Bi-dimensional pipe interface angle cutting control device

A technology of pipeline interface and control device, applied in welding/cutting auxiliary equipment, auxiliary device, program control and other directions, can solve the problems of low work efficiency, poor connection quality, pipeline leakage and maintenance, etc., to improve work efficiency and work efficiency. Accuracy, compact device structure, high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

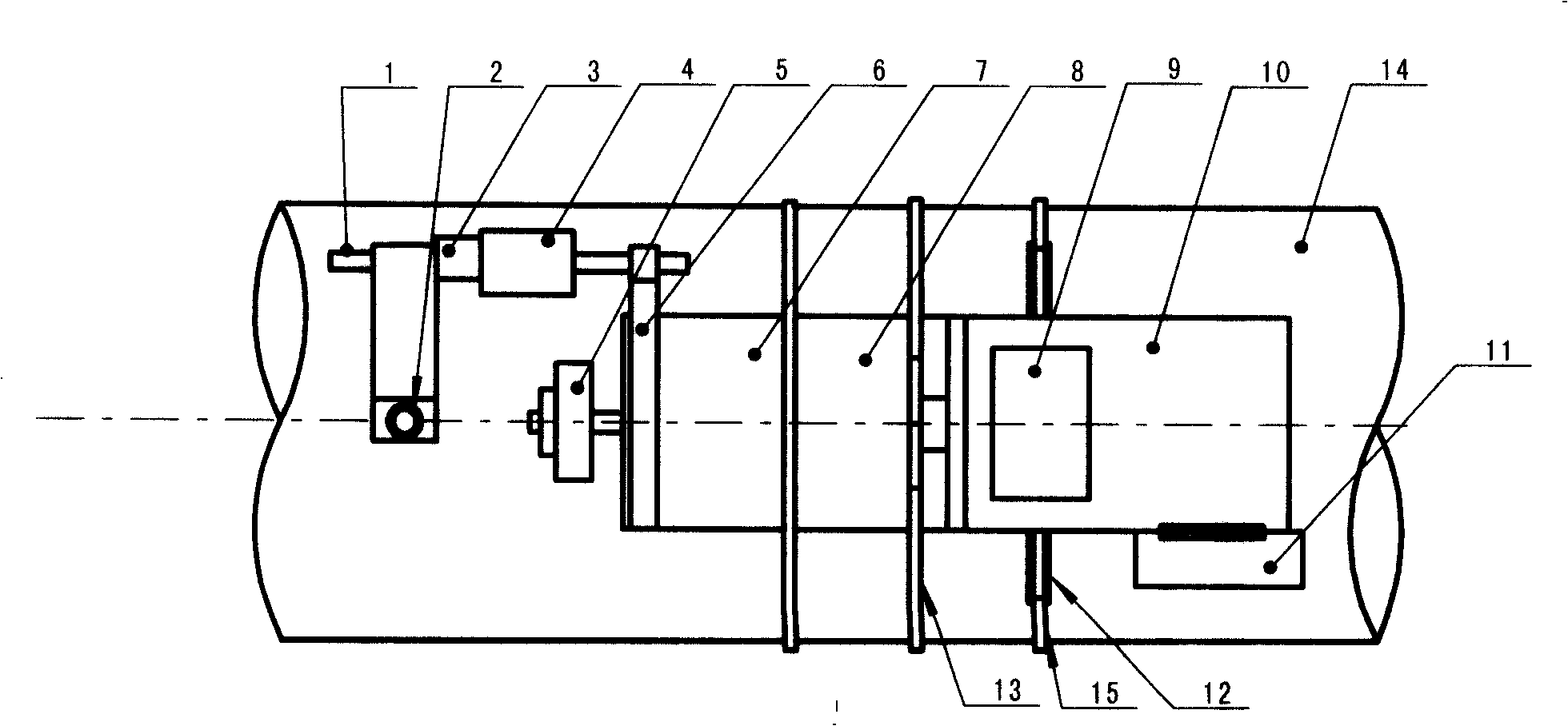

[0020] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

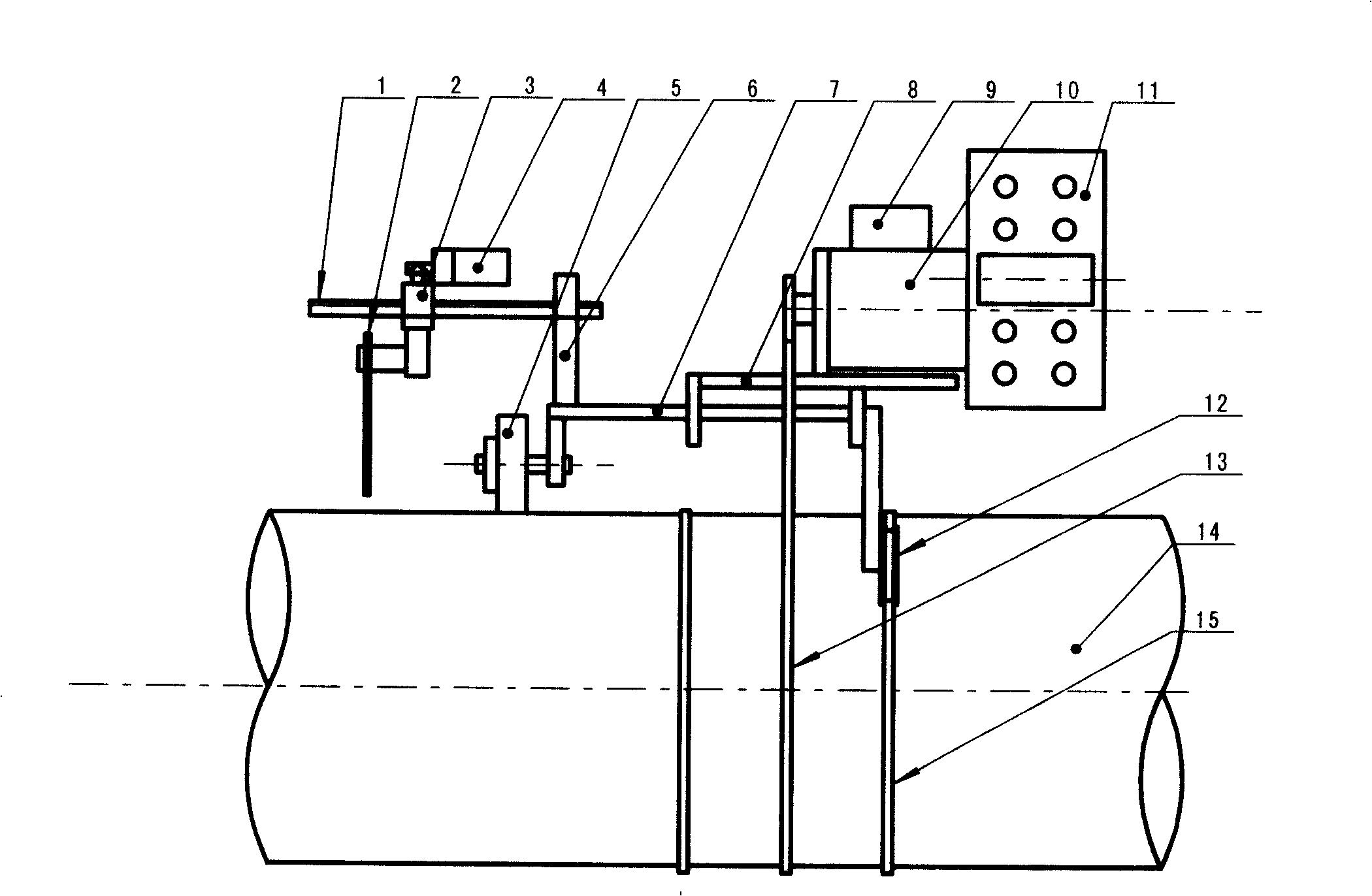

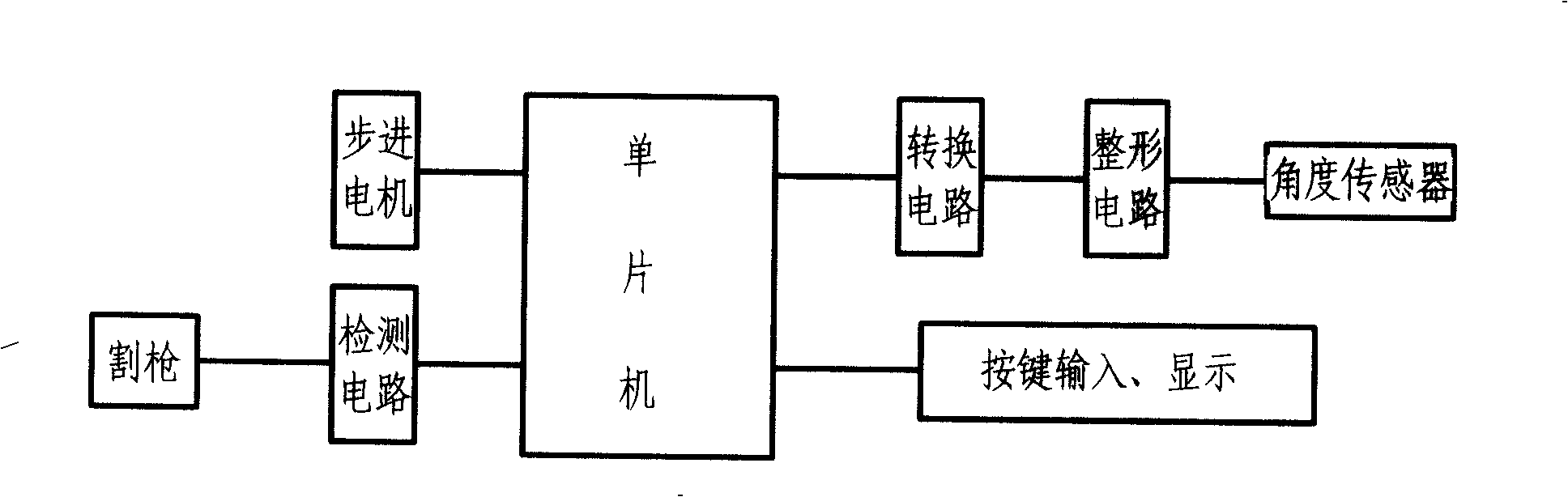

[0021] The two-dimensional pipeline interface angle cutting control device is installed on the pipeline 14 to be cut, and the whole mechanism is composed of a running mechanism and a rack running mechanism. First, the mechanical operating mechanism of the control device is described:

[0022] Running mechanism: there is a walking trolley 7 running on the pipeline, and the walking trolley runs on the pipeline through a walking wheel 5 at the front and two guide wheels 12 at the rear. Wherein the guide wheel walks on the flexible track 15 that is set in advance on the pipeline, to ensure the circular walking accuracy of the walking trolley. On the walking trolley, a walking motor 10 is fixedly installed through its fixed mounting plate 8, and an output shaft of the reducer of the walking motor (installed integrally with the walking motor, without a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com