Manufacturing method of transfer paper

A manufacturing method and technology of transfer paper, applied in the direction of temperature recording method, etc., can solve the problems such as unevenness of the adhesive film, easy curling, inconsistent thickness of the adhesive film, etc., and achieve the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

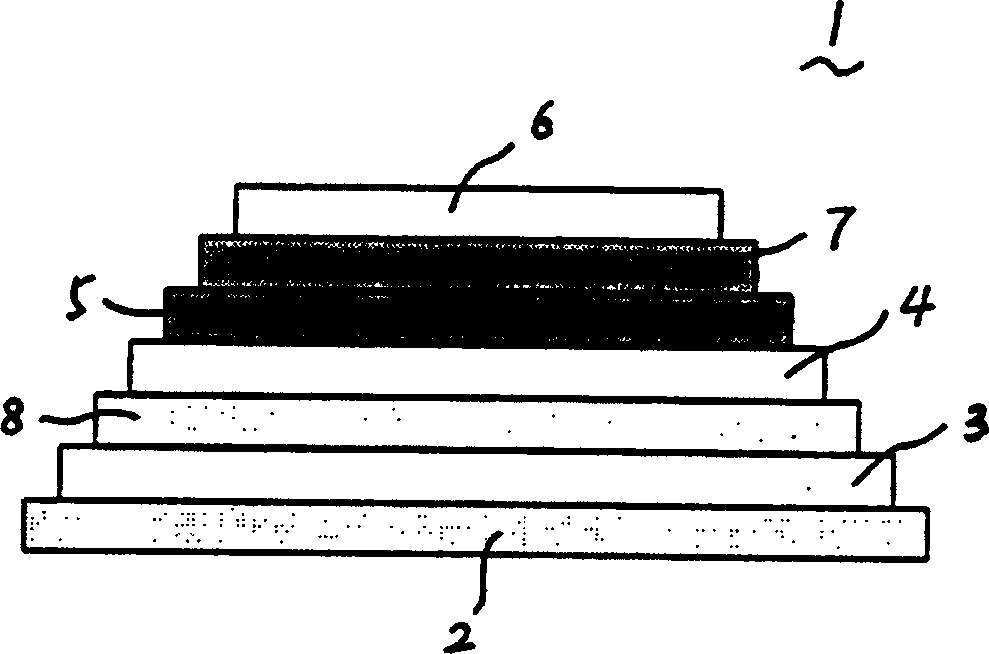

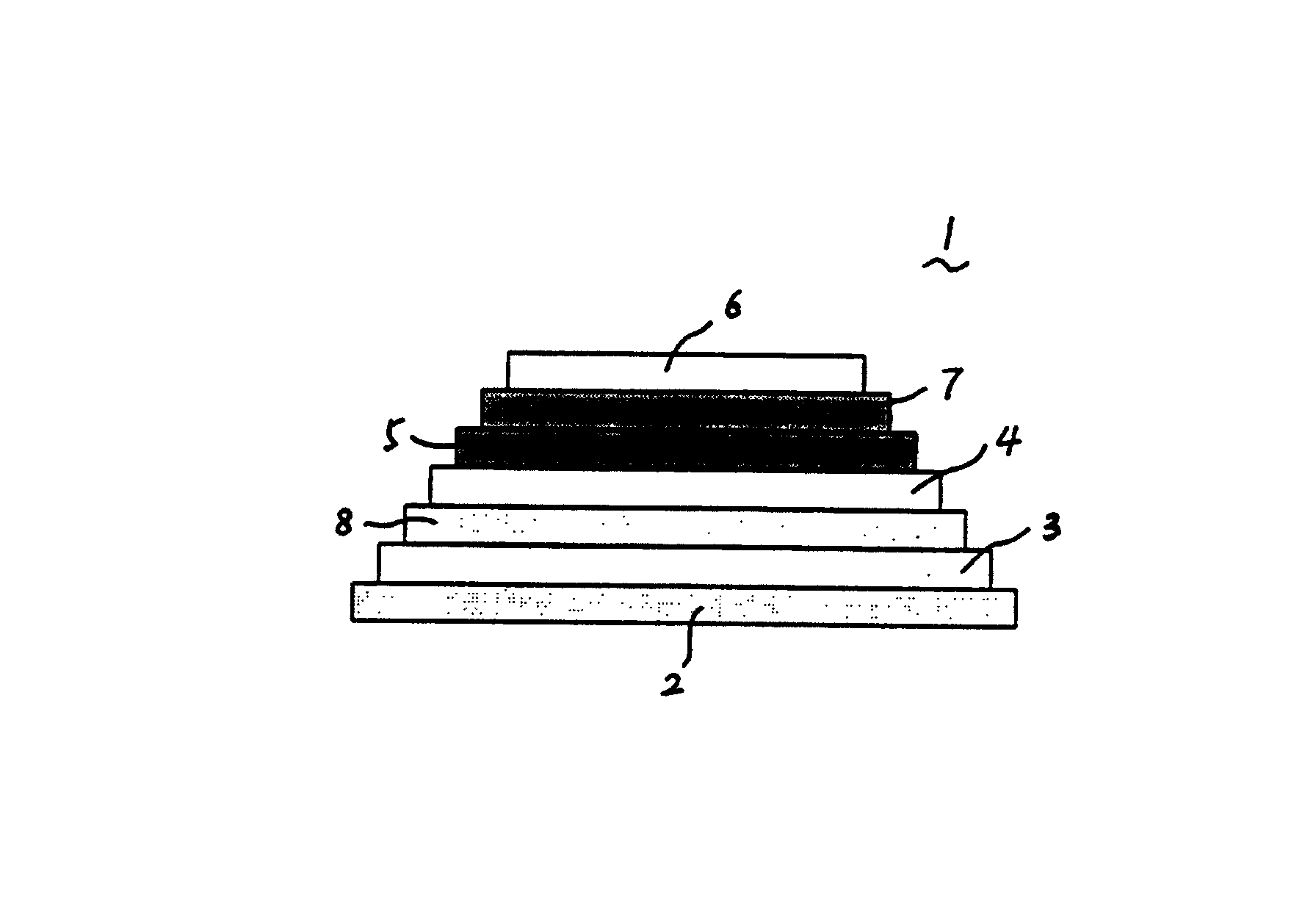

[0013] The manufacture method of transfer printing paper 1 of the present invention comprises the steps:

[0014] a, prepare a synthetic resin with good processability, and add an auxiliary agent for increasing the viscosity to form a mixture for making the adhesive film 6:

[0015] Synthetic resins with good processability are made into film 6, such as polyethylene, polypropylene, polyoxyethylene, polystyrene, polycarbonate, polyethylene terephthalate, nylon, polyvinylidene chloride, vinyl Vinyl acetate copolymer, vinyl chloride-vinyl acetate copolymer, polybutene, etc.;

[0016] The adhesive film 6 made of the above resin has good toughness and is suitable for adhesion on irregular surfaces;

[0017] In addition, since the adhesive film 6 can have good lamination performance only after it has a certain viscosity, it can be used as the carrier of the water transfer printing paper. Therefore, when making the adhesive film 6, certain additives must be added, and a variety of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com