Nano metal substrate for ultra-fine line FPC and COP material, and producing method

A nano metal, ultra-fine circuit technology, applied in the direction of circuit substrate materials, circuits, printed circuits, etc., to achieve the effect of improving surface energy, increasing adhesion, and improving resistance to ion migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

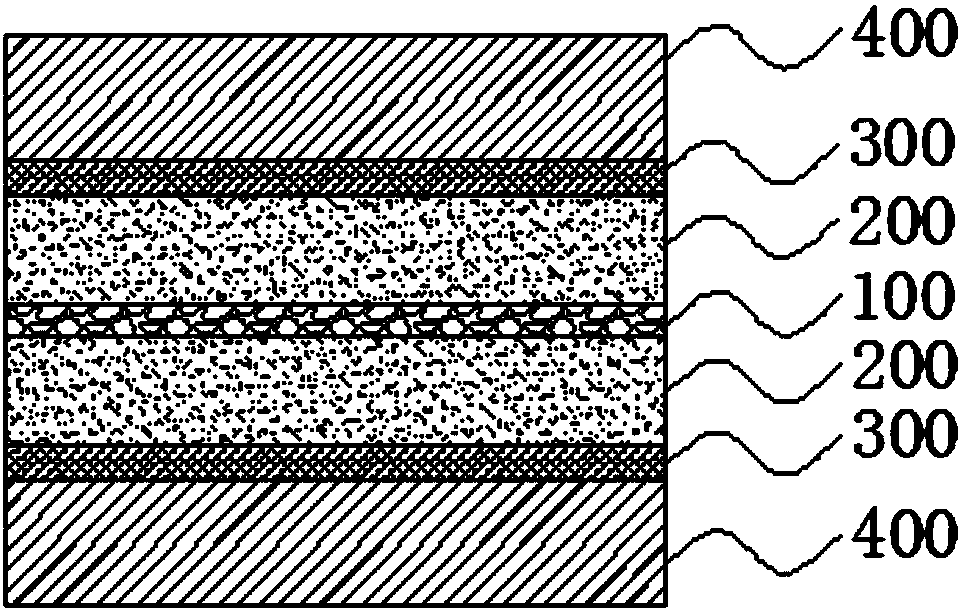

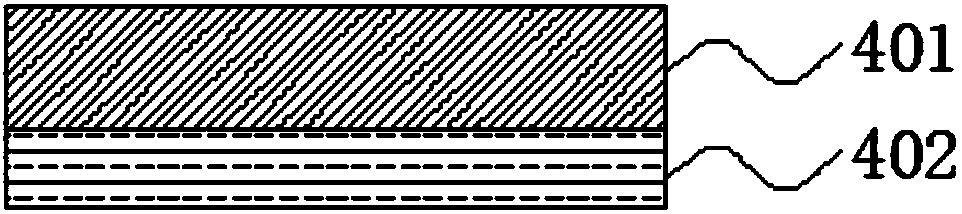

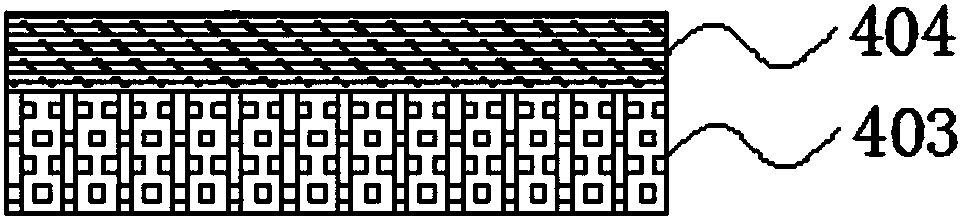

[0056] Embodiment: A nano-metal substrate for ultra-fine circuit FPC and COF materials, the present invention includes a first low adhesion layer 100, a polyimide layer 200 formed on at least one side of the first low adhesion layer 100, The ultra-thin nano-metal layer 300 and the protective film layer 400 formed on the other side of the polyimide layer 200, the ultra-thin nano-metal layer 300 is interposed between the polyimide layer 200 and the protective film layer 400 between;

[0057] The thickness of the first low adhesion layer 100 is 3-25um;

[0058] The thickness of the polyimide layer 200 is 5-50um;

[0059] The thickness of the ultra-thin nano-metal layer 300 is 0.09-0.8um;

[0060] The thickness of the protective film layer 400 is 6-60um;

[0061] The polyimide layer 200 is a polyimide layer with a surface roughness between 80-800 nm. The polyimide layer of the present invention adopts a PI film with a roughness of 80-800nm. A roughened PI resin can increase t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com