Patents

Literature

95results about How to "Full texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

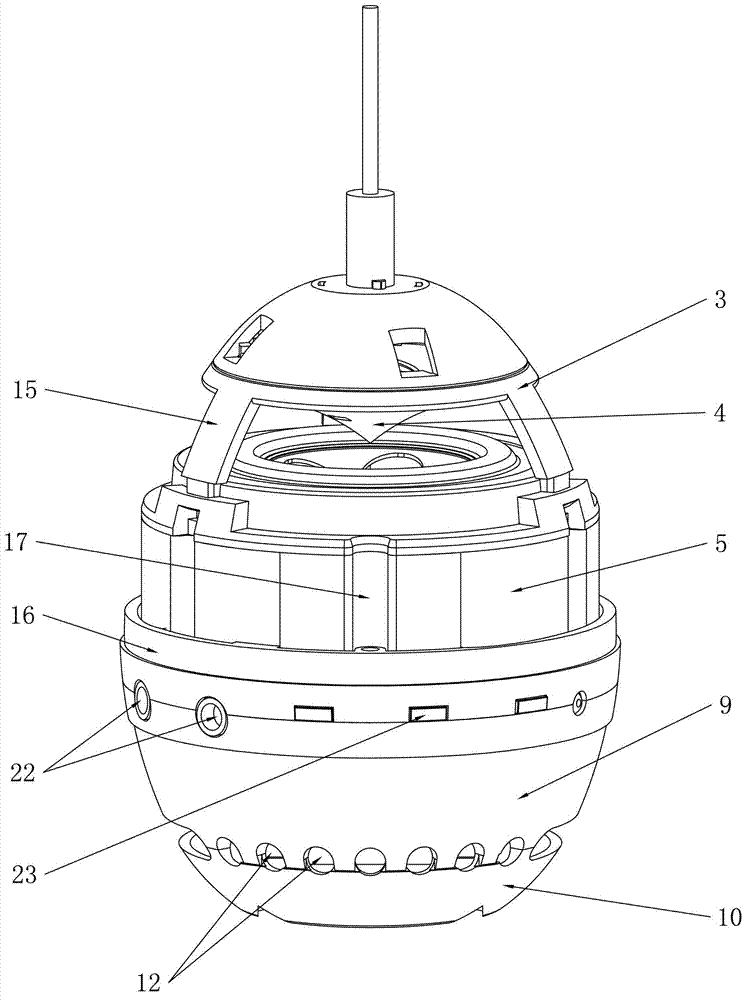

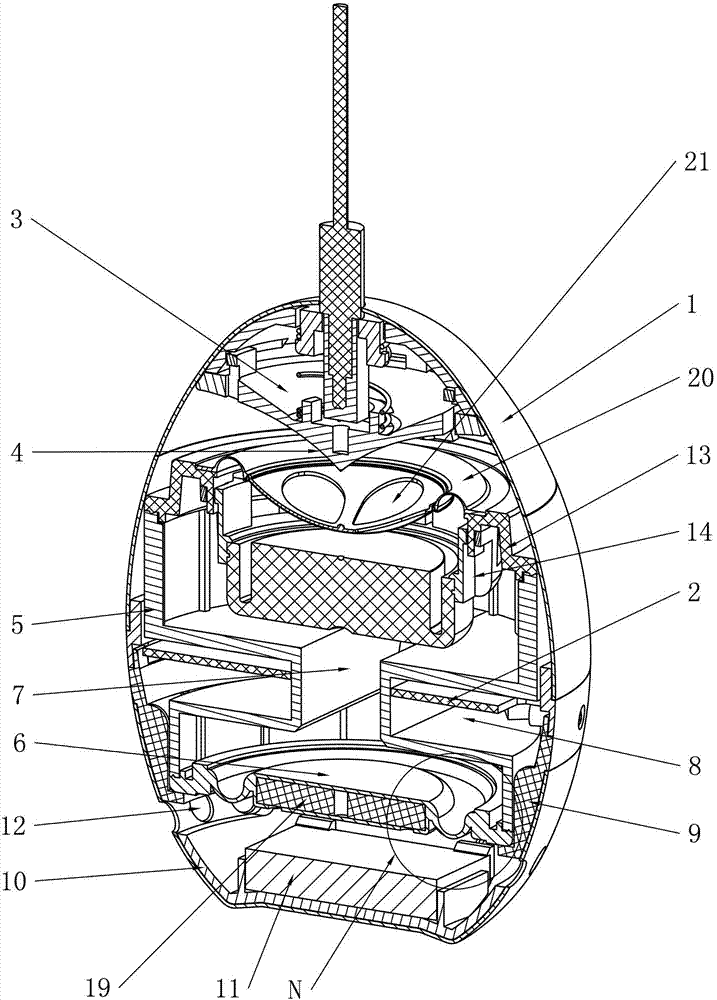

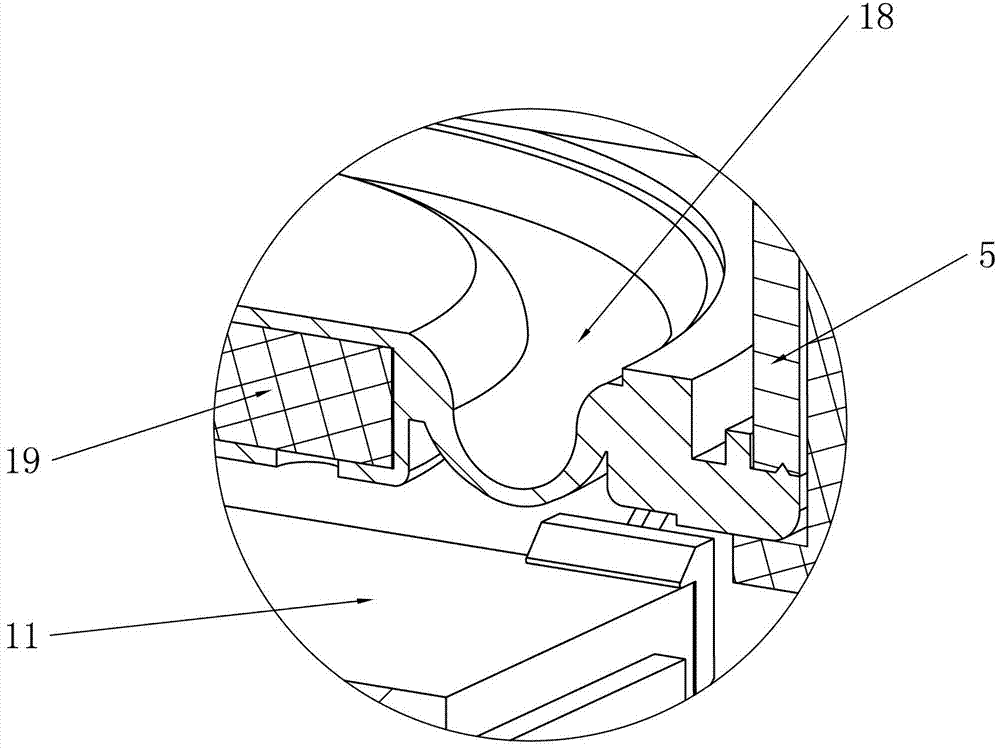

Egg-shaped 360-degree playing sound box

ActiveCN102868949AImprove bindingImprove sound qualityTransducer casings/cabinets/supportsPassive radiatorMedium frequency

The invention relates to a music playing device, in particular to an egg-shaped 360-degree playing sound box capable of being hung on a ceiling. The egg-shaped 360-degree playing sound box comprises an egg-shaped casing, and a sound box module and a power amplifier connected with the sound box module are installed in the casing. The sound box module comprises a horn, a connection chuck connected with the sound box module in clamping mode and corresponding to the horn is arranged in the casing, an arc face cone corresponding to the horn is arranged at the bottom of the connection chuck, and sound given out by the horn covers 360 degrees of the periphery. The sound box integrates the sound box module with a stress bass passive radiator effectively, enables music to cover the surrounding environment in full directions on one hand, and achieves the effect that the small-space small-size sound box can give out good bass on the other hand. The sound box achieves maximum utilization of effective space and optimum combination of sound in high frequency, medium frequency and low frequency, and enables played music to be good in tactile sense, true and clear.

Owner:NINGBO SHENGYA ELECTRONICS

Wood floor painting technology

The real wood lacquering process goes regular rolling coating, drying, sand polishing and dusting, using water base primed paint, putty, transparent prime paint, corrosive prime paint, common prime paint, transparent prime paint to coat the wood floor, then coating a layer of transparent paint, using scudding resistant paint to spray the wood floor, and last using rolling coating to paint the scudding surface. It improves the adhesive feature of the prime paint and the real wood floor, using paint of transparency with 1, ensuring good fidelity effect of the product, displaying natural color of the wood, using corrosion resistant prime paint with feature far better than that of the Al203, using two times of coating cloth to further enhance the corrosion resistance feature, with final spraying and rolling coating to finish the whole process.

Owner:ZHEJIANG CHANX WOOD

Method for preparing maize biology-based special-leather-feel top grade leisure shell fabric

ActiveCN102138709AFlat surfaceSoft touchTransfer printing processDyeing processFiberMoisture permeability

The invention discloses a method for preparing a maize biology base special-leather-feel leisure shell fabric. The method comprises the following steps of: (1) selecting raw materials; (2) performing variant compounding; (3) weaving; and (4) dyeing and performing post finishing. By adopting the method, the shell fabric has the advantages of smooth surface, flexible hand feel, high texture, water resistance, stain resistance, antistatic property, superior wrinkle resistance, luster and texture of a natural leather material, high air permeability, high moisture permeability, freeness from ironing, easiness for maintenance and the like, can be used for making autumn and winter clothes such as dust coats, jacks, cotton dresses and the like as well as spring and summer clothes such as unlined business suits, slack business suits, unlined jacks and the like, and can be washed with water or in a dry way.

Owner:DANYANG DANQI YUYUE TEXTILE

Preserved persimmon production method

InactiveCN1620885AAdvanced technologyFull of nutritionConfectionerySweetmeatsSweet tasteFruit Flavor

The present invention is candied persimmon producing process. The present invention has simple technological process, and the candied persimmon product has rich nutrients, good and sweet taste and rich fruit flavor. The candied persimmon producing process includes the steps of: deastringency of persimmon, peeling, slicing, hardening and color protection, sensing, soaking in sugar, stoving, shaping and packing.

Owner:王国义

Ultrafine fiber polyurethane synthetic leather for golf gloves and manufacturing method of leather

ActiveCN104264499AHigh densityGood flexibilityLamination ancillary operationsSynthetic resin layered productsSurface layerHigh density

The invention provides ultrafine fiber polyurethane synthetic leather for a pair of golf gloves and a manufacturing method of the leather. The manufacturing method of the leather comprises the following steps: (1) utilizing an oiling agent to oil original base fabric A, and drying; (2) buffing the original base fabric A oiled and dried in the step (1), so as to obtain base fabric B; (3) utilizing a polyurethane binding agent to enable a slurry of a surface-layer dry-method polyurethane resin to be adhered onto the front of the base fabric, and peeling off release paper to obtain synthetic leather C; (4) adopting a printing-coating method to coat a surface treating agent on the synthetic leather C by adopting a printing roller, and drying to obtain the ultrafine fiber polyurethane synthetic leather for the pair of golf gloves. The ultrafine fiber polyurethane synthetic leather disclosed by the invention has the characteristics of short fold recovery time, high density, no dart and rich patterns, and further has the characteristics of high softness, air and water vapor permeability and the like; the synthetic leather surface has good tender skin feeling and slip limiting feeling, and can be comparable with the natural leather for the pair of golf gloves.

Owner:HUAFON MICROFIBER SHANGHAI

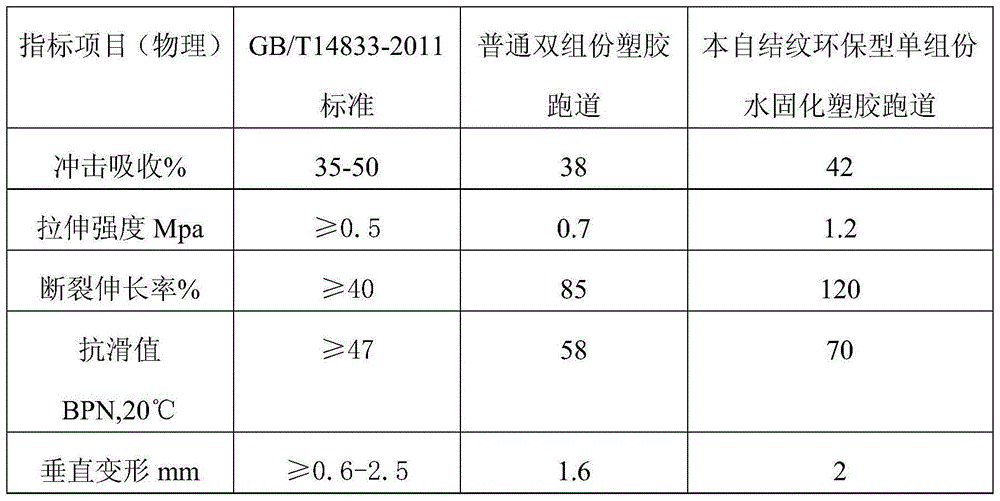

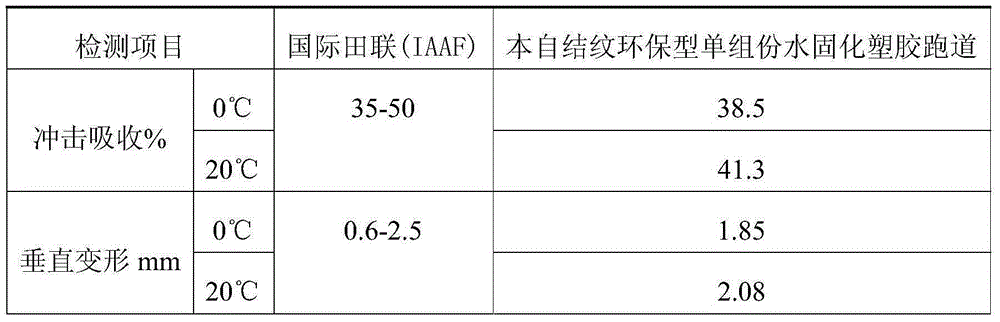

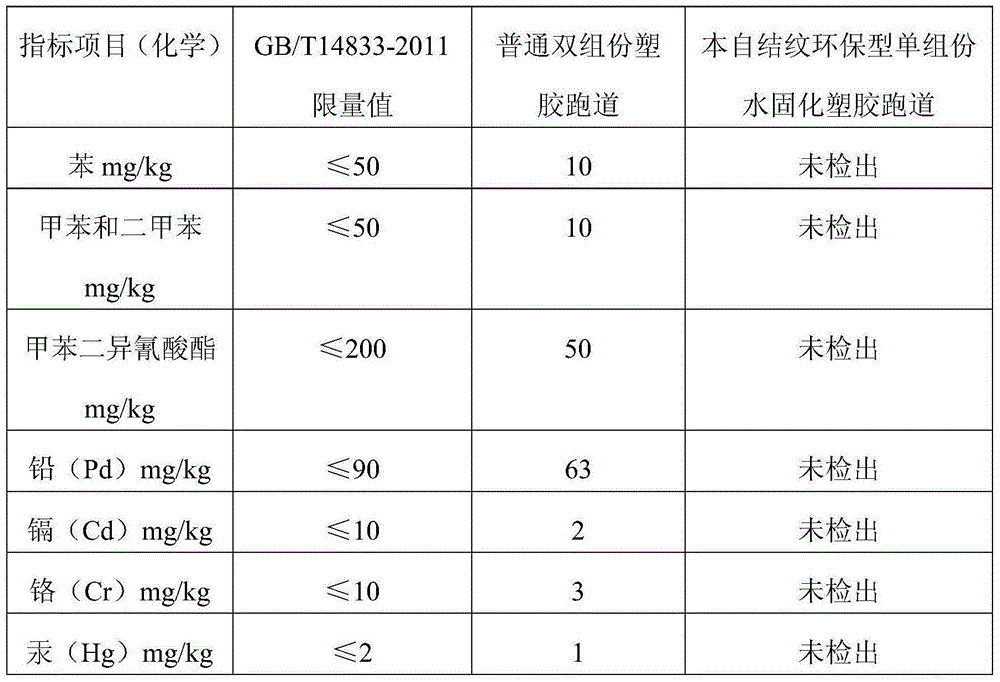

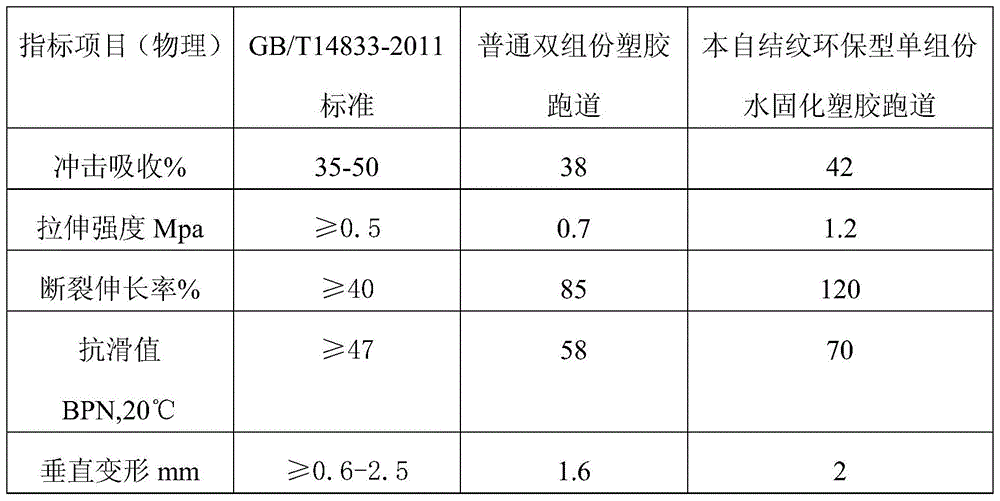

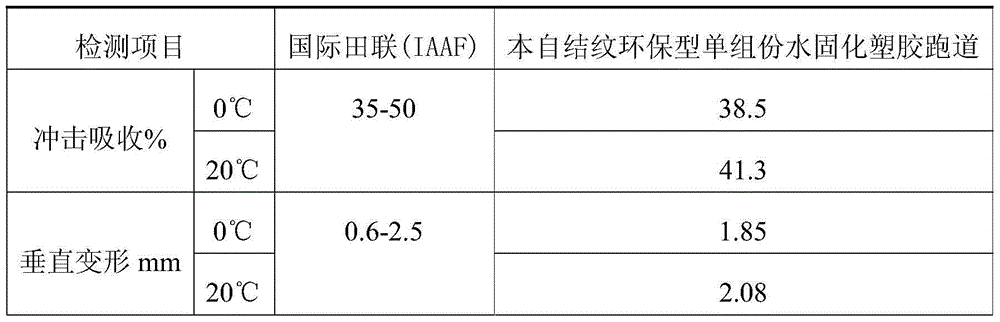

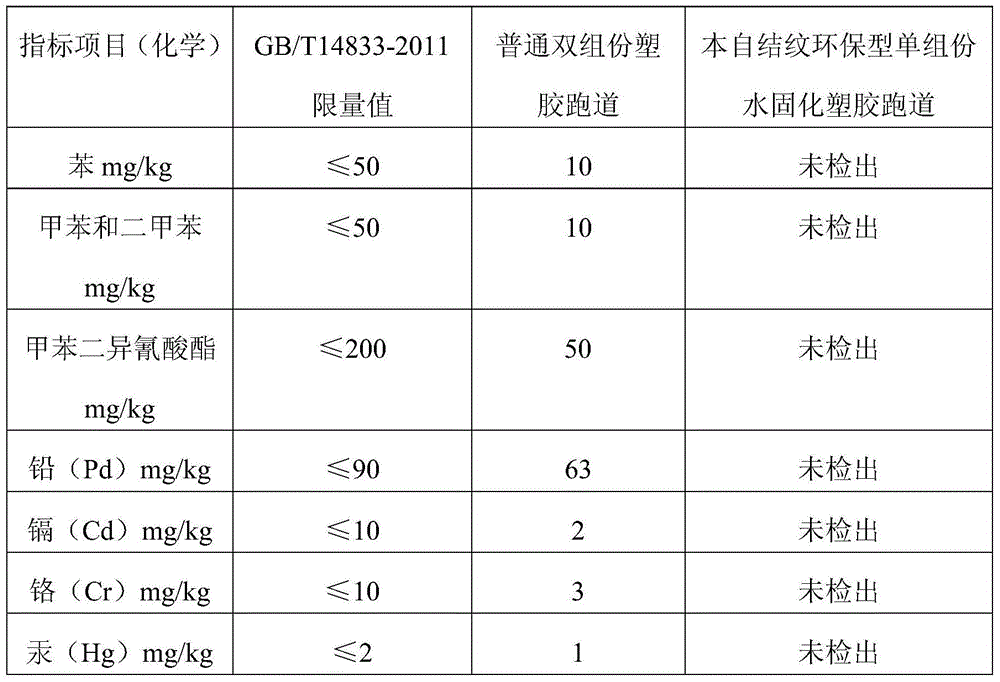

Laying method of automatic texture formation particle-free environmentally-friendly plastic track

The invention discloses a laying method of an automatic texture formation particle-free environmentally-friendly plastic track. The method comprises the following steps: S21, laying a substrate layer: mixing an environmentally-friendly single-component water solidified plastic track material with black micelles according to a weight ratio of 1:4-6, and laying the substrate layer on a dry and solidified cement base or asphalt base; S22, laying a reinforcing layer: spreading a layer of the black micelles on the dry and solid base layer, and lying the environmentally-friendly single-component water solidified plastic track material to cover the substrate layer; and S23, laying an automatic texture formation layer: uniformly mixing 10-12 parts of an automatic texture formation finish, 1-3 parts of EPDM particle rubber powder and 3-6 parts of quartz sand to form an automatic texture formation layer material, fully stirring, and spraying the obtained material on the dry and solidified reinforcing layer. The track has the advantages of environmentally friendly material, no shedding of particles, good durability, plump and uniform surface textures, high tensile strength and long service life, and all performance indexes of the track accord with technical requirements of International Association of Athletics Federations and GB / T14833-2011.

Owner:广州帝森康体设备有限公司

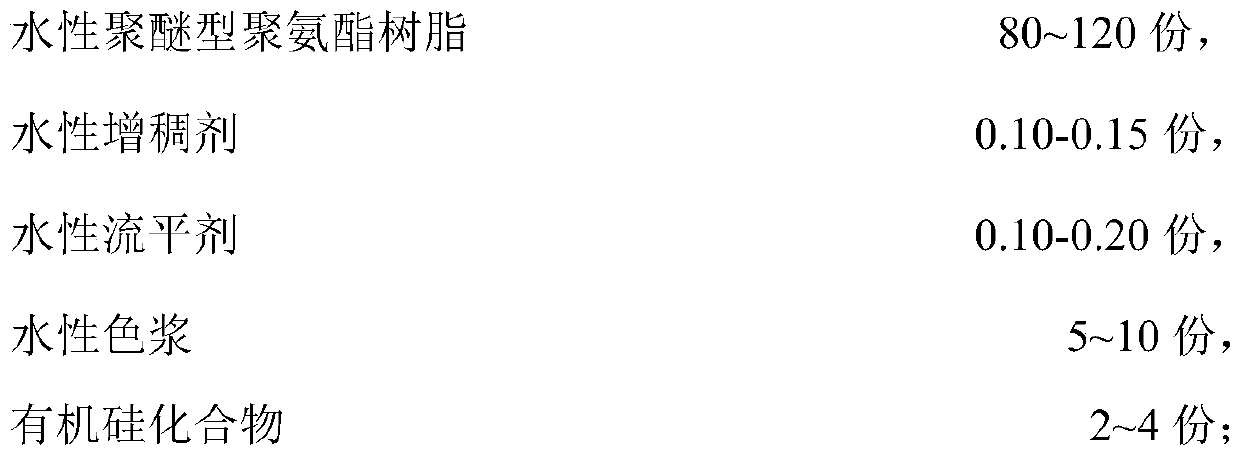

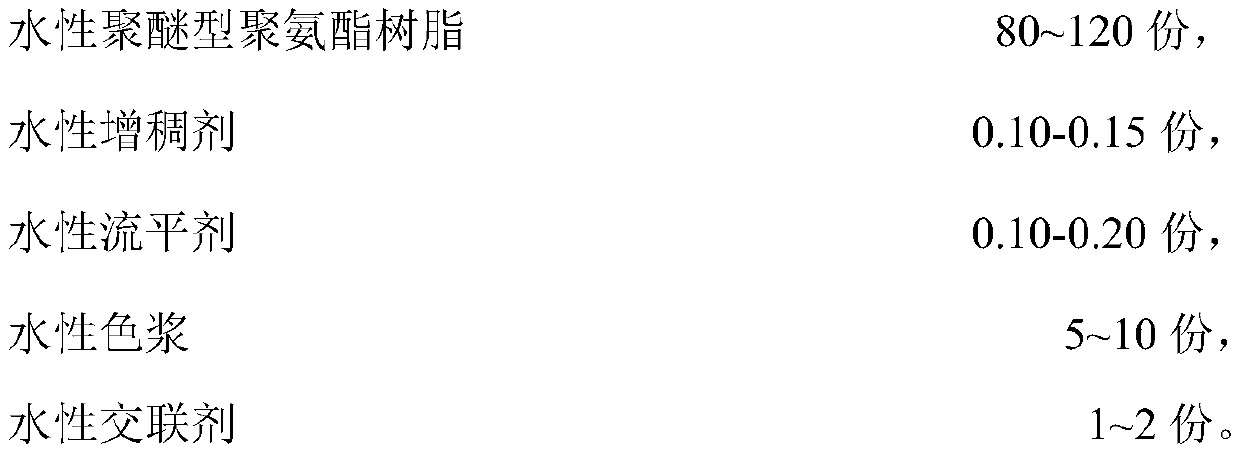

Skin-friendly and environment-friendly polyurethane synthetic leather for earphone sleeve and preparing method of leather

InactiveCN110541312APromote environmental protectionReduce usageGrip property fibresCoatingsSurface layerSolvent free

The invention discloses skin-friendly and environment-friendly polyurethane synthetic leather for an earphone sleeve and a preparing method of the leather. The leather sequentially comprises a dry-method surface layer, a middle layer, a foaming layer and a base cloth layer from outside to inside. The dry-method surface layer is prepared from, by weight, 80-120 parts of waterborne polyether type polyurethane resin, 0.10-0.15 part of a waterborne thickener, 0.10-0.20 part of a waterborne leveling agent, 5-10 parts of waterborne color paste and 2-4 parts of an organic silicon compound. The middlelayer is prepared from, by weight, 80-120 parts of waterborne polyether type polyurethane resin, 0.10-0.15 part of a waterborne thickener, 0.10-0.20 part of a waterborne leveling agent, 5-10 parts ofwaterborne color paste and 1-2 parts of a waterborne crosslinking agent. By means of the waterborne solvent-free process, the finished product can be controlled to be free of DMF, environmentally friendly and healthy; the prepared polyurethane synthetic leather is long in service life, excellent in hydrolysis resistance, soft in surface touch and plump in texture.

Owner:ANHUI ANLI MATERIAL TECH

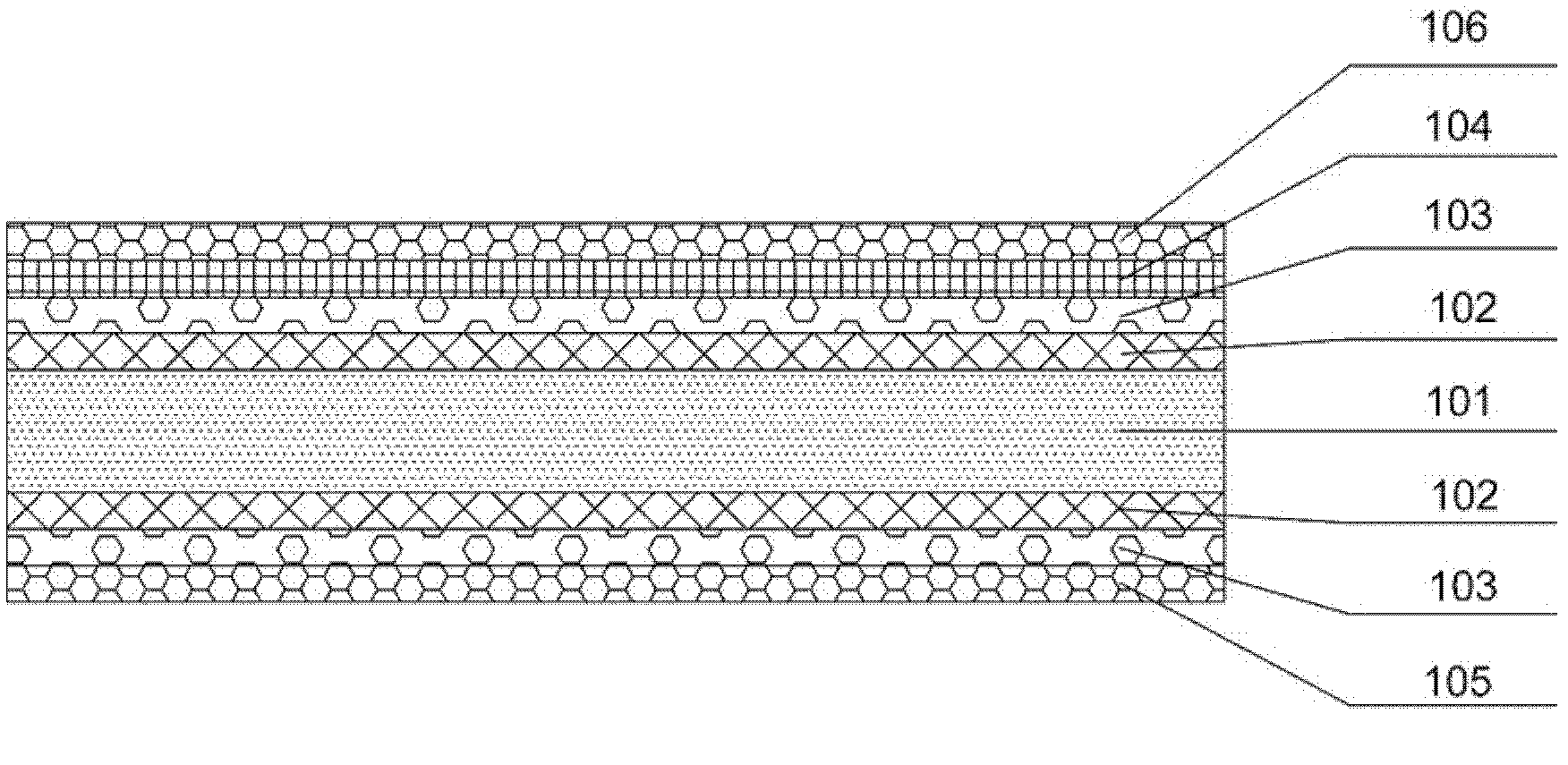

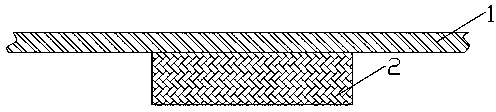

Cleansing color coated steel plate for purification and preparation method thereof

InactiveCN102275353AImprove adhesionImprove surface propertiesSynthetic resin layered productsMetal layered productsEnvironmental resistanceCoated surface

The present invention relates to the technical field of materials, in particular to a cleansing color-coated steel sheet for purification and a preparation method thereof. The cleansing color-coated steel sheet for purification comprises: a smooth galvanized substrate (101); The chemical conversion layer (103), the primer layer (104), and the top paint layer (106) are sequentially upward from the surface, and the chemical conversion layer (103) and the back paint layer are sequentially downward from the lower surface of the substrate (101) (105). The present invention greatly improves the adhesion of the coating by improving the structure and process of the color-coated steel plate, and obtains a clean color-coated plate with a delicate and smooth outer coating surface. Compared with the existing color-coated steel plate, its The advantages are: good surface characteristics, bending processing performance, easy cleaning and resistance to repeated scrubbing, non-toxic and environmentally friendly, and the preparation method of the present invention is simple and effective, with less equipment investment and low cost, and is very suitable for large industrial production.

Owner:SUZHOU YANGTZE NEW MATERIALS CO LTD

Superfine fiber synthetic leather, preparation method thereof and printing material composition

The invention discloses a preparation method for superfine fiber synthetic leather, which comprises the following step of: performing printing treatment, water washing, and dry rubbing on the superfine fiber synthetic leather obtained by cover making of a dry-process overlaying process, wherein a printing material in printing treatment comprises the following components in part by weight: 100 parts of waterborne polyurethane resin, 10 to 50 parts of water, preferably 20 to 40 parts of water, and 5 to 40 parts of water-based ink, preferably 10 to 30 parts of water-based ink; the temperature of water washing is 40 to 90DEG C, preferably 50 to 70DEG C; and the time of water washing is 15 to 50 minutes, preferably 25 to 40 minutes. The invention also discloses the superfine fiber synthetic leather prepared by the method. The superfine fiber synthetic leather is washable superfine fiber synthetic leather, and has excellent comprehensive physical properties, dual-color effect and the handfeel of natural leather. The invention also discloses a printing material composition.

Owner:HUAFON MICROFIBER SHANGHAI

High-temperature ceramic grisaille painting decorating method

The invention provides a high-temperature ceramic grisaille painting decorating method. The method is characterized in that high-temperature ceramic grisaille painting decorating is served as an application background, high-temperature glaze, high-temperature coloring materials and various additives are reasonably mixed, a technical barrier of decorating before glazing in a high-temperature glaze grisaille painting decorating process is broken through, decorating and glazing are integrated so as to realize an artistic effect of simultaneous decorating and glazing, complicated processes are simplified, and a unique artistic style is obtained. A fired product has the advantages of smooth and bright surface, unique decoration pattern style, various random patterns, smoothness, naturality, full quality and vividity, various decorative effects, accurate expression and wide market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Thermal-insulation protective coating for aluminum alloy doors and windows and preparation method thereof

InactiveCN107083185AImprove waterproof performanceGood adhesionAnti-corrosive paintsMicrosphereThermal insulation

The invention discloses a thermal-insulation protective coating for aluminum alloy doors and windows. The thermal-insulation protective coating is prepared from, by weight, 50-60 parts of fluoro-siloxane resin, 10-16 parts of bisphenol A diglycidyl ether, 12-16 parts of hollow microspheres, 30-40 parts of solvent, 6-8 parts of nano additive, 9-13 parts of processing aid, 1-3 parts of silane coupling agent, 4-6 parts of thickening agent and 20-30 parts of heat insulation packing. The thermal-insulation protective coating is low in thermal conductivity, good in thermal insulation effect and strong in corrosion resistance. The chemical properties of the thermal-insulation protective coating are stable, the surface hardness is better, and the thermal-insulation protective coating is resistant to friction and convenient to construct and is formed at a time. In addition, the raw material components of the thermal-insulation protective coating are safe and reliable, are harmless to the human body and are easy to obtain, the cost is lower, the process is simple and clear and easy to operate and achieves industrialized production, and the coating has a higher practical value and good application prospect.

Owner:合肥市旺友门窗有限公司

Preparing method for sports apparatus grip leather capable of adjusting wet skid resistance along with temperature change

InactiveCN105803815AHold firmlyWon't slipPolyurea/polyurethane coatingsTextiles and paperWater basedMicrobubbles

The invention relates to a preparing method for sports apparatus grip leather capable of adjusting wet skid resistance along with temperature change.The method includes the following steps that 1, water-based dry method grip leather Bes slurry is prepared, wherein a dispersing agent, a crosslinking agent, tap water, filling powder, a foaming agent, foam stabilizer, water-based color paste and thickener are sequentially added into water-based polyurethane resin and stirred to obtain the water-based dry method grip leather Bes slurry; 2, printing slurry is prepared, wherein tap water, a defoaming agent, a flatting agent and thickener are sequentially added into resin and stirred to obtain the printing slurry; 3, the water-based dry method grip leather Bes slurry is introduced into a foaming machine to be foamed physically, and then water-based dry method grip leather Bes foamed slurry with air microbubbles is obtained; 4, elastic knitted fabric is uniformly coated with the water-based dry method grip leather Bes foamed slurry and dried to obtain water-based dry method grip Bes; 5, the printing slurry is printed on the water-based dry method grip Bes and dried to obtain the sports apparatus grip leather.The preparing method is simple in process and easy to implement.

Owner:LANZHOU KETIAN NEW MATERIAL CO LTD

Novel celluloid paint for lacquer painting

The invention provides a novel celluloid paint for lacquer painting. The celluloid paint comprises nitrocellulose, resin, a plasticizer, a strong solvent and a diluent, wherein the ratio of the contents of resin and part of plasticizer to the content of nitrocellulose is 1.5: 1; and under such condition, the celluloid paint can overcome the shortcoming that a white primer film is yellowed after long-time use, has the work effect entirely different from the colored work effect of the traditional lacquer painting, is bright in color and brings a vivid sense.

Owner:平遥恒隆泰漆艺有限公司

Preparation method of slim mirror-plane artistic porcelain painting and product prepared by preparation method

The invention relates to a preparation method of a slim mirror-plane artistic porcelain painting which consists of a preform body and glazes, wherein the preform body is prepared from the following components in percentage by weight: 15-20% of soft soil, 5-10% of hard soil, 30-40% of porcelain stones, 10-15% of tremolite, 15-20% of pyrophyllite and 15-20% of albite; the bottom glaze is prepared from the following components in percentage by weight: 55-65% of frit I, 10-15% of frit II, 1-2% of aluminum oxide, 3-5% of calcined kaolin and 15-25% of kaolin. The preparation method comprises the following steps: preparing the preform body and the glazes, roll-pressing and molding the preform body, drying, biscuiting, applying bottom glaze, applying surface glaze, performing colored drawing, and performing high-temperature glaze firing to obtain the slim mirror-plane artistic porcelain painting. By combining the latest international ceramic ink-jet printing technology with the conventional hand painting process of Jingdezhen, the famous scripts and paintings at all times and in all over the world are manufactured into 3D artistic porcelain paintings which are exquisite in product quality, rich in frame and fine in texture, can be widely applied to the decoration of airplanes, stations, homes and office buildings, and have wide application prospect.

Owner:JINGDEZHEN JINGFUGONG CERAMIC CULTURE

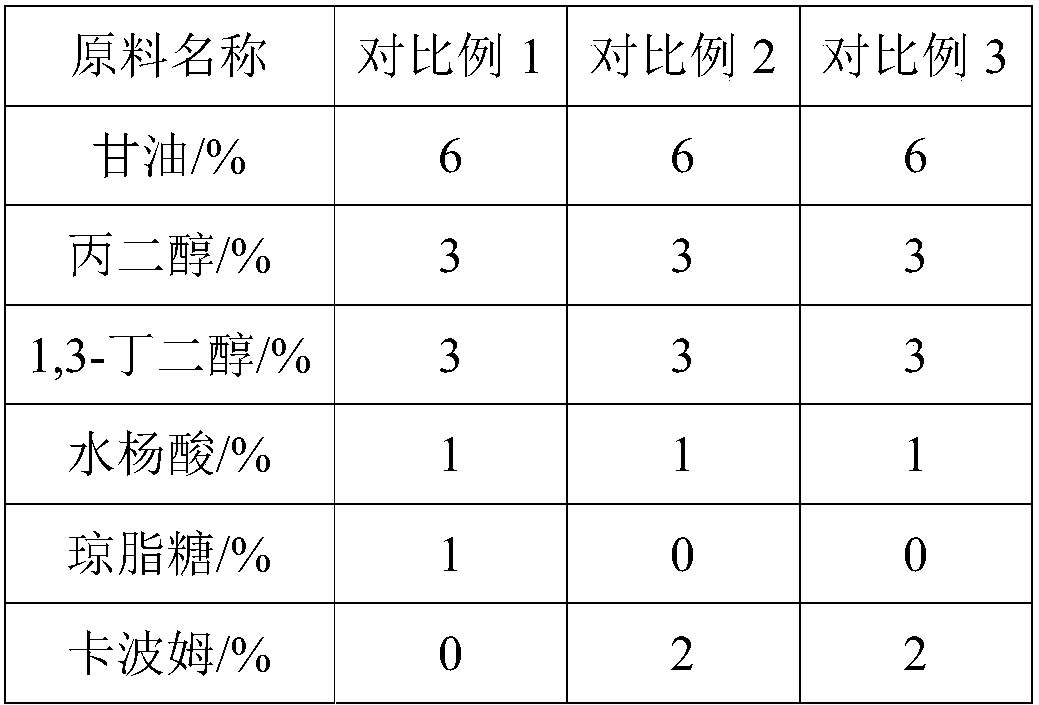

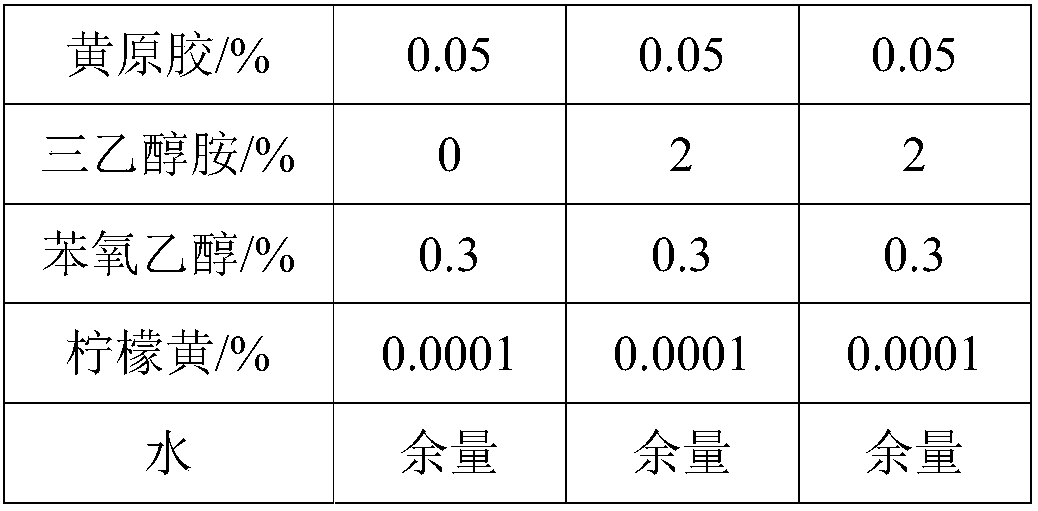

A smoothie acne-removing gel and its preparation method

ActiveCN109199895ANatural sourceLow costCosmetic preparationsToilet preparationsPreservativeSalicylic acid

The invention discloses a smoothie acne-removing acne gel and its preparation method. The smoothie acne-removing gel is prepared from humectant, acne-removing agent, bio-polysaccharide glue, preservative, pigment and water. A Chinese medicinal preparation is prepare by mixing humectant, bio-polysaccharide gum and acne-removing agent evenly, adde water, stirring, heating to dissolve completely, stir, cooling to 40-45 DEG C, adde preservative and pigment, and keeping stir; as that temperature drop to 32-37 DEG C, the stirring speed is adjust to high-speed stirring, the temperature drops further,and the stirring is maintain for 25-45 minutes after the temperature drops to room temperature. The acne removing gel is novel in appearance and rich in texture when used. And solves the problem thatthe common hydrogel is difficult to thicken salicylic acid, so that the salicylic acid maintains good acne removing activity.

Owner:广州玮弘祺生物科技有限公司

Purified cotton linen-like bamboo joint twill and fabricating process

InactiveCN103966725AIncrease thicknessRaise the ratioWoven fabricsVegetal fibresPolymer sciencePolymer chemistry

The invention relates to purified cotton linen-like bamboo joint twill. Warps of the purified cotton linen-like bamboo joint twill are 58.3tex cotton and 72.9tex cotton / 18 bamboo joint yarns, and wefts are 58.3tex cotton and 7.9tex spandex wrap yarns. The ratio of flat yarns to the bamboo joint yarns in the warps is 4:1, roughness of the bamboo joint yarns is 2, and the texture structure is fabricated by two upper needles as one lower needle and inclined rightwardly. As the ratio of the rough bamboo joint yarns to basic yarns is increased and proportion of the flat yarns and the bamboo joint yarns is increased, average bamboo joint distance and bamboo joint length of the bamboo joint yarns are matched so as to display characteristics of fullness and clearness of bamboo joints on the twill, uniformity, neatness, stiffness, smoothness and high linen-like sense of the twill. Technically, slashing adopts sectional and size separating grooves for sizing, feed, backing-off tension and wet-area tension of two sizing grooves are reasonably controlled, and uniform extension of the bamboo joint yarns and the flat yarns is uniform, and reasonable sizing formula and sizing process is selected, sizing effect is good, denting process selects high-elasticity and rough reeds, the fabricating process includes normal tension, early opening and late closing, palm frame height is reasonable adjusted, the bamboo joints are almost free of breakage, flaws on the twill surface are reduced, efficiency of a fabricating machine is improved, energy consumption is reduced, and clear grains and full texture of the twill surface are guaranteed.

Owner:ZHEJIANG XIANGJIA TEXTILE

Knee-protection and warm-keeping trousers

InactiveCN103393228AGood warmth retentionImprove wear resistanceTrousersWoven fabricsFiberEngineering

The invention discloses a pair of knee-protection and warm-keeping trousers which comprises a warm-keeping trousers body and kneecaps arranged on the knee positions of the warm-keeping trousers body, wherein the kneecaps are arranged on the side, close to the human body, inside the warm-keeping trousers body. Lint fibers and khaki fibers are woven in a blended mode to form the warm-keeping trousers body, warps and wefts are mutually woven to form the kneecaps, plush fibers are woven to form the warps, and vinylon fibers are woven to form the wefts. According to the knee-protection and warm-keeping trousers, the lint fibers and the khaki fibers are woven in the blended mode to form the warm-keeping trousers body, so that the knee-protection and warm-keeping trousers are good in warm keeping effect, durable and comfortable to wear; the plush fibers and the vinylon fibers are woven in a blended mode to form the kneecaps, so that the wear resistance is good, the warm keeping effect is very good, and the texture is thick, solid and plump.

Owner:CHANGSHU HENGQIN GARMENT

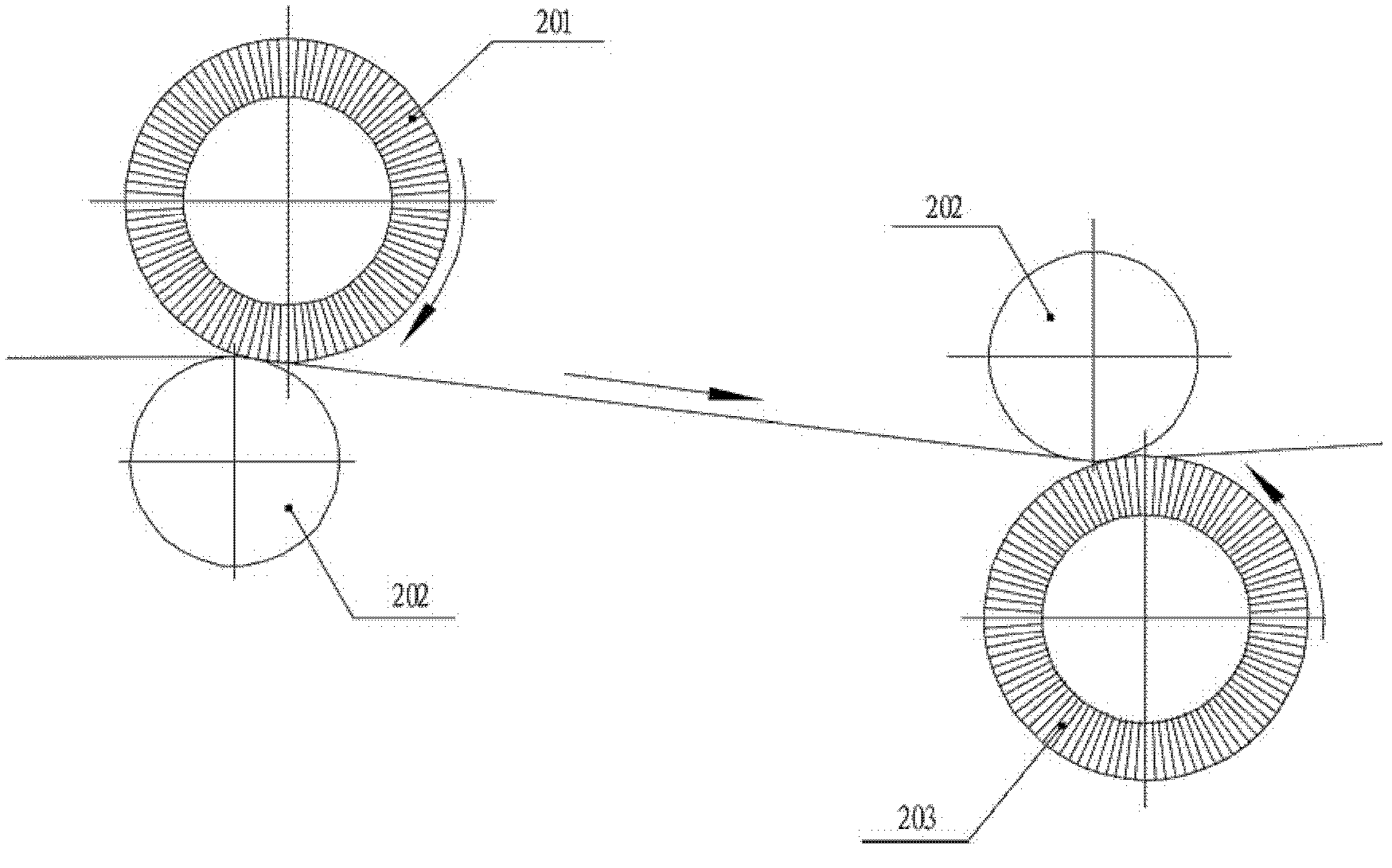

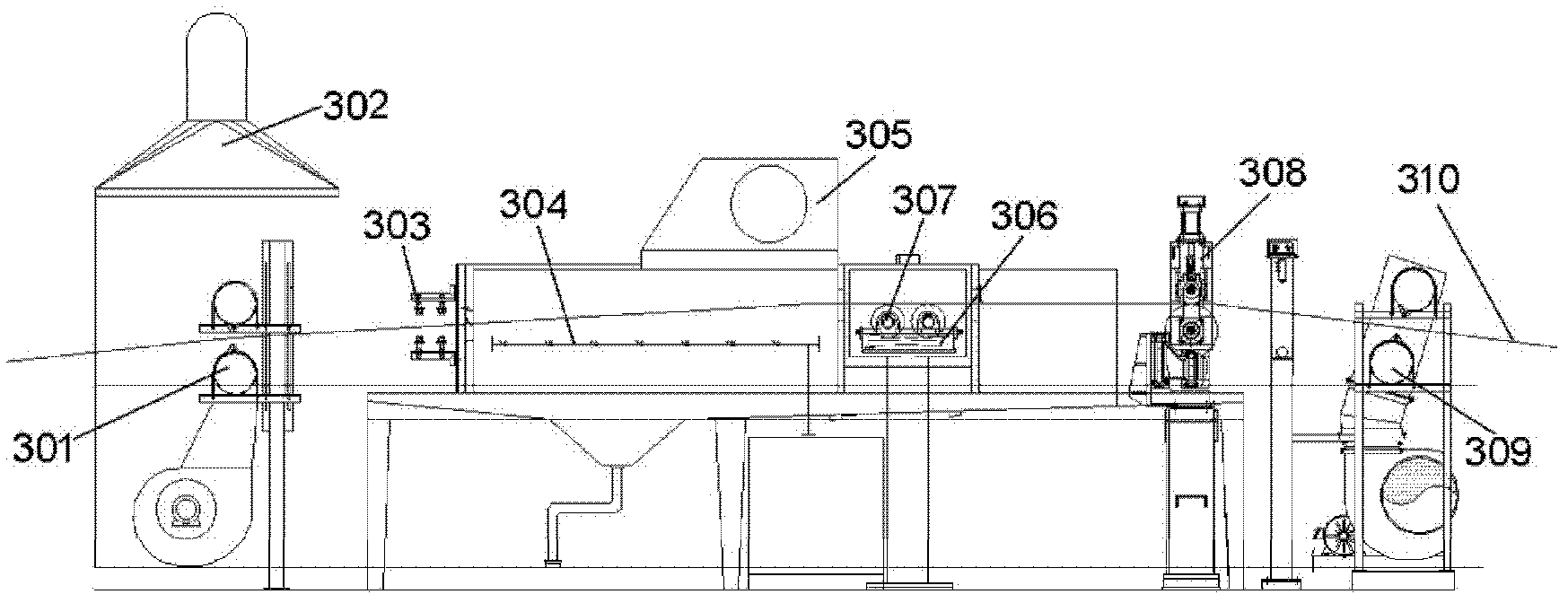

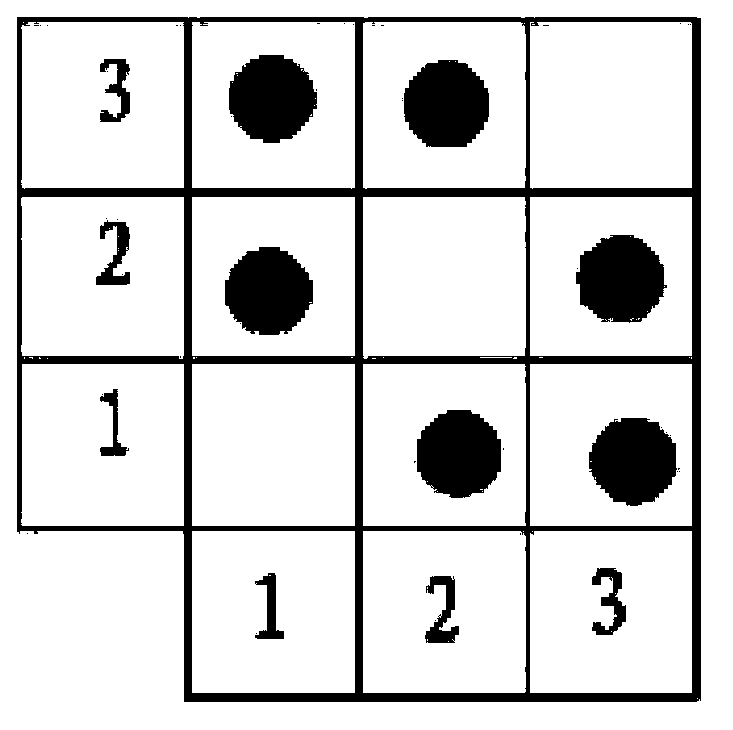

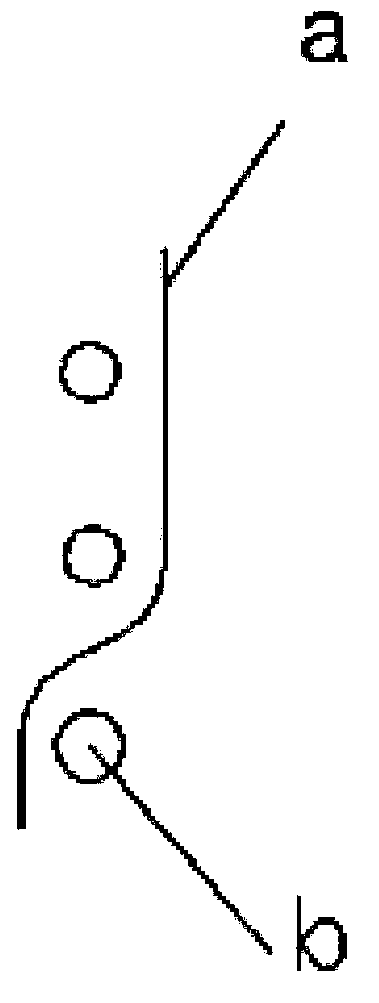

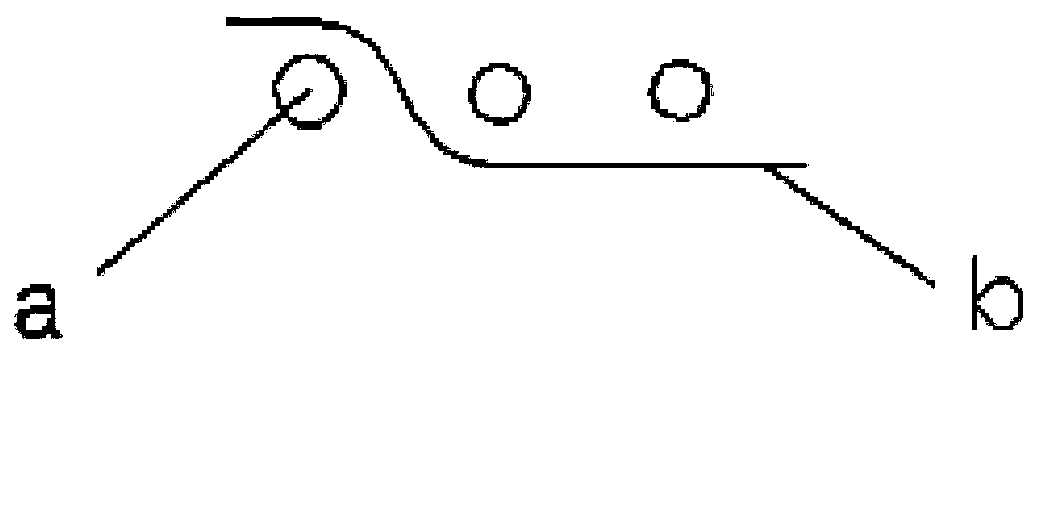

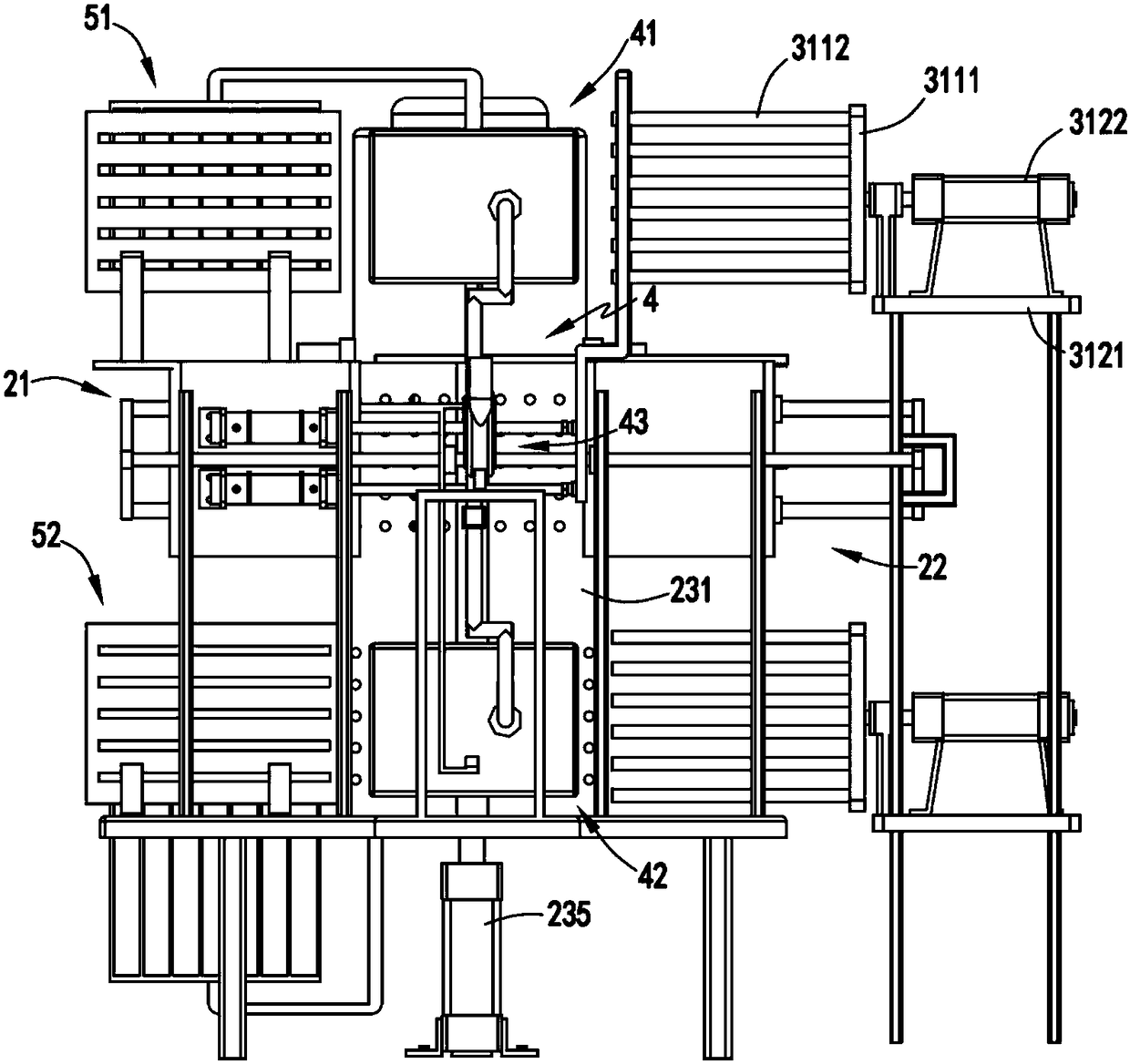

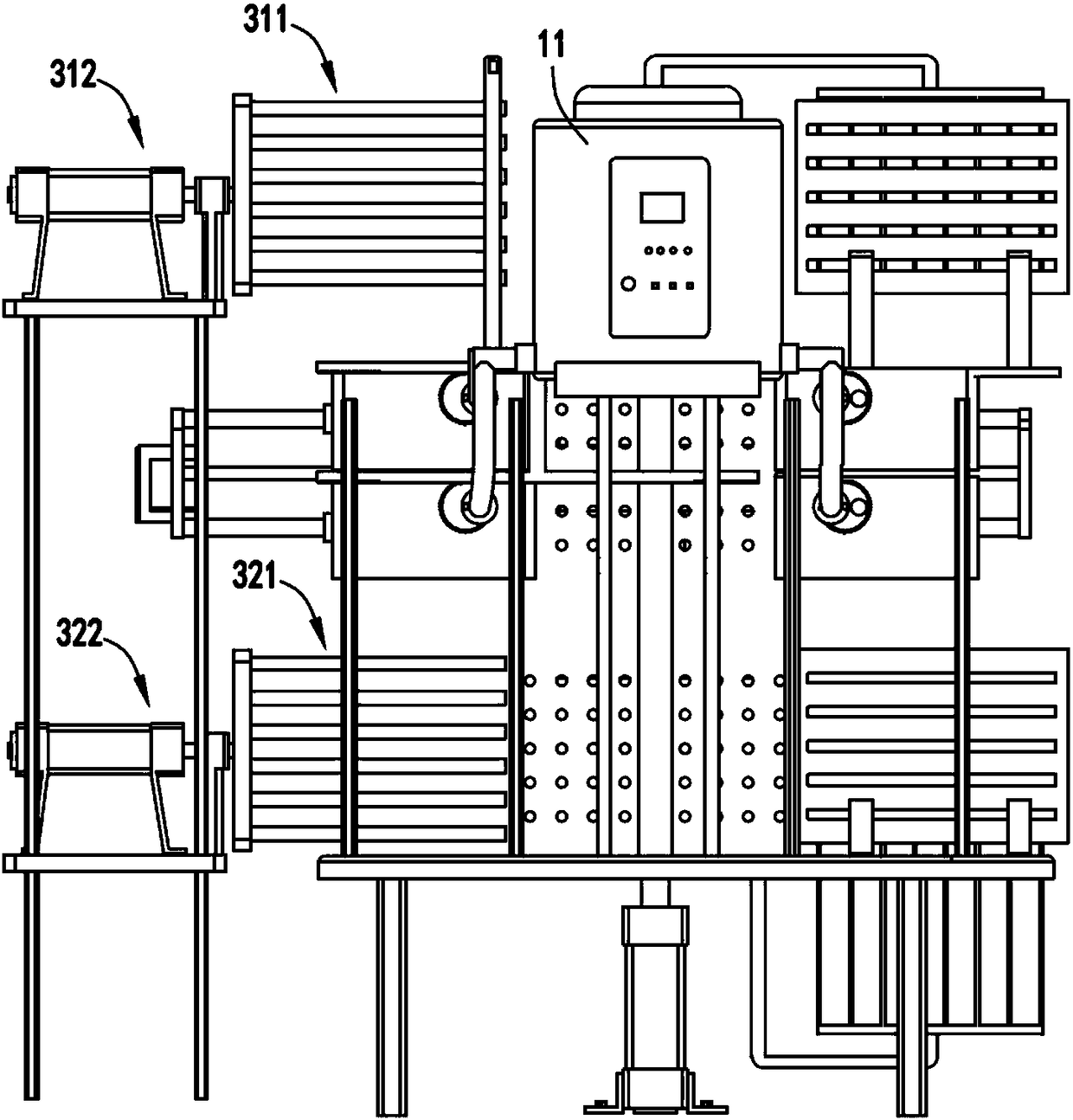

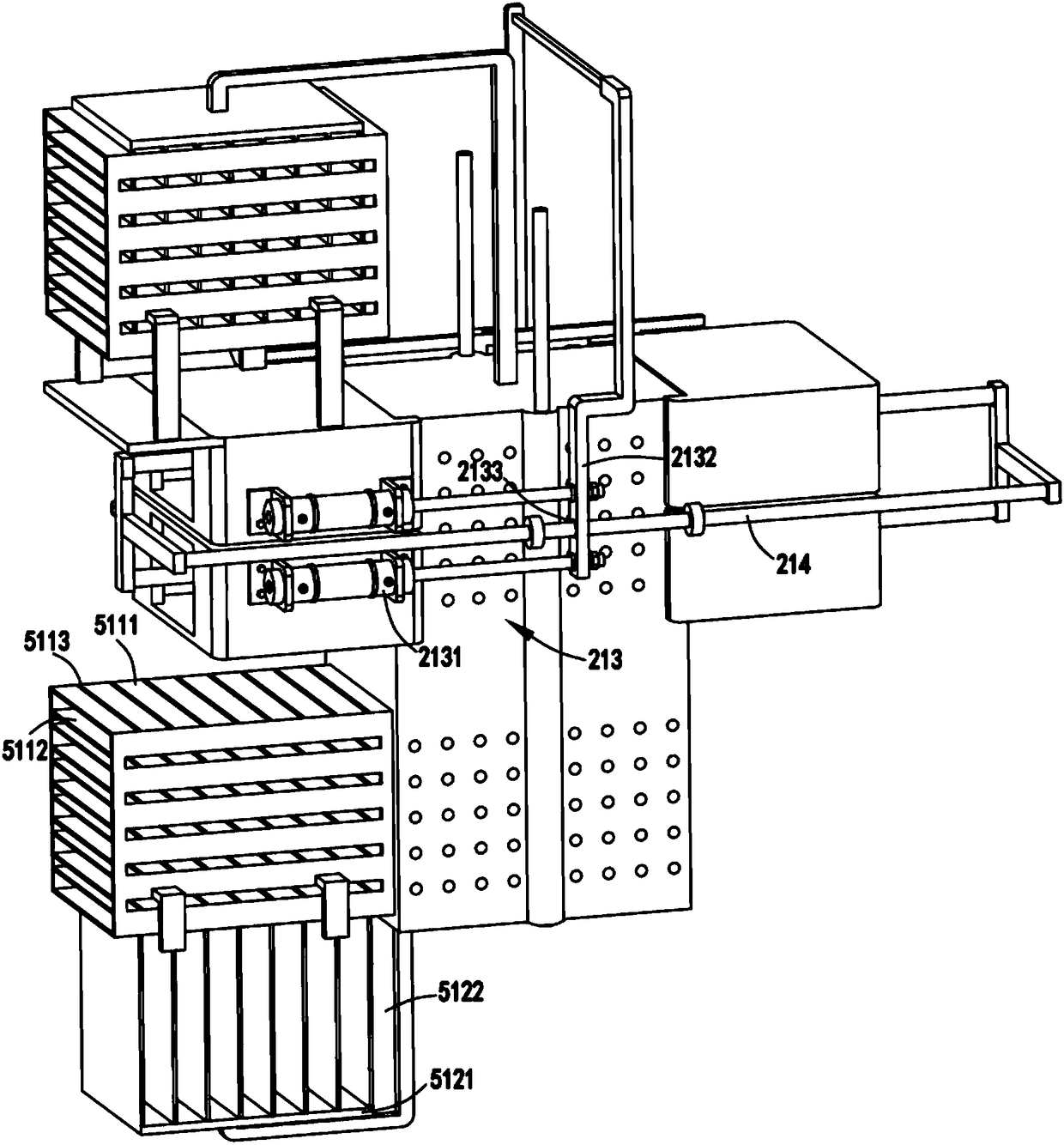

Modified master batch granulating system and technology capable of degrading express waybill labeling paper

The invention relates to a modified master batch granulating system and technology capable of degrading express waybill labeling paper. The system comprises a supply device, a forming device, an ejection device, a cooling device and a pelletizing device. The supply device comprises a smelting furnace and a material supplementing mechanism. The forming device comprises a first filler mechanism, a second filler mechanism and a forming mechanism, a forming channel is formed between the two filler mechanisms, the forming mechanism moves along the forming channel, and a forming die of the forming mechanism comprises a forming part a and a forming part b. The ejection device comprises an ejection mechanism a and an ejection mechanism b. The cooling device comprises a first cooling unit, a secondcooling unit and an air blowing mechanism, wherein the first cooling unit and the second cooling unit are used for cooling materials formed in the forming part a and the forming part b, and the forming die is provided with a cooling groove. The pelletizing device comprises a pelletizing mechanism a and a pelletizing mechanism b which are used for pelletizing materials ejected by the two ejectionmechanisms. The modified master batch granulating system and technology capable of degrading express waybill labeling paper solve the problems that during granulating, strip-shaped materials need to be dragged and transported, the strip-shaped materials are prone to getting tensile failures or slipping in the dragging process, the later pelletizing effect is influenced, the intermittent forming granulating efficiency is low, and the pelletizing effect is not stable.

Owner:ZHEJIANG SHANLIAN NEW MATERIAL TECH CO LTD

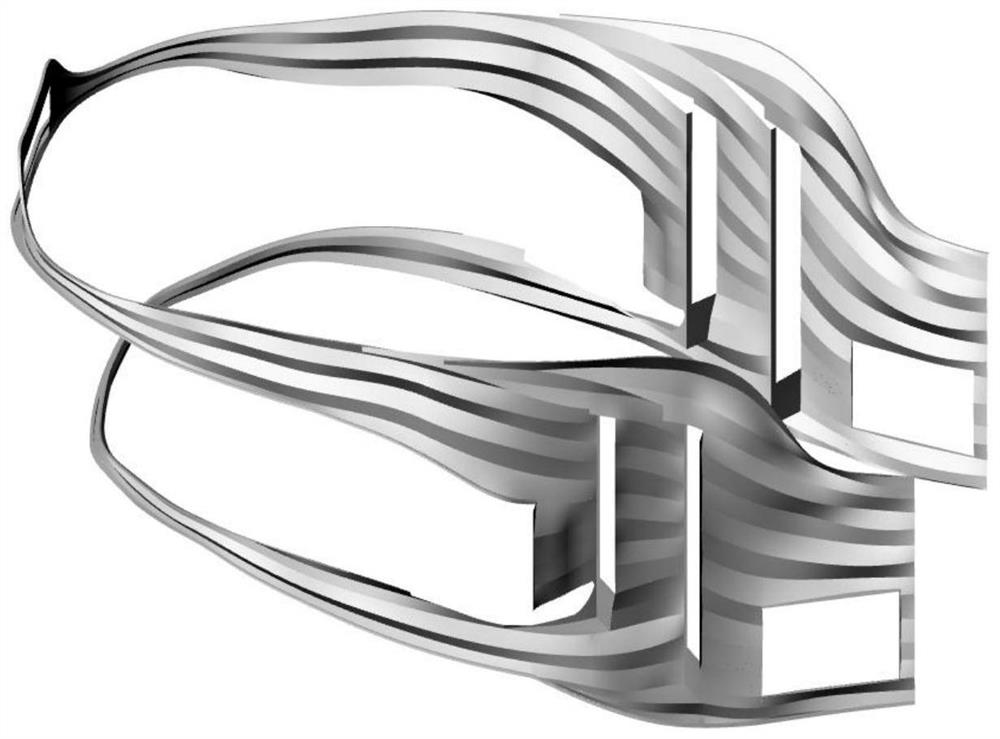

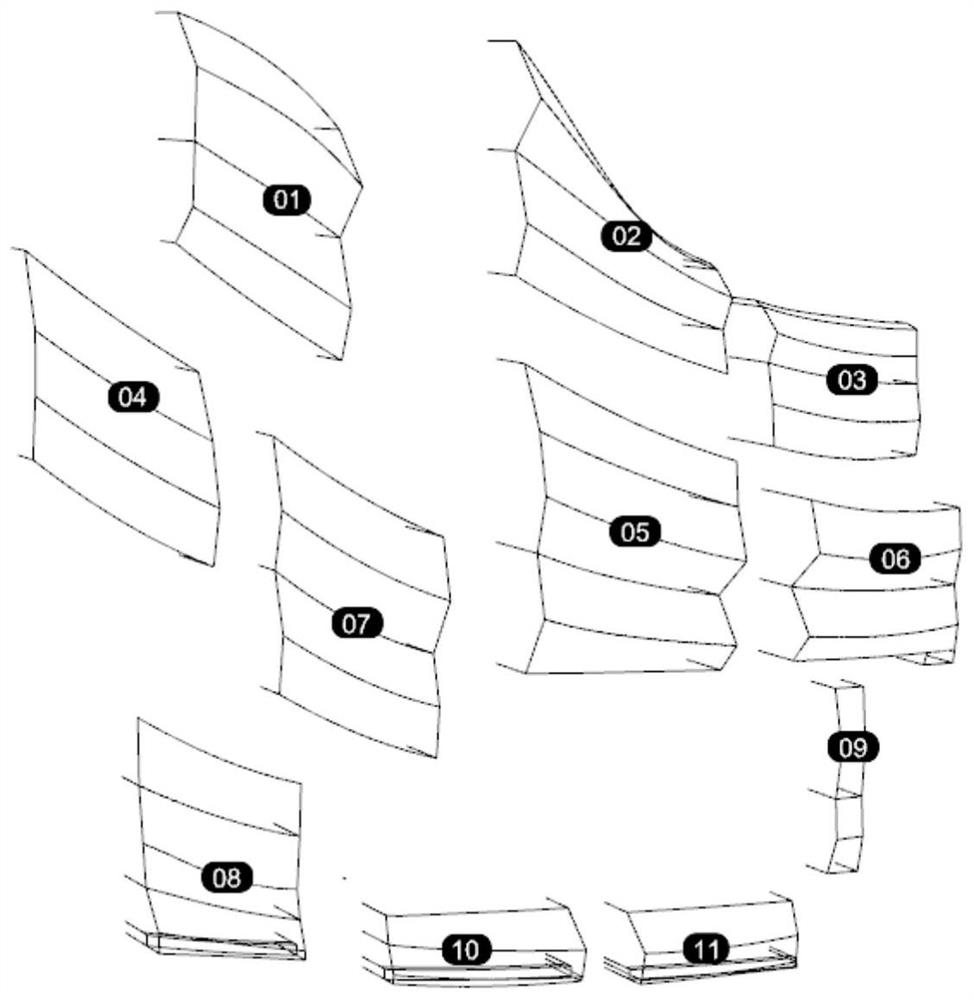

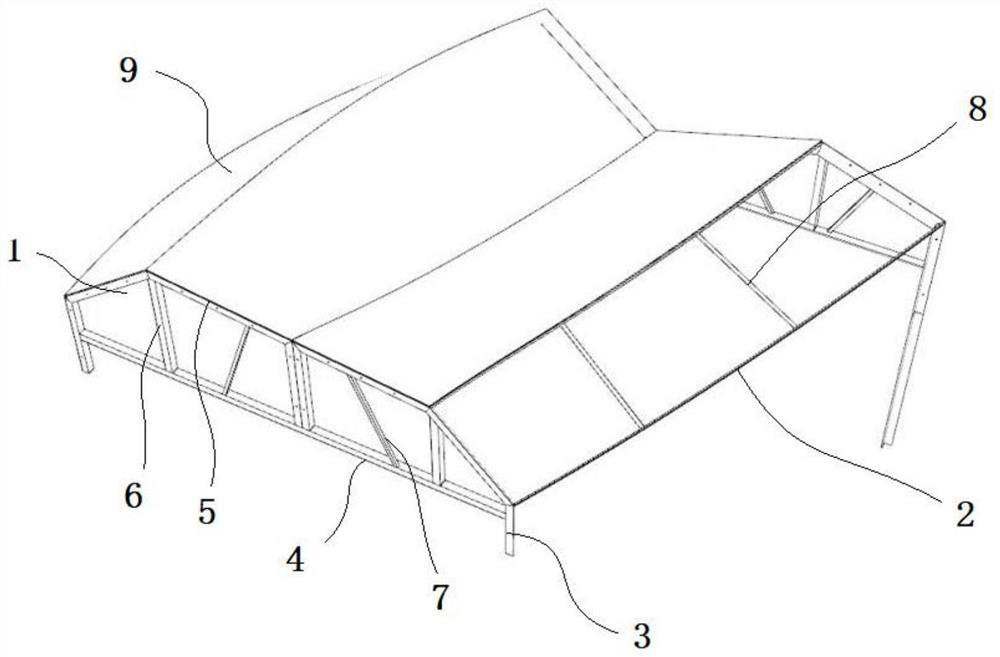

Indoor theater large-area multi-curve complex artistic decorative surface modularized structural design and combination thereof

PendingCN111894222AGood practiceGuaranteed smoothnessCovering/liningsSteel platesModular construction

The invention relates to an indoor theater large-area multi-curve complex artistic decorative surface modularized structural design and combination thereof. A large-area multi-curve complex artistic decorative surface is a large ribbon shaped wood decorative surface, the surface is a semi-enclosed structure with a C-shaped overall shape, the large ribbon shaped wood decorative surface structurallycomprises a base layer framework, unit members and a wood decorative surface layer, the base layer framework is installed on an inner wall of a large artistic venue, the multiple unit members are installed on a base layer framework and spliced into a ribbon shape, the wood decorative surface layer is laid on a unit member combination spliced into a ribbon shape, the unit members structurally comprise base frames and steel plate coverings, steel frames are longitudinally used as main bodies of the base frames, flat steels bent by a numerical control machine are transversely used as flat steels, and the unit structure combination is a ribbon framework composed of the multiple unit members. According to a multi-curve complex artistic decorative surface modularized structural and the combination thereof, finished ribbon decoration is flexible, drifting and rich in texture, and consistent good comments of a designer and an owner are obtained.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Laying method of self-knotted grain-free environment-friendly plastic runway

The invention discloses a laying method of an automatic texture formation particle-free environmentally-friendly plastic track. The method comprises the following steps: S21, laying a substrate layer: mixing an environmentally-friendly single-component water solidified plastic track material with black micelles according to a weight ratio of 1:4-6, and laying the substrate layer on a dry and solidified cement base or asphalt base; S22, laying a reinforcing layer: spreading a layer of the black micelles on the dry and solid base layer, and lying the environmentally-friendly single-component water solidified plastic track material to cover the substrate layer; and S23, laying an automatic texture formation layer: uniformly mixing 10-12 parts of an automatic texture formation finish, 1-3 parts of EPDM particle rubber powder and 3-6 parts of quartz sand to form an automatic texture formation layer material, fully stirring, and spraying the obtained material on the dry and solidified reinforcing layer. The track has the advantages of environmentally friendly material, no shedding of particles, good durability, plump and uniform surface textures, high tensile strength and long service life, and all performance indexes of the track accord with technical requirements of International Association of Athletics Federations and GB / T14833-2011.

Owner:广州帝森康体设备有限公司

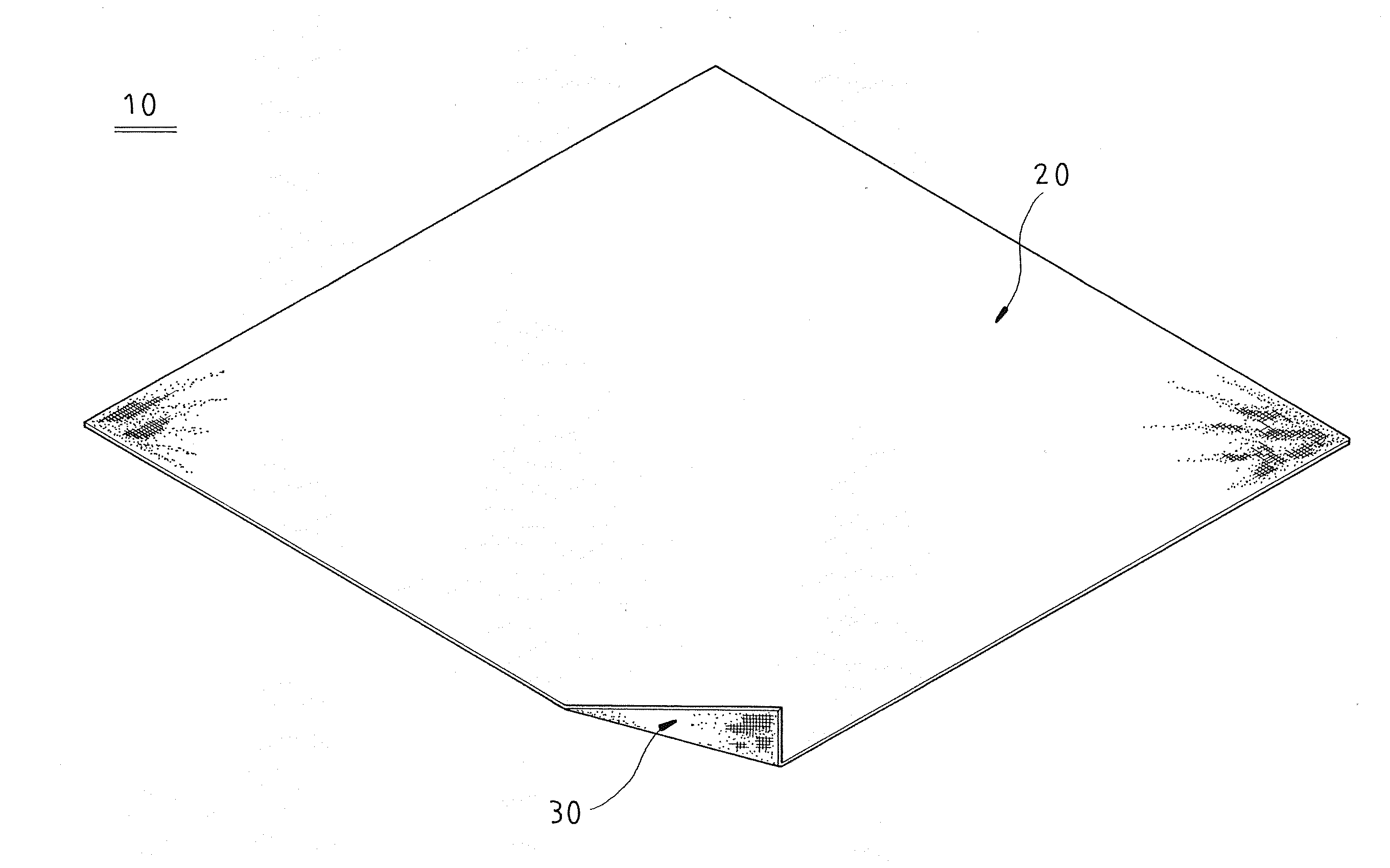

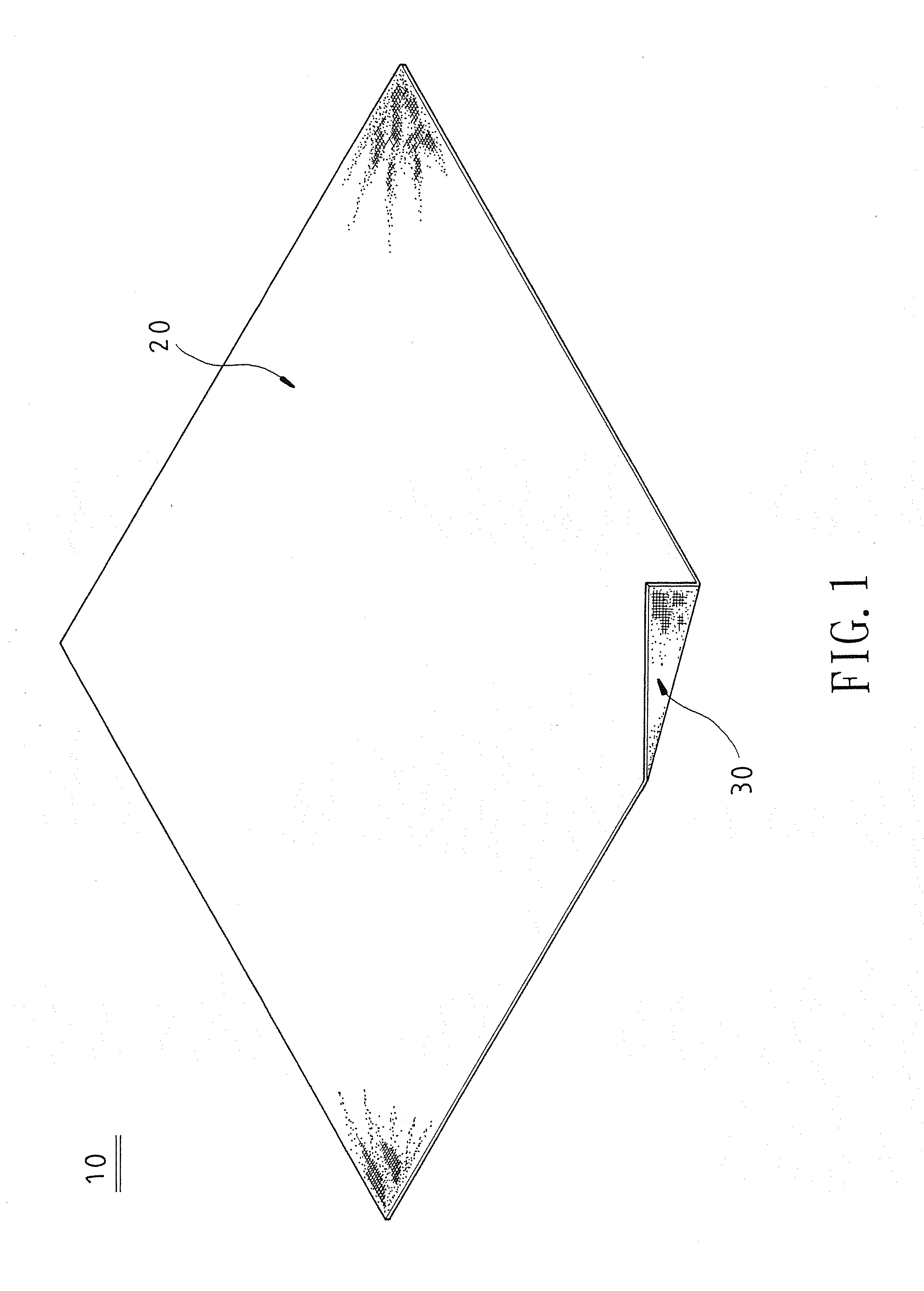

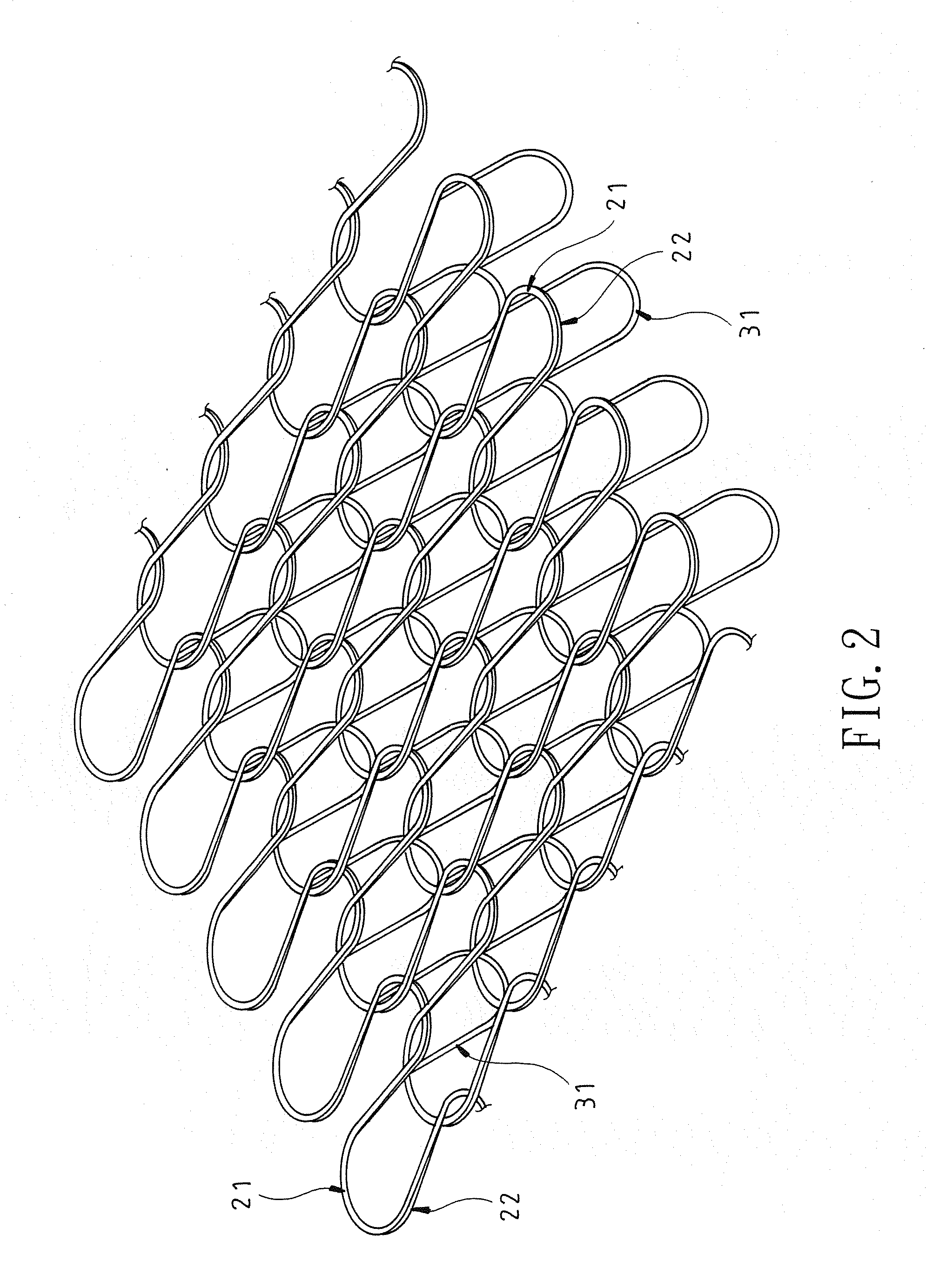

Fabric structure

InactiveUS20130309930A1Improve cohesionGood warmth retentionOrnamental textile articlesWarp knittingYarnSurface layer

A fabric structure includes a surface-layer textile and an inner-layer textile, and the surface-layer textile is a yarn combination formed by stacking two cotton yarns, and the inner-layer textile is a cashmere yarn processed by a plurality of manufacturing procedures such as selecting, washing, carding, dyeing and twisting the yarns, and a circular knitting method is used for knitting the two cotton yarns and the cashmere yarn alternately to foam the fabric structure, and the surface layer is a cotton textile, and the inner layer is a cashmere textile, so that the fabric structure provides a wear-resisting surface layer and a warmth keeping inner layer, prevents fur balls, and features skin-friendly smoothness, softness, and comfort.

Owner:LAI HENRY

Application of three-dimensional (3D) technology to woven pictures

InactiveCN102950962AStrong three-dimensional senseFull textureSpecial artistic techniquesImage data processingComputer Aided DesignGrating

The invention relates to application of three-dimensional (3D) technology to woven pictures, wherein the 3D woven pictures is woven by using a weaving machine at a high speed through combining the digital jacquard weaving CAD (Computer Aided Design) technology with the digital weaving technology, adopting the digital printing principle of rendering the colour by using points and six primary colours, utilizing the weaving jacquard technology and adopting polyester filament yarns with bright colours as materials. The application of the 3D technology to the woven pictures, disclosed by the invention, has the advantages that the organic combination of the digital jacquard weaving CAD technology and the digital weaving technology is realized; the digital printing principle of rendering the colour by using the points and the six primary colours is adopted, picture intersection points are expressed in the form of pixel points and the red and blue colour rendering principle of stereographs is utilized to ensure that the number of the whole intersection points of products is up to 10200 per square centimeter and the number of the colour rendering intersection points is up to 2000 per square centimeter; and therefore, the stereoscopic impression is strong, the texture is full, the style and features of photochromes and painting original works are vividly reproduced and the purpose of enabling flat images to form the grating soluble change stereoscopic effect on fabrics is realized.

Owner:TIANJIN TEXTILE ENG RES INST

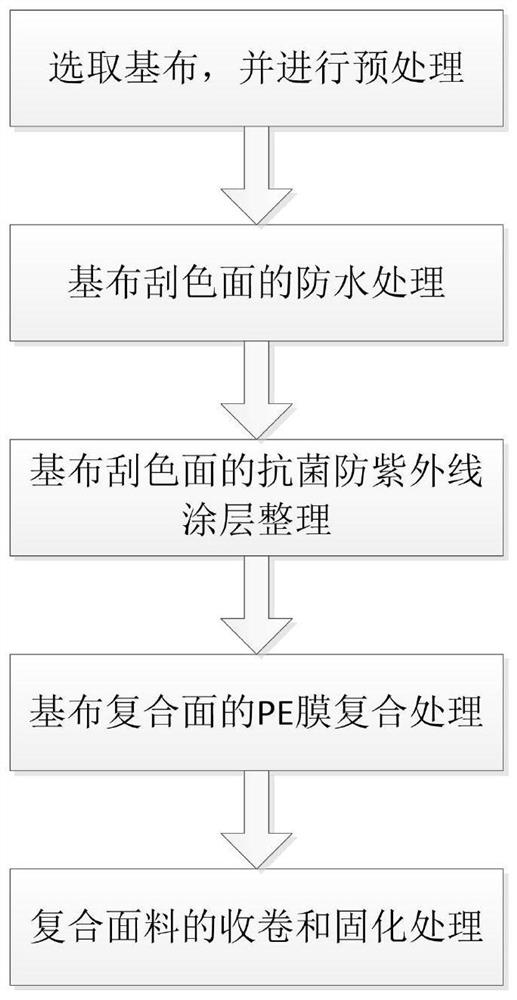

Method for improving yellowing resistance of antibacterial ultraviolet-proof composite curtain fabric

PendingCN114193866AAntibacterialFunctionalLamination ancillary operationsSynthetic resin layered productsPolymer scienceEngineering

The invention discloses a method for improving the yellowing resistance of an antibacterial and ultraviolet-proof composite curtain fabric. The method comprises the following steps: S1, selecting base cloth and performing pretreatment; s2, performing color scraping surface waterproof treatment on the color scraping surface of the base cloth; s3, preparing antibacterial and ultraviolet-proof color paste, blade-coating the color scraping surface of the base cloth with the antibacterial and ultraviolet-proof color paste, and then sequentially performing drying treatment and calendaring treatment on the color scraping surface; s4, bonding a PE film to the composite surface of the base cloth; s5, carrying out rolling and curing treatment on the compounded fabric to obtain a finished product of the antibacterial and ultraviolet-proof type composite curtain fabric. On the premise of ensuring that the composite curtain fabric has antibacterial and ultraviolet-proof properties, the yellowing resistance of the fabric is improved, the use requirement standard of customers is met, and the processing cost and the popularization difficulty of products are reduced.

Owner:CHANGZHOU TAILUN TEXTILE CO LTD

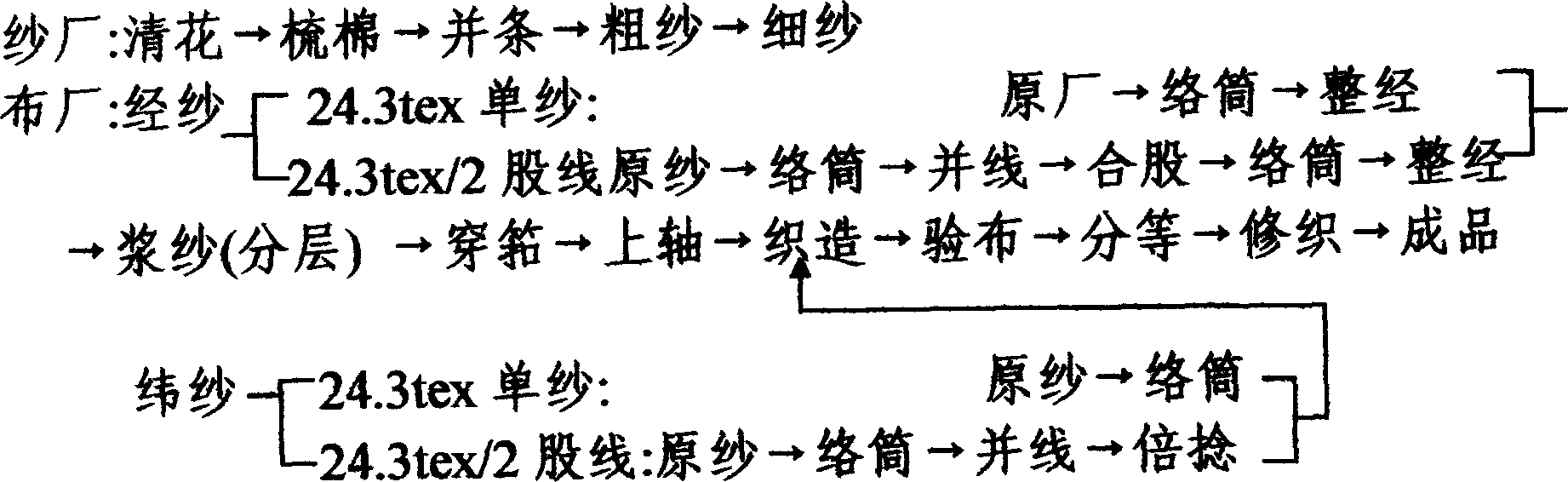

Pure cotton different warp different weft cloth

InactiveCN1534120AFull textureThe three-dimensional effect is clear and obviousWoven fabricsCotton clothSmooth surface

A cotton cloth with different warps and different wefts is made through pre-treating warp through winding, beaming, sizing and reeding, pre-treating weft through winding, and weaving to obtain a 1 / 1 plain cloth. It features that the warp and weft respectively are C24.3 tex and C24.3 tex / 2, the warp density is 260 / 10 cm, the weft density is 222 / 10 cm, and the yarns with different thicknesses are alternatively arranged. Its advantages are clear checkes on cloth, smooth surface and high softness, crisp handle and fullness.

Owner:TIANYI TIANJIN TEXTILE GROUP

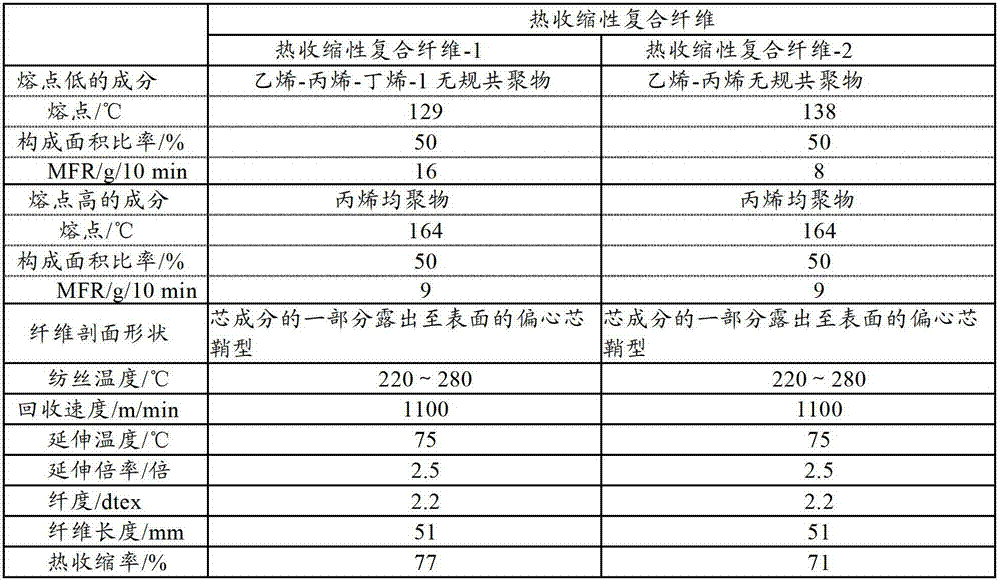

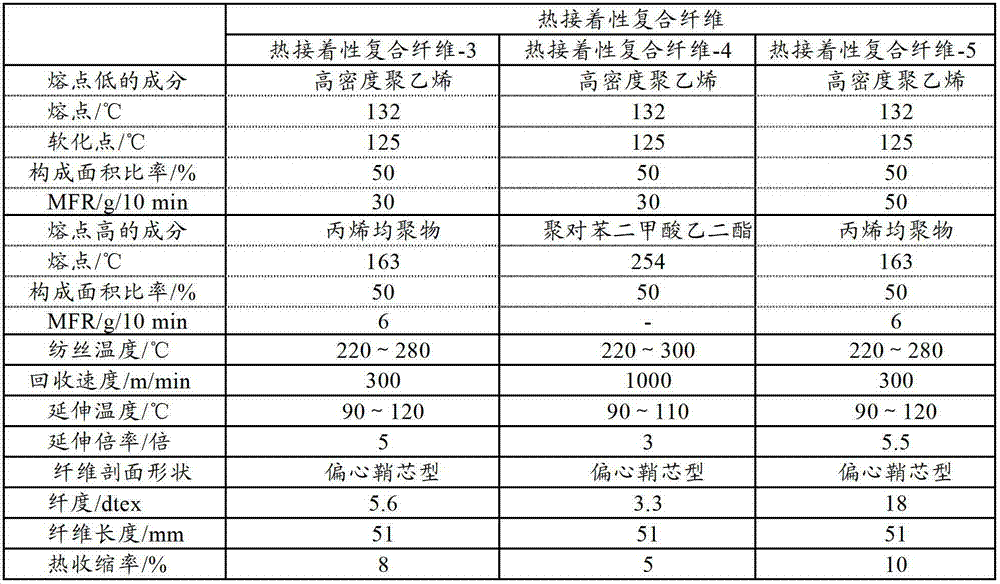

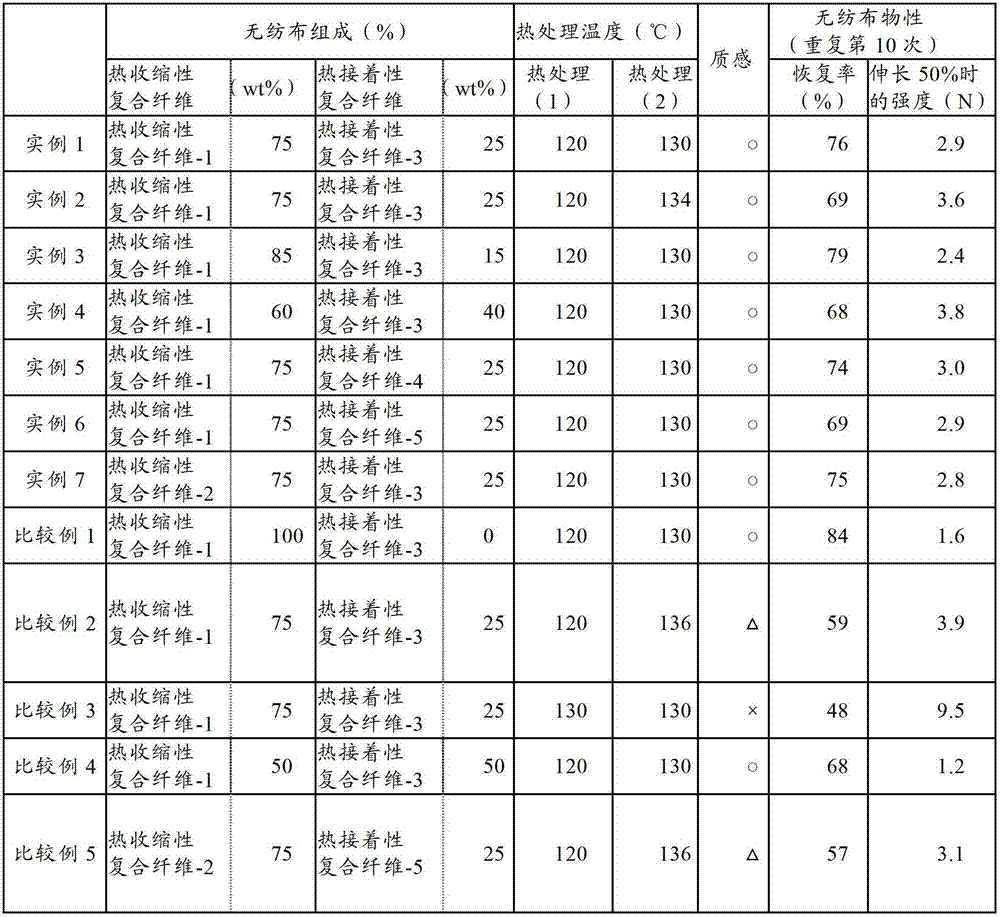

Telescopic non-woven fabric and method of manufacturing the same

ActiveCN102877217AImprove textureFull strengthBreathing masksHeating/cooling textile fabricsNonwoven fabricPolyresin

The invention provides a telescopic non-woven fabric and a method of manufacturing the same. The telescopic non-woven fabric evenly comprises thin plate splines formed by, by mass, 90%-60% of a heat shrinkable composite fiber (A) obtained by using at least two resin components having different melting points, and 10%-40% of a heat bonding composite fiber (B) obtained by using at least two resin components having different melting points. By a specific heat treatment (1), the heat shrinkable composite fiber (A) is shrunk; and by a specific heat treatment (2), the resin component having the lowest melting point is fused to realize the heat bonding between fibers, so that the fibers are jointed integrally.

Owner:JNC CORP +1

Pretreatment method for keeping freshness and tenderness of quick-frozen wild edible mushrooms

InactiveCN103960348AImprove fullnessIncrease the creaminess of the mouthfeelFruit and vegetables preservationBiotechnologyPretreatment method

The invention discloses a pretreatment method for keeping the freshness and tenderness of quick-frozen wild edible mushrooms, belongs to the technical field of edible mushroom processing, and aims at solving the problem of poor taste caused by a fact that much juice in conventional quick-frozen wild edible mushrooms is lost and the mushrooms are rotted after the mushrooms are unfrozen. Before quick-freezing, the wild edible mushrooms are impregnated into a dextrin solution in vacuum; the fullness and the fine taste of mushroom bodies are increased by adding micromolecule starch hydrolysis products into the mushroom bodies, so that the problem of poor taste caused by the fact that much juice in the conventional quick-frozen wild edible mushrooms is lost and the mushrooms are rotted after the mushrooms are unfrozen is obviously relieved.

Owner:LIJIANG ZHONGYUAN GREEN FOOD

Jun porcelain bluish white glaze and preparation method thereof

The invention discloses Jun porcelain bluish white glaze and a preparation method thereof. The Jun porcelain bluish white glaze is prepared from the following raw materials in parts by weight: 43 parts to 48 parts of melilite, 13 parts to 19 parts of calcite, 15 parts to 21 parts of quartz, 2 parts to 3 parts of tin oxide, 2.5 parts to 3.5 parts of fired talc, 0.9 part to 1.1 parts of zirconium silicate, 1.5 parts to 2.5 parts of zinc oxide, and 1.5 parts to 2.5 parts of tourmaline. The preparation method of the Jun porcelain bluish white glaze comprises the following steps: (1) adding water into the raw materials and mixing; carrying out ball milling to obtain glaze slurry; (2) glazing; (3) firing at firing temperature of 1280 to 1300 DEG C. The Jun porcelain bluish white glaze and the preparation method of the Jun porcelain bluish white glaze disclosed by the invention have the beneficial effects that by adding chemical raw materials including tin oxide, zinc oxide and zirconium silicate into a conventional raw material, so that the finished product rate is increased from originally being less than 50 percent to 80 percent or above; by adding the tourmaline, the product can slowly release negative ions to surrounding environment, so that certain antibacterial and deodorizing effects are achieved.

Owner:燕俊峰

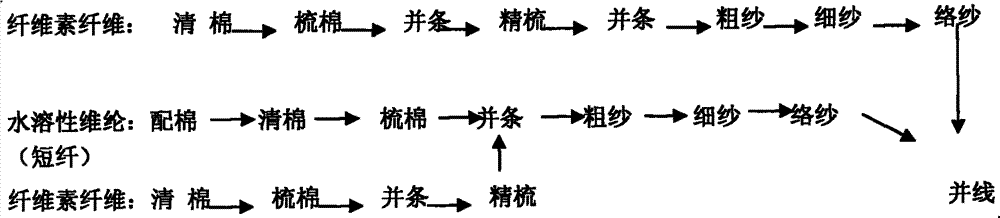

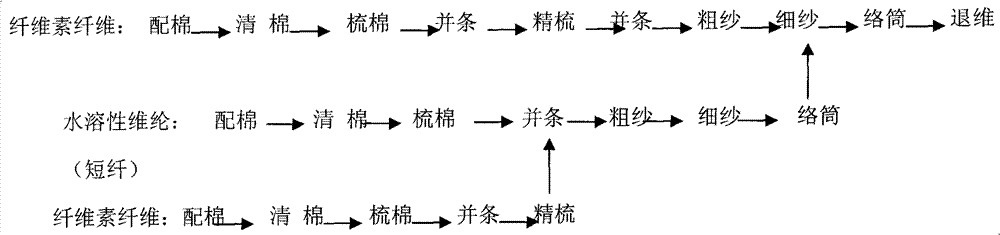

Energy-saving and low-pollution method for processing soft yarns

The invention discloses an energy-saving and low-pollution method for processing soft yarns. In the method, yarns serving as a main component and yarns containing a water-soluble vinylon component are compounded and then subjected to PVA-removing treatment to obtain a product. The method has the advantages that: the amount of the used water-soluble fiber is small; and pollution discharge is reduced and the cost is low.

Owner:JIANGSU NANTONG SECOND COTTON

Humanoid hair functional protein fiber and wet-spinning method thereof

PendingCN110453306AFull textureGood drapabilityArtificial thread manufacturing machinesConjugated cellulose/protein artificial filamentsAcrylonitrileHair streams

The invention relates to acrylic fibers and a production method, in particular to humanoid hair functional protein fiber and a wet-spinning method thereof. A spinning solution for wet spinning is prepared from protein powder which is obtained by processing animal hair and / or human hair and an acrylonitrile copolymer, wherein the acrylonitrile copolymer is prepared through copolymerization of, by weight, 35-55 wt% of acrylonitrile, 35-45 wt% of vinylidene chloride, 6-8 wt% of allyl monomers containing sulfonic acid groups and 3.5-6.0 wt% of olefine acid ester. Since protein hair produced by means of the method has handfeel and properties extremely similar to those of human hair, and the humanoid hair functional protein fiber is very suitable for manufacturing top-grade wig products.

Owner:HENAN REBECCA HAIR PRODS TNC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com