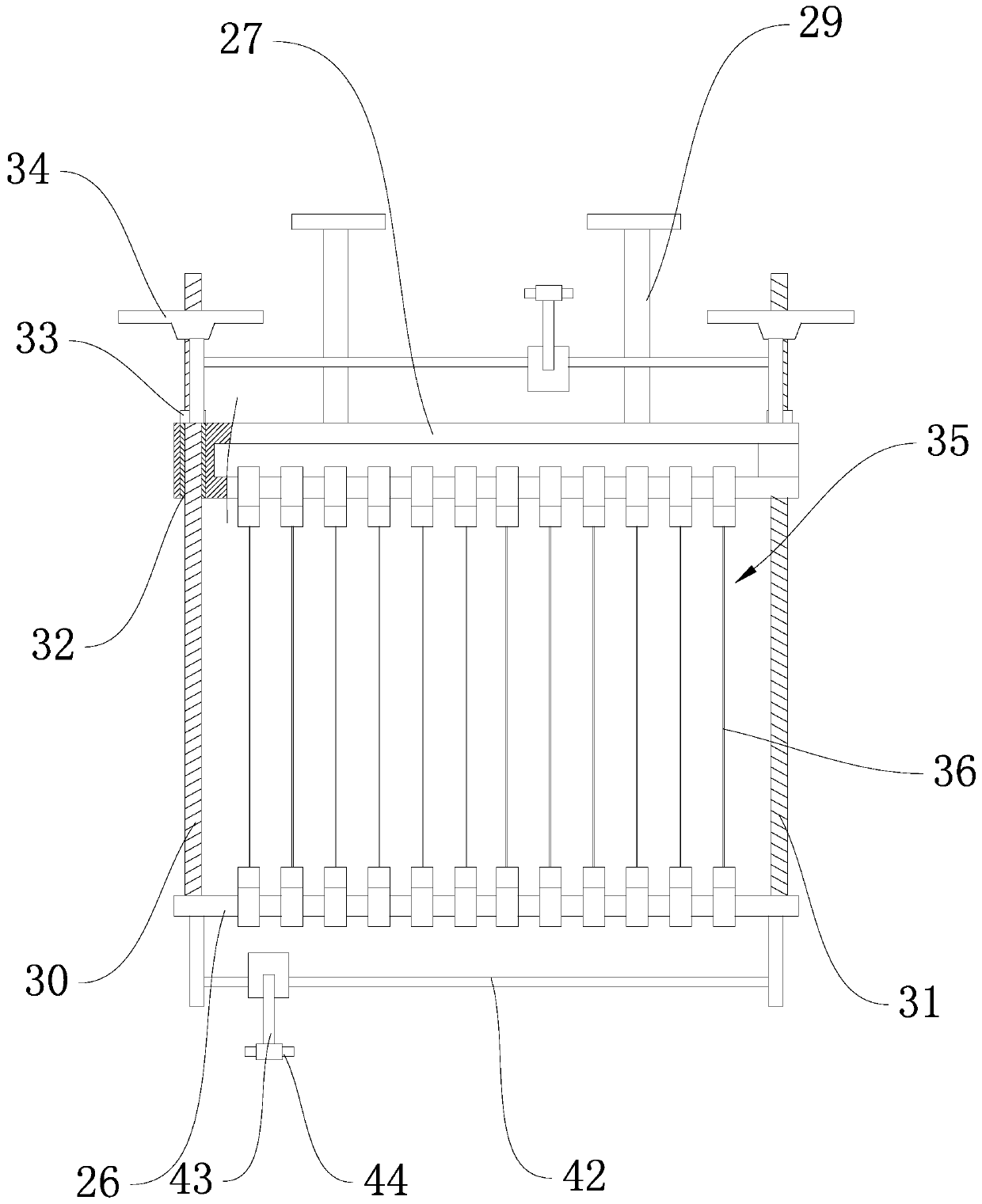

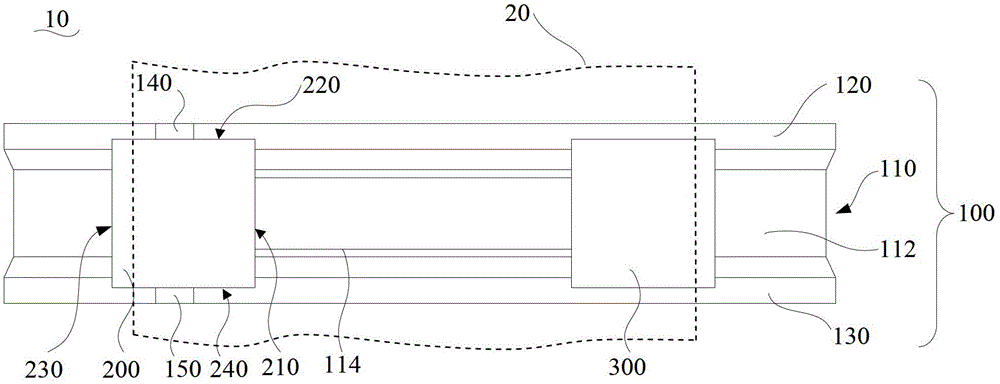

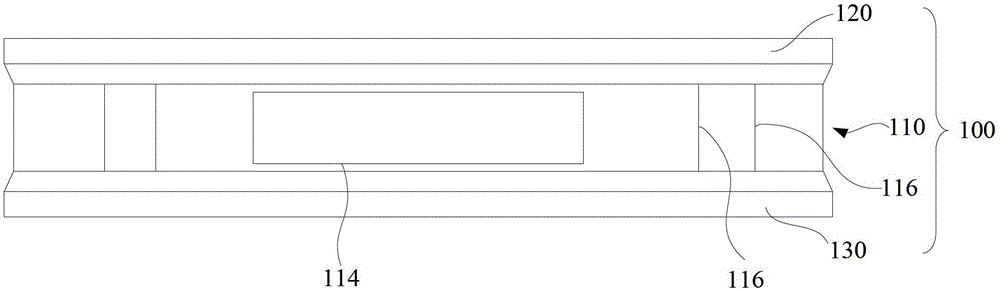

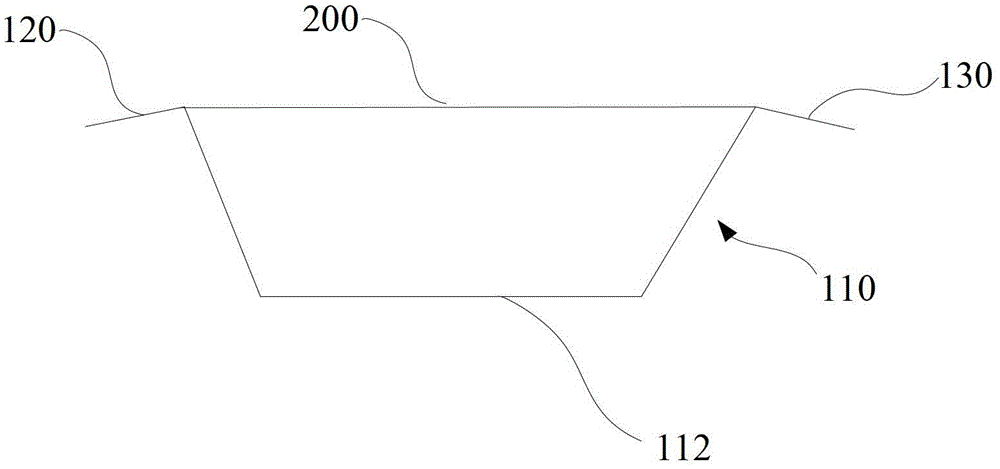

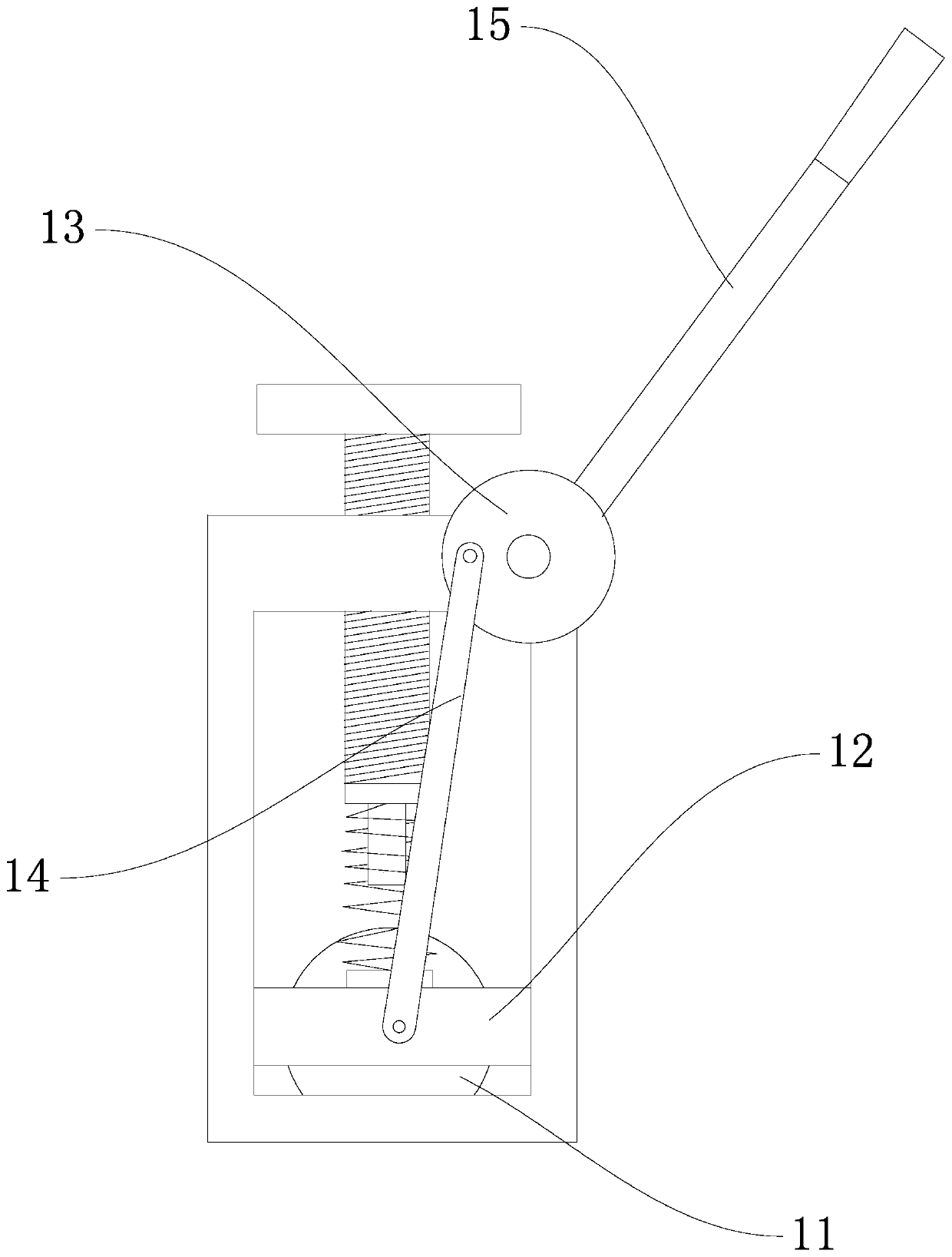

Pole piece strip cutting device with pressing function

ActiveCN106684314AWon't curlPrevent looseningElectrode rolling/calenderingSecondary cellsEngineeringPole piece

The invention discloses a pole piece strip cutting device with a pressing function. The device comprises a base, wherein a placement plate is mounted above the base; a support plate A and a support plate B are respectively arranged on the two sides of the placement plate; two externally tangent pressing shafts are placed between the support plate A and the support plate B in parallel; one end of each pressing shaft is connected with the support plate A, and the other end of each pressing shaft is connected with the support plate B; the pressing plates are located right above the middle of the placement plate, and are connected with the support plate A and the support plate B through chutes; a fixing plate and a cutter are further arranged above the placement plate and placed between the support plate A and the support plate B in parallel; and one end of the cutter is connected with the support plate A, and the other end of the cutter is connected with the support plate B. The device provided by the invention has the advantages that a pole piece can be kept strained throughout a strip cutting process through the pressing shafts and the fixing plate, so that the pole piece can be prevented from curling or loosing, and a large number of burrs at the edges of a pole piece strip obtained through cutting can be avoided.

Owner:绵阳绿环新能源环保科技有限公司

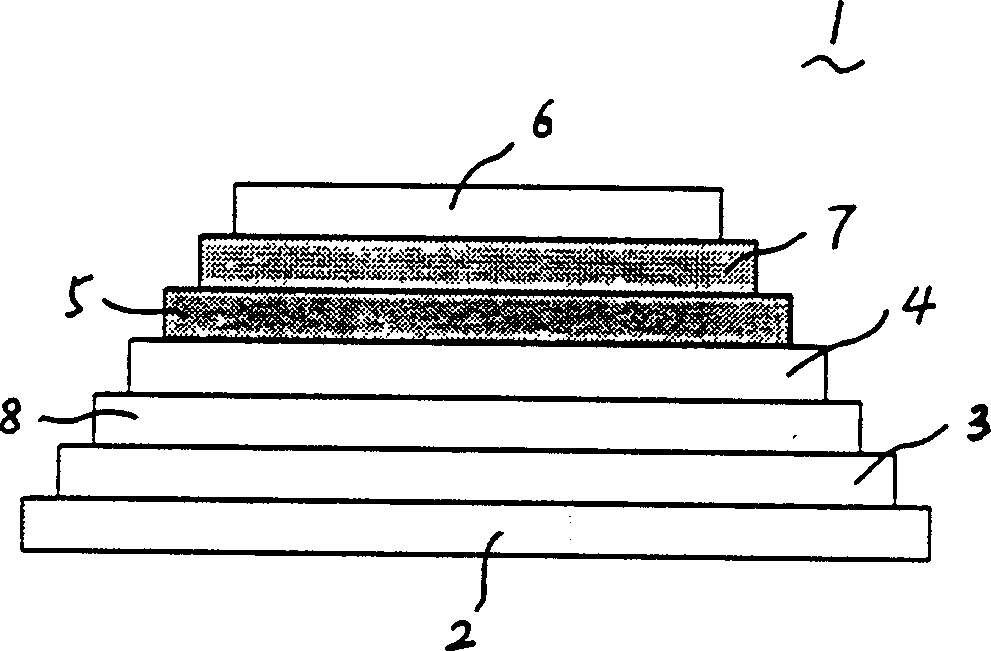

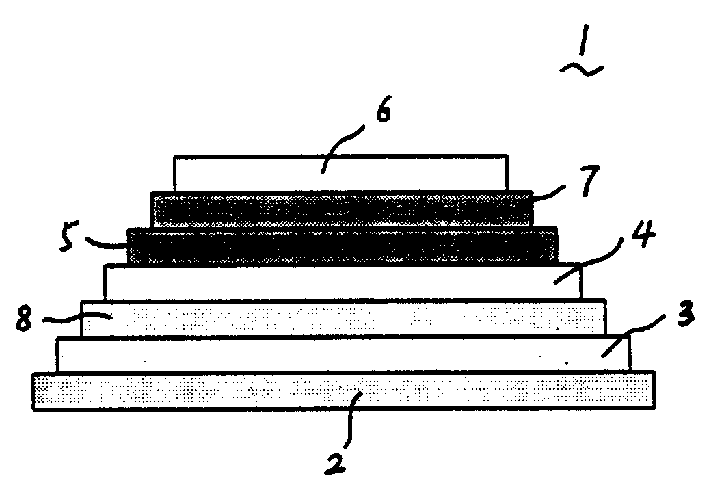

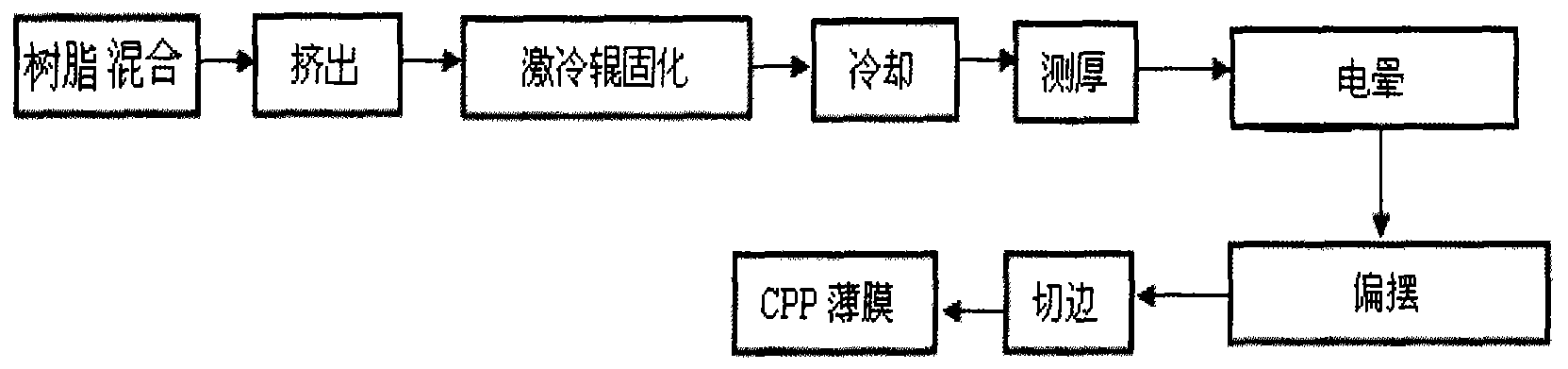

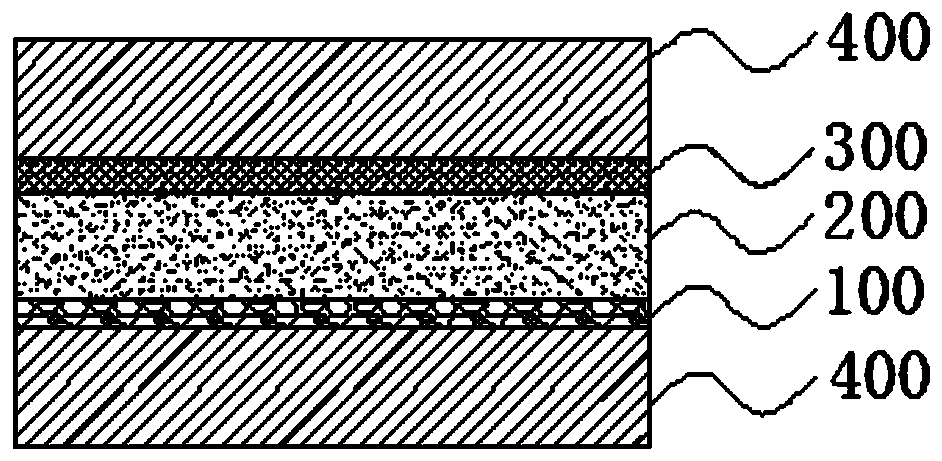

Manufacturing method of transfer paper

InactiveCN1199809CImprove toughnessUniform thicknessThermographyWater solublePulp and paper industry

The present invention relates to a method for manufacturing transfer paper, in particular to a method for manufacturing transfer paper for printing patterns on the outer surface of a product, comprising the following steps: a. pre-arranging a layer of hydrosol layer (3 ), the pattern layer (5) is printed on the base paper (2); b, the synthetic resin with good processability is prepared, and the auxiliary agent for increasing the viscosity is added to form the mixture for making the adhesive film (6); c. Use extrusion molding method, calendering molding method or drool molding method to make the above mixture into a film (6); d. Cover the printed pattern layer on the backing paper (2) after step a to make a film Good film (6).

Owner:增城市运豪五金塑料有限公司

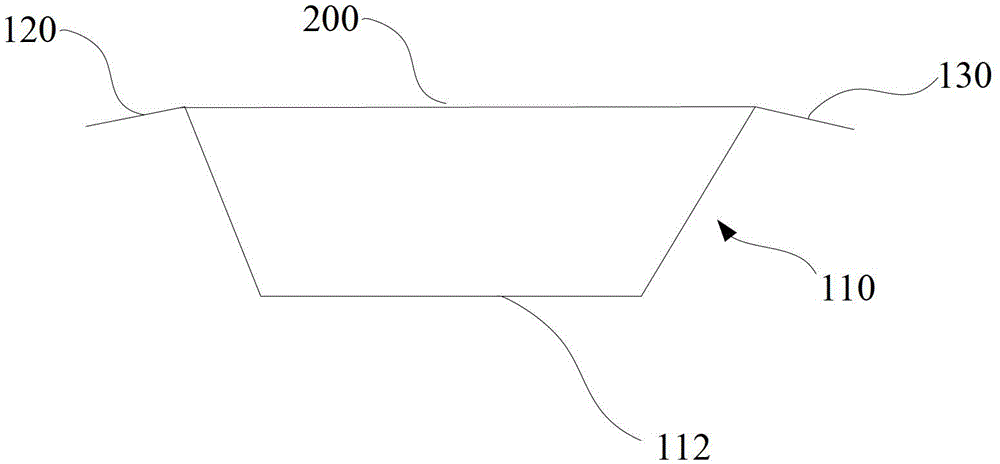

Partition plate for coating cavity

InactiveCN103334086AQuality improvementWon't curlVacuum evaporation coatingSputtering coatingEngineeringFlange

The invention relates to a partition plate for a coating cavity. The partition plate comprises a U-shaped groove plate, a first flange, a second flange, a first baffle and a second baffle, wherein a window penetrating through the groove bottom is formed in the middle part of the groove bottom of the U-shaped groove plate; the first flange and the second flange are respectively connected with the tops of the two side walls of the U-shaped groove plate; and the first baffle and the second baffle both stretch over the U-shaped groove plate and are connected with the first flange and the second flange. The partition plate for a coating cavity provided by the invention can effectively reduce heat transfer to a flexible base material; and by adopting the partition plate for a coating cavity, a high-quality flexible functional film can be obtained.

Owner:NANCHANG O FILM TECH CO LTD +2

Processing technology of mink-wool-like fabric

InactiveCN111391463AFeel goodImprove aestheticsSucessive textile treatmentsWeft knittingYarnChamois leather

The invention relates to a processing technology of a mink-wool-like fabric, which comprises the following steps: 1. raw material treatment, namely, carrying out treatment before weaving on raw materials; 2, fabric weaving, namely, weaving yarns by using a circular weaving machine; 3, fabric shaping, namely, feeding the woven fabric into shaping equipment for shaping; 4, raising, namely, performing raising treatment on the shaped fabric by adopting raising equipment; 5, fabric compounding, namely, compounding the fabric and suede velvet by adopting compounding equipment; 6, washing, namely, washing the compounded fabric in a water tank; 7, drying, namely, taking out the washed fabric and drying the washed fabric by using drying equipment; step 8, scalding, namely, scalding the dried fabricby using scalding equipment; and 9, shearing, namely, shearing the fabric subjected to scalding treatment by adopting shearing equipment. The method has the advantages that through multiple processes, the woven mink-wool-like fabric can be softer, and the hand feeling of the mink-wool-like fabric is improved.

Owner:海宁市金石毛绒股份有限公司

Boiling-resistant high-barrier composite coiled film

The invention provides a boiling-resistant high-barrier composite coiled film, and relates to the technical field of film materials. The composite coiled film sequentially comprises a polypropylene film external layer, a polyurethane ink layer, a polyurethane glue external layer, a monox-plated polyester film, a polyurethane glue internal layer and a polypropylene film internal layer from outside to inside, the polypropylene film external layer and the monox-plated polyester film are bonded through the polyurethane glue external layer, the polypropylene film internal layer and the monox-plated polyester film are bonded through the polyurethane glue internal layer, and the polyurethane ink layer is printed between the polypropylene film external layer and the polyurethane glue external layer. The boiling-resistant high-barrier composite coiled film has advantages of super high barrier performance, realization of no curling of films at a high temperature, and resistance to 135DEG C high temperature boiling.

Owner:ANHUI KAIHANG PACKAGING TECH CO LTD

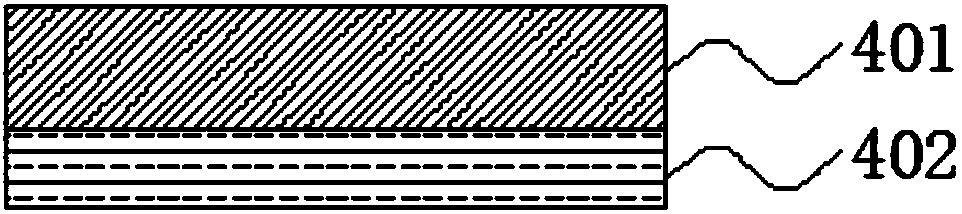

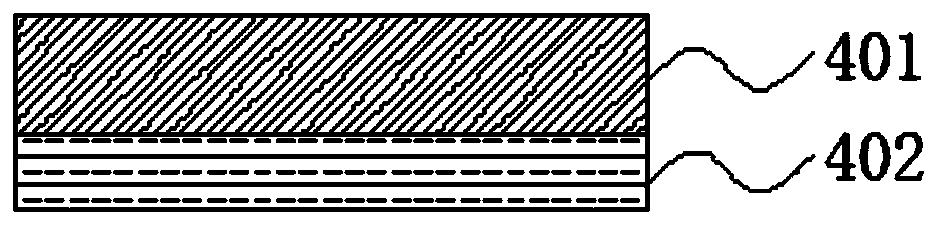

Nano metal substrate for ultra-fine line FPC and COP material, and producing method

PendingCN108428673AImprove adhesionHigh surface energyFlexible printed circuitsSemiconductor/solid-state device detailsEtchingNanotechnology

The invention discloses a nano metal substrate for ultra-fine line FPC and COP material, comprising a first low adhesion layer, a polyimide layer formed on at least one face of the first low adhesionlayer, and an ultra-thin nano metal layer and a protection film layer, which are formed on the other face of the polyimide layer. The ultra-thin nano metal layer is disposed between the polyimide layer and the protection film layer. The thickness of the first low adhesion layer is 3-25 [mu]m; the thickness of the polyimide layer is 5-50 [mu]m; the thickness of the ultra-thin nano metal layer is 0.09-0.8 [mu]m; the thickness of the protection film layer is 6-60 [mu]m; the surface roughness of the polyimide layer is 80-800nm; the ultra-thin nano metal layer is a sputtering layer or an electro-plated layer. The invention is advantageous in that ion migration resistance, size stability, chemical proofing, heat and high temperature resistance, and adhesive power are good; the nano metal substrate is suitable for laser processing, and suitable for processing blind holes / micro holes without easily generating needle holes, and is also suitable for etching of fine lines without side etching; the design of nano copper is adopted, and the demand of substrate fine line development can be met.

Owner:KUSN APLUS TEC CORP

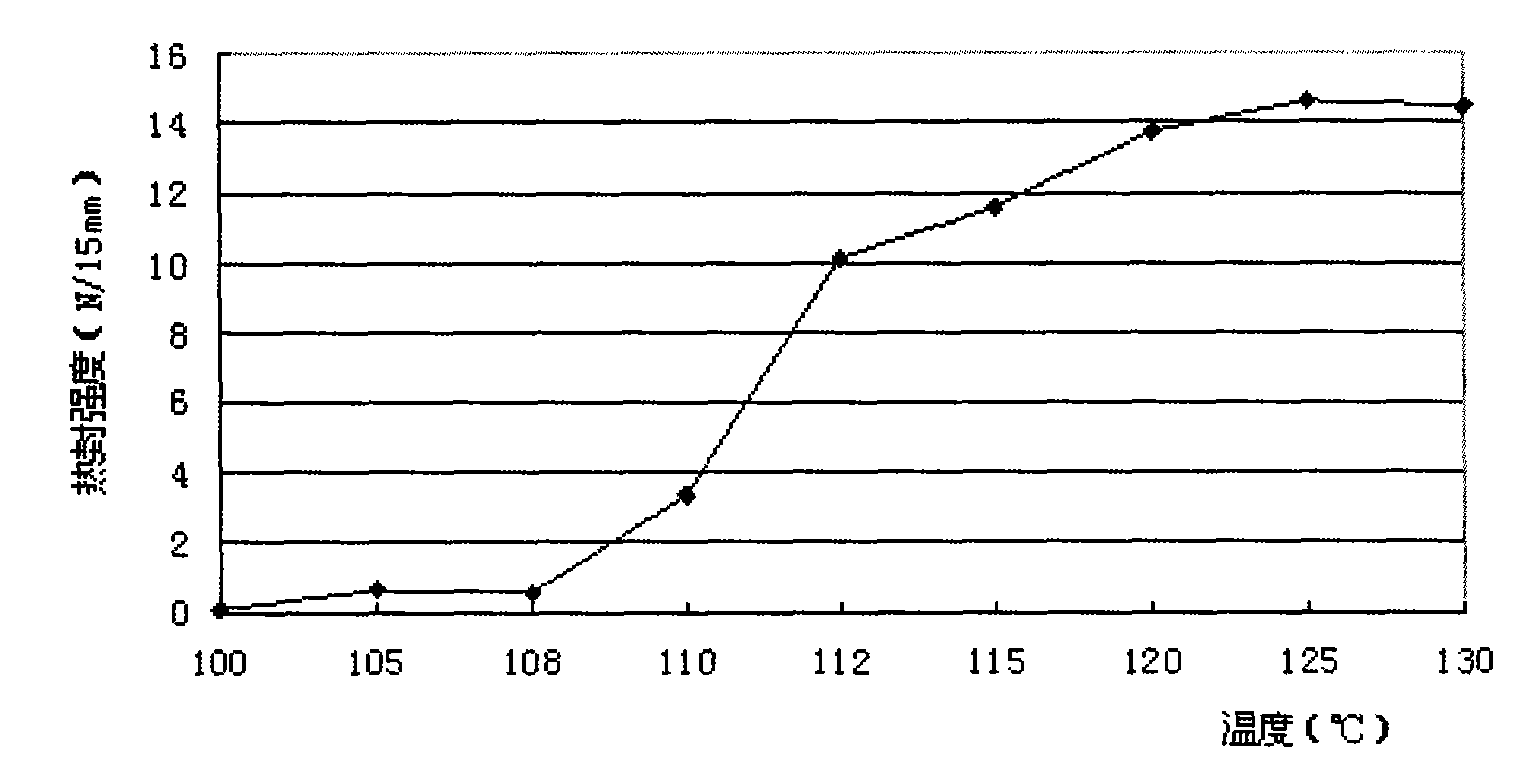

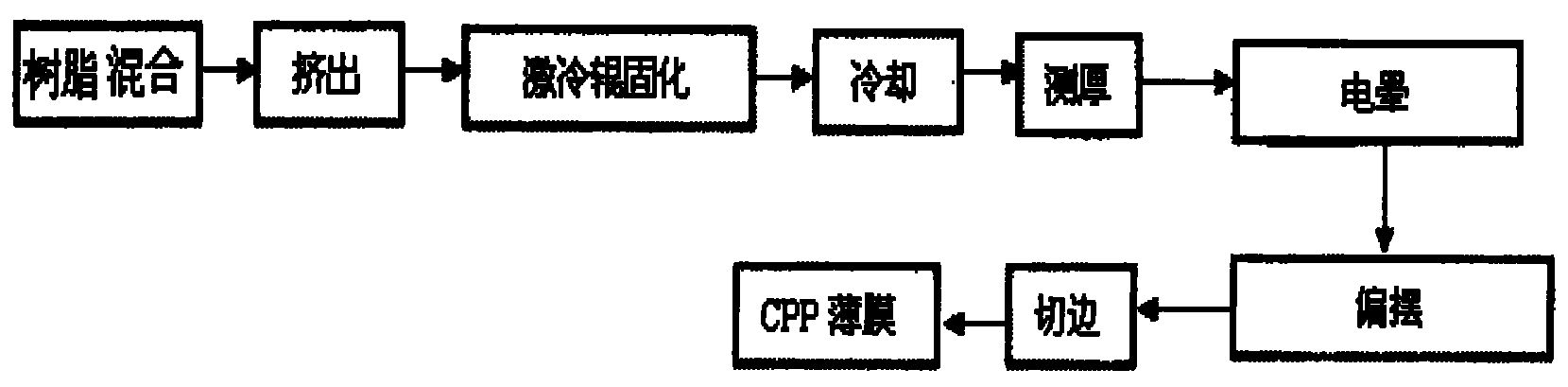

Low-temperature heat-sealing polypropylene film and preparation method thereof

Owner:HUANGSHAN NOVEL

Garment

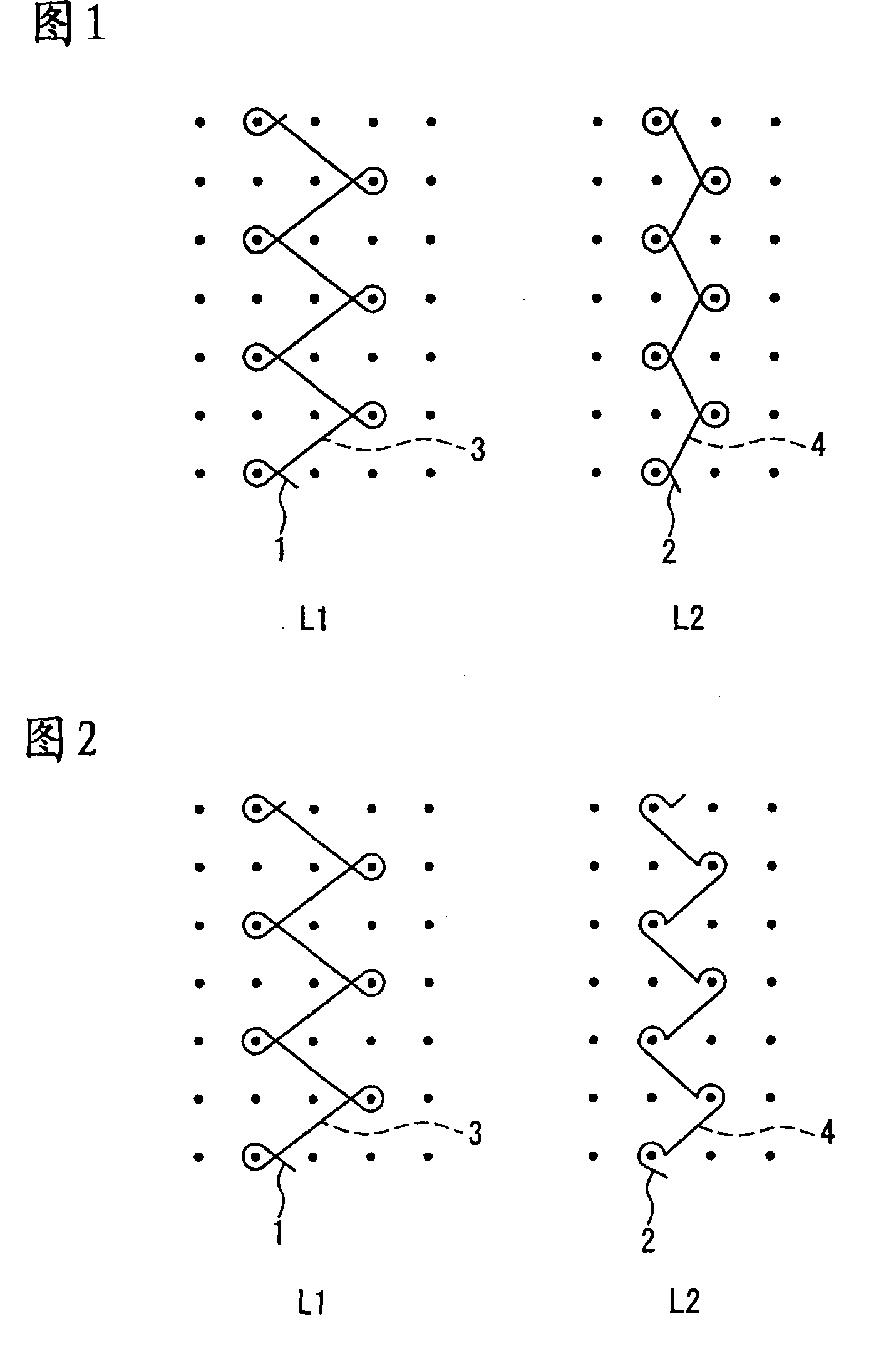

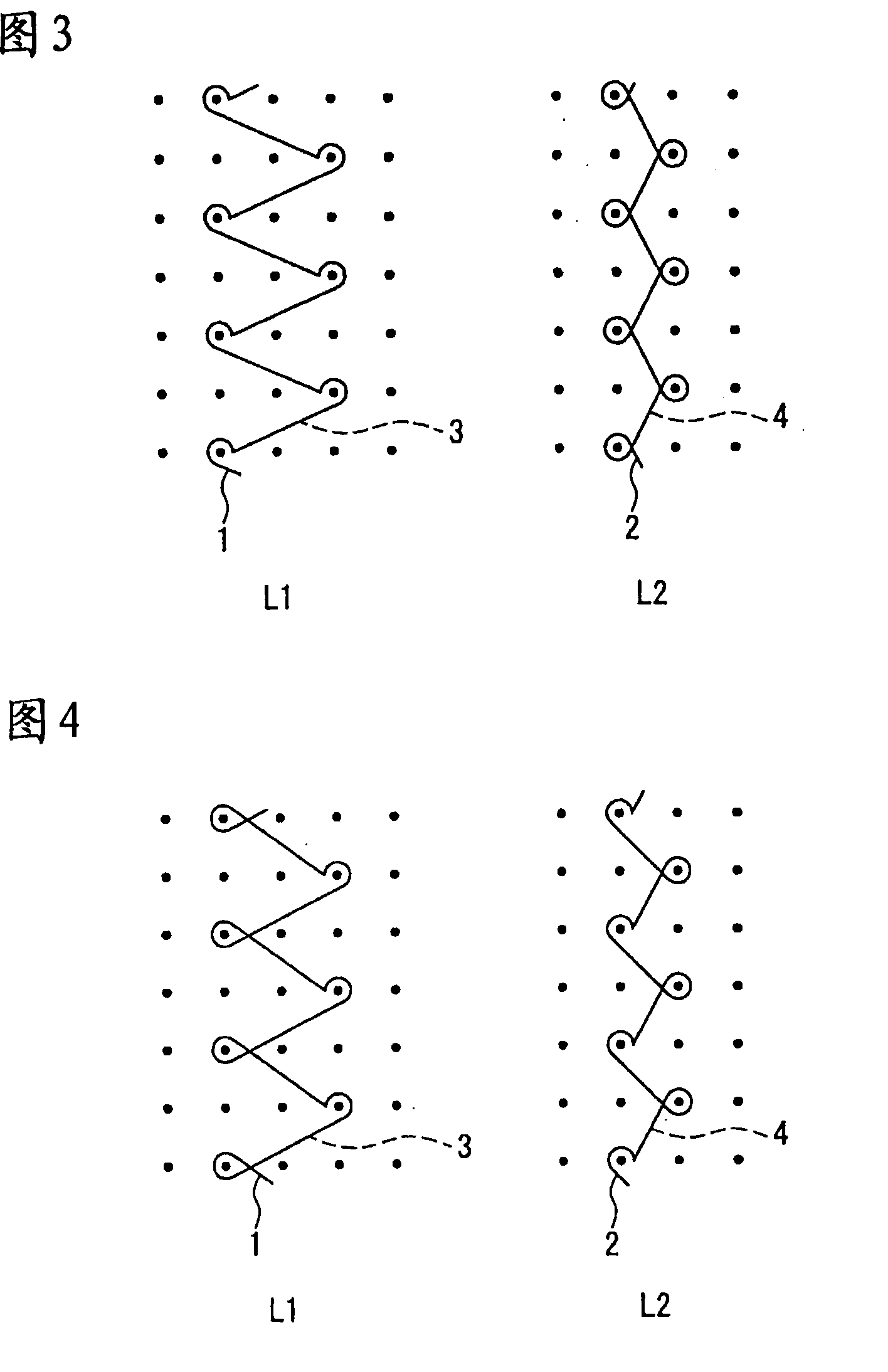

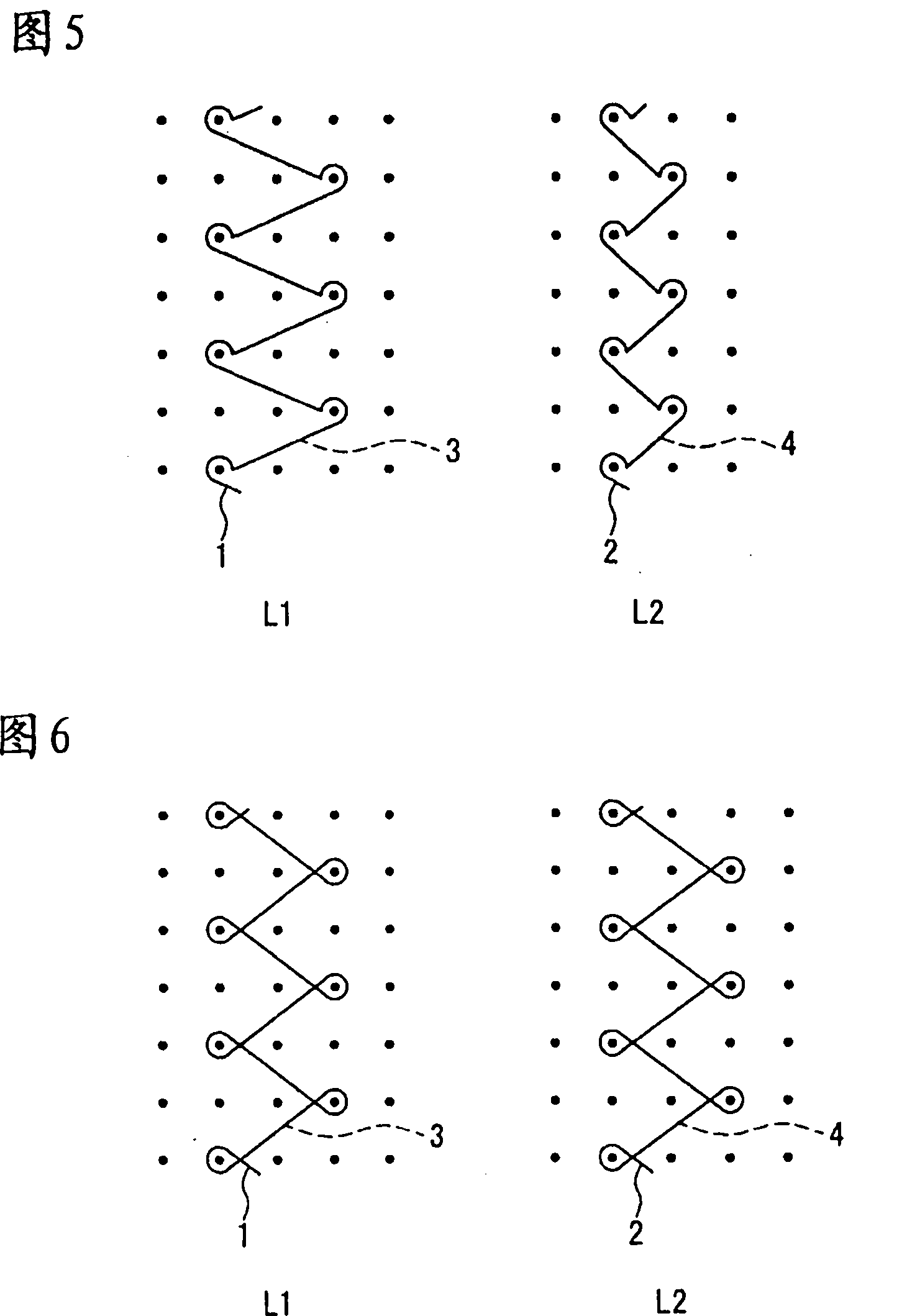

A garment having hems, at least part of which consists of a hem remaining in cut-up form and not any requiring framing work, obtained by employing part piece (P), which is constituted of a stretchy warp knitted fabric and has a hem remaining in cut-up form and not requiring any framing work, in at least part of the fabric constituting the garment, wherein the part piece (P) is constituted of a stretchy warp knitted fabric comprising non-elastic yarns (1) of plain cord texture and elastic yarns (2) of denbigh texture or plain cord texture, the elastic yarns (2) and the non-elastic yarns (1) running along with each other. Thus, there can be provided a stretchy garment wherein the tear strength of the hem remaining in cut-up form and not requiring any framing work is enhanced and wherein curling of the hem is prevented.

Owner:WACOAL

Nano metal substrate and manufacturing method for ultra-fine circuit fpc and cof materials

ActiveCN108621513BLower CTE (coefficient of thermal expansion) valueSize up and downSynthetic resin layered productsElectrical equipmentChip on filmFine line

The invention discloses a nano-metal substrate for an ultrafine line FPC (Flexible Printed Circuit) and COF (Chip On Film) material and a manufacturing method. The nano-metal substrate comprises a polyimide layer with a low thermal expansion coefficient, a roughened polyimide layer formed on at least one side of the polyimide layer with a low thermal expansion coefficient, an ultra-thin nano-metallayer and a protective film layer formed on the other side of the roughened polyimide layer; the roughened polyimide layer is arranged between the polyimide layer with a low thermal expansion coefficient and the ultra-thin nano-metal layer; and the ultra-thin nano-metal layer is arranged between the roughened polyimide layer and the protective film layer. The nano-metal substrate is excellent inion migration resistance, dimensional stability, chemical resistance, heat resistance, high-temperature resistance and adhesion, suitable for laser processing blind holes / micropores, not easy to generate pinholes, suitable for fine line etching, and not easy to be etched. The invention adopts nano-copper design to meet the needs of thinning development of substrates.

Owner:KUSN APLUS TEC CORP

A pole piece strip cutting device with a pressing function

ActiveCN106684314BWon't curlPrevent looseningElectrode rolling/calenderingSecondary cellsPole pieceMechanical engineering

The invention discloses a pole piece strip cutting device with a pressing function. The device comprises a base, wherein a placement plate is mounted above the base; a support plate A and a support plate B are respectively arranged on the two sides of the placement plate; two externally tangent pressing shafts are placed between the support plate A and the support plate B in parallel; one end of each pressing shaft is connected with the support plate A, and the other end of each pressing shaft is connected with the support plate B; the pressing plates are located right above the middle of the placement plate, and are connected with the support plate A and the support plate B through chutes; a fixing plate and a cutter are further arranged above the placement plate and placed between the support plate A and the support plate B in parallel; and one end of the cutter is connected with the support plate A, and the other end of the cutter is connected with the support plate B. The device provided by the invention has the advantages that a pole piece can be kept strained throughout a strip cutting process through the pressing shafts and the fixing plate, so that the pole piece can be prevented from curling or loosing, and a large number of burrs at the edges of a pole piece strip obtained through cutting can be avoided.

Owner:绵阳绿环新能源环保科技有限公司

A kind of anti-flash film cutting machine

The invention provides a thin film slitting machine capable of preventing burrs, and belongs to the technical field of machinery. The thin film slitting machine solves the technical problems of poor slitting effect and the like which exist in an existing thin film slitting machine. The thin film slitting machine capable of preventing the burrs comprises a machine frame, wherein a material feedingroller is rotationally arranged on the machine frame, and a plurality of extension rollers and adhesion rollers are sequentially and rotationally arranged on one side of the material feeding roller; the extension rollers and the adhesion rollers are all rotationally arranged on the machine frame, and a tensioning structure used for tensioning a thin film is arranged between the extension rollers and the adhesion rollers; the sides, far away from the extension rollers, of the adhesion rollers are also sequentially provided with a cutting mechanism and a winding mechanism, wherein the cutting mechanism is used for slitting the thin film and is adjustable in width, and the winding mechanism is used for winding the thin film after slitting; and a strip separating block capable of separating cut adjacent thin film strips in a staggered mode is arranged between the cutting mechanism and the winding mechanism, and the strip separating block is fixedly arranged on the machine frame. The thin film slitting machine has the advantage of being good in slitting effect.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

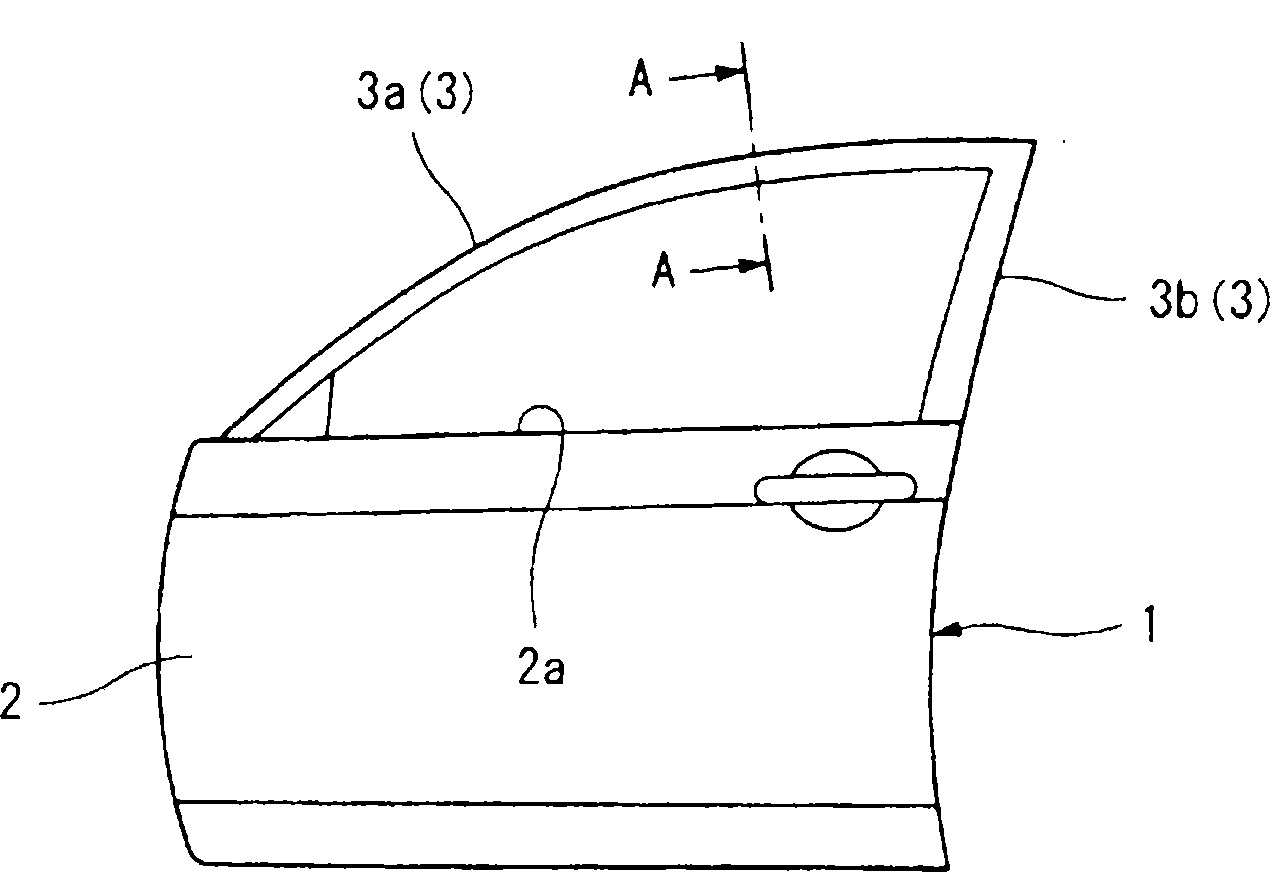

Installation structure of glass run channel

ActiveCN102416851BWon't curlWill not affect the shapeEngine sealsVehicle sealing arrangementsEngineeringCar door

Owner:KINUGAWA RUBBER IND CO LTD

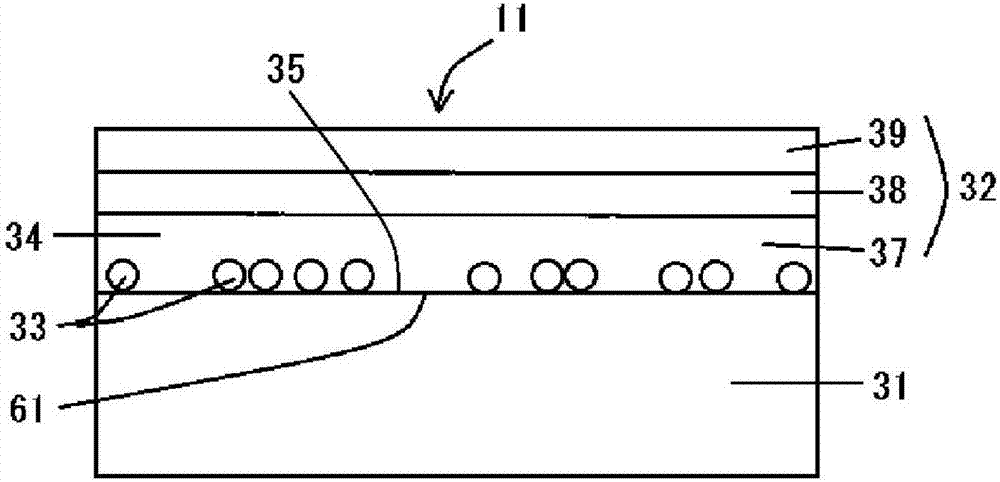

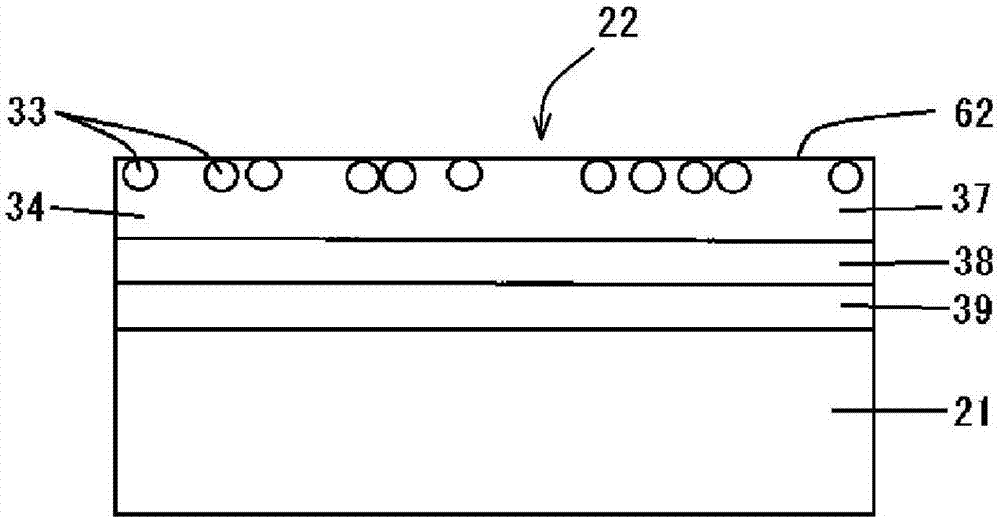

Antiviral transfer sheet and method for producing same, and antiviral shrink film and method for producing same

InactiveCN107073808AEnsure transparencyThe degree of hindrance is reducedBiocideDecorative surface effectsVolumetric Mass DensityMaterials science

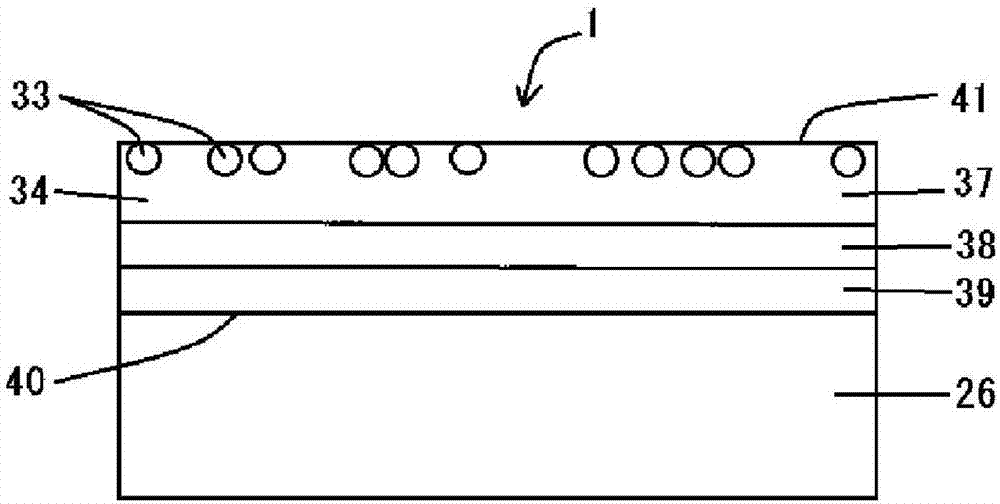

A method for producing an antiviral transfer sheet for increasing the density of an antiviral agent / antimicrobial agent on the surface serving as the outermost layer after transfer, wherein the production method obviates the need for a large amount of antiviral agent or the like and eliminates the opacity of the layer having an antiviral function. An inorganic antiviral powder 33 is arranged on one side of a base sheet 31, a hard coat agent 34 is positioned in the form of a layer on top of the inorganic antiviral powder 33, and a functional layer 37 comprising the inorganic antiviral powder and hard coat agent is formed on the base sheet. Next, an antiviral transfer sheet 11 is produced by forming an adhesive layer 39 on top of the functional layer 37 in contact with the functional layer 37 or with other layers interposed therebetween.

Owner:NISSHA PRINTING COMPANY

Partition for coating chamber

InactiveCN103334086BQuality improvementWon't curlVacuum evaporation coatingSputtering coatingEngineeringFlange

The invention relates to a partition plate for a coating chamber, comprising a U-shaped groove plate, a first folded edge, a second folded edge, a first baffle plate and a second baffle plate; the middle part of the groove bottom of the U-shaped groove plate is provided with a through groove The window at the bottom; the first flange and the second flange are respectively connected to the top of the two side walls of the U-shaped groove; the first baffle and the second baffle are both across the U-shaped groove edge and the second edge connection. The partition plate for the coating chamber can effectively reduce the conduction of heat to the flexible base material, and a high-quality flexible functional film can be obtained by applying the partition plate for the coating chamber to coat the film.

Owner:NANCHANG O FILM TECH CO LTD +2

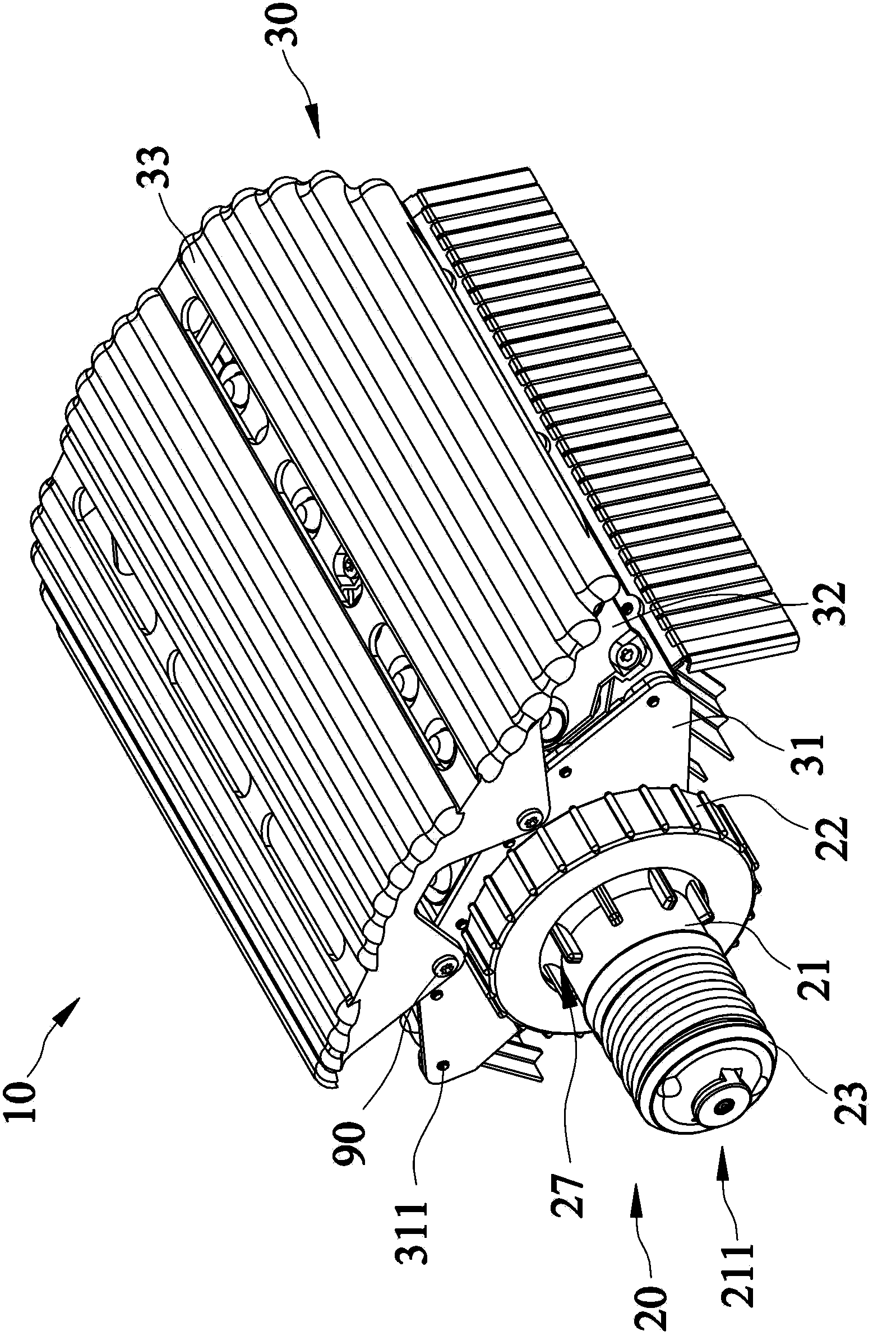

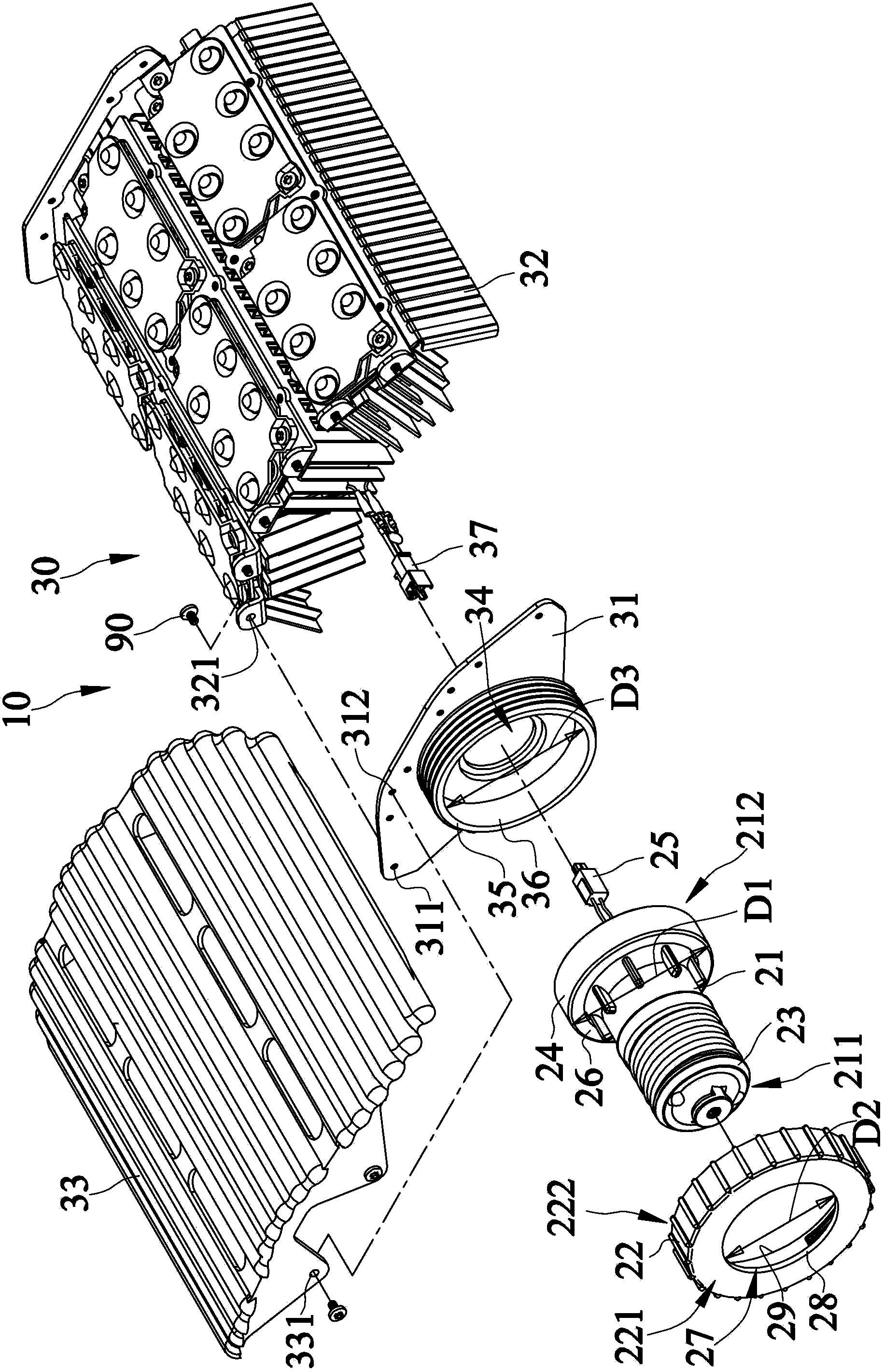

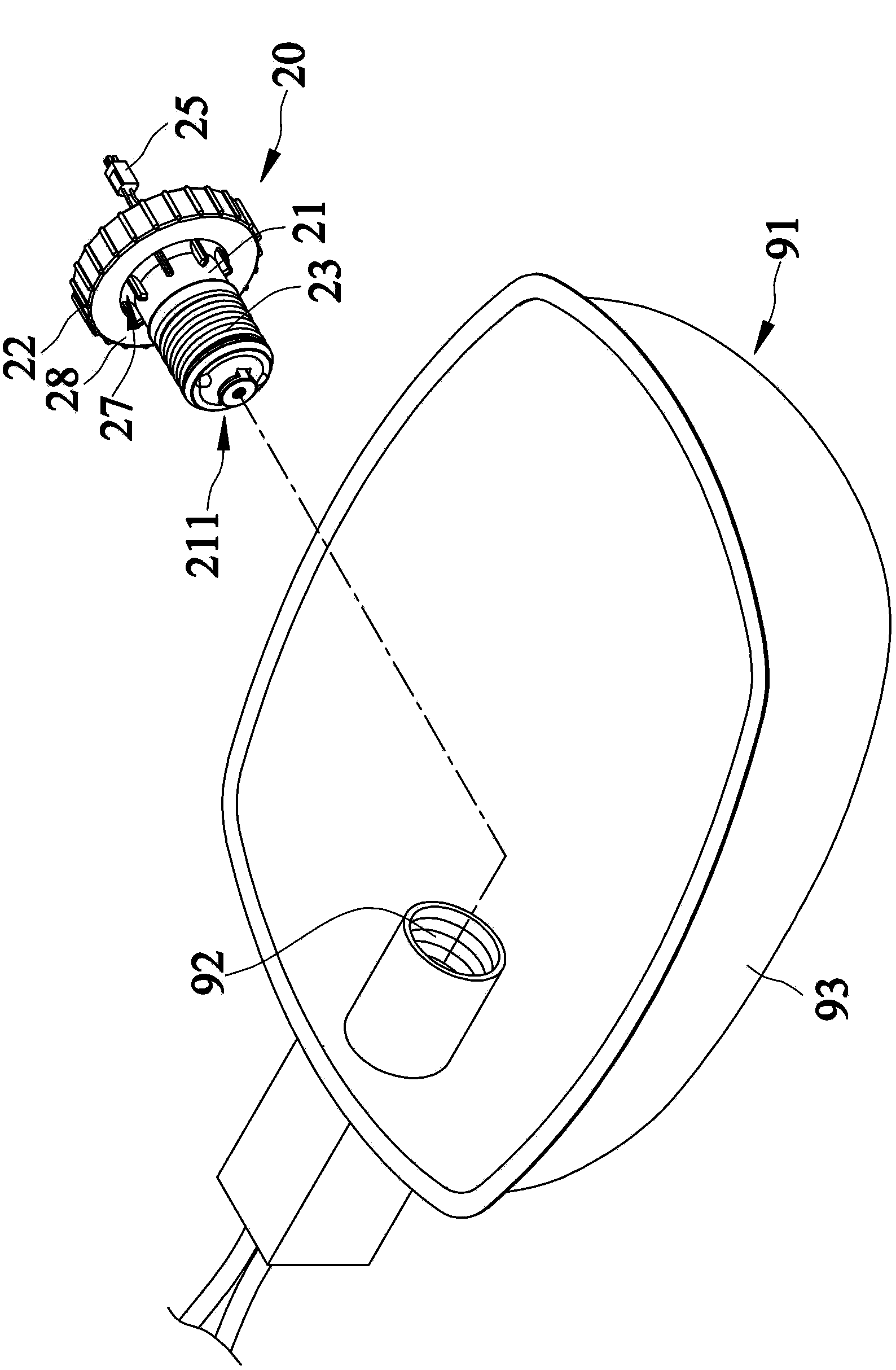

Flat lighting device fixed with any angle

InactiveCN103423616ASmall sizeReduce brightnessLighting support devicesPoint-like light sourceEffect lightEngineering

The invention provides a flat lighting device fixed with any angle. An LED lamp replaces a prior mercury lamp, a prior mercury lamp holder is used, a plurality of structures which can be disassembled and assembled are arranged at a head base of the lamp so that many parts of the lamp can be assembled respectively when the lamp is installed, and the known problems that an LED lamp is incorrect in illumination angle and a light source module is insufficient in luminance are solved. The head base and a light source module are assembled respectively so that the illumination angle of the LED lamp can be corrected in the installation process. Due to respective assembly, the light source module can be manufactured into a high-brightness light source module which is large in size and in a flat shape; as the light source module does not need to rotate repeatedly in the lamp holder, interference cannot exist between the light source module and the lamp holder even when the size of the light source module increases and the light source module is flat in shape.

Owner:SUNBEEN TECH

A film cutting machine with edge anti-roll

ActiveCN108408455BWon't curlEasy to rewindArticle deliveryWebs handlingMechanical engineeringEngineering

The invention provides a film slitting machining preventing edge curling and belongs to the mechanical technical field. The film slitting machining preventing edge curling solves the technical problemthat an existing film slitting machine is poor in cutting effect. The film slitting machining preventing edge curling comprises a machine frame. A feeding roller is rotationally arranged on the machine frame. A plurality of extension rollers and adhesion rollers are sequentially and rotationally arranged on one side of the feeding roller. The extension rollers and the adhesion rollers are rotationally arranged on the machine frame. A tensioning structure used for tensioning the film is arranged between the extension rollers and the adhesion rollers. The side, far away from the extension rollers, of the adhesion rollers is further sequentially provided with a cutting mechanism used for film slitting and a coiling mechanism for slit film. A heating roller used for preventing the edges of the film strips from curling and a strip separating block capable of separating adjacent cut film strips in a staggered manner are sequentially arranged between the cutting mechanism and the coiling mechanism. The strip separating block and the heating roller are fixedly arranged on the machine frame. The film slitting machine preventing edge curling has the advantage of being good in slitting effect.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

Strain gauge assembly and test method for testing thermoset cast pbx cure stress

InactiveCN103940534BFixed and accurateNo compatibility issuesForce measurement by permanent gauge deformationForce measurement by elastic gauge deformationLiquid stateSlurry

The invention relates to a strain gauge assembly for testing the curing stress of a thermosetting pouring PBX and a testing method thereof. The strain gauge assembly for testing the curing stress of the thermosetting pouring PBX comprises a base material and a strain gauge which is wrapped in the base material, the strain gauge is in a tiling shape in the base material, and the base material is composed of hydroxyl-terminated polybutadiene, dioctyl adipate, aluminite powder, 2 / 4- toluene diisocynate and triphenylbismuthine. The testing method of the curing stress of the thermosetting pouring PBX comprises the steps of calibrating the strain gauge assembly, arranging the strain gauge assembly, pouring an elastic body, and testing the stress in the curing process. The strain gauge assembly can be randomly placed at different positions in the pouring PBX, in the testing process, the compatibility of the base material and chemical slurry is good, the strain gage can not be curled or corroded by liquid chemical slurry due to the protection of the base material, and the testing effect on the curing stress of the pouring PBX is obvious.

Owner:XIAN MODERN CHEM RES INST

Silicon steel sheet production device and production process for controlling damping thickness fluctuation of non-oriented silicon steel

PendingCN114433663AWon't curlImprove plasticityWork cooling devicesWork heating devicesEngineeringMechanical engineering

The invention relates to the technical field of silicon steel production and plate rolling, in particular to a silicon steel sheet production device and process for controlling damping thickness fluctuation of non-oriented silicon steel, the silicon steel sheet production device comprises a leveling device and a machine shell, the leveling device is located in the machine shell, and the leveling device comprises a cooling assembly and further comprises a flattening mechanism located at the bottom of the cooling assembly; the flattening mechanism comprises a base shell, the bottom of the base shell is fixedly connected with the inner wall of the bottom of the machine shell, the inner walls of the two sides of the base shell are fixedly provided with the same trapezoidal mounting frame, the inner walls of the two sides of the trapezoidal mounting frame are rotationally connected with multiple sets of transmission rollers, and the multiple sets of transmission rollers are arranged in an arc-shaped array. By arranging the flattening mechanism, the surface of a silicon steel sheet is smooth and flat, the thickness of the silicon steel sheet is uniform before the silicon steel sheet is rolled, and the problem that traditional silicon steel sheet production equipment cannot meet the requirement for producing high-product-quality silicon steel is solved.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

Feeding device for shredder without thrust

The invention provides a non-thrust feeding device of a tobacco cutter. The non-thrust feeding device comprises a distributing mechanism, a guide structure, a conveying belt and a feeding underframe. The distributing mechanism is arranged at a feeding port of the guide structure, the guide structure is positioned above the feeding end of the conveying belt, a storage bin is penetratingly arranged at the lower end of the guide structure, the conveying belt is mounted on a belt support and is accommodated in the storage bin, the discharging end of the conveying belt is positioned between an upper copper bar chain and a lower copper bar chain of the tobacco cutter, the lower end of the storage bin is connected with the belt support, and a vibrator is rigidly connected to the lower end of the belt support. A glass plate is connected to the top surface of the feeding underframe elastically, and the upper end of the glass plate is connected with the belt support. The non-thrust feeding device of the tobacco cutter can enable tobacco leaves not to be subjected to any thrust, so that the quantity of netted tobacco (coalesced tobacco) and scraps contained in cut cigarette tobacco is decreased substantially.

Owner:SHANGHAI TOBACCO GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com