Patents

Literature

88 results about "Chamois leather" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chamois leather (/ˈʃæmi/) is a type of porous leather, traditionally the skin of the chamois (Rupicapra rupicapra), a type of European mountain goat but today it is made almost exclusively from the flesh split of a sheepskin.

Artificial suede-type leather and process for producing the same

InactiveUS20060035556A1Good light fastnessBrilliant colorationSynthetic resin layered productsWoven fabricsPolyesterLight irradiation

This invention relates to a suede-like artificial leather using ultra-fine polyester fibers and a polyurethane, and provides a suede-like artificial leather free from the occurrence of specking and having graceful surface appearance and high light fastness. The suede-like artificial leather comprising a fiber-entangled substrate mainly containing ultra-fine polyester fibers with a fiber fineness of 0.7 dtex or less and a polyurethane, and is dyed, and is wherein said polyurethane contains at least one each of yellow pigments, red pigments and blue pigments, and that said artificial leather satisfies all of the following properties (1) through (3) as measured by the methods described in the specification; (1) The infrared reflectance at 850 nm is 60% or more; (2) The surface temperature during light irradiation is 105° C or lower; (3) The light fastness is class 3 or better. Especially since the suede-like artificial leather of this invention has high light fastness, it can be most suitably used for car seats.

Owner:TORAY IND INC

Suede artificial leather and production method thereof

ActiveUS7951452B2Excellent color developmentExcellent fastness to lightSynthetic resin layered productsPaper/cardboard layered productsElastomerMechanical property

The suede artificial leather of the present invention comprises a three-dimensional entangled body comprising a superfine fiber having a fineness of 0.2 dtex or less and an elastomeric polymer A, and satisfies the requirements (1) to (4) as specified in the specification. By meeting the requirements, the suede artificial leather acquires excellent color fastness to light and color development in a wide range of colors and a high quality with good suede feeling, surface touch, hand, mechanical properties and color fastness.

Owner:KURARAY CO LTD

Chamois leather gold-stamping method

ActiveCN102926243ABright surfaceTo achieve the effect of breathability and impermeabilityTextile decorationScreen printingRough surface

The invention relates to a cloth treatment method and especially relates to a chamois leather gold-stamping method. The chamois leather gold-stamping method is a chamois leather surface treatment technology. The chamois leather gold-stamping method solves the problem that in the existing gold-stamping method, gold-stamping slurry needs to be printed on a cloth by a 33T screen printing plate at least two times so that patterns are clear and bright-colored; gold-stamping processes are complex; and technical requirements are high. A chamois leather gold-stamped cloth obtained by the chamois leather gold-stamping method has beautiful patterns and a bright leather surface, and solves the problem that the existing chamois leather product is cleaned difficultly, has a rough surface and is maintained difficultly.

Owner:RUGAO XIDONG YARN DYED CO LTD

Chamois initation artificial leather and manufacturing method thereof

InactiveCN1497098AExcellent color developmentHigh fastnessDyeing processWoven fabricsElastomerChamois leather

Provided is sueded artificial leather having good color developing properties and color fastness to light in a wide range of color tones, having a good sueded feel, surface touch, and feeling, and therefore having a sense of high quality. This suedey artificial leather is composed of a three-dimensionally interwoven material formed out of ultrafine fibers having a dtex of <=0.2 and a polymeric elastic material A and satisfies the following requisites (1) to (4): (1) the three-dimensionally interwoven material contains 0-8wt.% of at least one pigment A selected from an organic pigment having an average particle diameter of 0.01-0.3[mu]m and carbon black having an average particle diameter of 0.01-0.3[mu]m, (2) the polymeric elastic material A contains 1-20wt.% of at least one of another pigment selected from another organic pigment having an average particle diameter of 0.05-0.6[mu]m and the other carbon black having an average particle diameter of 0.05-0.6[mu]m, or of pigment particles containing the other organic pigment and having the average particle diameter of 0.05-0.6[mu]m, as a pigment B; (3) the polymeric elastic material A and the three-dimensionally interwoven material are contained in a weight ratio of 15:85 to 60:40; and (4) the ultrafine fibers existing at the surface have raised fluffs of which the average length is 10-200[mu]m.

Owner:KURARAY CO LTD

Preparation method of double-sided leather

The invention discloses a preparation method of double-sided leather. The preparation method comprises the following steps: uniformly stirring and filtering 5-10 parts of dimethylformamide and 0.5-2 parts of a color paste to obtain slurry; uniformly mixing and swelling 100-120 parts of dimethylformamide and 20-30 parts of wood flour, and then uniformly mixing with the slurry; adding 100 parts of polyurethane wet process resin to be uniformly mixed and defoamed; scraping the defoamed slurry on a glaze of suede, and then, solidifying, squeezing, water-washing and drying to obtain a wet base; uniformly mixing 100 parts of polyurethane dry process resin, 15-20 parts of dimethylformamide, 15-20 parts of butanone, 15-20 parts of methylbenzene, 0.5-1.0 parts of an assistant and 3-5 parts of a toner, scraping the mixed slurry on release paper, and then binding the wet base and separating from the release paper; uniformly mixing and filtering 100 parts of bonding glue, 20-30 parts of butanone, 10-14 parts of a bridging agent and 3-5 parts of an accelerant; and scraping the mixed and filtered slurry on the hair side of the suede, and binding a transfer membrane. According to the preparation method disclosed by the invention, the double-sided leather with a release paper pattern and a transfer membrane pattern is obtained.

Owner:KUNSHAN XIEFU NEW MATERIALS LTD BY SHARE LTD

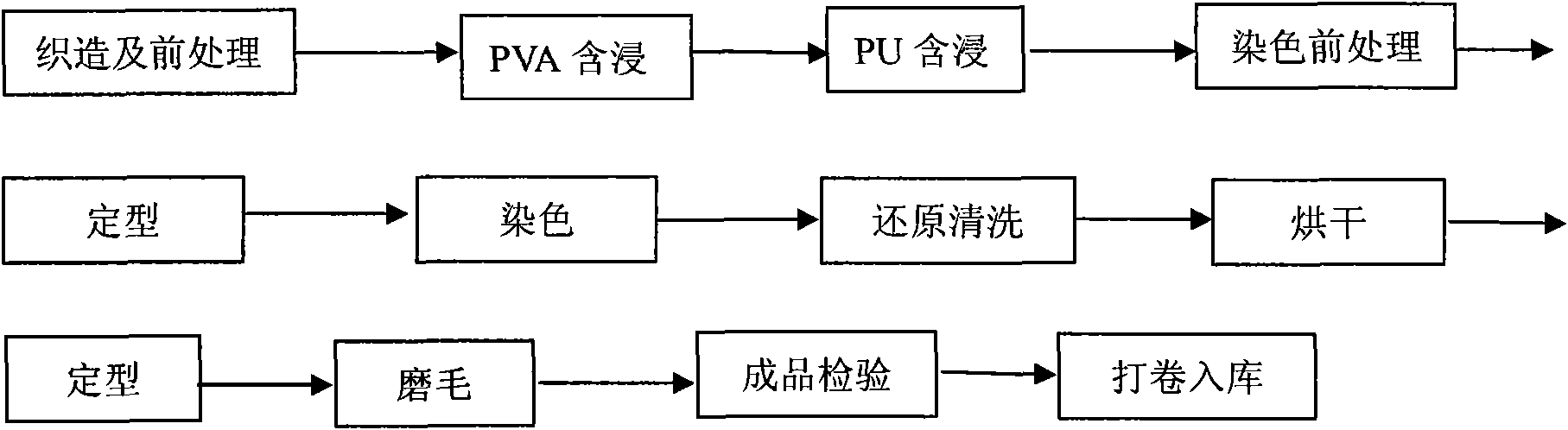

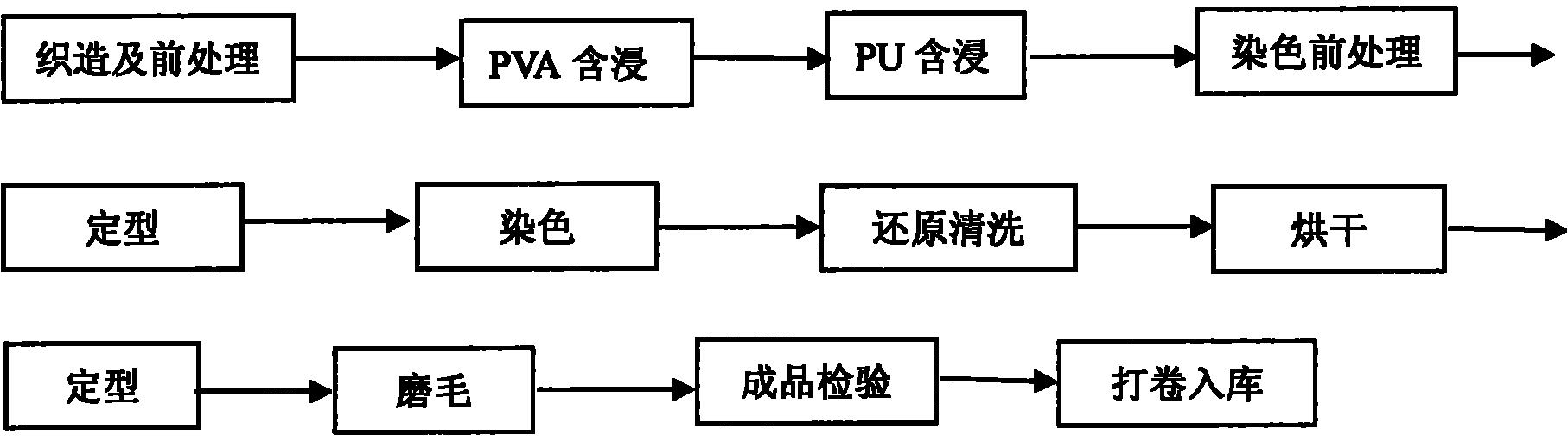

Manufacturing process of high-emulation chamois leather fabric

ActiveCN101886315ASolve technical problemsImprove the feeling effectFibre treatmentHeating/cooling textile fabricsProduct inspectionChamois leather

The invention discloses a manufacturing process of high-emulation chamois leather fabric, comprising the steps of a, weaving and pre-treatment; b, PVA impregnation; c, PU impregnation; d, dyeing pre-treatment; e, forming; f, dyeing; g, reduction clearing; h, drying and forming; i, deburring; and j, product inspection, rolling and warehousing. The product manufactured by the process has the advantages of brilliant color, softness, deftness, good touch, great air permeability, wide application field, low cost and high product additional value and the like.

Owner:ZHEJIANG MEISHENG NEW MATERIALS CO LTD

Preparation method of figured islands-in-sea wool suedette interior trim leather of car

ActiveCN104963211AHas a pungent smellImprove breathabilityNon-woven fabricsPolyurethane dispersionChamois leather

The invention relates to a preparation method of figured islands-in-sea wool suedette interior trim leather of a car. The preparation method comprises the following steps: (a) opening 100% of 3.5Dx51mm Dacron figured islands-in-sea fibers through a nonwoven opening machine; (b) needling vertically so that the fibers are entangled and occluded to form a fabric; (c) transporting the fabric to a fibrewoven machine for surface finishing, and then ironing the fabric by adopting a heat roller with temperature of 110-120 DEG C at speed of 10-15m / min; (d) soaking the ironed fabric into polyving akohol solution with temperature of 80-90 DEG C and mass concentration of 8-10%, then soaking in waterborne polyurethane dispersoid, drying at 110-115 DEG C, and placing into deionized water with temperature of 80-95 DEG C for removing polyvinyl alcohol, thus obtaining suedette, namely Beth; (e) soaking the Beth into NaOH or KOH solution with mass concentration of 5-10%, wherein the pick-up ratio is 100%; adjusting the pH till the pH is neutral, and drying; (f) dyeing and drying; and (g) carrying out sanding treatment. With the adoption of the preparation method, polyvinyl alcohol can be removed in alkaline solution, and thus the suedette interior trim leather with good breathability is obtained.

Owner:江苏尚科聚合新材料有限公司

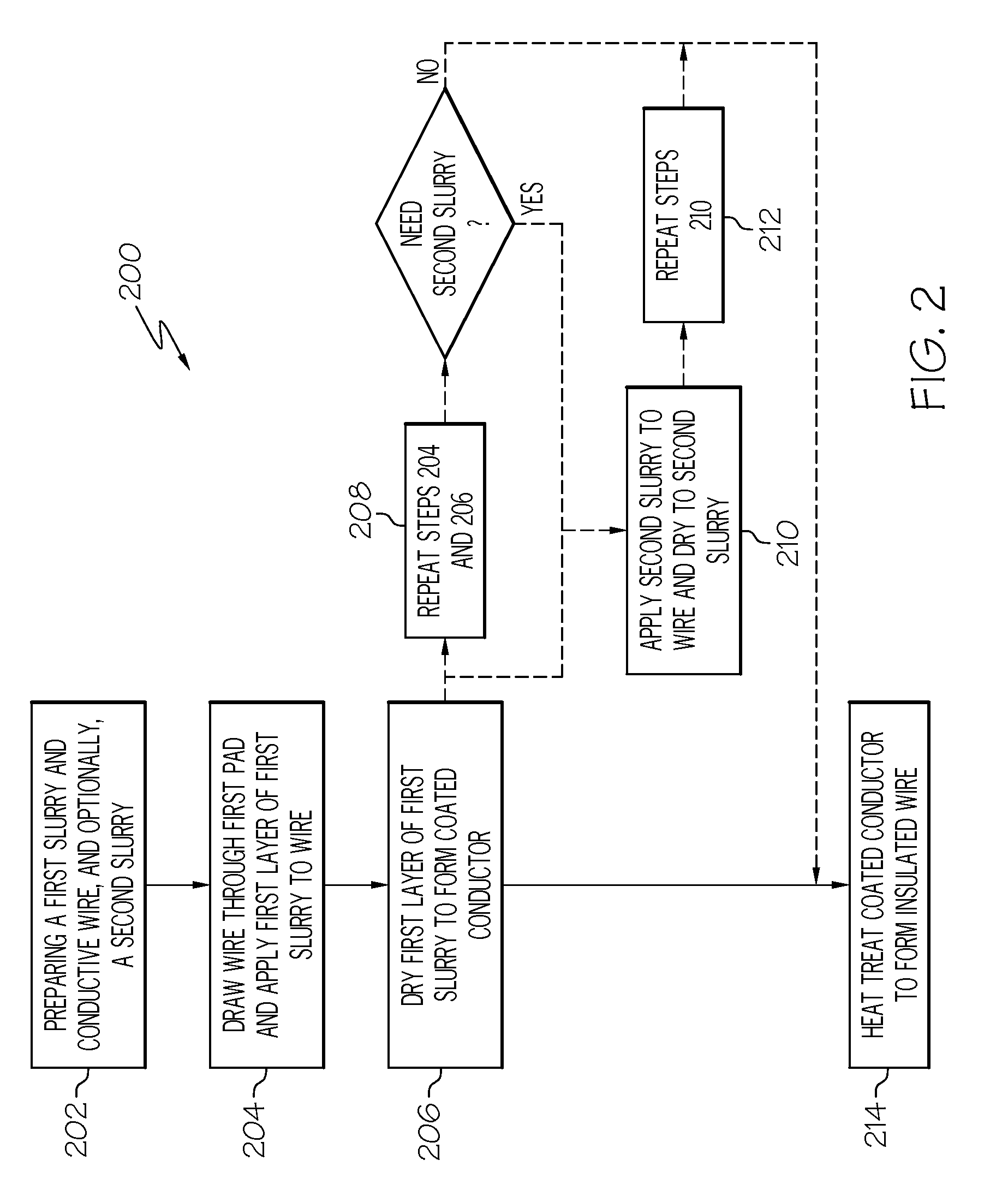

Methods of manufacturing flexible insulated wires

Methods of manufacturing insulated wires are provided. In an embodiment, by way of example only, a method includes drawing a conductive wire through a first pad to apply a layer of a first slurry onto the conductive wire, the first pad comprising a chamois leather material and including the first slurry disposed on the chamois leather material, wherein the first slurry comprises a first dielectric precursor material and a first binder having an organic component and heat treating the conductive wire to form the insulated wire.

Owner:HONEYWELL INT INC

Ecological chamois fabric and manufacturing process thereof

ActiveCN105040247AHigh densityHigh imitation leatherWeft knittingHeating/cooling textile fabricsWater savingYarn

The invention relates to ecological chamois fabric and a manufacturing process thereof, and belongs to the technical field of high-grade textile fabric. The ecological chamois fabric consists of sea-island filaments, low stretch yarns, spandex filaments and monofilament yarns; a surface layer is made of the sea-island filaments, and the sea-island filaments account for 50 percent of weight percentage; a middle layer is made of the monofilament yarns, and the monofilament yarns account for 20 percent of the weight percentage; a bottom layer is formed by interweaving the low stretch yarns and the spandex filaments, wherein the low stretch yarns account for 22 percent of the weight percentage, and the spandex filaments account for 8 percent of the weight percentage. The ecological chamois fabric manufactured through the process disclosed by the invention can be independently and directly used for manufacturing shoe materials and clothing; two layers do not need to be glued by a chemical agent, and the surface layer and the bottom layer of the ecological chamois fabric are not separated forever; moreover, the ecological chamois fabric has the characteristics that any toxic and harmful chemical additives are not used, and four sides are high in elastic, soft and anti-crease; meanwhile, the process is water-saving and environmental friendly; the ecological chamois fabric can directly replace natural chamois, and has very remarkable ecological benefits.

Owner:ZHEJIANG MEISHENG NEW MATERIALS CO LTD

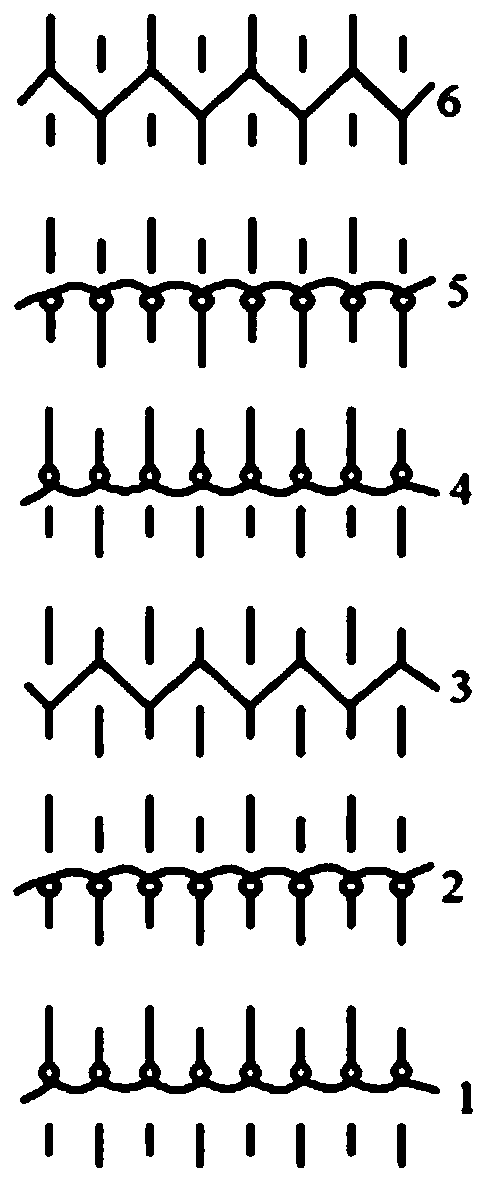

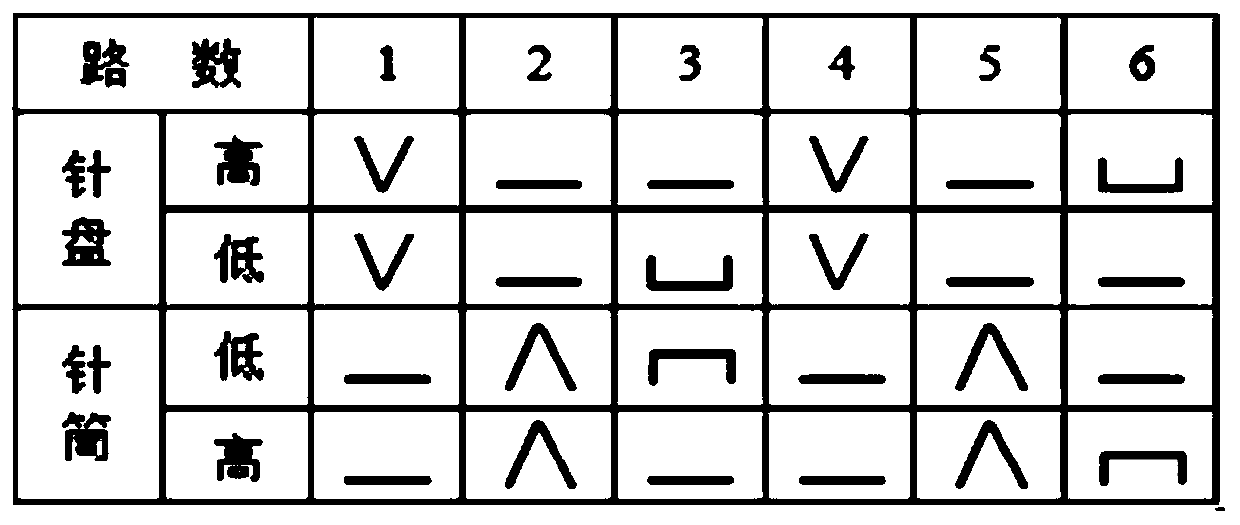

Preparation method of weft-knitted chamois suede super-imitated leather fabric

InactiveCN110924184APromote formationSoft and comfortableFibre treatmentPolymer scienceChamois leather

The invention discloses a preparation method of weft-knitted chamois suede super-imitated leather fabric. Sea-island filament microfibers are used as a raw material and are woven into grey cloth on adouble-sided circular knitting machine, the texture structure of the grey cloth is double-rib texture or air layer texture, and the grey cloth is subjected to post-finishing process treatment to obtain super-imitated leather base cloth; the super-imitated leather base cloth is soaked in polyurethane slurry, excess slurry is rolled out, and then the super-imitated leather base cloth is cured, so that both sides of the super-imitated leather base cloth form polyurethane leather films; and the obtained super-imitated leather base cloth with the polyurethane leather films formed is sequentially subjected to water washing, drying, double-sided grinding, dyeing process, shaping, brushing and finished product shaping to obtain a finished product. The weft-knitted chamois suede super-imitated leather fabric is soft in hand feeling, excellent in resilience and deformation resistance, rich in color and good in anti-pilling performance, and the practical application value in the fields of clothing and the like is improved.

Owner:JIANGSU JUJIE MICROFIBERS TEXTILE GRP

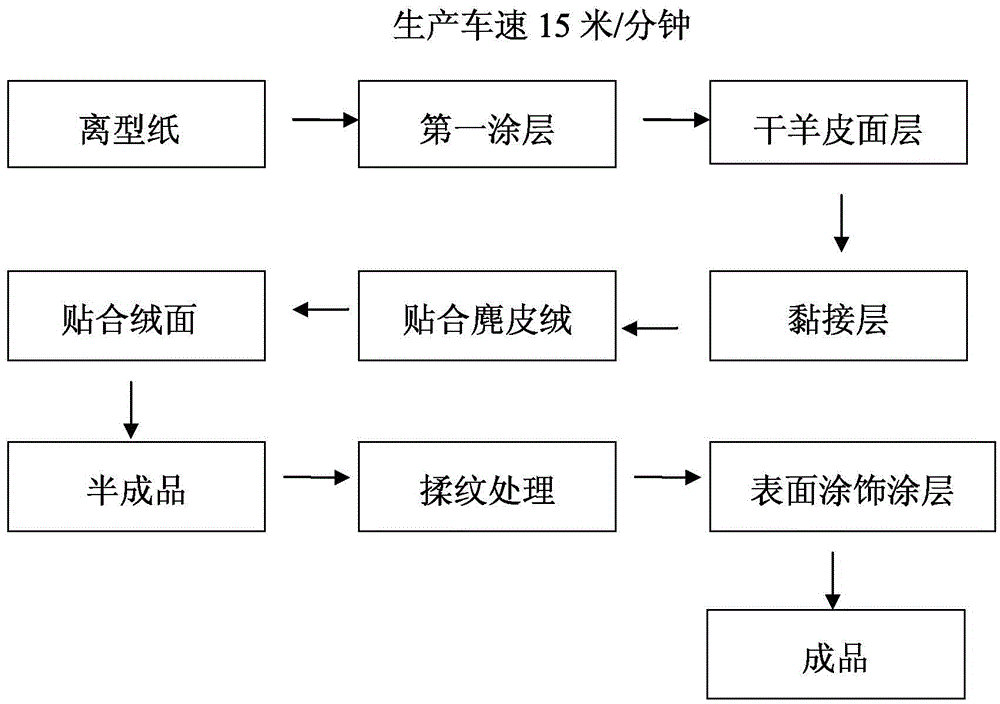

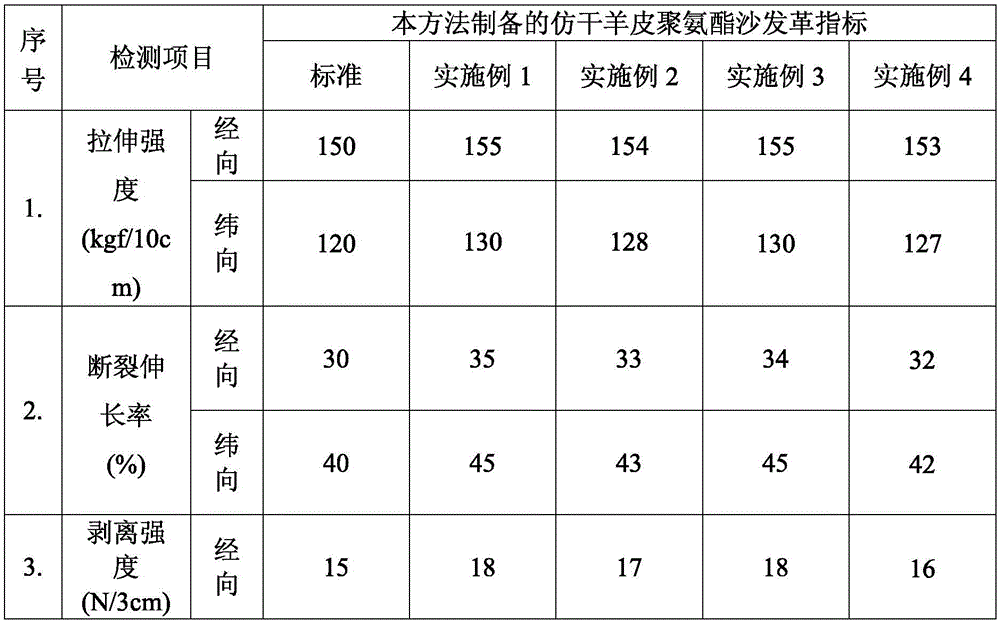

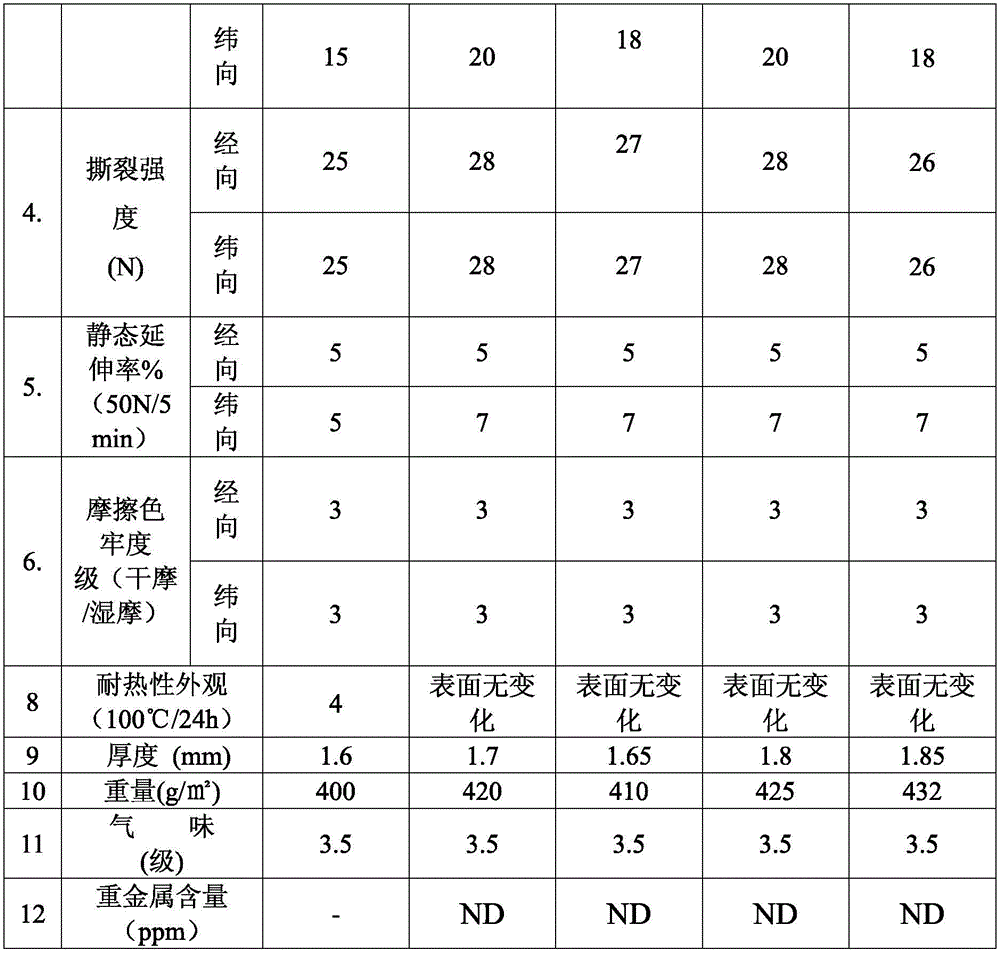

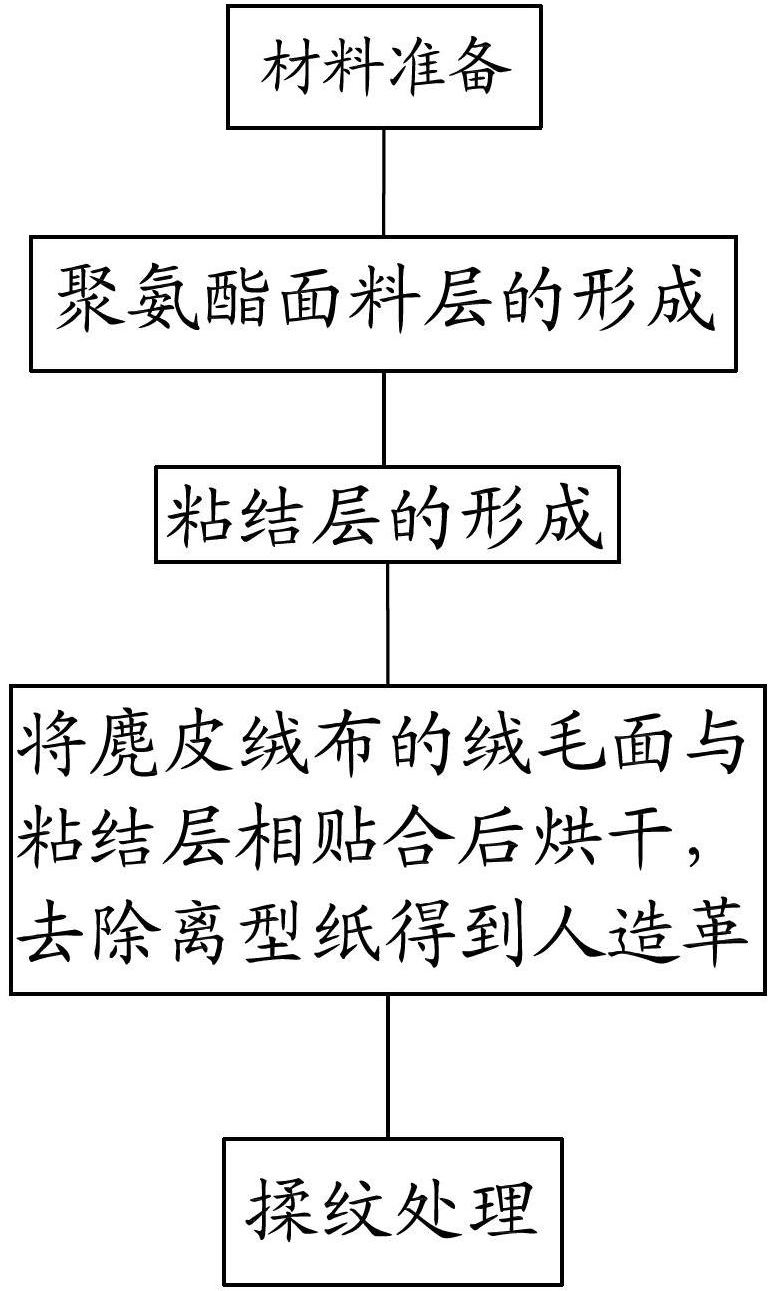

Preparation method of dry-sheepskin-imitated polyurethane sofa leather

The invention provides a preparation method of dry-sheepskin-imitated polyurethane sofa leather. The preparation method comprises the following steps: preparing a dry sheepskin surface layer with double-colored patterns through a dry method; scraping and coating a bonding layer on the surface layer, and fitting chamois leather fluff on the bonding agent; after carrying out gradient drying and curing, wetly bonding single-faced fluff and cotton-imitated fluff to prepare a semi-finished product; carrying out rear-phase treatment; and after rubbing lines and carrying out surface finishing on a coating, carrying out the gradient drying to obtain a finished product. According to the polyurethane sofa leather manufactured by using the method for manufacturing the dry-sheepskin-imitated polyurethane sofa leather, the touch feeling and the visual effect are similar with those of real sheepskin, the post-processing of the polyurethane sofa leather is easy and physical performances meet international leather utilization requirements.

Owner:马鞍山瑞高科技有限公司

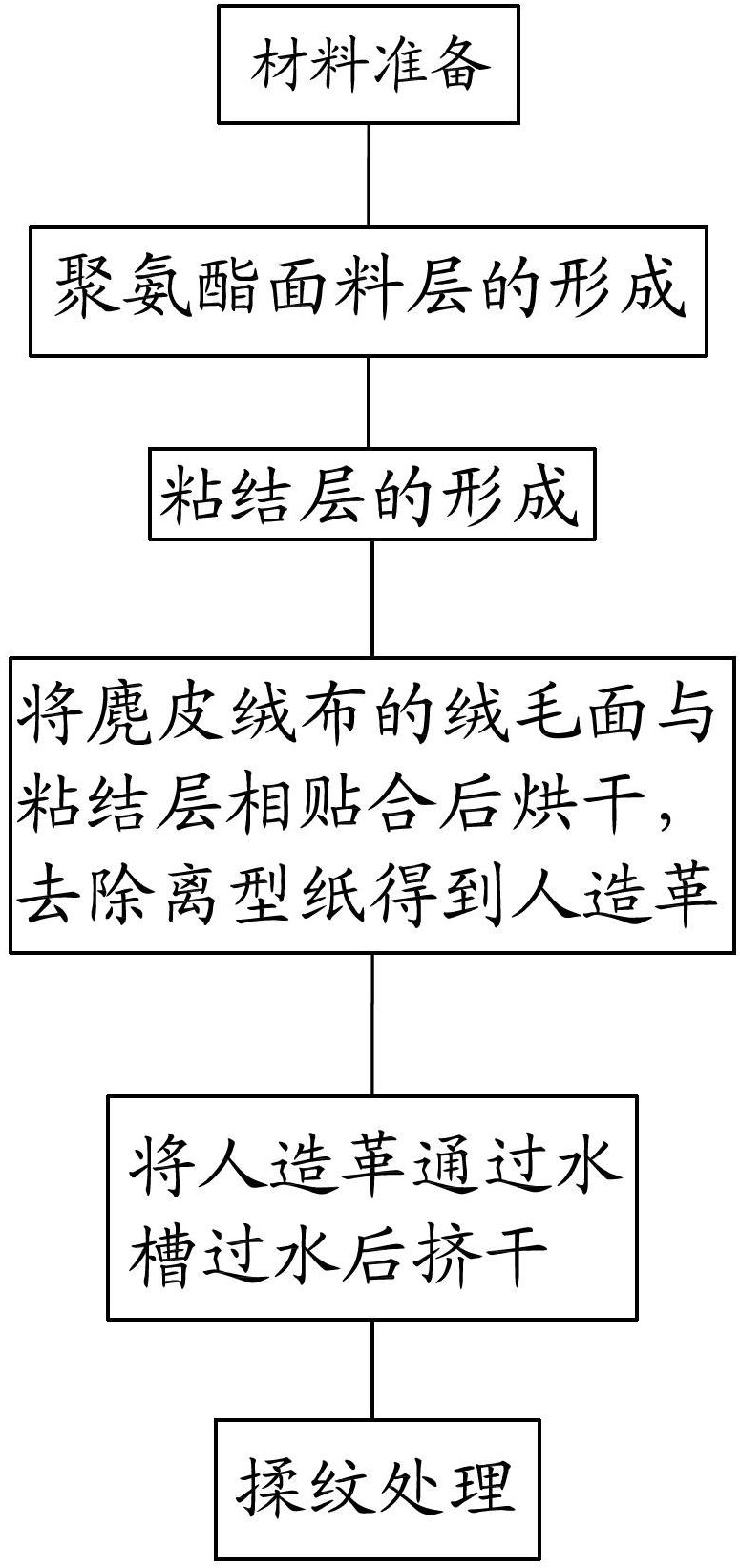

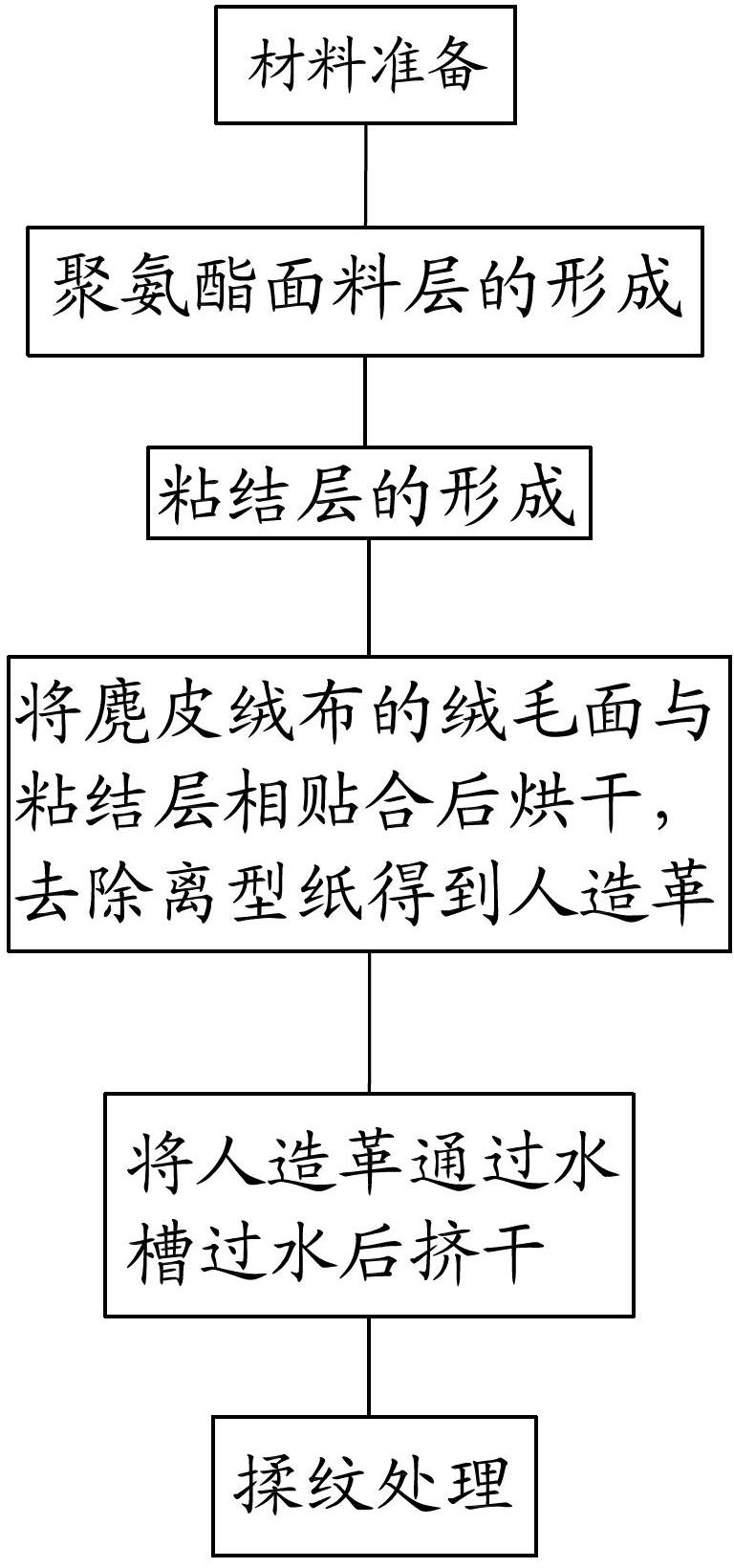

Production method of zero-dermatoglyph imitation leather composite sofa fabric

InactiveCN105965992AComfortable textureImprove breathabilityLamination ancillary operationsLaminationHot stampingPolyester

The invention discloses a method for making a composite sofa fabric imitating cowhide with zero-point leather pattern. The composite sofa fabric imitating cowhide with zero-point leather pattern is composed of a suede surface layer, a linen middle layer and a single-face fleece bottom layer. The manufacturing method is as follows: first The surface layer of suede is dyed, printed and bronzed. The dyeing temperature is 180-190°C, and then compounded with the middle layer of linen. The adhesive for compounding includes polyester polyol, butanol, bridge release agent and accelerator , the component ratio is 10:3.5:1.2:0.5, the compounding temperature is 220-230°C, after compounding, let it stand for 24 hours, then wash and dry; finally compound with the bottom layer of single-sided fleece, compound adhesive II Including polyester polyol and ethanol, the composition ratio is 10:3.5, and the compounding temperature is 220-230°C. The invention has the texture and texture of real leather, the texture of the fabric is comfortable, warm in winter and cool in summer, has good air permeability and is easy to take care of.

Owner:浙江百佳虹科技股份有限公司

Micro suede artificial leather and manufacturing method thereof

ActiveCN102677481AGood touchImprove the simulation effectLamination ancillary operationsSynthetic resin layered productsChamois leatherEngineering

The invention provides a micro suede artificial leather. The micro suede artificial leather is composed of a polyurethane fabric layer, a bonding layer and a chamois leather flannelette layer, the bonding layer is located between the polyurethane fabric layer and the chamois leather flannelette layer, a fuzzing of the chamois leather flannelette layer is bonded to the bonding layer, uneven grains are arranged on the surface of the polyurethane fabric layer, fissured grains are arranged at positions of dimpled grains of the polyurethane fabric layer and on the bonding layer which the dimpled grains correspond to, and fluffs of the chamois leather flannelette layer are exposed out of the fissured grains. According to the micro suede artificial leather, the micro suede artificial leather is close to genuine leather, feels good, is good in breathability and scratch resistance, the micro suede artificial leather feels highly fluffy, and the fluffs are not prone to fall off when scratched. Besides, a manufacturing method of the micro suede artificial leather is further provided.

Owner:FUJIAN POLYTECH TECH CO LTD

Method for producing chamois leather using epoxidized oil

The invention belongs to leather process technology, in particular a method for producing chamois leather using epoxidized oil, comprising the following steps: putting the pretanned pelt or fur into the normal temperature controlled rotary drum, adding alkaline solution to adjust pH value into alkaline, draining the alkaline solution, and adding catalyst or accelerant and epoxidized oil into the rotary drum, keeping the temperature at a certain temperature for several times, after reacting, recycling the remaining oil, then washing using degreasant and / or alkali, then adjusting pH value, aluminum tanning, aldehyde tanning or other tanning, and then drying, dampening and milling, finally gaining the chamois leather. The invention enables epoxidized oil to directly react with collagen and fix oil on the hide fiber, so that the shortcoming that traditional oil tanning takes oil as raw material, instead of reactant is overcome, and oil oxidizing process of traditional chamois leather is omitted. The chamois leather produced by the method has advantages of high intensity, good flexibility, strong hygroscopicity and water-wash resistance, applicable for the leather for cleaning, filtering and washing clothes.

Owner:SICHUAN UNIV

Super-soft, stereoscopic and heat-preservation suedette knitted fabric and preparation method thereof

InactiveCN108547041AStrong three-dimensional senseHigh glossWeft knittingHeating/cooling textile fabricsChamois leatherShrinkage rate

The invention discloses super-soft, stereoscopic and heat-preservation suedette knitted fabric and a preparation method thereof and relates to knitted fabric. The method comprises the steps that A, composite filaments different in shrinkage rate and spandex filaments different in shrinkage rate are selected and woven into blank with a middle air layer structure through weaving equipment; B, the fabric blank cloth is subjected to open-width washing and then pre-shaped; C, the fabric blank cloth is dyed through a disperse dyeing agent; D, the fabric blank cloth is dewatered; E, the fabric blankcloth is slit; F, the fabric blank cloth is dried; G, the fabric blank cloth is napped; H, the fabric blank cloth is lustered; I, the fabric is subjected to open-width reshaping. The fabric has the advantages that through special napping and lustering treatment, the fabric has excellent touch feeling and luster, the surface of the fabric is similar to real chamois leather, and by adopting the airlayer structure, the fabric has a good heat preservation effect.

Owner:NINGBO DAQIAN TEXTILE

Manufacturing method for microfiber suedette for top-grade automobile interior trim

InactiveCN106012579AImprove sun resistanceAvoid emissionsSucessive textile treatmentsVehicle componentsWater basedThree level

The invention discloses a manufacturing method for microfiber suedette for top-grade automobile interior trim. The method includes the steps of material selection, fuzzing, processing before dyeing, dyeing, sanding and dipping in insolation-resistant auxiliaries, so that a finished product is obtained. Due to the fact that water-based PU resin which is high in insolation and extremely good in environmental protection is adopted, the insolation-resistant effect of the resin is improved, no organic solvent is contained, the microfiber suedette can be prevented from emitting poisonous gas, and the process is simple, concise, easy to operate and environmentally friendly and saves more energy. Through dipping of the insolation-resistant auxiliaries in the later period, the fiber insolation-resistant fastness is improved by three levels or more, the fiber insolation-resistant fastness of the finished microfiber suedette reaches the fifth level to the sixth level, and the requirement for automobile interior trim is met. Through continuous grinding of base cloth and a semi-finished product, the cloth cover is more fine and smooth, the writing effect is obvious, and the chamois leather feeling is higher. Large-scale production of the microfiber suedette can be achieved, and the price of the microfiber suedette is 50% lower than that of foreign products. The microfiber suedette for interior trim is low in cost, free of emission of poisonous gas, resistant to insolation, simple in manufacturing process, low in cost and capable of being produced on a large scale.

Owner:昌邑誉华纺织材料有限公司

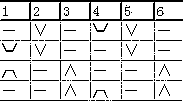

High-density warp-knitted suede imitated non-woven microfiber leather fabric and production method thereof

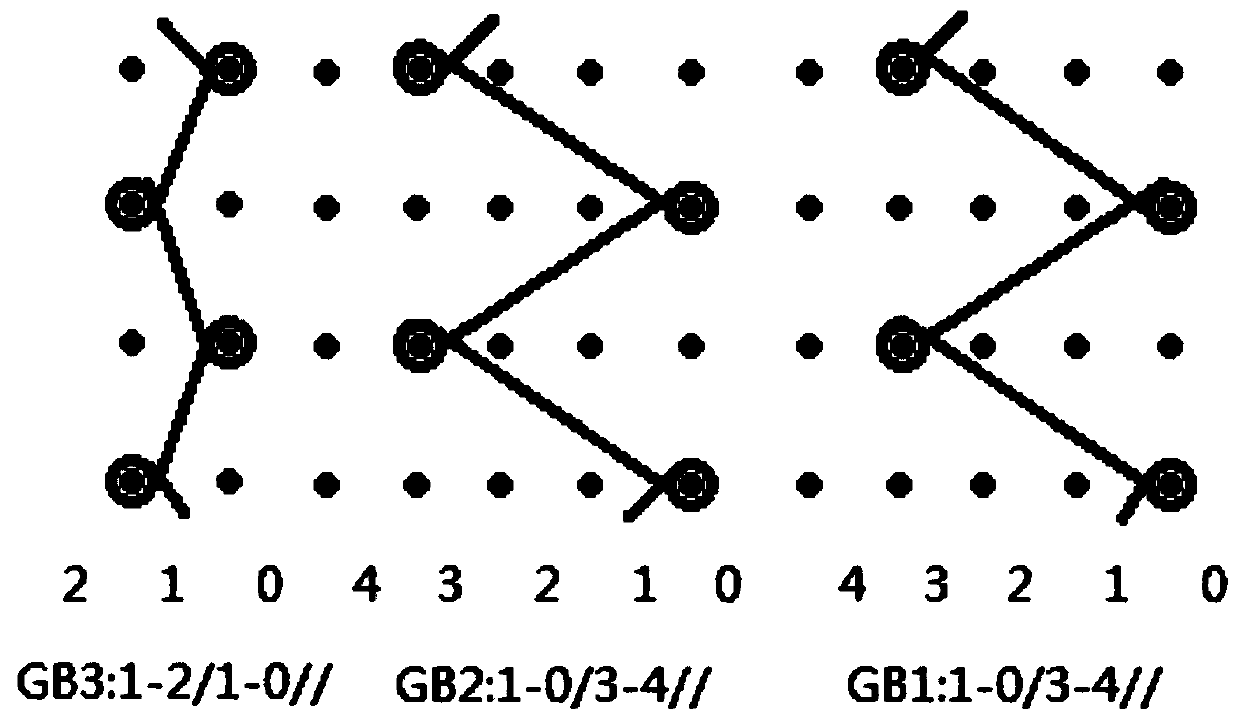

The invention discloses a high-density warp-knitted suede imitated non-woven microfiber leather fabric. The fabric is characterized in that the fabric is formed by carrying out knitting on a warp knitting machine by adopting three guide bars, a first guide bar is formed by knitting 88dtex / 36f or 105D / 36F island composite yarns, the yarn laying code GB1 of the first guide bar is 1-0 / 3-4 / / , a secondguide bar is formed by knitting FDY 30D / 12F polyester high-shrinkage yarns, the yarn laying code GB2 of the second guide bar is 1-0 / 3-4 / / , the third guide bar is formed by knitting FDY 30D / 12F polyester high-shrinkage yarns, the yarn laying code GB3 of the third guide bar is 1-2 / 1-0 / / , the three guide bars are fully threaded, the island composite yarns form the front surface of the fabric, the high-shrinkage yarns form the back surface of the fabric, and the surface of the fabric is provided with short suede formed by brushing and sanding treatment. The invention further discloses a production method of the high-density warp-knitted suede imitated non-woven microfiber leather fabric. The warp-knitted suede imitated non-woven microfiber leather fabric has the characteristics of short densesuede feeling and no elasticity of non-woven microfiber leather, the category of a conventional warp-knitted elastic suede product is enriched, and the application field of warp-knitted suede is widened.

Owner:JIANGSU JUJIE MICROFIBERS TEXTILE GRP

Production process of thick cattlehide-simulating top grade sofa decorative shell fabric

InactiveCN107287917AAvoid environmental issues such as pollutionImprove breathabilitySynthetic resin layered productsWarp knittingSurface layerChamois leather

The invention discloses a production process of a thick cattlehide-simulating top grade sofa decorative shell fabric. The production process comprises the following steps: selecting a warp knitted chamois leather-simulated shell fabric as base cloth of a surface layer, performing galling, dyeing, sanding and printing, and compounding the base cloth with PU resin to prepare a surface layer; selecting warp knitted like lint and performing processes such as dyeing, galling and sizing as an intermediate layer; and selecting galled cloth by a looped pile by a circular knitting machine and performing processes such as dyeing, sizing and galling as a bottom layer. According to the production process of the thick cattlehide-simulating top grade sofa decorative shell fabric disclosed by the invention, the produced shell fabric is good in ventilating property, similar to genuine leather in hand feel and texture, and meets the demand of cattlehide in thickness. The production process avoids environmental pollution in a genuine leather production process.

Owner:TONGXIANG LONGXIANG TEXTILE

Suede Like Artificial Leather with Excellent Strength and Elongation Properties

InactiveUS20080293316A1Easy to installShape stableDomestic upholsterySynthetic fibresFiberConstant load

The present invention relates to a suede-like artificial leather with excellent strength and elongation properties. The suede-like artificial leather comprises a composite sheet having polyurethane filled therein, the composite sheet comprising: a non-woven fabric of ultrafine short fibers entangled with each other and having a thickness less than 0.3 denier; and a woven or knitted fabric placed in the non-woven fabric, entangled with the ultrafine short fibers of the non-woven fabric, and having an constant load elongation of 10 to 30% at a load of 8 kgf, wherein the tensile strength in longitudinal and lateral directions is 35 to 60 kgf / 50 iτini and the constant load elongation in longitudinal and lateral directions is 8 to 25%. The suede-like artificial leather is useful as materials for vehicles and furniture requiring durability because of its excellent tensile strength and constant load elongation.

Owner:KOLON IND INC

Production method of imitated cattlehide high-grade decorative fabric

InactiveCN107244118AImprove breathabilityLamination ancillary operationsPattern makingSurface layerChamois leather

The invention discloses a production method of imitated cattlehide high-grade decorative fabric. According to the production method, weft-knitted woven chamois leather is taken as a surface layer base cloth, and a surface layer fabric is obtained via alkali treatment, sanding, dyeing, carding, fixing, printing, and gold stamping; looped pile large diameter circular knitting machine terry fabric is selected, and is subjected to dyeing, napping, and embossing so as to obtain a base layer fabric; combination of one side of the surface layer fabric without gold stamping with one side of the base layer fabric processed via napping is carried out; and water washing and drying are carried out so as to obtain the imitated cattlehide high-grade decorative fabric. The production method of the imitated cattlehide high-grade decorative fabric is capable of stimulating the patterns of natural leather; the weft-knitted woven chamois leather is subjected to gold stamping and combination with PU resin, and combination with one side brush processed via embossing, so that an obtained finished product possesses the patterns, the handfeel, and the texture of natural leather, and excellent permeability is achieved.

Owner:TONGXIANG LONGXIANG TEXTILE

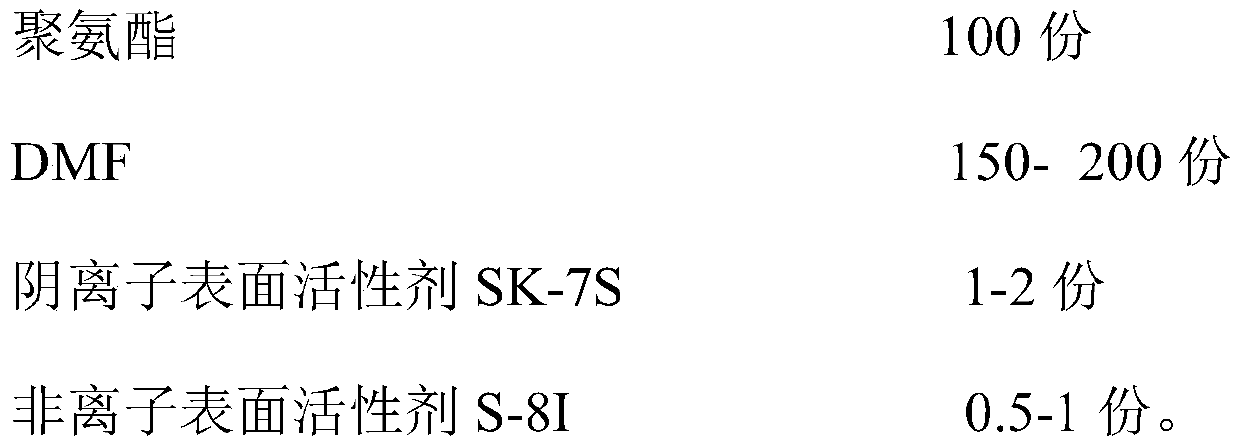

Method for preparing polyurethane coating agent for artificial chamois leather

InactiveCN102417573AImprove water repellencyIncrease elasticityFibre treatmentPolyesterChamois leather

The invention discloses a method for preparing a polyurethane (PU) coating agent for artificial chamois leather. The method comprises the following steps of: mixing dehydrated castor oil polyester polyol, dimethyl formamide (DMF), a chain extender 1,4-butanediol and a T12 catalyst, maintaining the temperature of an obtained solution to be 50 DEG C, adding molten and metered methylene diphenyl diisocyanate (MDI), raising the temperature to 85 DEG C step by step, keeping the temperature and reacting for 3 hours, and adding a terminator, namely methanol to terminate the reaction to obtain a solvent type PU solution. Therefore, the polyurethane coating agent prepared by the method is suitable for coating the artificial chamois leather and has the advantages of high thermal stability and plumphandfeel, coating micropores are uniform, and the artificial chamois leather can be emerized easily; meanwhile, the coated artificial chamois leather has high air permeability and moisture permeability, and excellent appearance and handfeel.

Owner:SUZHOU FANGYOU NEW MATERIAL

Suede fabric pasting technology

ActiveCN102433766AFeel goodImprove breathabilitySynthetic resin layered productsTextiles and paperChamois leatherEngineering

The invention relates to a suede fabric pasting technology, and belongs to the technical field of a suede fabric production technology. The suede fabric pasting technology comprises the following steps of 1, coating a first poly urethane (PU) layer on a release paper, 2, enabling the release paper with the first PU layer to pass orderly through baking ovens respectively having preset temperaturesof 110+ / -5 DEG C, 115+ / -5 DEG C and 120+ / -5 DEG C for drying, 3, coating a second PU layer on the first PU layer, 4, enabling the release paper with the first PU layer and the second PU layer to passorderly through baking ovens respectively having preset temperatures of 80+ / -5 DEG C and 80+ / -5 DEG C for drying, 5, pasting a suede fabric base cloth on the second PU layer, 6, enabling the release paper with the first PU layer, the second PU layer and the suede fabric base cloth to pass orderly through baking ovens respectively having preset temperatures of 135+ / -5 DEG C, 135+ / -5 DEG C, 140+ / -5DEG C, 140+ / -5 DEG C and 135+ / -5 DEG C for drying, and 7, peeling the release paper to obtain a finished product. A suede fabric product prepared by the suede fabric pasting technology has the advantages of good handle, good permeability, good wear resistance and good cold resistance.

Owner:ZHEJIANG MEISHENG NEW MATERIALS CO LTD

Production technology for environment-friendly imitated calf skin leather

InactiveCN109177390AReduce pollutionSucessive textile treatmentsLamination ancillary operationsEnvironmental resistanceChamois leather

The invention discloses a production technology for environment-friendly imitated calf skin leather. The production technology comprises the following steps: S1) preparing an environment-friendly chamois fabric as a surface layer; S2) preparing a warp knitted flannelette as a bottom layer; S3) compounding: adopting a factice compounding process for compounding the surface layer with the bottom layer; S4) washing: washing the compound fabric acquired in the step S3) with water and drying. According to the production technology for environment-friendly imitated calf skin leather disclosed by theinvention, superfine raw material dacron is used, so that the hand feeling of natural chamois can be acquired without alkali decrement treatment for the fabric in the whole dyeing process and the pollution caused by emission of decrement sewage can be reduced; the clean environment-friendly production of textile fabric can be achieved in the whole production process; through the specific production technology, the environment-friendly super-soft imitated leather fabric can be produced.

Owner:TONGXIANG LONGXIANG TEXTILE

Process for the production of a microfibrous chamois woven-non-woven fabric containing an elastomeric nanocomposite matrix

A composite material is described, comprising: (a) microfibers selected from synthetic microfibers; (b) elastomer / lamellar clay nanocomposite matrix; said lamellar clay being selected from organophilic lamellar clays and functionalized organophilic lamellar clays. Dyed chamois woven-non-woven fabrics are also described, obtained starting from said composite material.

Owner:ALCANTARA

High-imitation leather sofa lining

The invention relates to the technical field of textile fabric, in particular to a sofa lining. The high-imitation leather sofa lining comprises a basic layer lining, a surface layer lining and a bottom layer lining, wherein the basic layer lining is one of chamois cloth, warp knitting cloth or woven fabric, the surface layer lining is one of PU or PVC, the bottom layer lining is nylon cloth, and a silica gel layer is compounded between the basic layer lining and the bottom layer lining; leather powders are adsorbed and bonded on the surface of the surface layer lining. According to the high-imitation leather sofa lining, the leather powders are bonded on the surface of the surface layer lining, thus the formed surface is very similar to the leather, the silica gel layer is compounded between the basic layer lining and the bottom layer lining, thus the intensity of the lining is high, and the tear resistance of the lining is good; the lining is soft in hand feel, dampproof and waterproof, low in cost, and capable of completely replacing leather products and becoming the high-imitation leather sofa lining.

Owner:张忠华

Production technology of three-laminated crinkled high-grade decoration fabric

InactiveCN107364210ASoft touchShort processTransfer printingLamination ancillary operationsSurface layerChamois leather

The invention discloses a production technology of a three-laminated crinkled high-grade decoration fabric. A weft woven suede-like fabric is selected as the base cloth of a surface layer, and is subjected to alkali treatment, dyeing, sanding and printing, and the obtained cloth is compounded with PU resin to produce the surface layer; a large-diameter weft knitting machine is selected as a middle layer; a large-diameter weft knitting machine terry fabric is dye, set and napped to form a bottom layer. The production technology of three-laminated crinkled high-grade decoration fabric can reduce the process flow for producing a high-grade artificial leather fabric, and the artificial leather fabric produced through the technology obtained through compounding three layers, so the fabric is thick, has soft hand feeling, is close to leather in hand feeling, has a natural pattern, and can replace the leather as a high-end sofa fabric.

Owner:TONGXIANG LONGXIANG TEXTILE

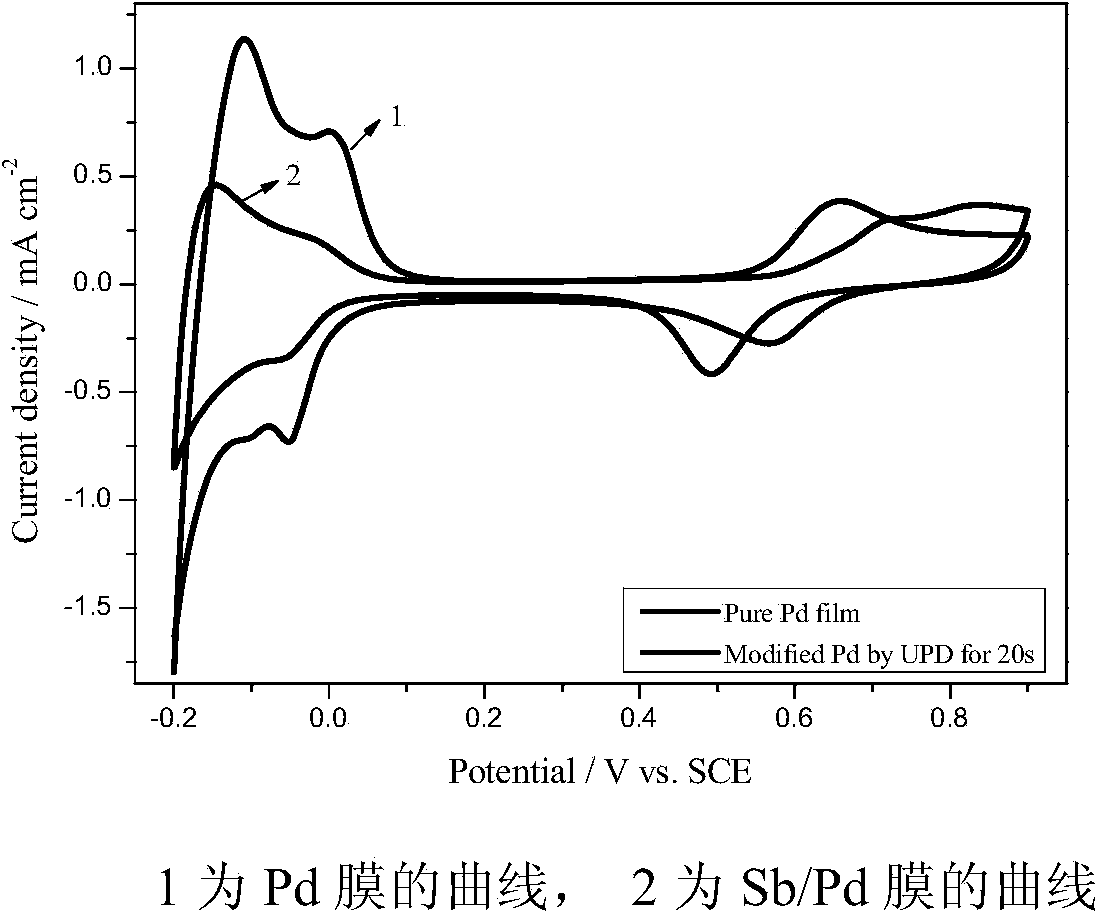

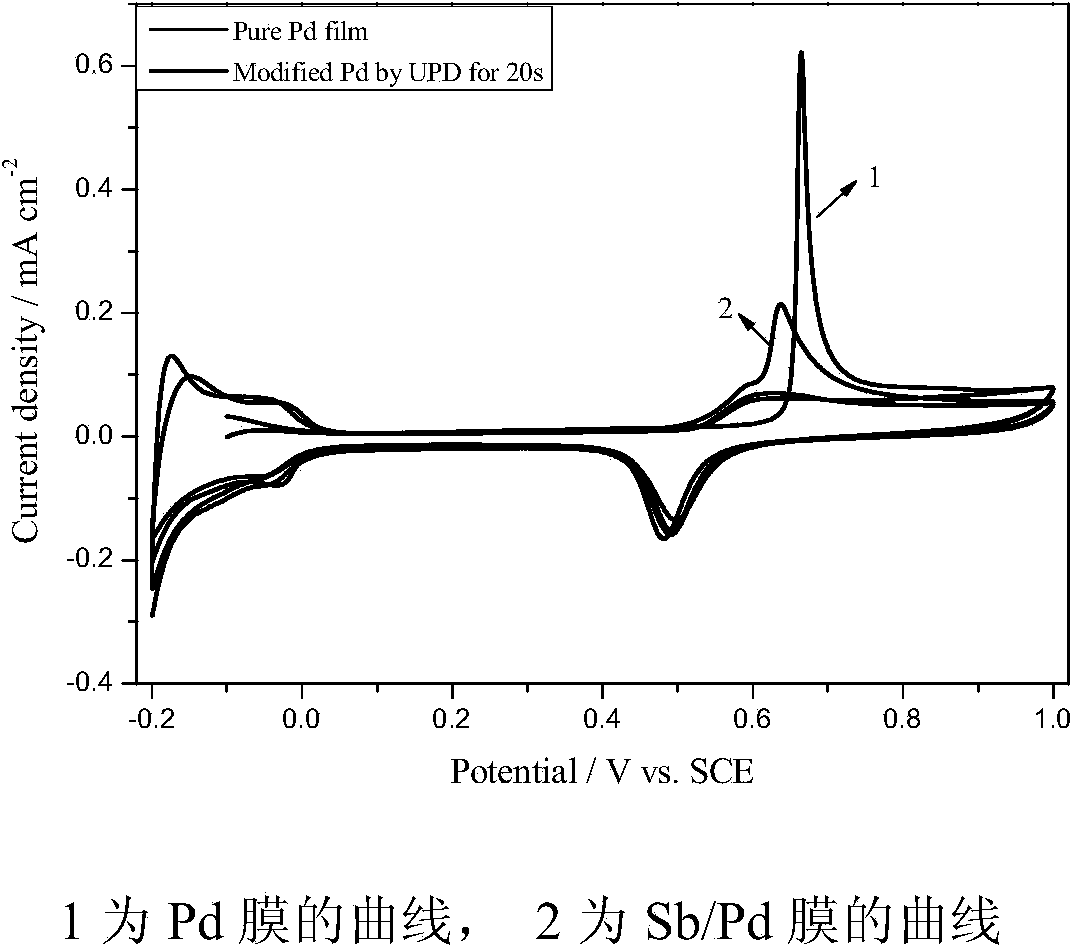

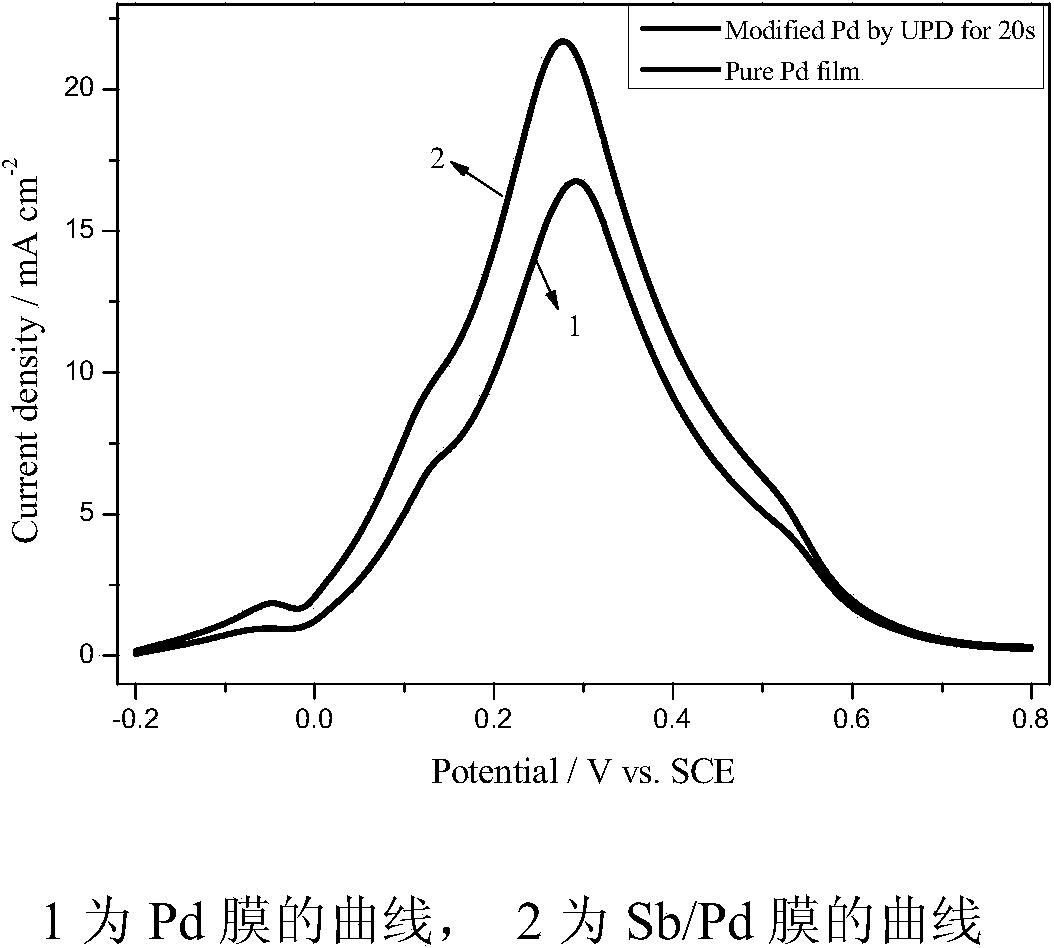

Modification method of Pd membrane electrode based on formic acid electrooxidation

InactiveCN104022290AImprove adsorption capacityImprove catalytic performanceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsChamois leatherAntimony potassium tartrate

The invention relates to a modification method of a Pd membrane electrode based on formic acid electrooxidation. The modification method comprises the steps of carrying out underpotential deposition on the surface of Pd by utilizing Sb, depositing a single layer of Sb on the surface of a Pd substrate so as to improve a Pd surface structure, polishing a glassy carbon electrode on a piece of chamois leather to form a mirror surface, then carrying out electrochemical cleaning in 0.1M of HClO4 by adopting a cyclic voltammetry, depositing the Pd in a Pd plating solution, then carrying out controlled potential electrodeposition (0.2-0.3Vvs.SEC) in 0.1mM of antimony potassium tartrate (APT)+0.5M of H2SO4 for 10-30s, and depositing the single layer of Sb on the surface of the Pd substrate. Compared with the prior art, with the adoption of the modification method, the single layer of Sb is deposited on the surface of the Pd substrate by virtue of a simple UPD (Under Potential Deposition) technology, and the Pd electrode modified by the Sb has the relatively good catalytic effect on formic acid.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

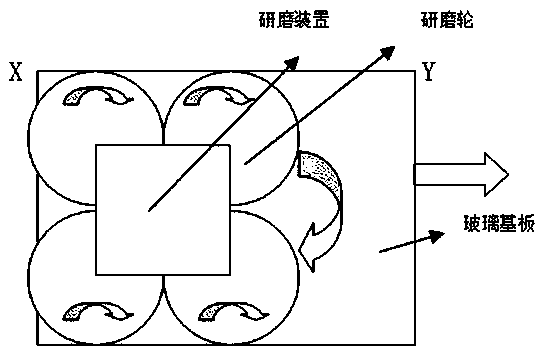

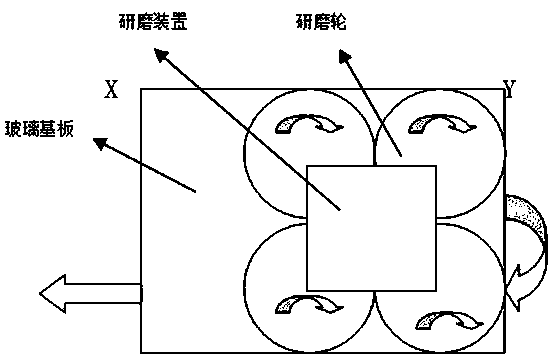

Grinding and polishing method for TFT-LCD glass base plate

InactiveCN109909869AImprove grinding precisionImprove grinding efficiencyLapping machinesLapping toolsTime rangeChamois leather

The invention relates to a grinding and polishing method for a TFT-LCD glass base plate. The grinding and polishing method includes the existing steps of rough grinding and fine grinding. The grindingand polishing method is characterized by comprising the following steps that a grinding machine is used for rough grinding in the first stage, the grinding amount is 15 microns to 20 microns, and theroughness degree is controlled to be within 0.15 micron; secondly, the grinding machine is adopted for fine grinding in the second stage, the grinding amount is 5 microns to 10 microns, and the roughness degree is controlled to be within 0.1 micron; and thirdly, the grinding machine is adopted for grinding and polishing in the third stage, a grinding disc and a grinding disc bearing are made of iron materials, the material of a grinding pad is in a chamois leather simulating type, the frequency of an upper plate can be 50 hertz to 60 hertz, the frequency of a lower plate can be 20 hertz to 30hertz, the grinding time ranges from 5 min to 10 min, the grinding amount is 5 microns to 10 microns, and the roughness degree is controlled to be within 0.01 micron. The grinding and polishing method has the beneficial effects that firstly, the rotating speed can be adjusted more reasonably according to technological requirements, and the grinding precision and the grinding efficiency are improved; secondly, a polishing machine is little affected by the temperature, a rotary disc works stably, and the grinding precision is greatly improved; and thirdly, under grinding is reduced, and the product quality is improved.

Owner:BENGBU CHINA OPTOELECTRONIC TECH CO LTD

Method for producing chamois leather using epoxidized oil

The invention belongs to leather process technology, in particular a method for producing chamois leather using epoxidized oil, comprising the following steps: putting the pretanned pelt or fur into the normal temperature controlled rotary drum, adding alkaline solution to adjust pH value into alkaline, draining the alkaline solution, and adding catalyst or accelerant and epoxidized oil into the rotary drum, keeping the temperature at a certain temperature for several times, after reacting, recycling the remaining oil, then washing using degreasant and / or alkali, then adjusting pH value, aluminum tanning, aldehyde tanning or other tanning, and then drying, dampening and milling, finally gaining the chamois leather. The invention enables epoxidized oil to directly react with collagen and fix oil on the hide fiber, so that the shortcoming that traditional oil tanning takes oil as raw material, instead of reactant is overcome, and oil oxidizing process of traditional chamois leather is omitted. The chamois leather produced by the method has advantages of high intensity, good flexibility, strong hygroscopicity and water-wash resistance, applicable for the leather for cleaning, filtering and washing clothes.

Owner:SICHUAN UNIV

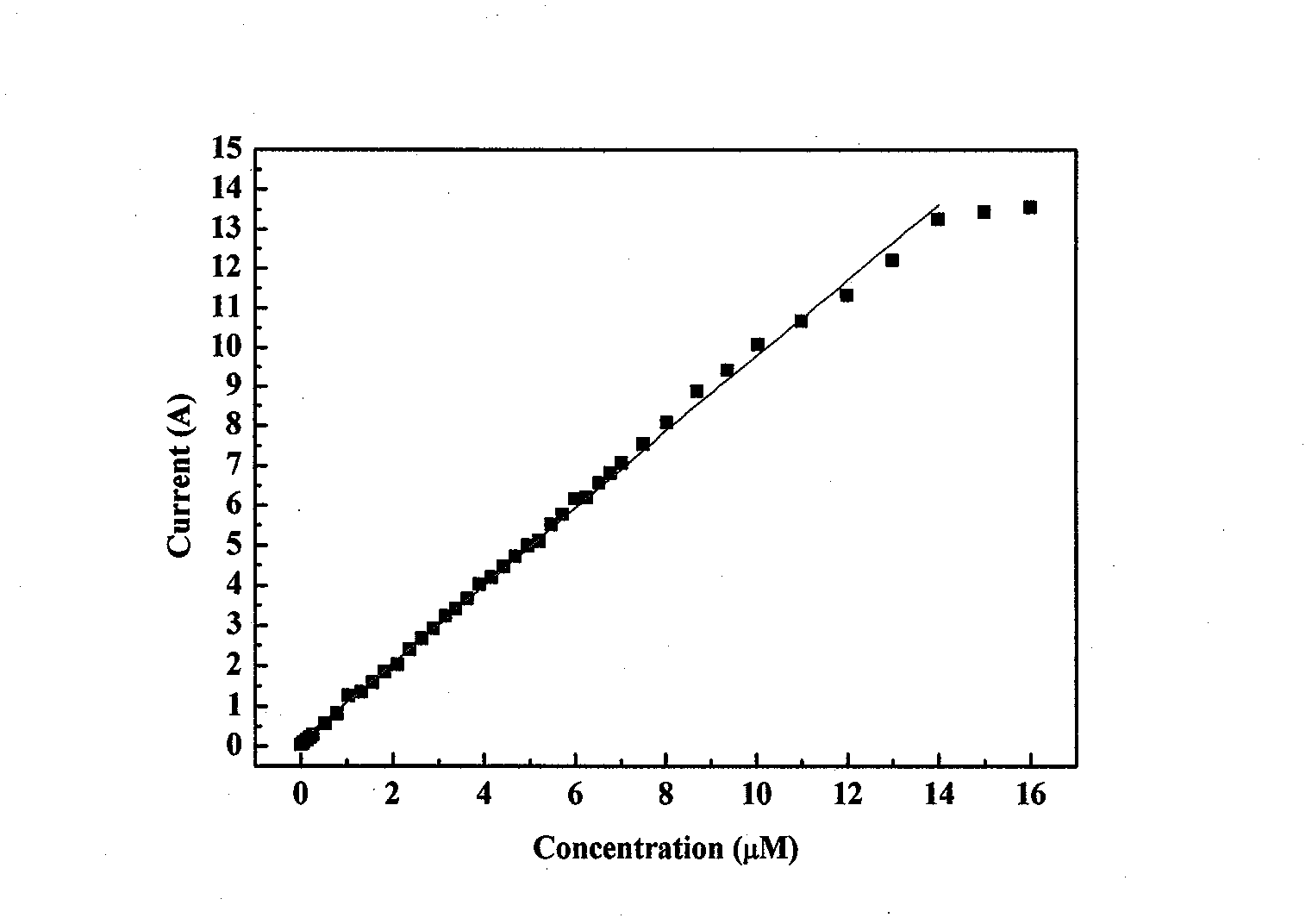

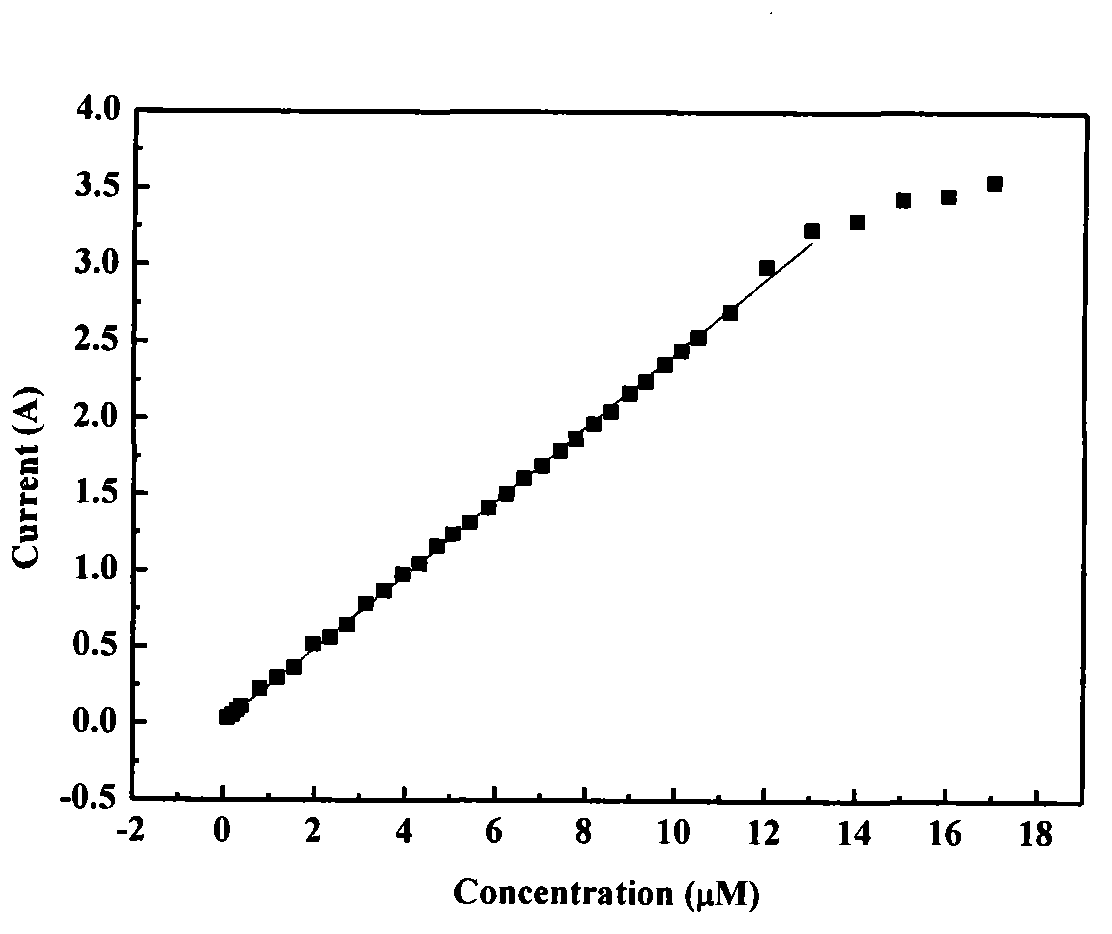

Disk type laccase sensor electrode and preparation method thereof

InactiveCN103323511AGood electrocatalytic oxidation activityImprove responsivenessMaterial analysis by electric/magnetic meansResponse sensitivityChamois leather

The invention relates to a disk type laccase sensor electrode and a preparation method thereof, which is characterized in that the electrode is composed of a stainless steel disk electrode sputtered with gold film and a chitosan-metal nanoparticle sensitive membrane loading laccase, and the thickness of the sensitive membrane is 5-10mum. The preparation process of the electrode comprises the following steps of: preparing a chitosan-metal nanoparticle sol by an in-situ reduction method, and placing the sol into a laccase solution for immobilizing the laccase; polishing a 360L stainless steel disk electrode sputtered with the gold film on chamois leather, after repeatedly flushing with secondary distilled water, treating with an ultrasonic wave and drying, activating 20 loops by electrochemical cyclic voltammetry sweep in a PBS solution with pH being 5.0, then placing the stainless steel disk electrode into a solution containing p-benzoquinone and chitosan-metal nanoparticles loading laccase, and preparing the chitosan-metal nanoparticle sensitive membrane on a surface of the stainless steel electrode by a benzoquinone electrochemical reduction, induction and deposition method, to obtain the laccase sensor electrode. The electrode has good electric catalytic oxidation activity on phenols, and the established disk type laccase sensor can be used for detecting different phenols in an environment, and has advantages of high response sensitivity, wide linearity range and low detection limit.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com