Process for treating residual ammonia water of coking

A technology of ammonia water and processing technology, which is applied in the field of ammonia distillation, can solve the problems of equipment corrosion environment, large steam consumption, and many impurities in ammonia water, and achieve the effects of high product quality, good economic benefits, and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

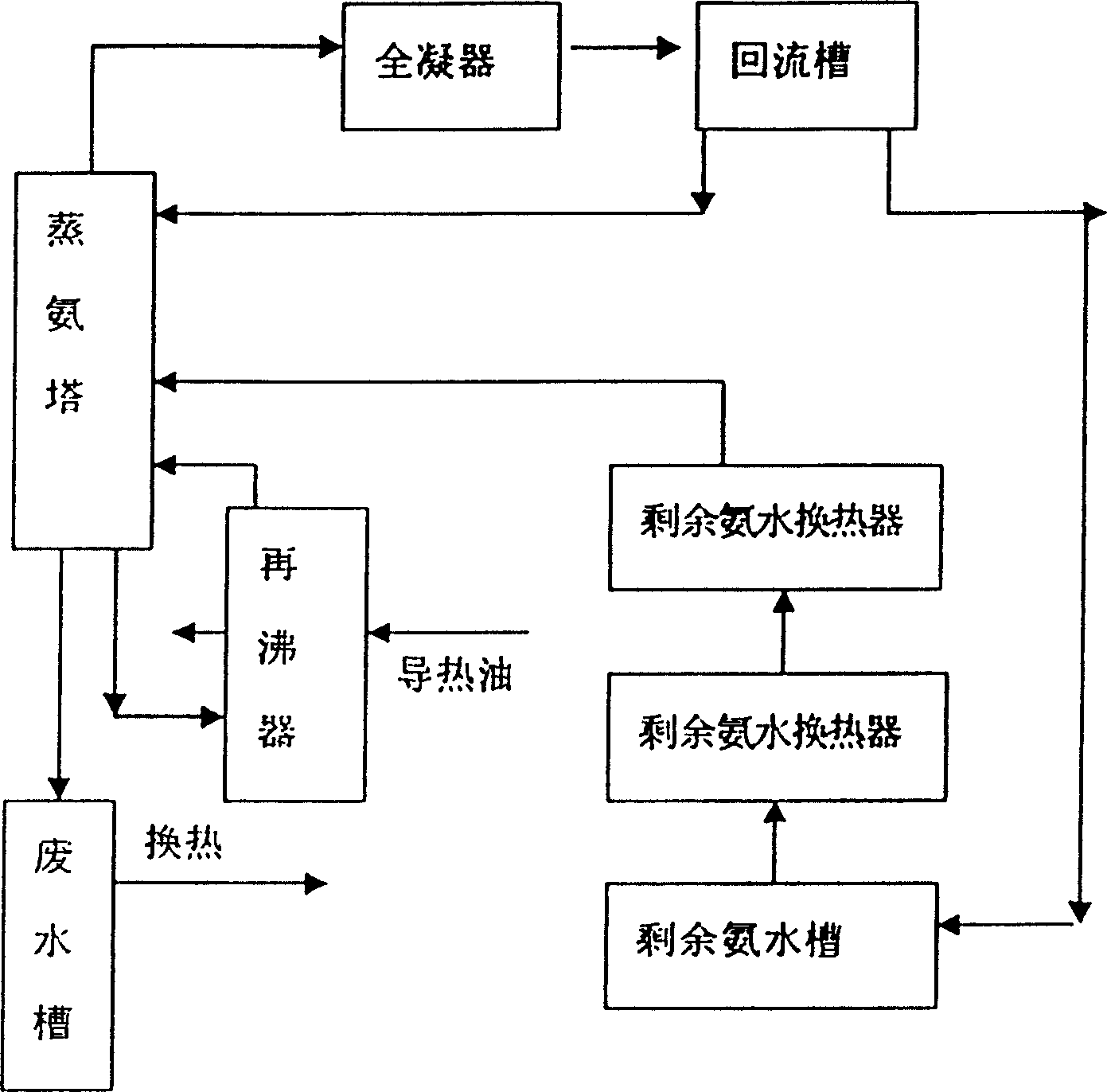

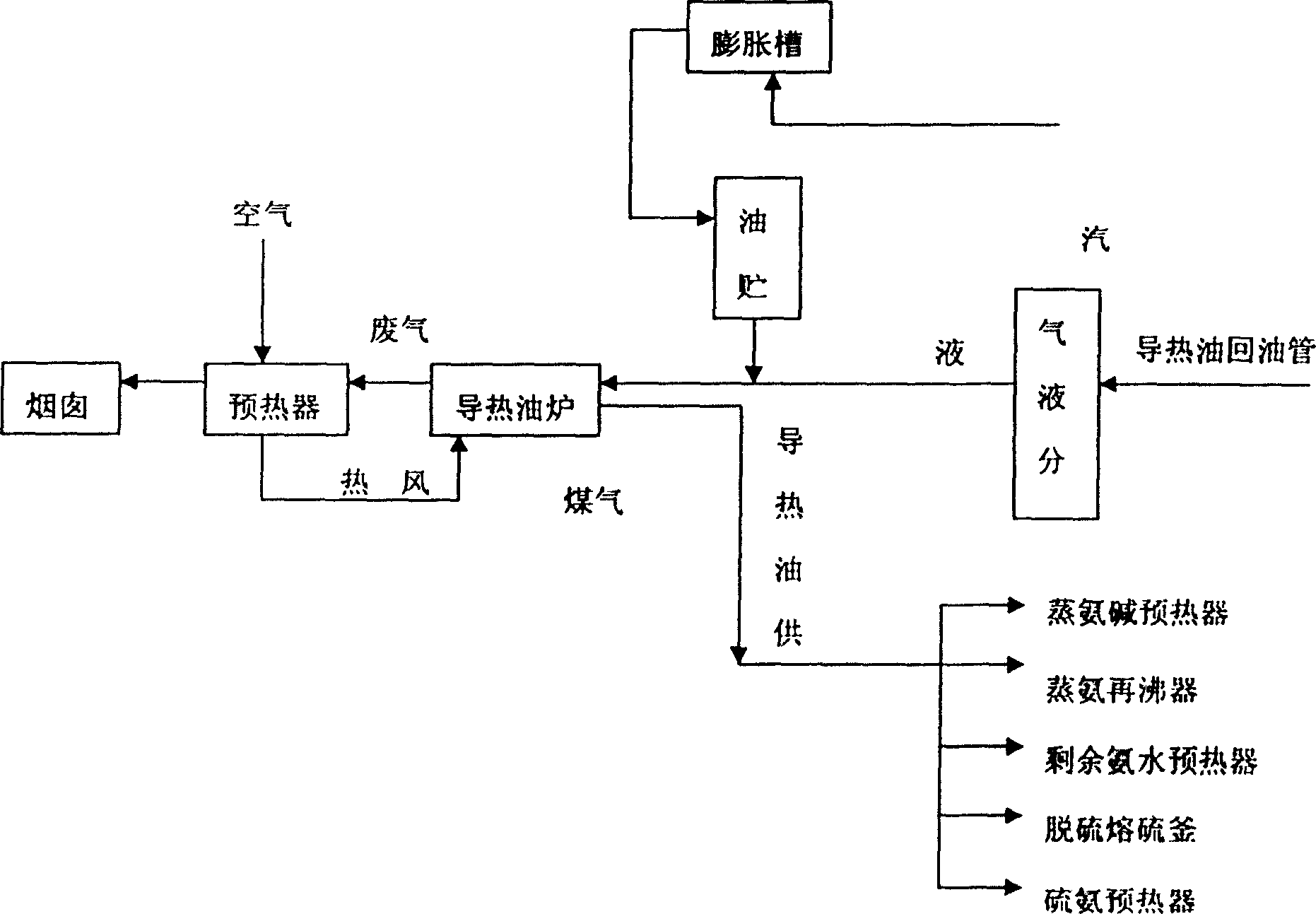

[0013] In the process design of the system, the PRO-II software of SIMSCI Company of the United States is used for system simulation and optimization, and the process conditions are determined, including the organizational form of the process, the theoretical plate number and feed position of the rectification column, the temperature, pressure and concentration distribution in the column, The reflux ratio and output, heat exchanger, reboiler and condenser load, etc. are simulated and calculated by using PRO-II software for different process methods, and the traditional simple distillation process is reformed to make the ammonia distillation process a strict process. The advanced chemical distillation unit achieves strict material balance and heat balance. In the implementation of the equipment, inclined-hole trays were used as internal components, and heat transfer oil was used as the heating medium of the reboiler. Some improvements were also made in equipment materials, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com