Modified master batch granulating system and technology capable of degrading express waybill labeling paper

A technology for modifying masterbatch and standard paper, which is applied in the field of granulation equipment, can solve the problems of easy breaking of strips, low granulation efficiency, slipping granulation efficiency, etc., and achieves stable process operation, high efficiency and high quality. , the effect of high molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

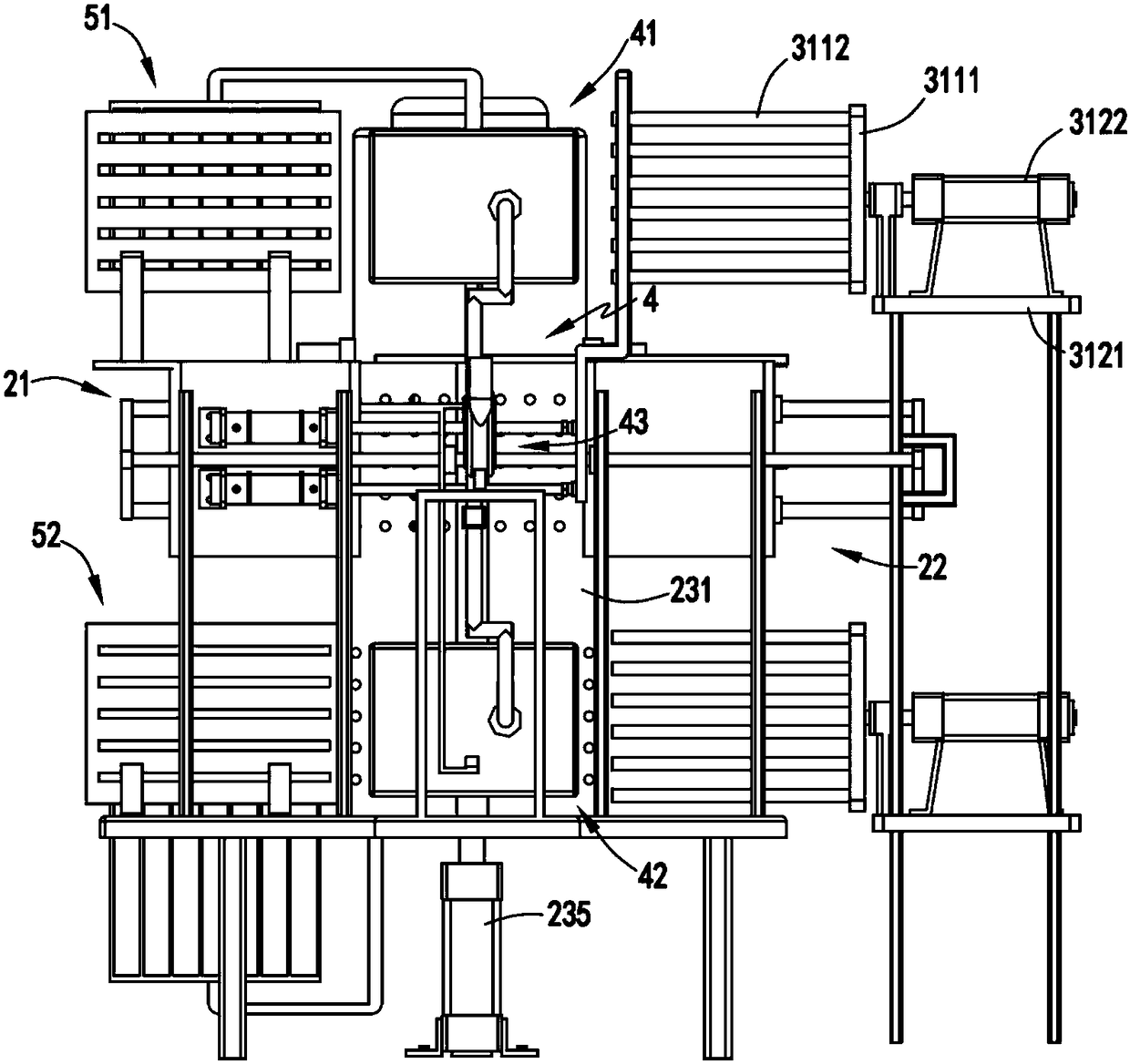

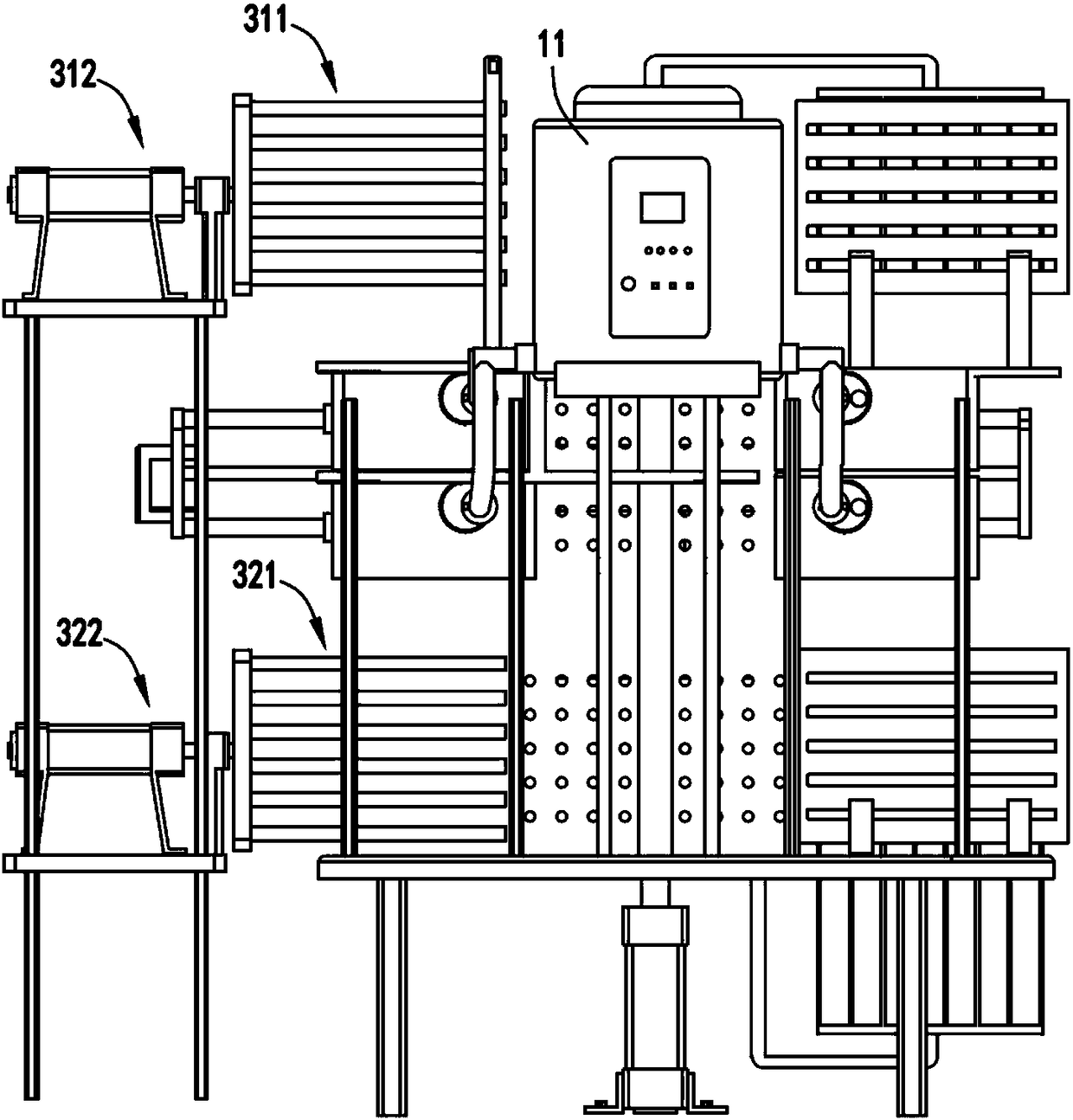

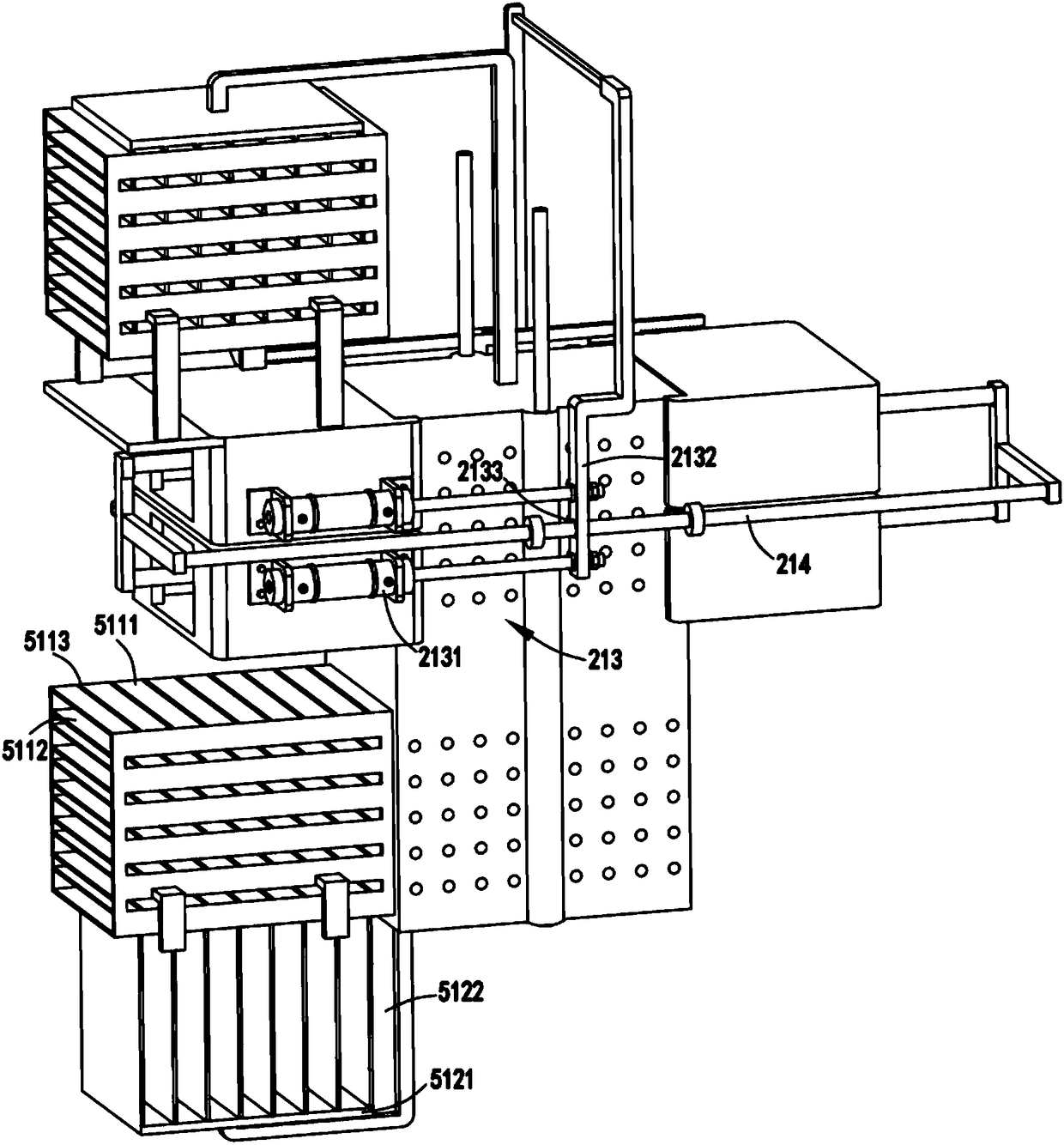

[0060] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, the modified masterbatch granulation system for degradable express bill labeling paper, including

[0061] A feeding device 1, the feeding device 1 includes a melting furnace 11 and a feeding mechanism 12 for controlling the backward supply of molten state raw materials in the melting furnace 11;

[0062] Forming device 2, described forming device 2 is arranged on the feeding device 1 side, and this forming device 2 comprises a first filling mechanism 21, a second filling mechanism 22 and a forming mechanism 23, and the first filling mechanism 21 and the second filling mechanism Forming channel 10 is formed between mechanism 22, and described forming mechanism 23 moves up and down along forming channel 10, and this forming mechanism 23 comprises forming die 231, and described forming die 231 compris...

Embodiment 2

[0085] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the feeding mechanism 12 includes an opening and closing member a121 arranged at the opening and closing passage 15 of the feeding pipe a13, an opening and closing passage 15 arranged at the feeding pipe b14 The opening and closing part b122 at and the driving part 123 for driving the opening and closing part a121 and the opening and closing part b122 to rotate synchronously.

[0086] Further, the opening and closing part a121 and the opening and closing part b122...

Embodiment 3

[0090] Such as Figure 13 As shown, the modified masterbatch granulation process for degradable courier labeling paper includes the following production steps:

[0091] a. Feeding process, the mixed raw materials are added into the melting furnace 11 for melting, and the molten material is transported backward through the feeding mechanism 12;

[0092] b. Forming process, the first filling mechanism 21 and the second filling mechanism 22 located at the forming station move back and forth alternately to squeeze the material in the corresponding stuffing box 211 into the corresponding forming mold 231 and in the process Alternately control the opening or closing of the feeding pipe a13 and the feeding pipe b14 of the feeding mechanism 12;

[0093] c. Cooling process, the forming mold 231 filled with material in step b is transferred to the corresponding discharge station, and the material in the forming mold 231 is cooled during the transfer process and after reaching the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com