Preparation method of weft-knitted chamois suede super-imitated leather fabric

A suede and super imitation leather technology, applied in the field of super imitation leather fabric manufacturing, can solve the problems of insufficient appearance color, elasticity, deformation resistance, poor dyeing uniformity of non-woven microfiber leather, easy shedding of fibers, etc. Good appearance and feel, excellent appearance, the effect of reducing the linear density of monofilament

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0033] A kind of preparation method of weft-knitted suede super imitation leather fabric of one embodiment of the present invention, comprises the following steps:

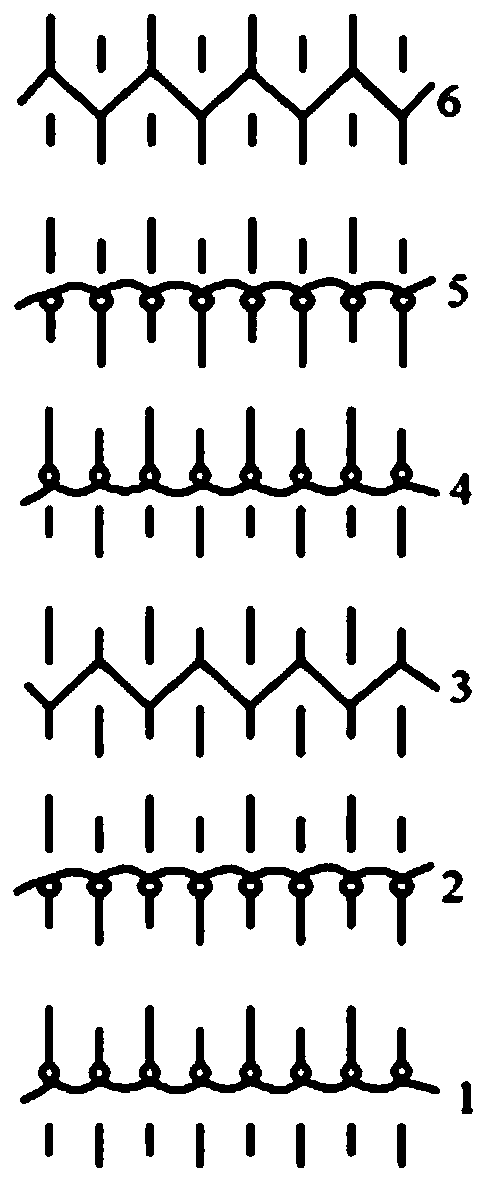

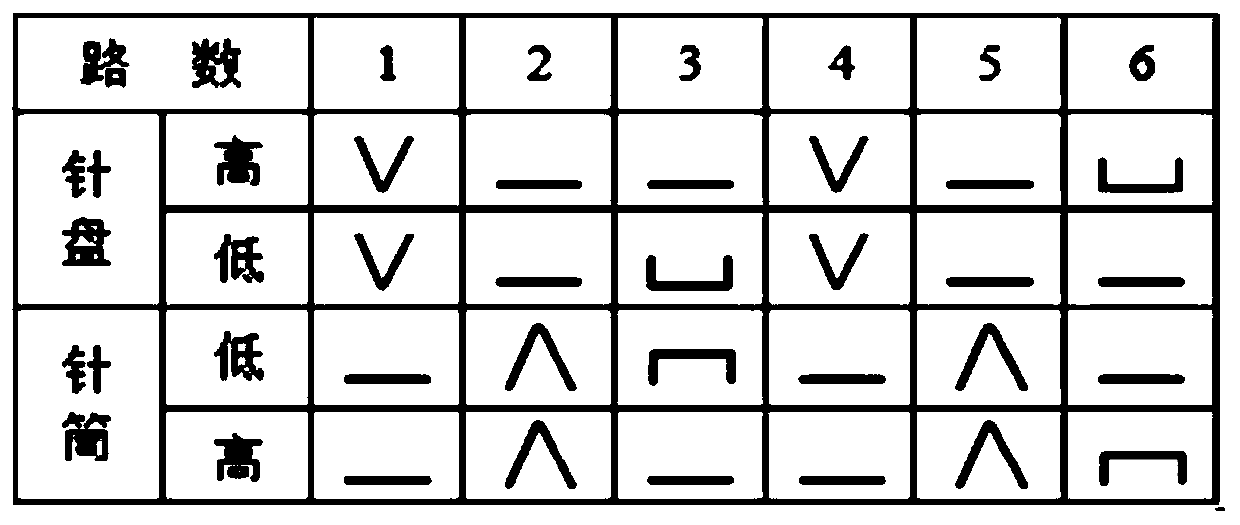

[0034] Step 1, preparation of base fabric: use 105D / 36F sea-island composite yarn as raw material, use air layer tissue to weave on a double-sided circular knitting machine with 28 needles, 32 needles, 36 needles or 40 needles to obtain gray cloth; specifically, the gray cloth The weaving diagram of the organizational structure is as follows figure 1 As shown, the triangular arrangement diagram of the upper machine is as follows figure 2 As shown, the air layer is knitted by the 6-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com