Partition for coating chamber

A technology for coating chambers and partitions, applied in the field of partitions for coating chambers, can solve the problems of flexible substrates being heated and curled, low-quality flexible functional films, etc., and achieve the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

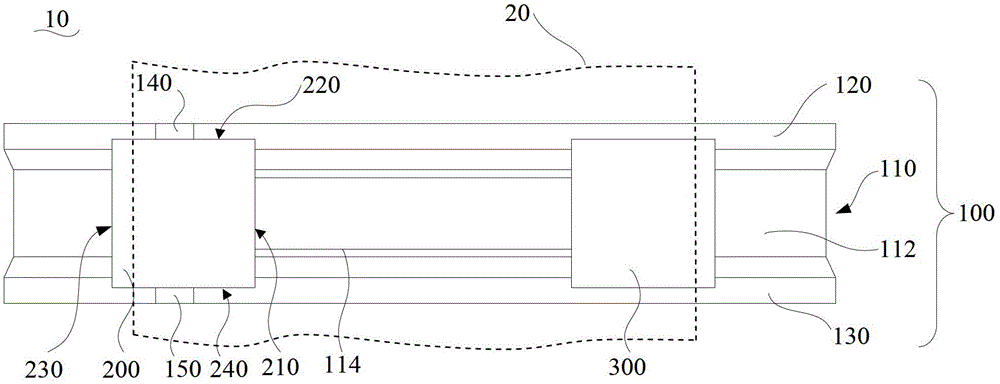

[0020] The separator for the coating cavity will be further described below with reference to the accompanying drawings.

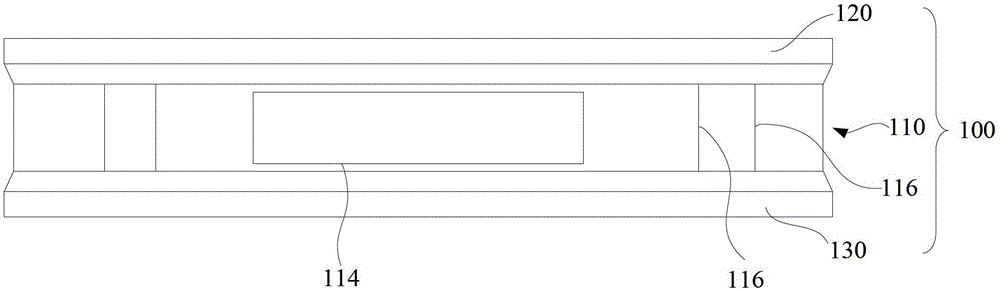

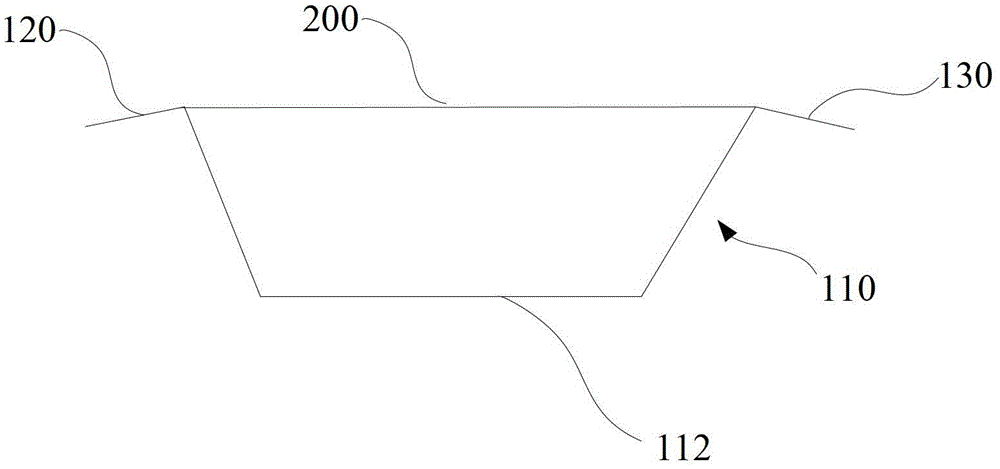

[0021] like figure 1 and figure 2 As shown, the separator 10 for a coating cavity in an embodiment includes a main body 100, a first baffle 200 and a second baffle 300, wherein the main body 100 includes a U-shaped groove plate 110, a first folding edge 120 and a second folding Side 130.

[0022] The U-shaped grooved plate 110 includes a groove bottom 112 and two side walls. A window 114 extending through the groove bottom 112 is provided in the middle of the groove bottom 112 . In this embodiment, the window 114 is rectangular. Under normal circumstances, the length of the window 114 (the direction in which the flexible substrate 20 moves) can be as large as possible under the conditions allowed by the size of the coating chamber, and the width of the window 114 usually needs to be based on the width of the area of the flexible substrate 20 that nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com