Patents

Literature

254results about How to "Accurate fault location" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

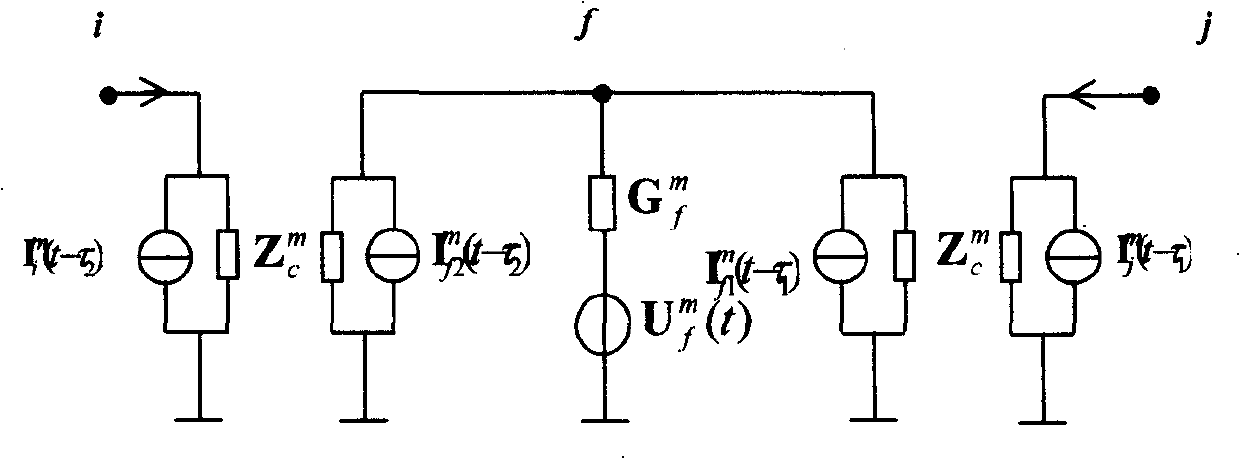

Cable-aerial mixed line fault travelling wave ranging method

InactiveCN101299538AMake up for the influence of frequency-dependent characteristicsAccurately determine the polarity of reflected wavesEmergency protective circuit arrangementsFault locationElectric power systemReflected waves

The invention relates to a cable-overhead joint line failure travelling wave range count method, particularly performing the effective fusion based on the failure range count method of the fundamental frequency and the travelling wave aiming at the particularity and the complexity of the cable joint line, belonging to the technical field of the power system relay protection. The invention judges the failure generating places firstly based on the cable-overhead junction derivated through the electric quantity at the two ends of the system attached with the negative sequence net after the failure, then performs the correct range count by the range count method of the single end; on the basis of considering the line zero modulus component couple, through comparing the performance of the current travelling wave line zero modulus component, the performance of each reflected wave is judged, to find out the fault point reflected wave, and then perform the correct range count.

Owner:KUNMING UNIV OF SCI & TECH

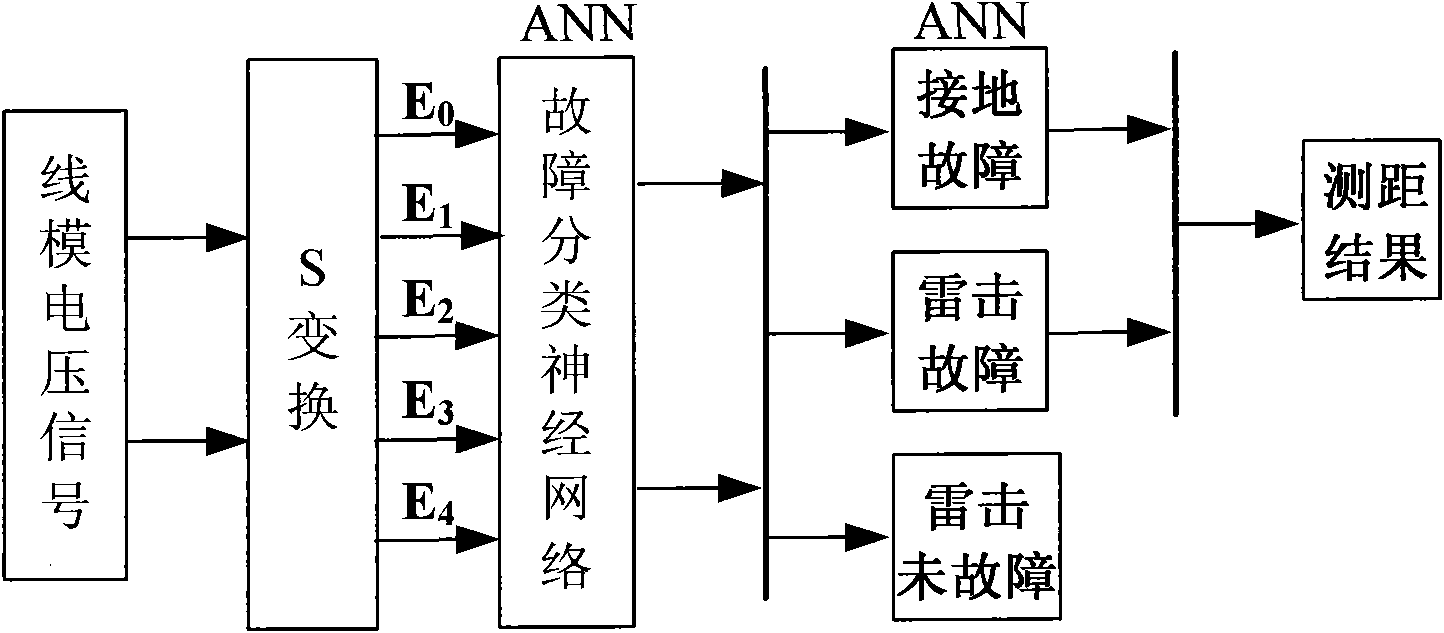

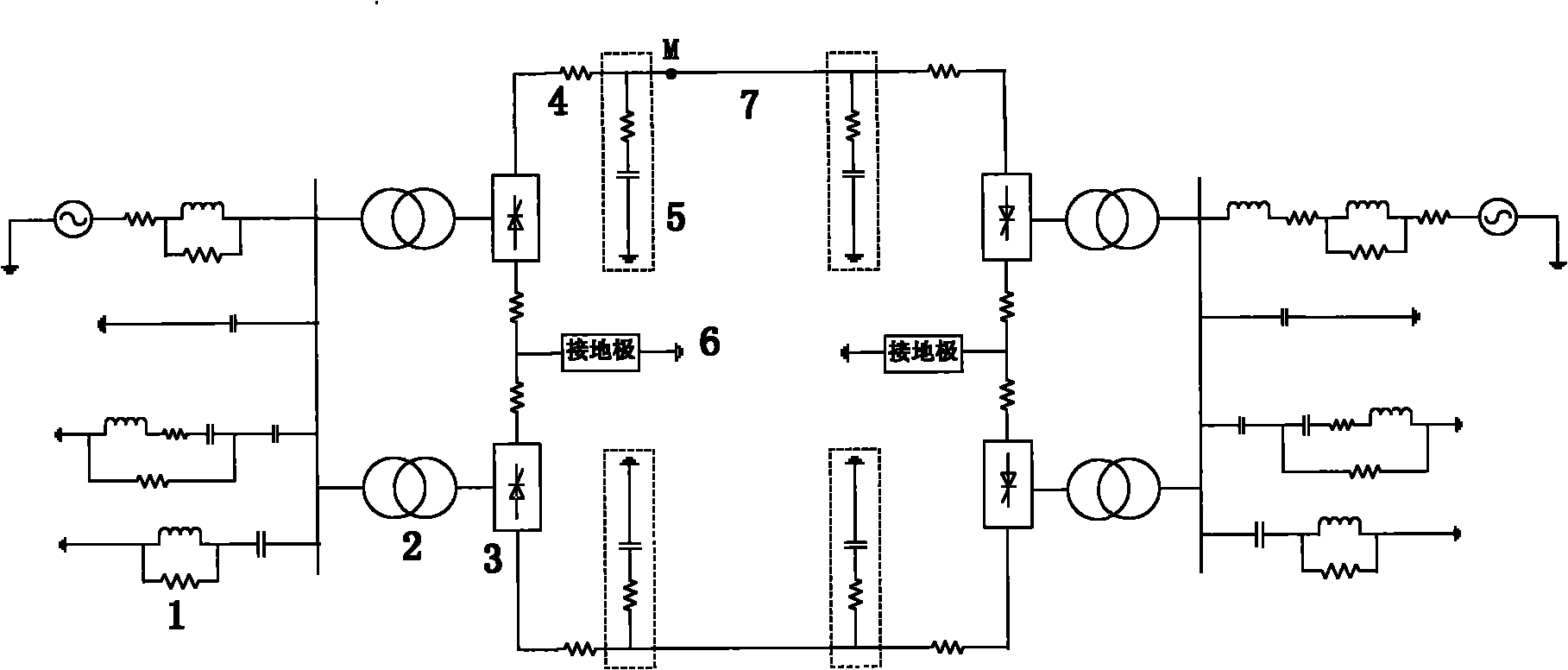

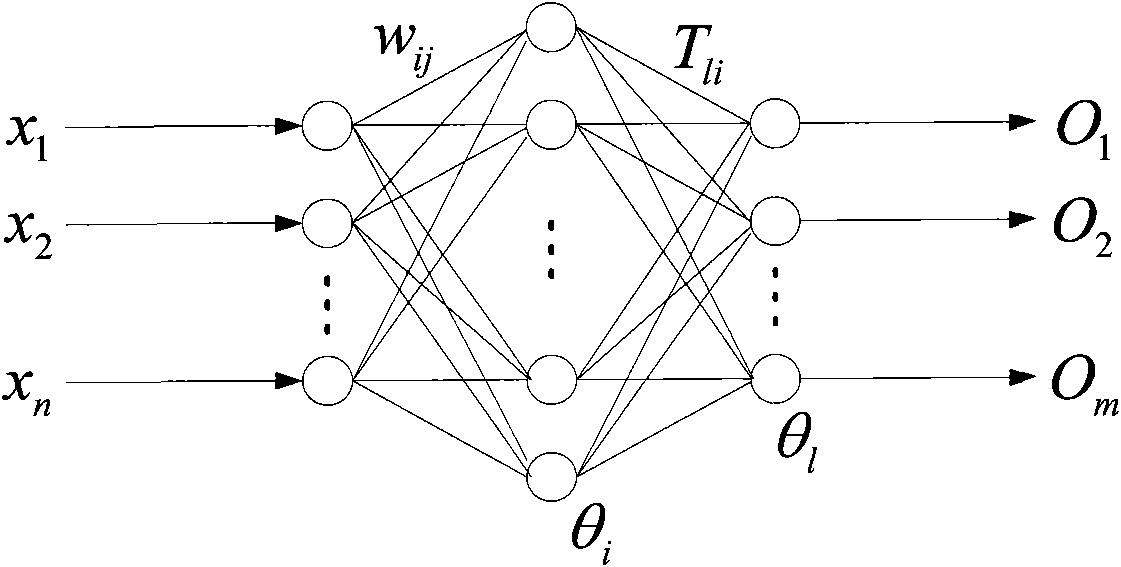

Intelligent fault classification and location method for ultra-high voltage direct current transmission line

ActiveCN101975910ALower requirementPracticalFault locationNeural learning methodsUltra high voltageElectric power system

The invention discloses an intelligent fault classification and location method for an ultra-high voltage direct current transmission line, and belongs to the technical field of relay protection of power systems. The method comprises the following steps of: classifying fault data by using a neural network by adopting a layered and distributed neural network model; distinguishing fault types; sending the classified data into different neural networks respectively for performing fault location; when the direct current transmission line has a fault and a sampling frequency is 10 kHz, selecting a discrete line mode voltage signal which has the sampling sequence length of 100 after the fault and performing S-transform, wherein a transform result is a complex time-frequency matrix of 51*100; solving the modulus of each element in the complex matrix to obtain transient energy distribution of the line mode voltage at all frequencies; selecting first five energy spectrums as sample properties; selecting a transfer function and a learning rule; setting proper neural network parameters for constructing a BP network model; and performing fault classification and fault location. A large number of simulation results show that the method has a good effect.

Owner:KUNMING UNIV OF SCI & TECH

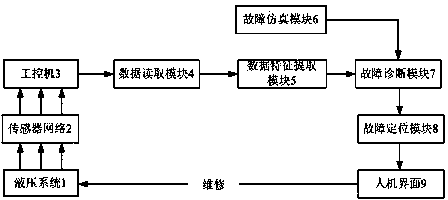

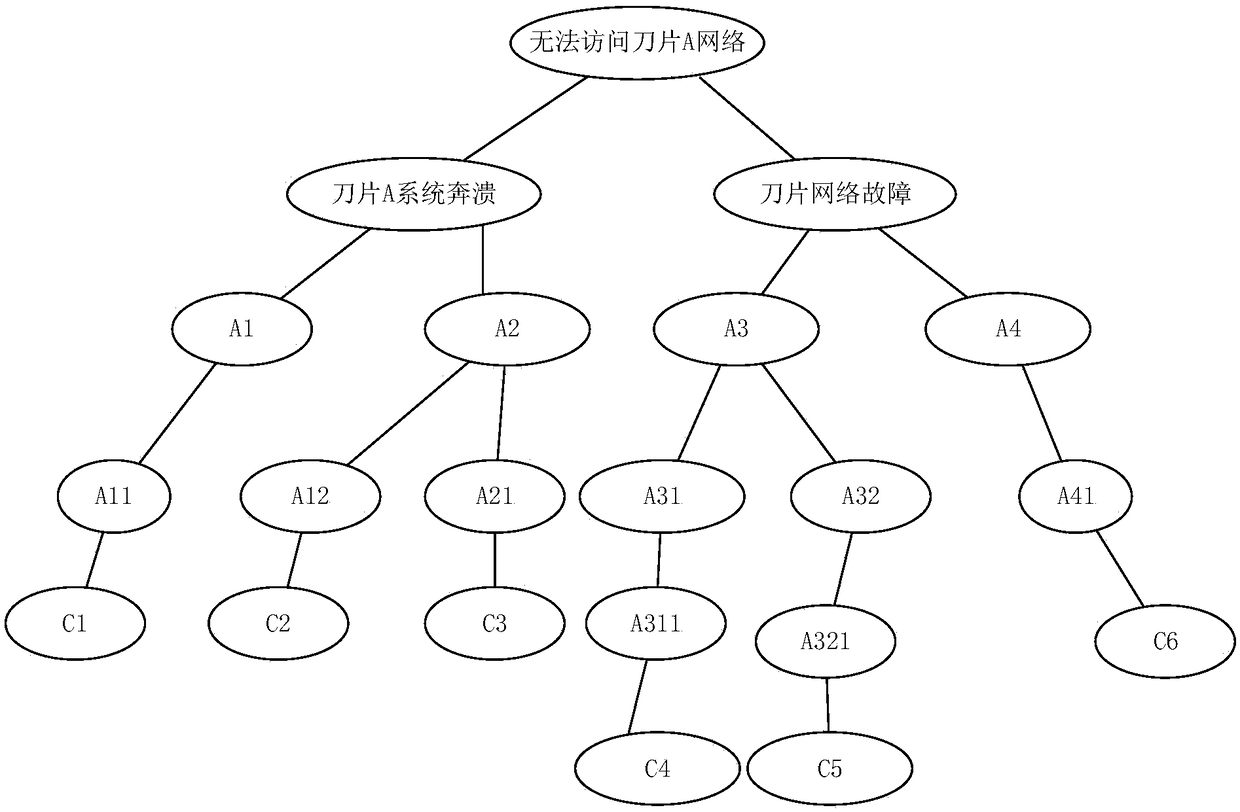

Online fault diagnosis method for hydraulic system

InactiveCN104061208AGuaranteed accuracyAccurate fault locationFluid-pressure actuator testingHuman–machine interfaceFeature extraction

The invention discloses an online fault diagnosis method for a hydraulic system. A sensor network (2) and an industrial personal computer (3) are used for acquiring a signal of a key position of the hydraulic system (1). Meanwhile, a system model is established for the hydraulic system (1), and fault injection simulation is carried out to obtain a simulation result serving as fault simulation data in a fault simulation module (6). The key characteristic information of the data provided by a data reading module (4) is found by a data characteristic extraction module (5), and fault diagnosis is carried out through a fault diagnosis module (7). A fault positioning module (8) can be used for positioning the fault according to fault information obtained by the fault diagnosis module (7), and providing a fault diagnosis result, fault causes, a detection flow and fault elimination measures, which are all displayed on a human-computer interface (9). According to the method, the false fault alarm rate is reduced, the capacities such as early warning are improved, and the method plays an important role in improvement of the reliability of the hydraulic system of product equipment.

Owner:BEIJING MECHANICAL EQUIP INST

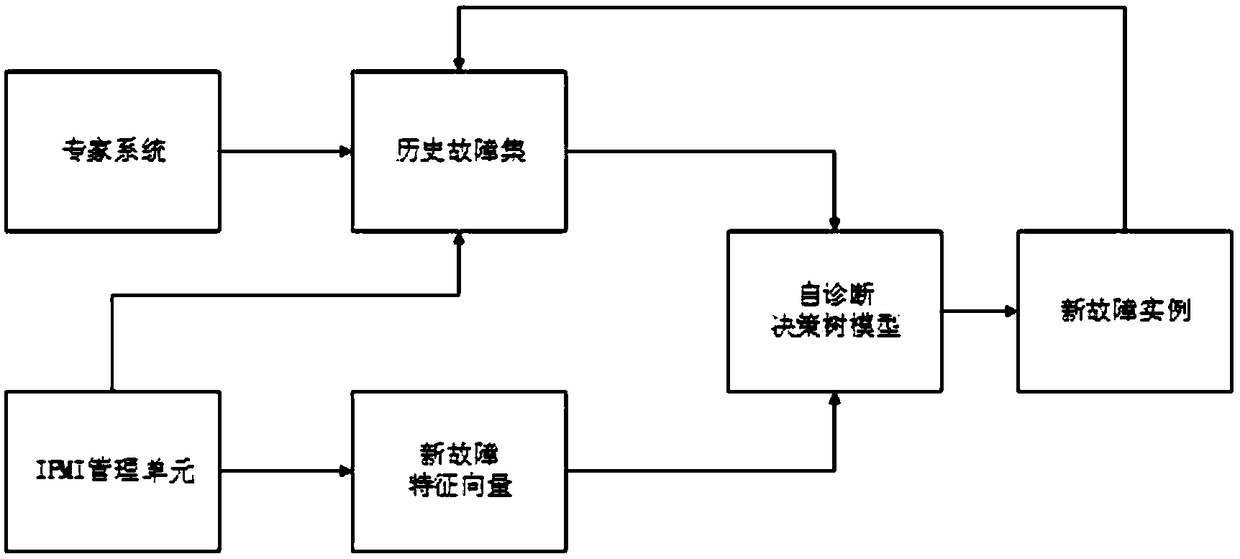

Server fault automatic detection system and detection method based on decision tree

ActiveCN109218114AFacilitate division of labor and cooperationImprove readabilityData switching networksFeature vectorManagement unit

The invention discloses a server fault automatic detection system and a detection method based on a decision tree, which combines an expert system and an IPMI management unit to generate a historicaldata set. The server running state data, i.e. Abnormal data stream, is obtained by IPMI management unit. According to the abnormal data stream, the new fault feature vector is extracted, and the new feature vector and the fault cause relation pair are formed into a fault data set, and the fault data set is trained into a self-diagnosing decision tree model. When the server fails while running, thecorresponding fault feature vectors are extracted, the fault types are automatically judged by the self-diagnostic decision tree model, After the fault is cleared, the fault feature vector and the fault cause relation are updated and the self-diagnosing fault tree model is updated. Therefore, the fault diagnosis system will be more accurate and reliable with the improvement of the history fault set.

Owner:XIAN MICROELECTRONICS TECH INST

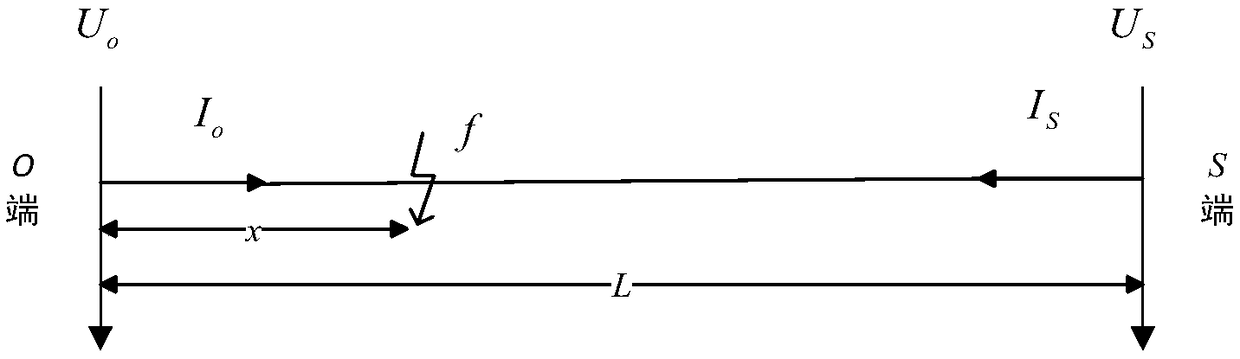

Two-end distance measuring method of transmission line fault under dynamic condition

ActiveCN102081132APrevent agingAvoid environmental problemsFault locationCable fault locationPhasor measurement unit

The invention relates to a two-end distance measuring method of transmission line fault under a dynamic condition, comprising the following steps of: acquiring two-end voltage and current signals through two-end phasor measurement units of the transmission line; then acquiring dynamic positive sequence impedance, admittance, wave impedance and propagation coefficients according to line parameter estimation and a dynamic line parameter method; and finally solving a nonlinear equation related to a fault distance according to the fact that positive sequence voltages derived from two ends to a fault point are equal by applying a Newton iteration method so as to obtain a dynamic distance measuring result of the transmission line fault. The two-end distance measuring method can more effectivelysolve the problem of line parameter and fault distance estimation under the dynamic condition and has accurate and reliable fault distance measuring result.

Owner:SOUTHWEST JIAOTONG UNIV

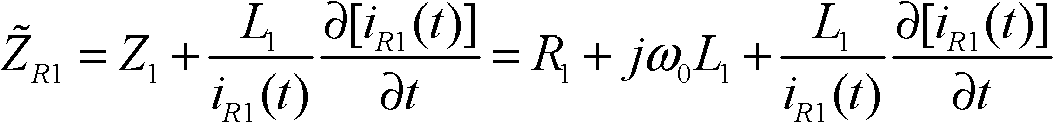

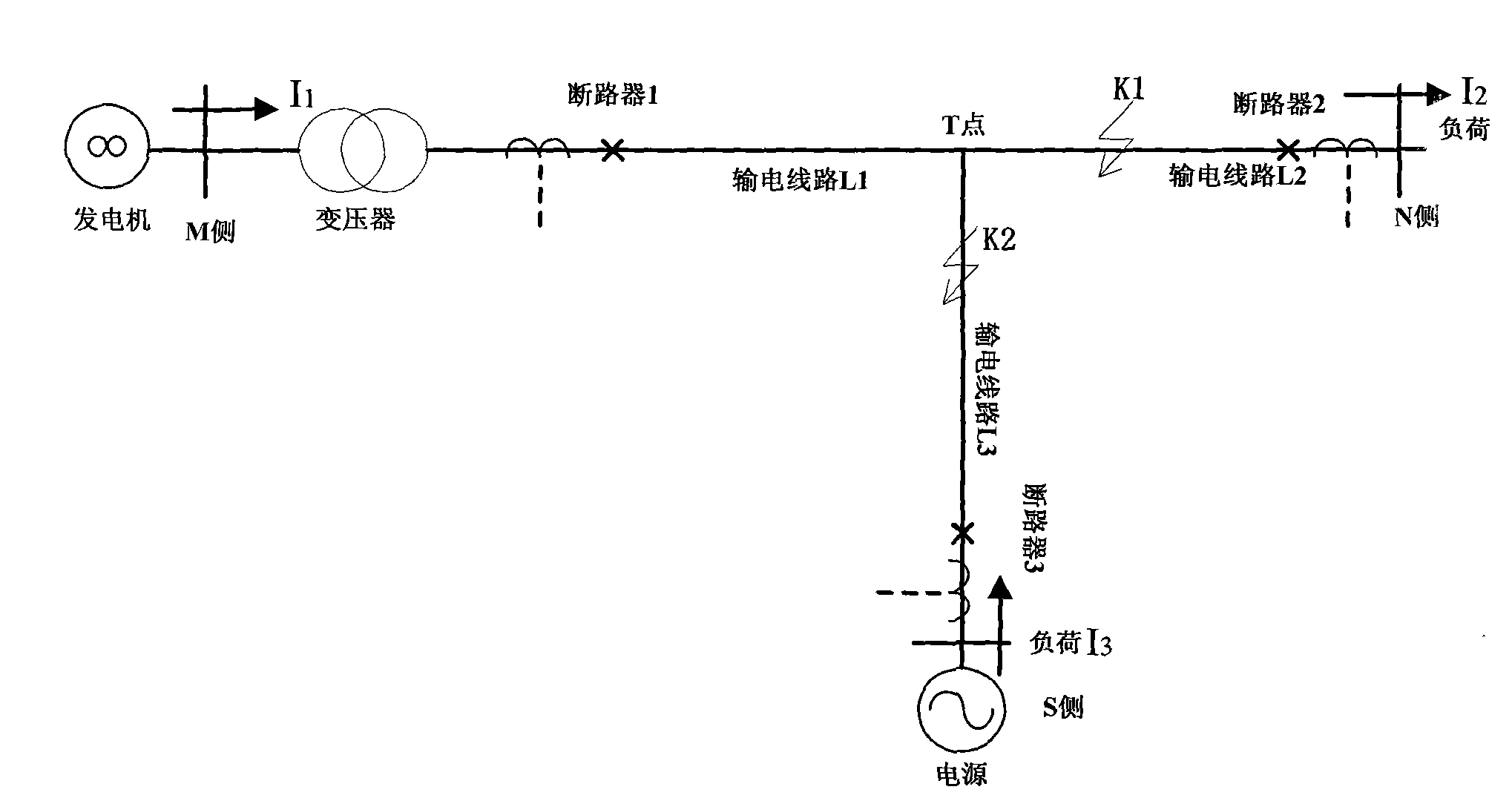

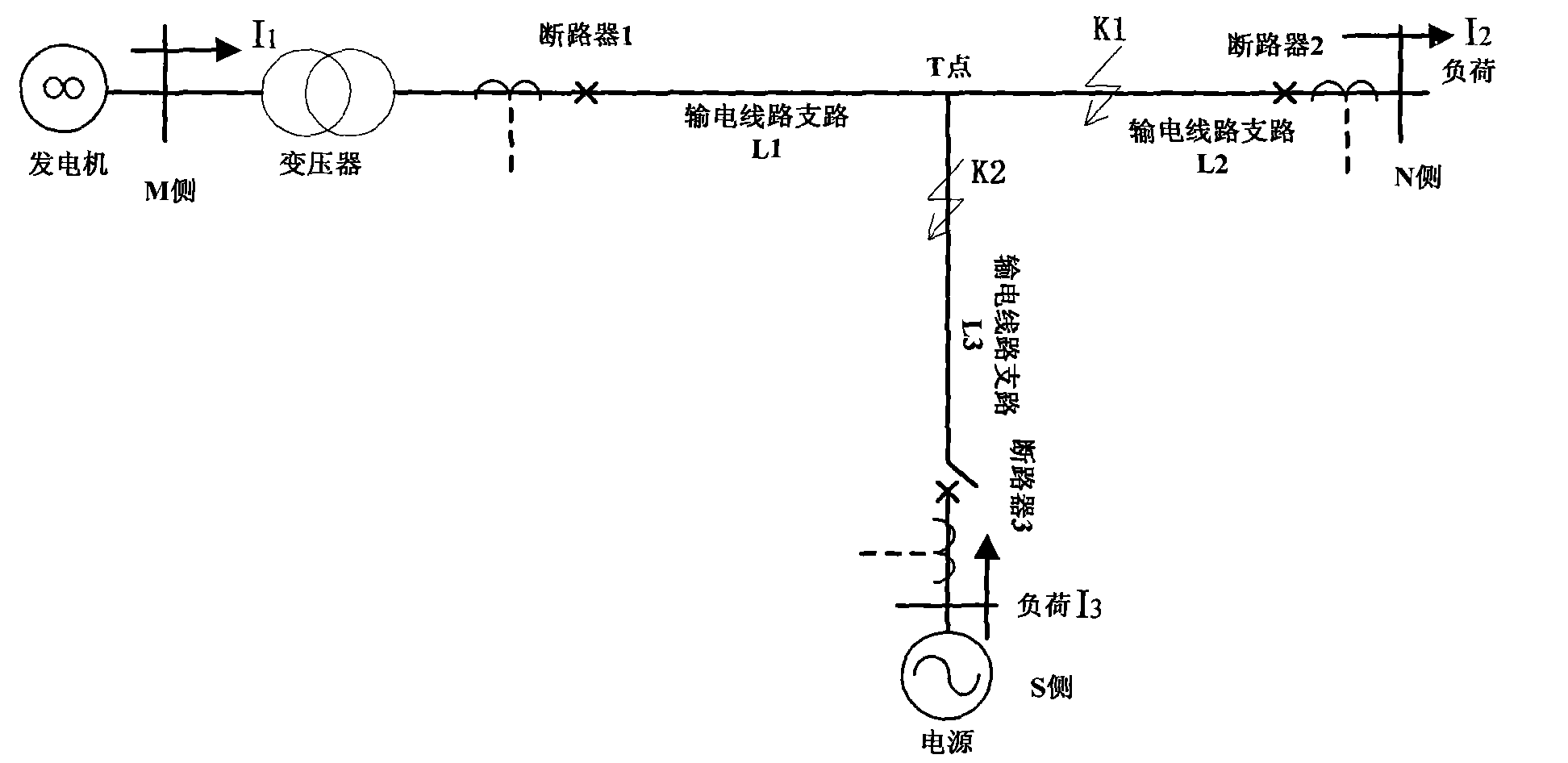

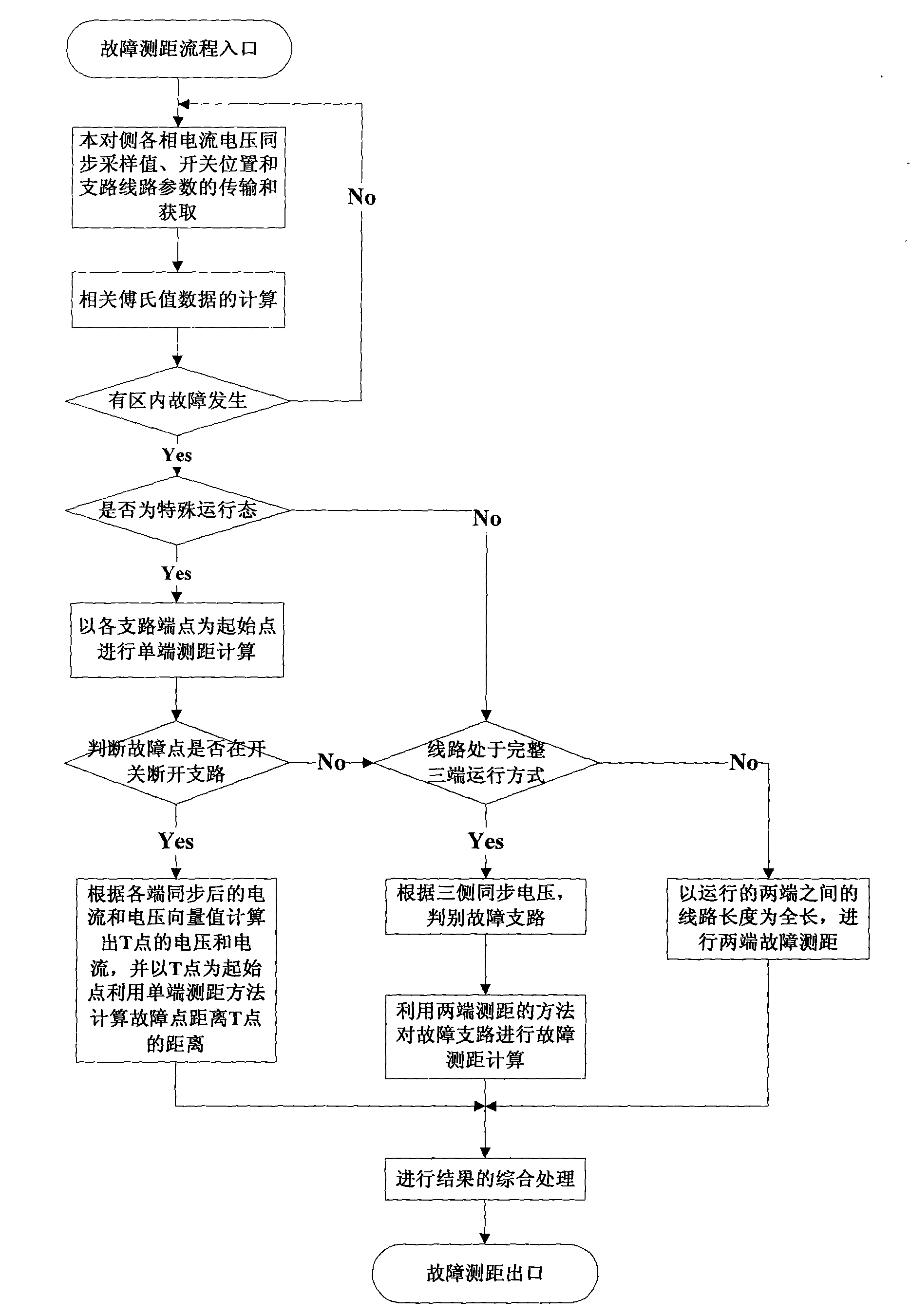

Fault localization method suitable for three-terminal T connection electric transmission line

ActiveCN101666847AMeet fault location requirementsAccurate fault locationFault locationInformation technology support systemCable fault locationReliability engineering

The invention discloses a fault localization method suitable for a three-terminal T connection electric transmission line, comprising the following steps: firstly, judging the running state of the three-terminal electric transmission line: if the line is in a three-terminal running mode, firstly identifying a fault branch line, and calculating the fault distance according to the electric quantityof both ends of a T connection point and the endpoint of the fault branch line; if the line is in a two-terminal running mode or one side branch line is in a three-terminal running mode in a hot standby state, firstly determining if a fault point is at a switch cut-off branch line or not, if so, adopting a single-terminal localization method to calculate the distance from the T connection point tothe fault point, thereby obtaining the fault distance from the endpoint of the branch line to the fault point; but if the fault point is not at the switch cut-off branch line, respectively carrying out fault localization calculation under the two-terminal running mode or the three-terminal running mode. The invention provides a fault localization method before / after converting the running mode ofthe three-terminal electric transmission line and a fault localization method when the line is in the two-terminal running mode or one side branch line is in the three-terminal running mode under thehot standby condition.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

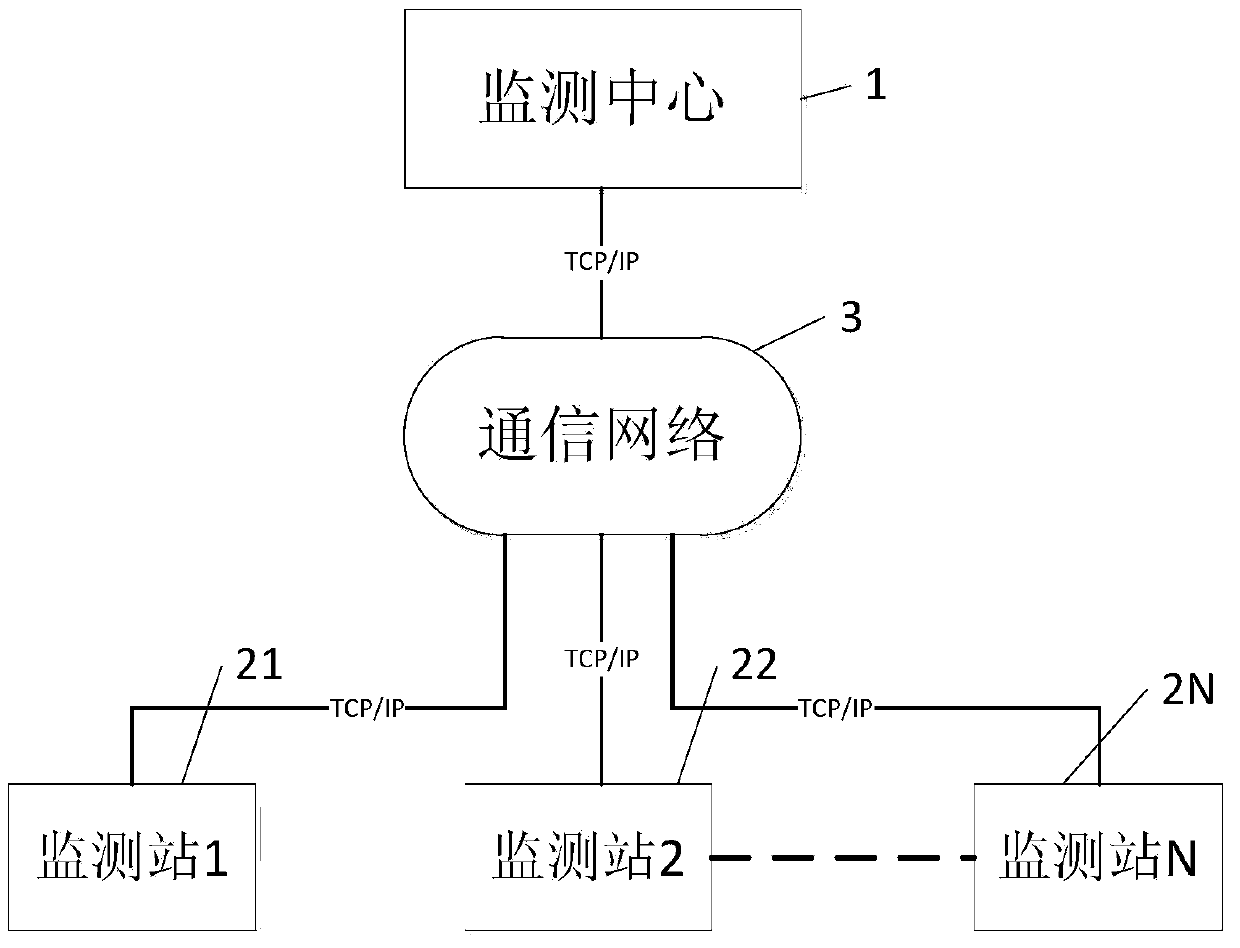

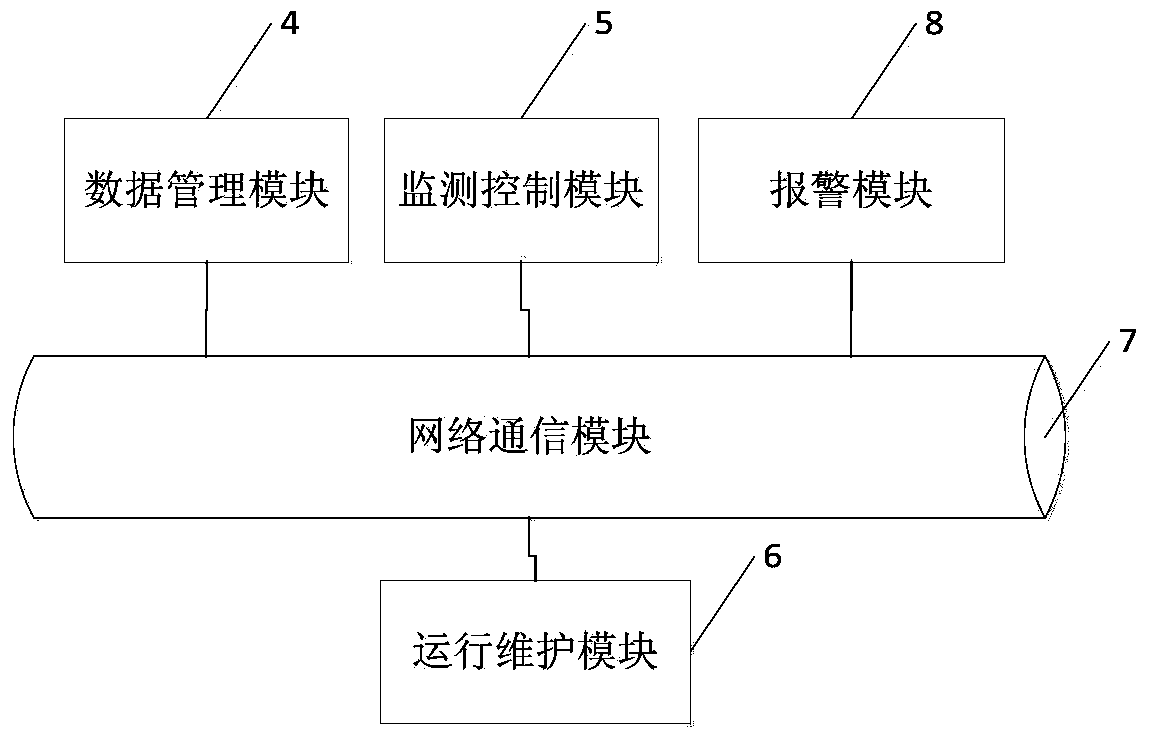

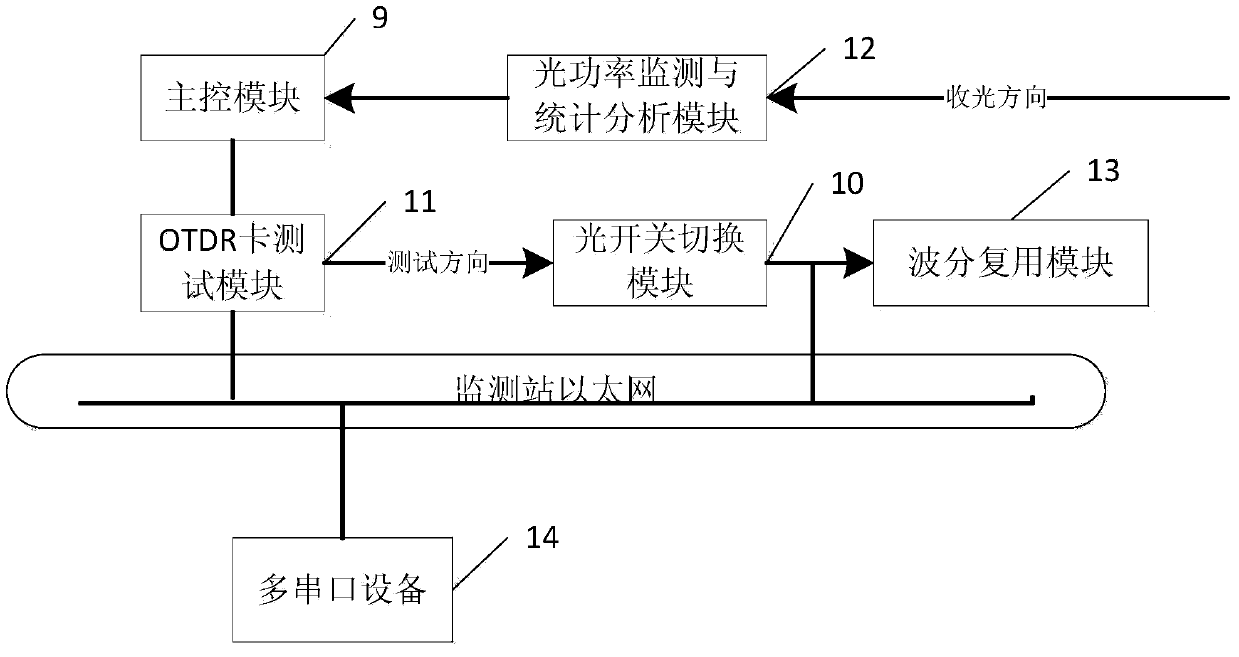

Transformer station optical fiber fault locating system and method

InactiveCN103441794ATo achieve the purpose of monitoringIncrease economic lossElectromagnetic transmissionTransformerGeolocation

The invention brings forward a transformer station optical fiber fault locating system and method, and relates to the field of optical fiber fault detection. A monitoring center comprises: a data management module, a monitoring control module and an alarm module. The data management module is used for maintaining and managing testing information of the monitoring center itself and testing information and parameter configuration information which are sent by a monitoring station. The monitoring control module is used for managing testing information and parameter configuration information of the monitoring station. Testing information and parameter configuration information of the monitoring station are analyzed and stored. Optical fiber performance information acquired by the monitoring station is sent to the monitoring control module to analyze, and the analyzed testing information, parameter configuration information and optical fiber performance information are judged so that warning information is obtained. Warning information is transmitted to the alarm module which is used for locating warning information via geographical location information pre-stored by the alarm module so that fault location information is displayed.

Owner:CHONGQING UNIV +2

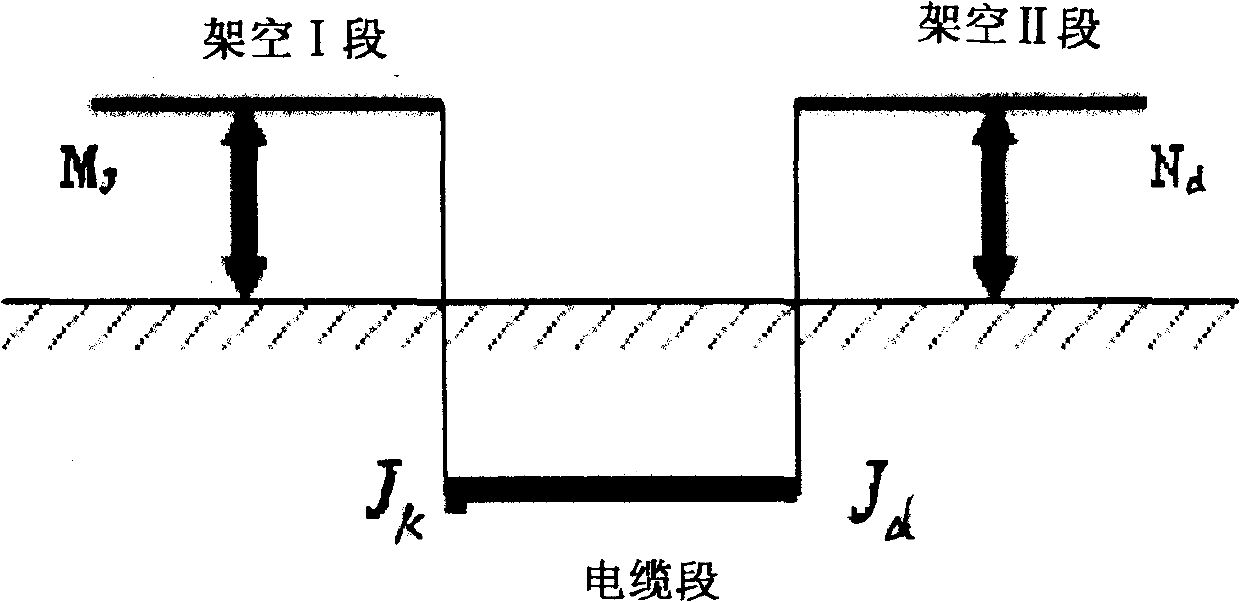

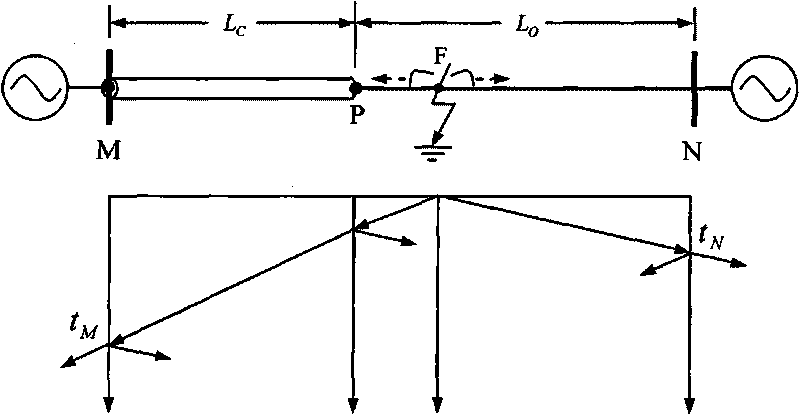

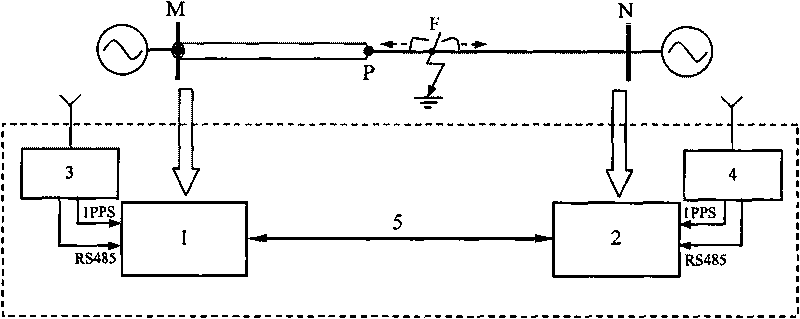

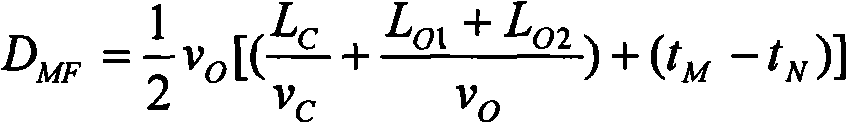

Method for positioning travelling wave fault of A type overhead line-cable joint line

InactiveCN101762775AImplementing Online Fault SegmentationAccurate fault locationFault locationLine segmentJunction point

The invention provides a method for positioning a travelling wave fault of an A type overhead line-cable joint line, comprising the following steps of: (1) by using a connection point of the overhead line and the cable as a boundary, respectively expressing lengths of a cable section and an overhead line section by using LC and LO, respectively expressing transmission speeds of transient travelling waves in the overhead line and the cable by using vO and vC, computing the time difference of achieving both ends (M, N) of the line by an initial travelling wave surge generated by the fault of the connection point P of the overhead line and the cable to be used as a setting valve; (2) measuring the absolute time of achieving both ends (M, N) of the line by the initial travelling wave surge generated by the fault of a certain point of the line, and expressing by using tM and tN; (3) determining the position of a fault point, wherein when tM-tN equal to delta TP, a fault point is the connection point P of the overhead line and the cable; when tM-tN is less than delta TP, the fault point is positioned a line MP section, and the distances between the fault point and the N end and the M end are respectively DNF=LC+LO-DMF; and when tM-tN is more than delta TP, the fault point is positioned a line MP section, and the distances between the fault point and the N end and the M end are respectively DMF=LC+LO-DNF. The method realizes the on-line fault sectioning and the fault distance measurement of the A type overhead line-cable joint line.

Owner:SHANDONG UNIV OF TECH

Circuit single-end ranging method based on phase aberration characteristic of positioning function

InactiveCN102023275AAccurate fault locationNot affectedFault locationInformation technology support systemPhase aberrationCapacitance

The invention belongs to the technical field of power system relay protection, and discloses a circuit single-end ranging method based on phase aberration characteristic of positioning function. The method deduces an operating voltage of reference positions and a fault point voltage based on distribution parameters by using electric quantity of a single end, and constructs a positioning function. When the reference positions are positioned on the left side and the right side of fault point, the positioning function has different phase characteristics; and when the reference positions are changed in front and back of the fault point, the phase of the positioning function has a unique stepped aberration. A circuit is subjected to N equal distribution, the equal distribution area containing the fault point is determined by using the phase characteristics, the step length is further reduced to determine the phase aberration position in the area, and then quick fault positioning of the single end can be realized. The method overcomes the defects of the traditional single-end ranging method, and theoretically is not affected by the factors such as distributed capacitance, transition resistance, opposite side running mode, communication facilities, load current and the like. The algorithm is simple, reliable and easy to realize, and the use value of the method is strong.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

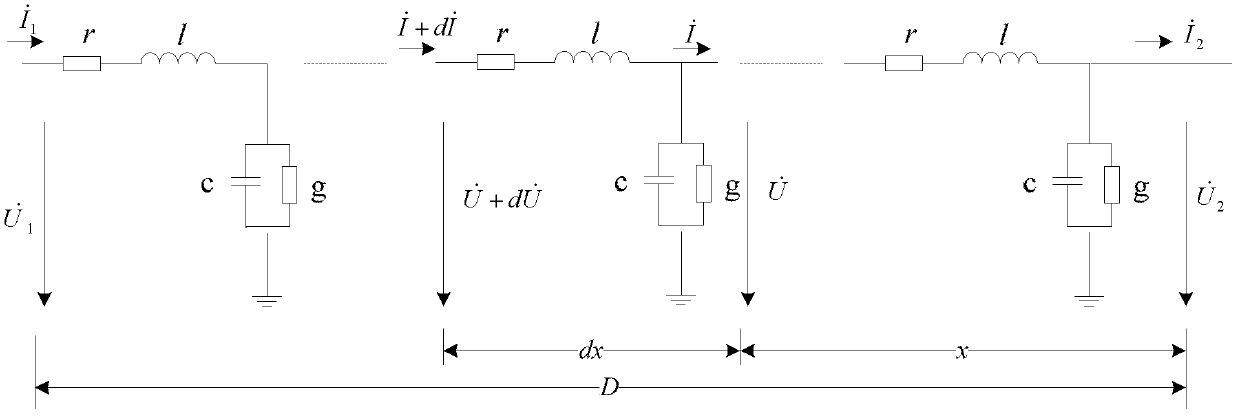

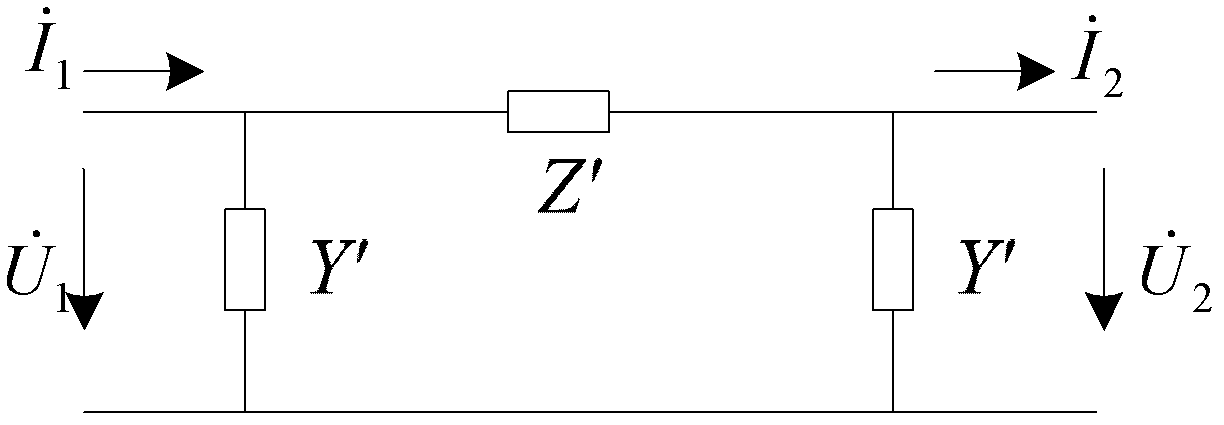

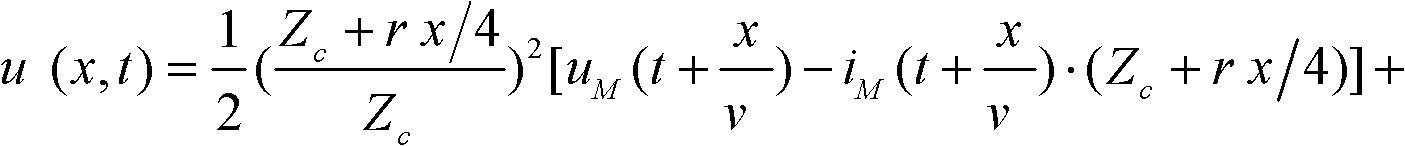

Accurate measurement and calculation method for parameters of power transmission line

InactiveCN102323484AImprove accuracyStability analysisResistance/reactance/impedenceElectric power systemMaterial resources

The invention discloses an accurate measurement and calculation method for parameters of a power transmission line. In the method, the parameters of the power transmission line are accurately calculated according to short-circuit impedance ZS and open-circuit impedance ZO of the power transmission line. The method comprises the following steps of: measuring the short-circuit impedance ZS and the open-circuit impedance ZO of the power transmission line with length of D; acculate calculating characteristic impedance zc and propagation coefficient gamma of the power transmission line according to a calculation formula provided by the invention; further, calculating impedance z and admittance y under the condition of unit length of the line through the formulas of z=zc gamma and y=gamma / zc; and accurately calculating impedance Z' and admittance Y' of an equivalent pi circuit of the power transmission line according to the calculation formula provided by the invention. By adopting the measurement and calculation method provided by the invention, the accuracy for the parameters of the power transmission line can be greatly improved, manpower and material resources are saved, tide current of a power system is stably analyzed; protection setting is performed; and fault positioning is more accurate.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

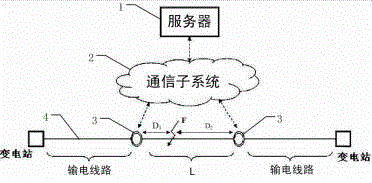

Fault monitoring system for power transmission line

InactiveCN105676070AAccurate fault locationEasy dischargeFault location by conductor typesForeign matterData information

The invention discloses a transmission line fault monitoring system, comprising: a terminal monitoring device, a communication subsystem and a server arranged on each section of the monitored transmission line; a measurement module is used to monitor the data information of the transmission line, and upload the collected data in real time To the server; the terminal host aggregates, preprocesses and uploads the monitored data and collected data, and controls the terminal monitoring device according to the command sent by the server; the camera device monitors visible light video image data, and the infrared thermal imager collects infrared image data ; The camera device and the infrared thermal imager are set in the same airborne platform to ensure the correspondence between the infrared image data and the monitoring object; the microwave Doppler detector detects foreign matter intrusion into the transmission line; Surveillance, analysis and early warning requirements. Dividing the transmission line into several sections can construct accurate transmission line fault location, so as to realize rapid fault removal.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

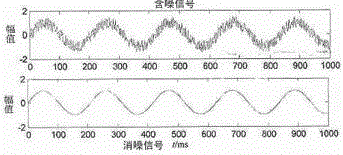

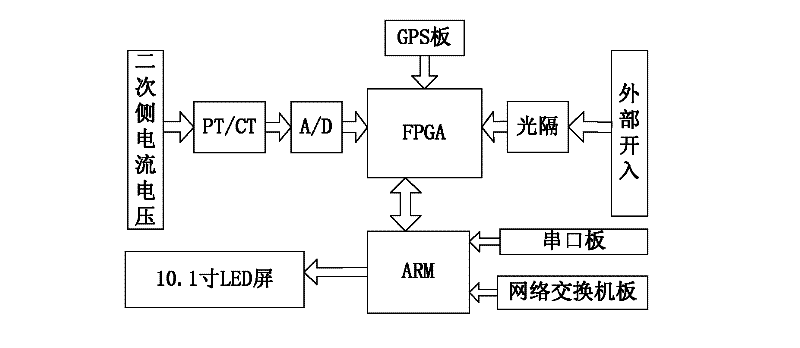

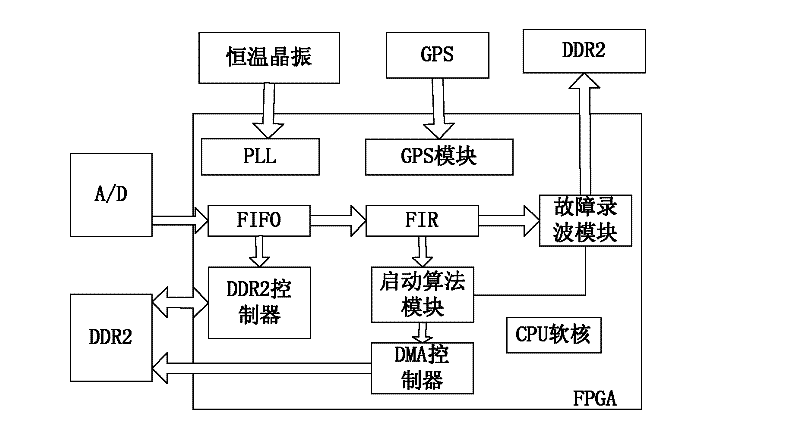

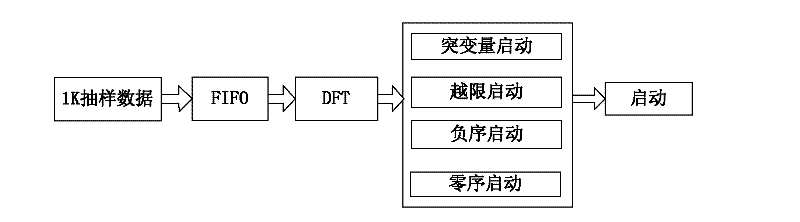

Failure message integrated device based on FPGA and ARM hardware platform

ActiveCN102401871ASave screen cabinet resourcesHighly integratedFault locationLow-pass filterElectric power system

The invention discloses a failure message integrated device based on FPGA and ARM hardware platform, which comprises a PT / CT board, an ARM board, a network switch board, a serial port board, a GPS board and a high speed acquisition board composed of an A / D sampling chip and an FPGA; the FPGA has a DDR2 controller, an DMA controller, an FIFO memory and an FIR low-pass filter; and the FPGA is also provided with a starting algorithm module and a fault recorder module. The device organically combines the functions of the fault recorder, a travelling wave distance measuring device and a failure message management sub-station by using parallel processing capability of the high speed AD chip and the FPGA, for realizing accurate localization of fault points when a power transmission line in an electric power system has a fault, and obtaining a complete fault report, thereby complying with intelligentization and miniaturization needs of secondary device of power grid.

Owner:ANHUI NANRUI JIYUAN POWER GRID TECH CO LTD +1

B-type overhead line-cable hybrid line traveling wave fault positioning method

InactiveCN101930048AImplementing Online Fault SegmentationAccurate fault locationFault locationTransient stateEngineering

The invention provides a B-type overhead line-cable hybrid line traveling wave fault positioning method, which comprises the following steps of: (1) using connecting points P1 and P2 of an overhead line and a cable as boundaries, representing lengths of an overhead segment MP1, a cable segment P1P2 and an overhead segment MP P2N by using LO1, LC and LO2 respectively, representing the propagation speed of a transient state travelling wave in the overhead line and the cable by using vO and vC respectively, and calculating the time difference from an initial travelling wave surge generated at a P1 point fault to two ends of M and N of the line and the time difference from an initial travelling wave surge generated at a P2 point fault to the two ends of M and N of the line, which serve as setting values; (2) measuring an absolute moment from an initial travelling wave surge generated at a certain fault to the two ends of M and N of the line, and representing the absolute moment by using tM and tN; and (3) determining the fault point position.

Owner:SHANDONG UNIV OF TECH

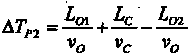

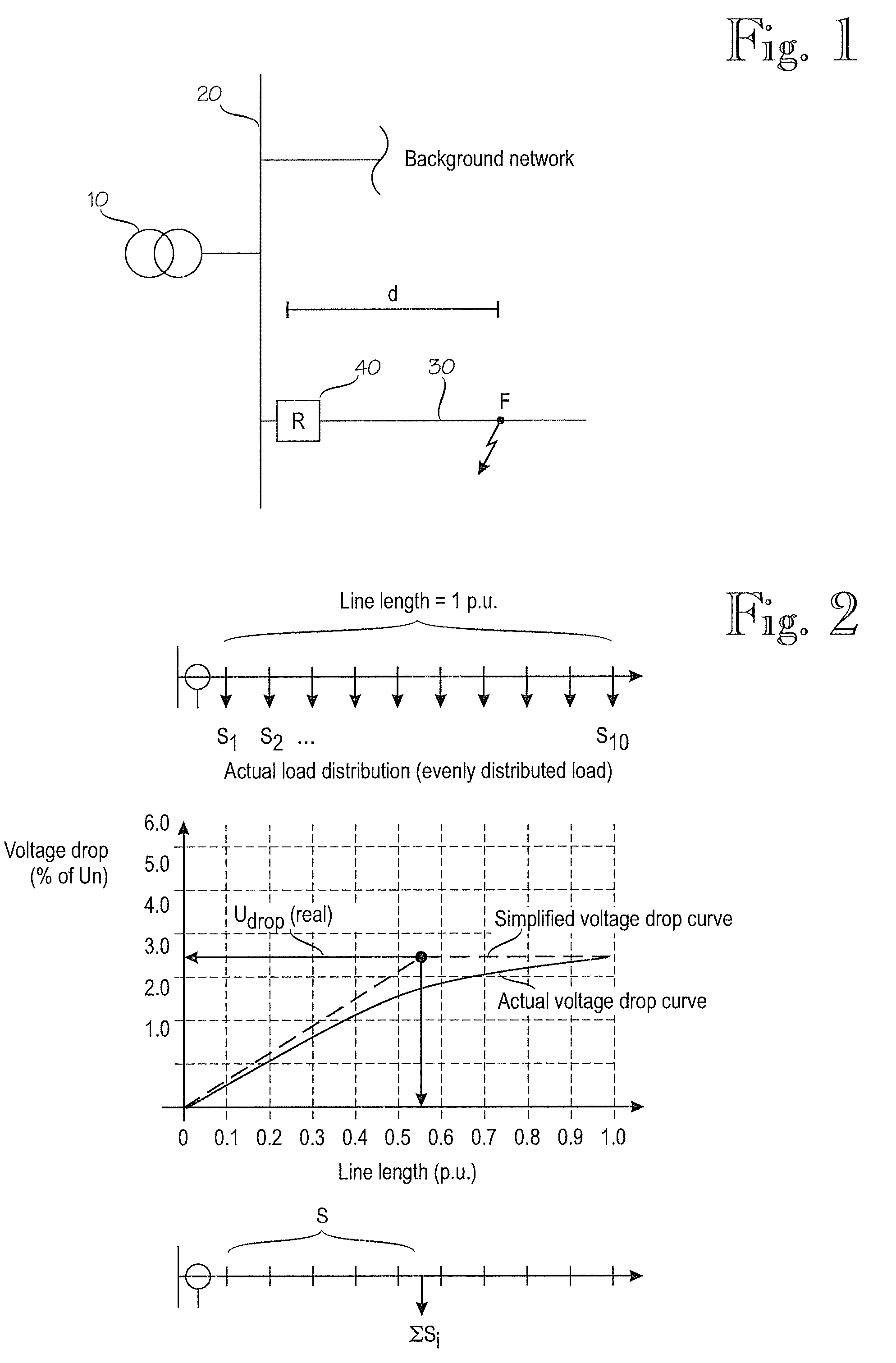

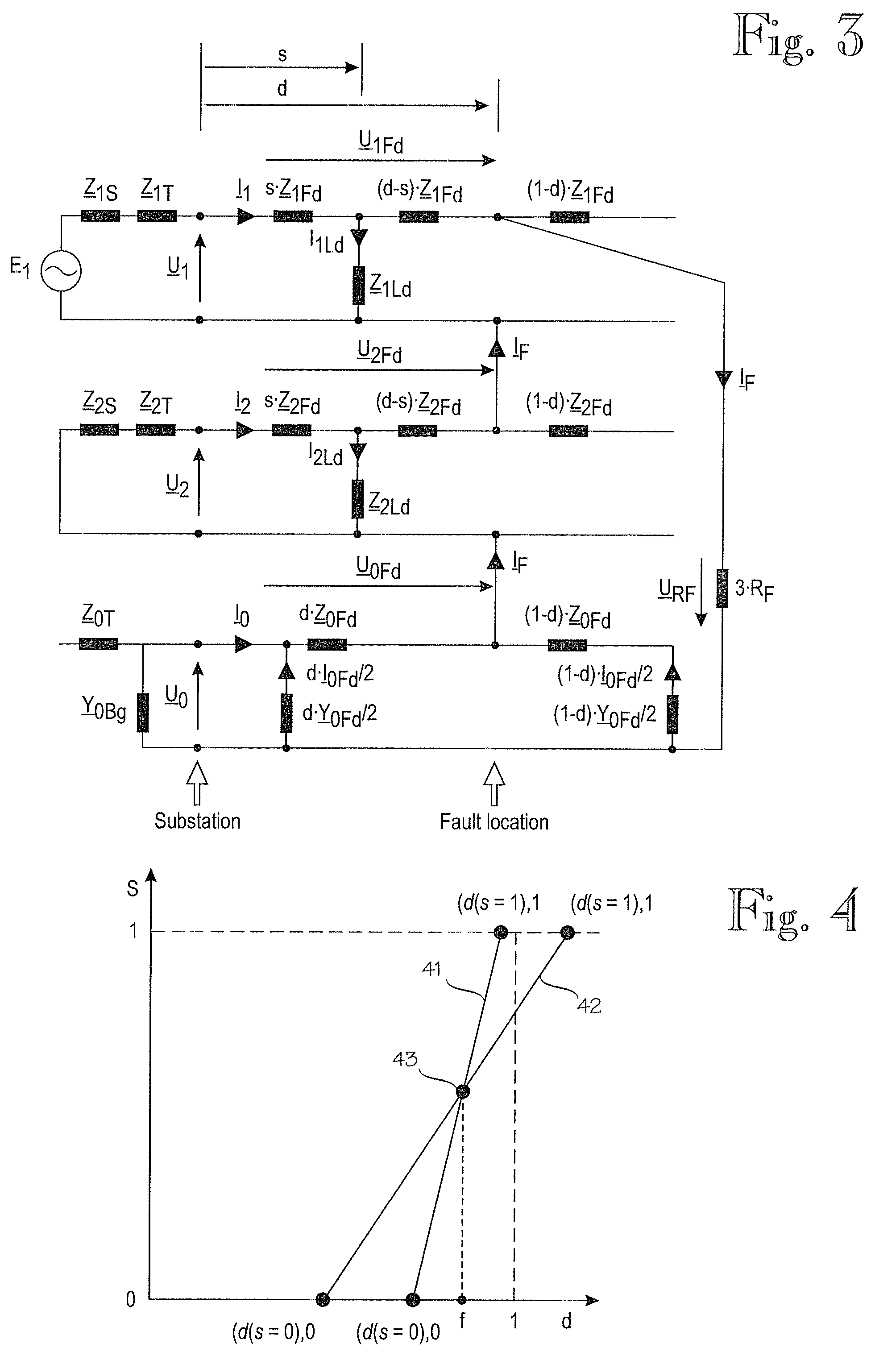

Method for determining location of phase-to-earth fault

ActiveUS20080297163A1Accurate fault locationImprove accuracyFault locationMeasurement pointPower grid

A method and apparatus for determining a location of a phase-to-earth fault on a three-phase electric line of an electric network, comprising determining, when the ratio of a fault current and load current has a first value, a first fault distance line which indicates an estimate of a distance of the fault from the measuring point in relation to an equivalent load distance, determining, when the ratio of the fault current and load current has a second value which differs from the first value, at least one second fault distance line, determining a distance at which the determined fault distance lines intersect when superimposed and determining the distance between the measuring point and the point of fault on the basis of the determined distance or distances of intersection.

Owner:ABB (SCHWEIZ) AG

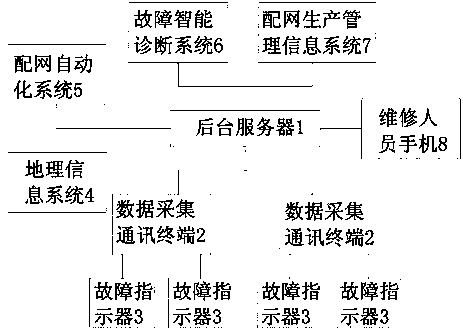

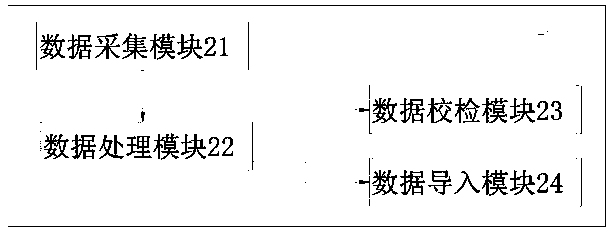

Intelligent overhead line fault positioning and monitoring system

InactiveCN103884962AAvoid disturbing influenceStrong targetingFault locationFault indicatorPower grid

The invention discloses an intelligent overhead line fault positioning and monitoring system. The system is precise in fault positioning, high in precision and capable of quickly isolating faults, avoids long-time outage and improves operation reliability of a power grid. The intelligent overhead line fault positioning and monitoring system comprises a background server, a data collecting communication terminal, multiple fault indicators, a geographic information system and a distribution network automated system, wherein the background server, the data collecting communication terminal, the fault indicators, the geographic information system and the distribution network automated system are sequentially connected in a communication mode, and the geographic information system and the distribution network automated system are respectively connected with the background server. After a fault positioning and monitoring platform receives motion messages of the fault indicators, the geographic information system is accessed, all fault indicators which work and do not work on the same line are defined as upstream fault indicators and downstream fault indicators respectively, and a fault area is reduced to obtain a precisely positioned fault area by analyzing and determining the upstream fault indicators of a positioned fault area and the downstream fault indicators in the positioned fault area.

Owner:ZHUHAI GENE COSMOS ELECTRIC TECH

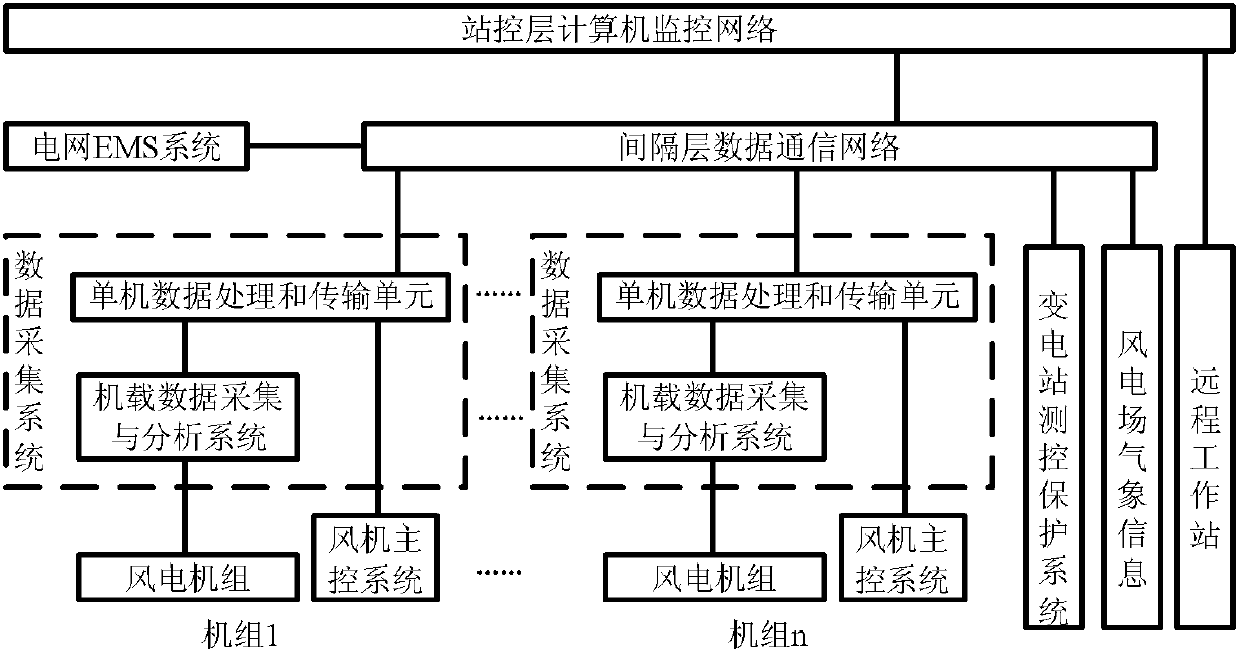

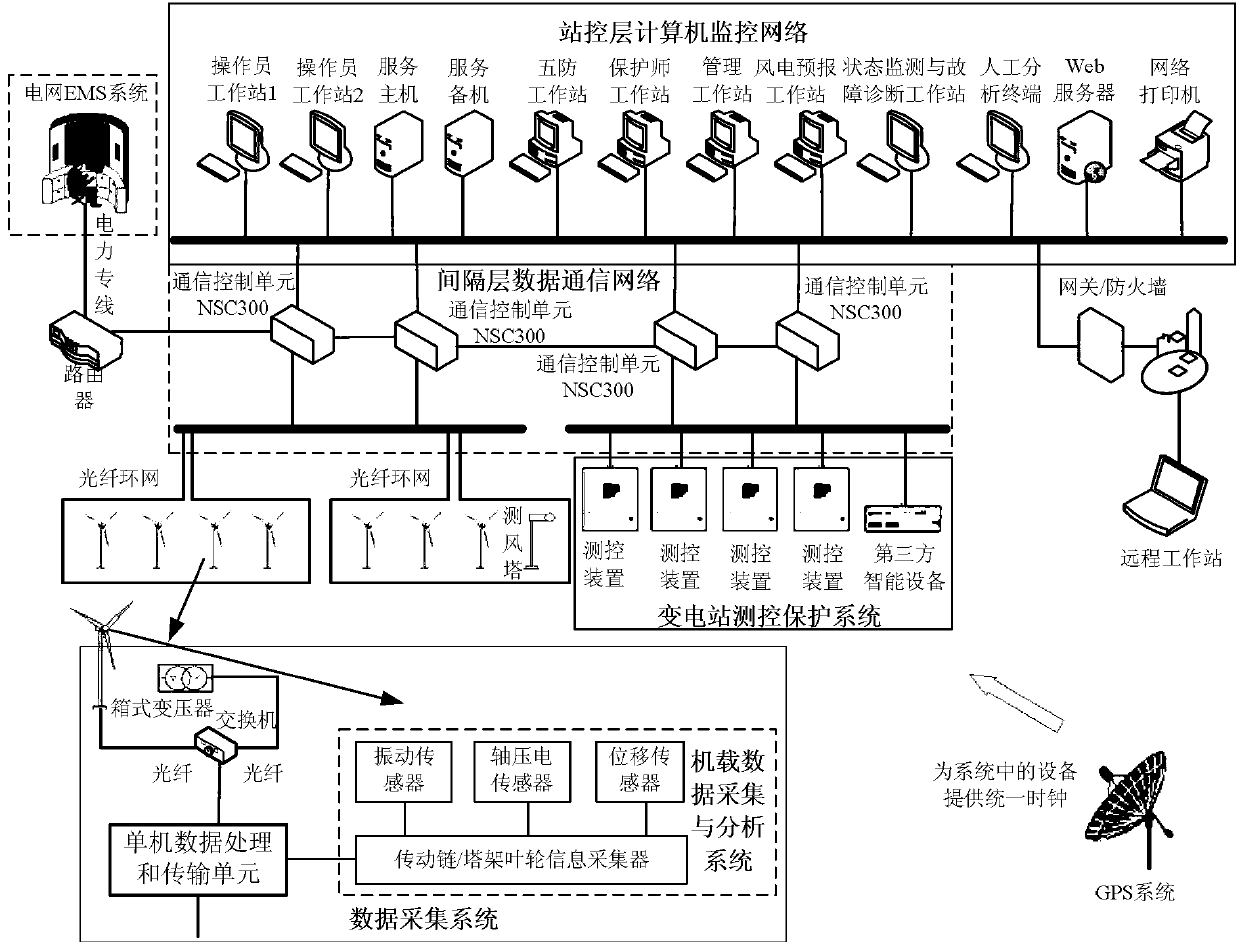

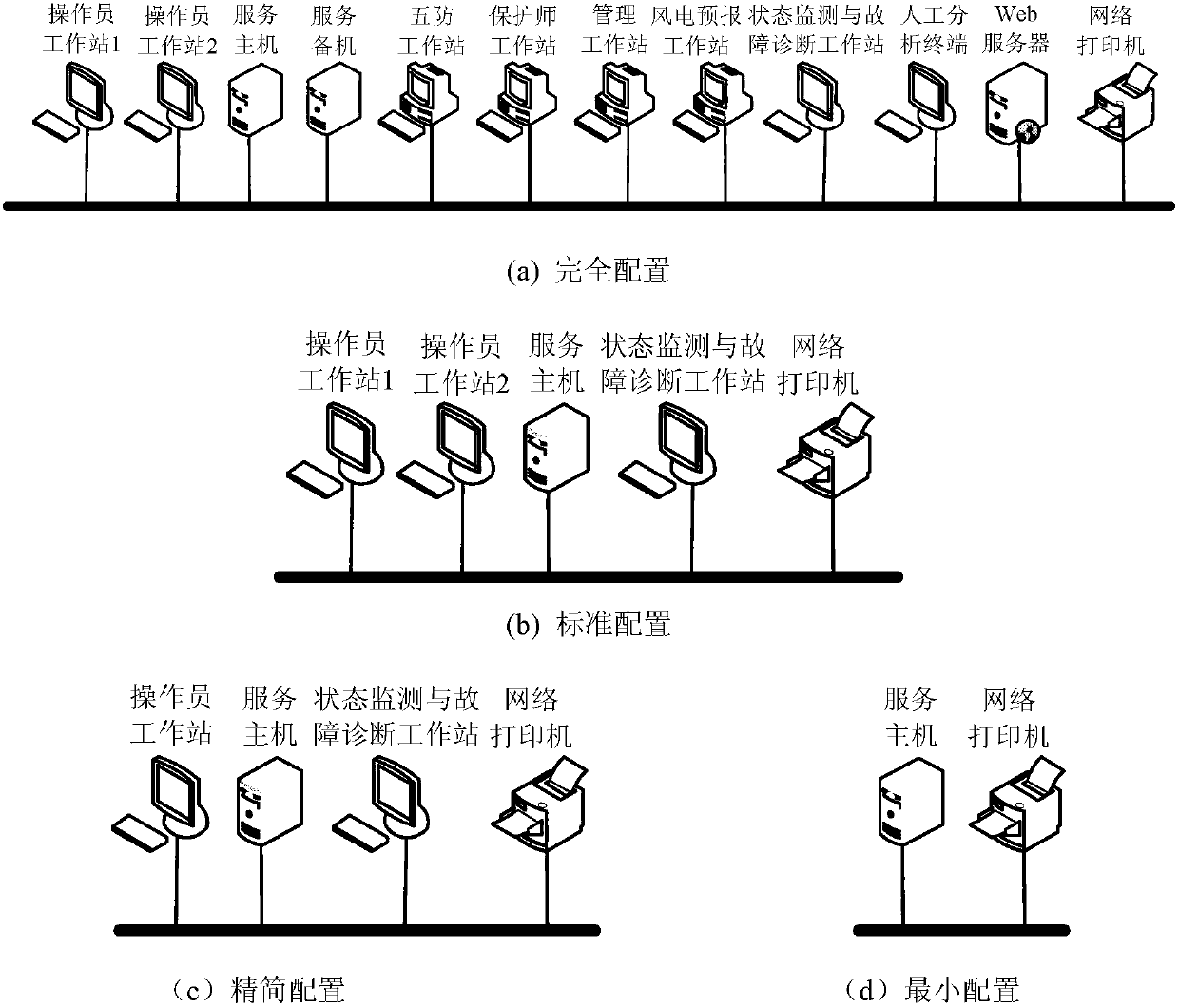

Wind power monitoring and fault diagnosis system

ActiveCN102999025ALow costAccurate fault locationTotal factory controlDynamo-electric machine testingAutomotive engineeringCondition monitoring

The invention provides a wind power monitoring and fault diagnosis system which comprises a station-control-level computer monitoring network, a bay-level data communication network, a power grid EMS (electronic management system), a data collection system, a transformer substation measuring and control protecting system, a remote working station and units (1...n). The station-control-level computer monitoring network respectively performs data interaction with the power grid EMS, the data collection system and the transformer substation measuring and control protecting system through the bay-level data communication network and controls the remote working station, the data collection system respectively collects data of each collection unit (1...n), and the station-control-level computer monitoring network receives meteorological information of a wind power plant. The wind power monitoring and fault diagnosis system can simultaneously realize functions of monitoring of electrical quantity of wind power and state monitoring and fault diagnosis of a wind power unit, precognition and alarming of fault states of the wind power unit can be realized while wind power monitoring is realized.

Owner:CHINA ELECTRIC POWER RES INST +1

Method for locating single-phase ground fault of a low current grounding system power distribution network

InactiveCN101545944ARealize automatic positioningReduce lossFault locationReturn currentPhase difference

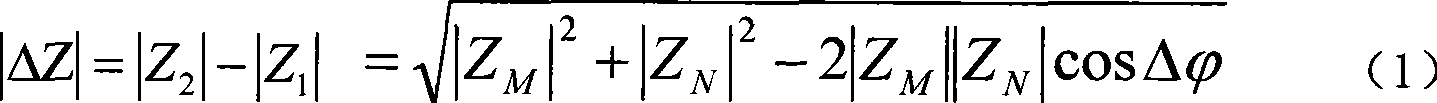

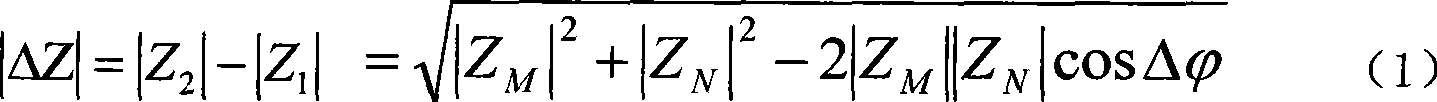

The present invention relates to a method for locating single-phase ground fault of a low current grounding system power distribution network, including determining a total length L[total] and a total impedance Z[total] between two lines of M and N, and injecting signals when occurring a fault, when a P point between the M and N positions occurring a single-phase ground fault, systems of the two positions inject signals at the M and N position, and measures the amplitude of a return current signal as well as a phase difference between the return current signal and the injection voltage signal, after a line selection device has selected the fault phase; calculating a loop total impedance Z[M] grounded through the P point from the M and N ends, the modulo of the Z[N], and a phase angle Phi[M] of the Z[M] and the Z[N], according to |Z| = |U| / |I|, the measured injection voltage, the amplitude of the return current signal and the phase difference, a distance from the fault point P to the M position is further calculated through the following formula. By the method of the invention, it is easy to detect when the signal amplitude is strong, the attrition in the power distribution network is low, the algorithm is high, and the accuracy is high.

Owner:HEFEI COMEON ELECTRONICS TECH

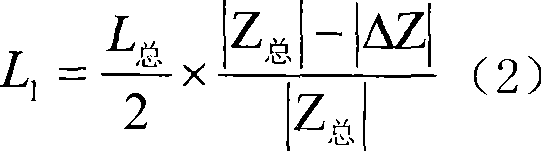

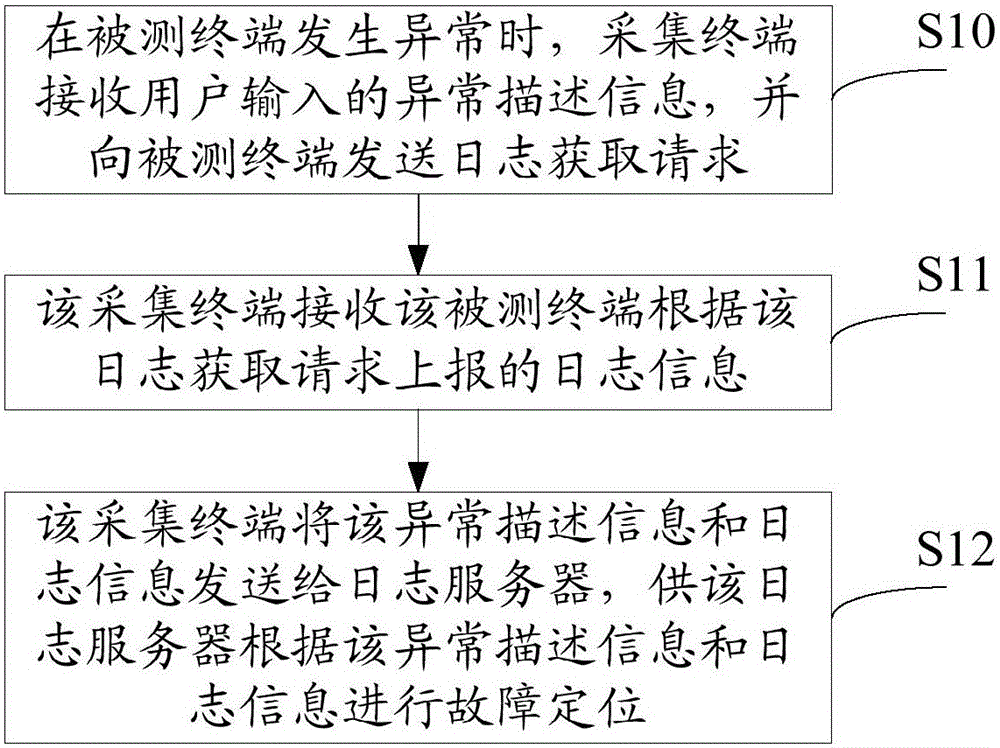

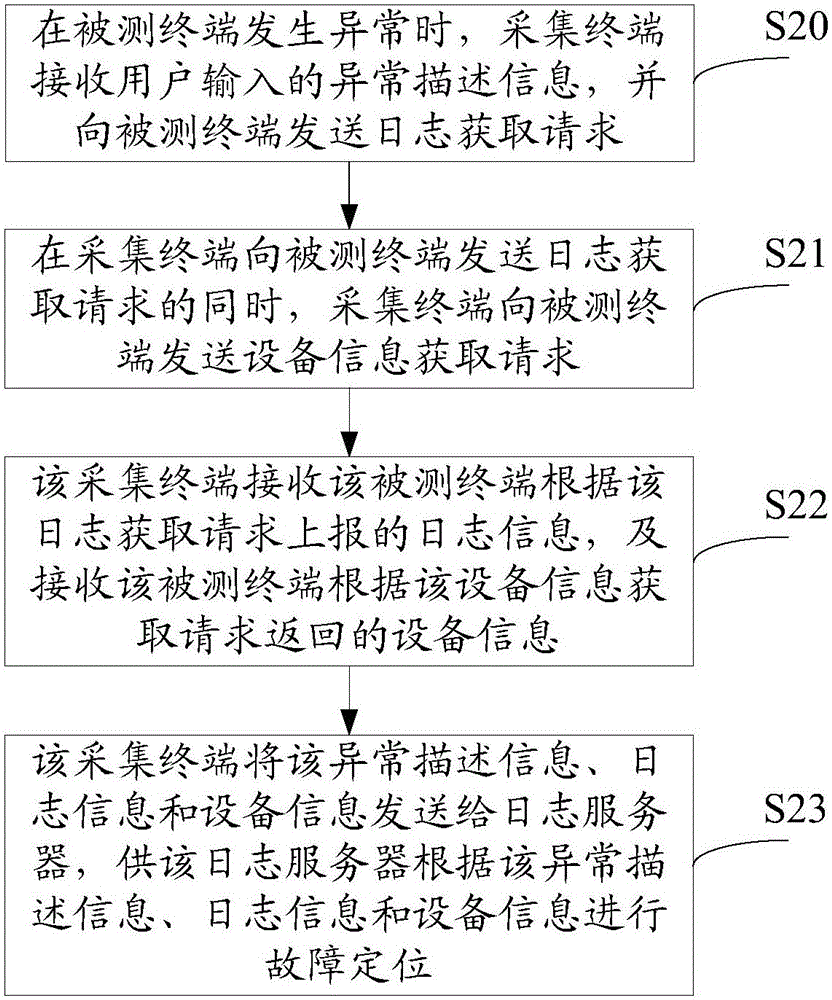

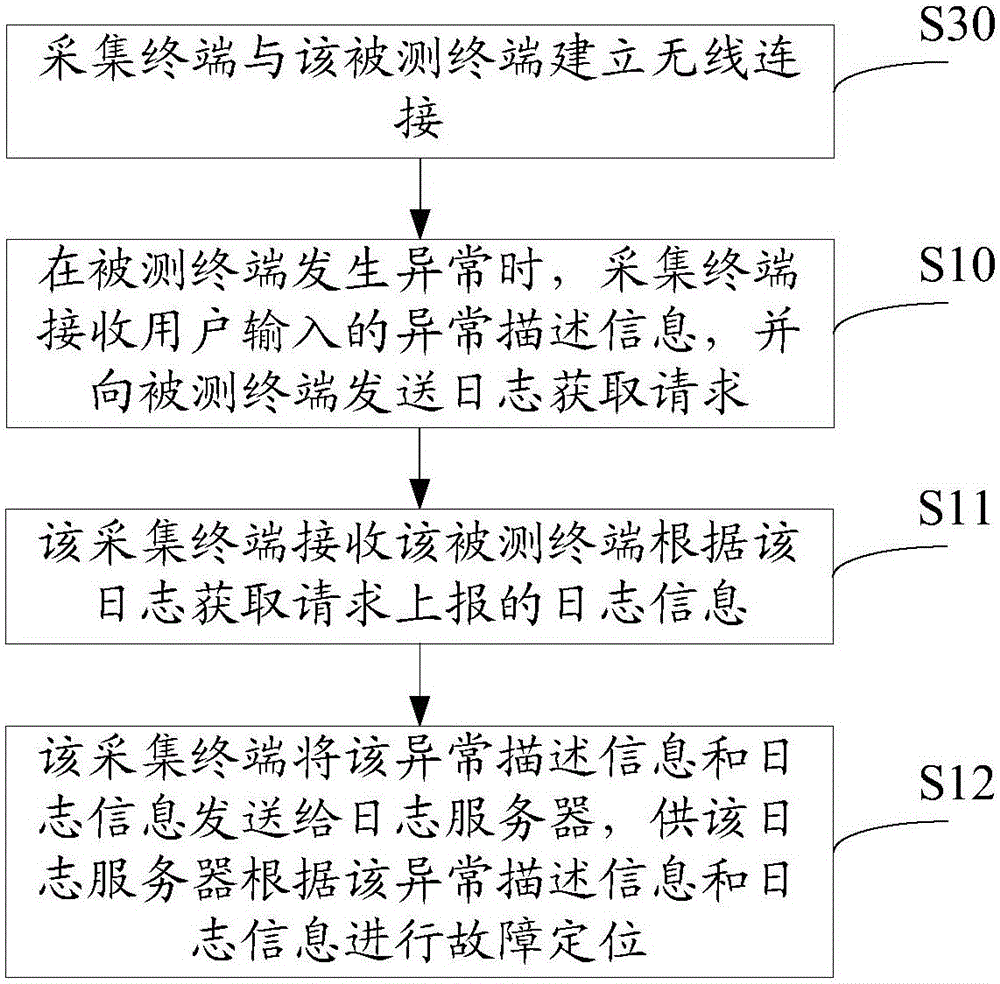

Log collection method and collection terminal

The invention discloses a log collection method. The method comprises the steps that when a tested terminal has an exception, a collection terminal receives exception description information input by a user and sends a log obtaining request to the tested terminal; the collection terminal receives the log information reported by the tested terminal according to the log obtaining request; the collection terminal sends the exception description information and the log information to a log server, and therefore the log server positions the fault according to the exception description information and the log information. The invention further discloses the collection terminal. By the adoption of the log collection method and the collection terminal, the exception description information and the log information of the tested terminal can be sent to the log server at the same time, and therefore the log server can rapidly and accurately position the fault of the tested terminal.

Owner:TCL TECH ELECTRONICS (HUIZHOU) CO LTD

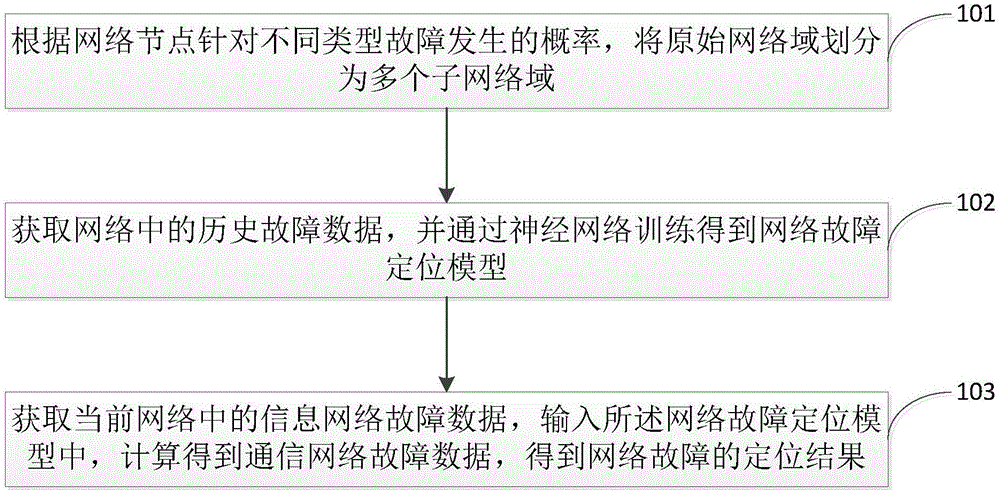

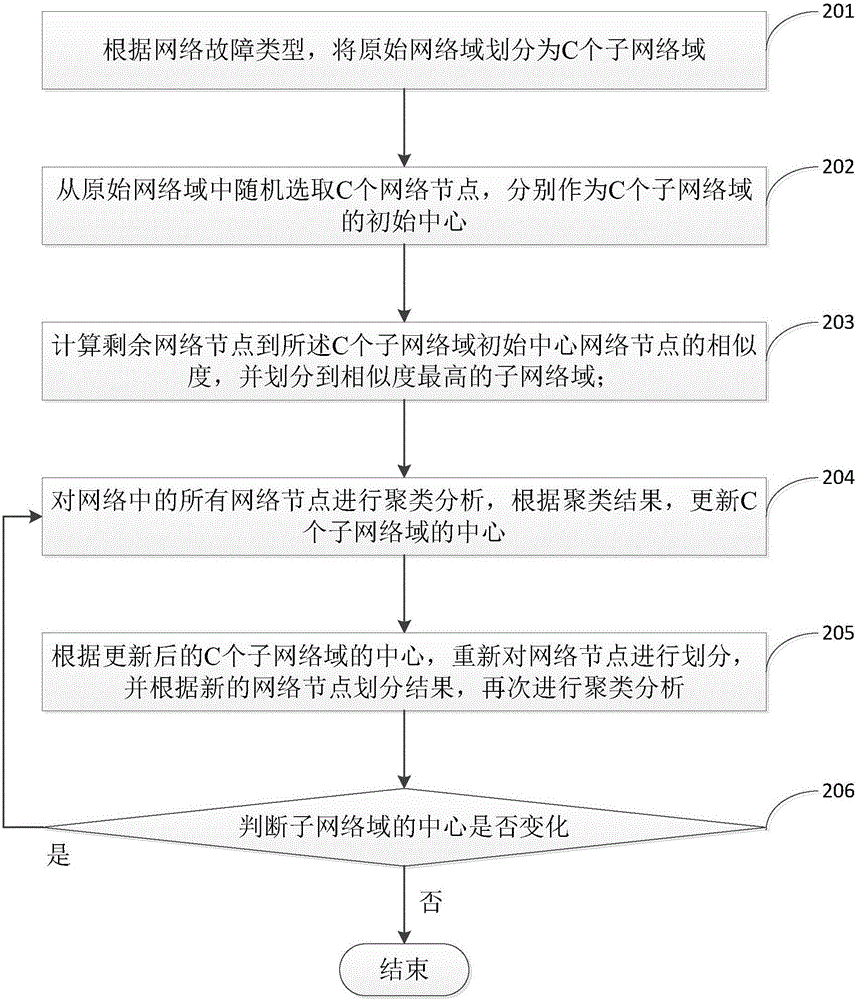

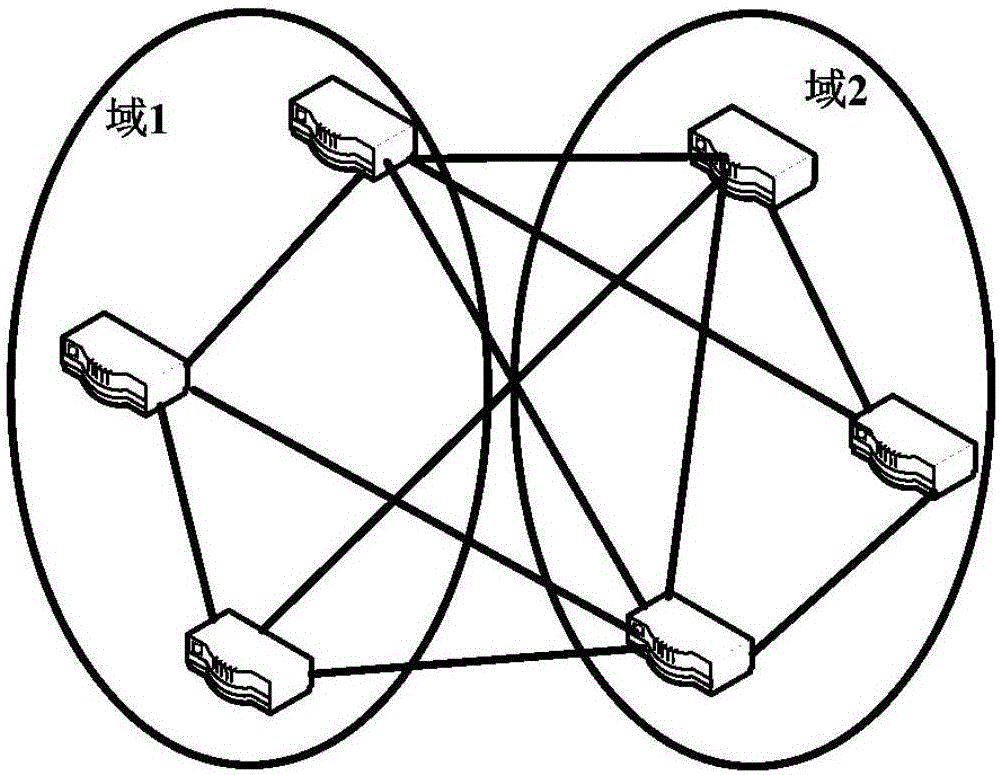

Network fault positioning method and device

ActiveCN106470122AHigh precisionImprove efficiencyData switching networksInformation networksFault occurrence

The invention discloses a network fault positioning method and a device. The method comprises steps of: dividing an original network domain into multiple sub network domains according to occurrence probability of different types of faults to a network node; acquiring history fault data in the network and obtaining a network fault positioning model through the neural network training; and acquiring information network fault data in the current network, inputting the information network fault data into the network fault positioning model and calculating to obtain communication network fault data so as to obtain a positioning result of the network faults. According to the invention, by considering dependency, between different layers, of the faults, the network domain with complex structure, high volume and many faults is divided into sub network domains with simplified structures, so more precise fault positioning can be performed; parallel positioning based on multiple sub network domains is performed, so fault positioning efficiency is improved; and by use of the neural network, the correlation between the network nodes is considered in the fault positioning, so accuracy of the network fault positioning is improved.

Owner:BEIJING HUITONG JINCAI INFORMATION TECH +5

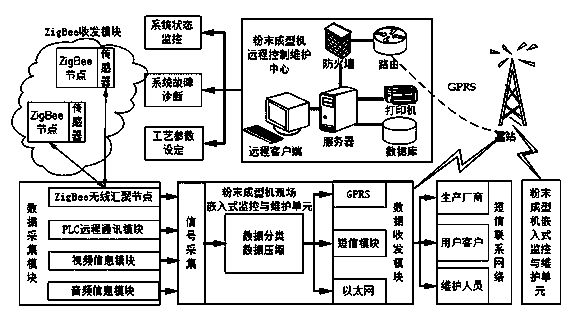

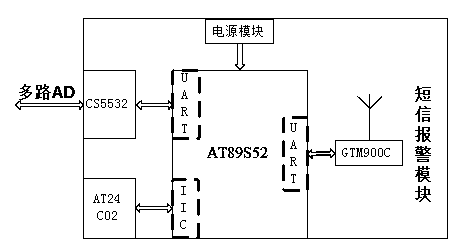

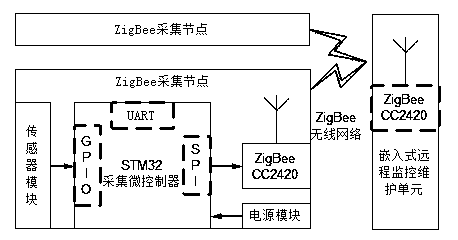

Embedded intelligent monitoring and remote maintenance system of powder forming machine

ActiveCN103777609AImprove failure recovery efficiencyAvoid wiring difficultiesTotal factory controlProgramme total factory controlData compressionDisplay device

The invention discloses an embedded intelligent monitoring and remote maintenance system of a powder forming machine. The embedded intelligent monitoring and remote maintenance system is composed of an on-site monitoring unit and a powder forming machine manufacturer remote maintenance center. A workshop on-site monitoring platform has the function of obtaining the important running state of the powder forming machine through real-time data interaction with a main controller of the powder forming machine and through workshop field data collected through data collection devices such as a sensor, a video collection device and an audio collection device, the function of displaying the real-time running state of the powder forming machine on a display device, the function of alarm prompt and the like. Meanwhile, the on-site monitoring unit can conduct data compression and data classification on state parameters of the powder forming machine and sends data to a remote maintenance center of a device producer and a person in charge of a certain part of the powder forming machine through an Ethernet interface, a GPRS interface and a short message sending module, and therefore online monitoring and remote fault diagnosis of the powder forming machine, and the maintenance service are achieved, and related personnel are notified. The embedded intelligent monitoring and remote maintenance system is low in cost, complete in function, high in configurability and high in tailing capability, functional modules can be increased or reduced according to the on-site running state of the powder forming machine, and the embedded intelligent monitoring and remote maintenance system has high universality.

Owner:NANJING UNIV OF SCI & TECH +1

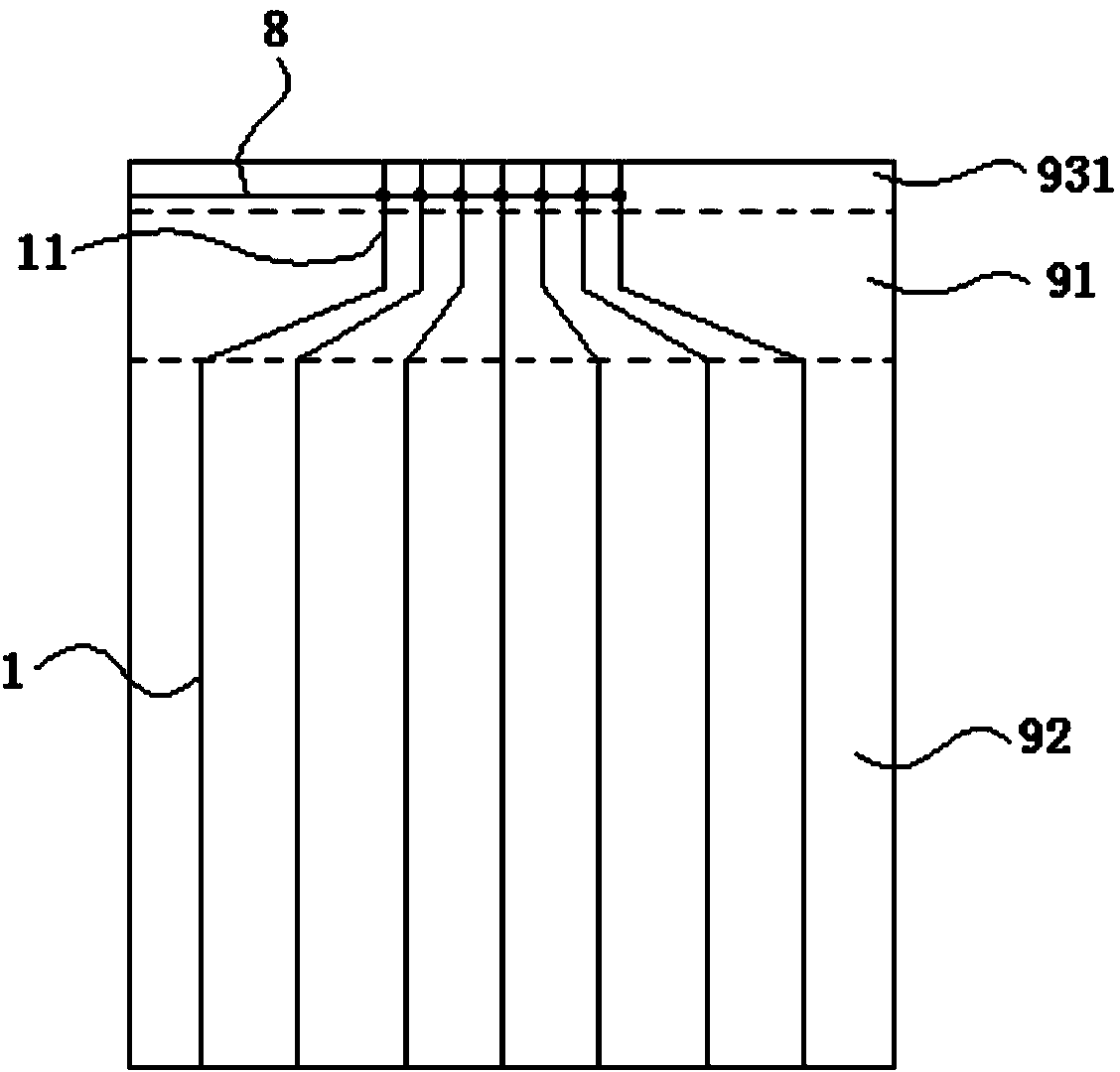

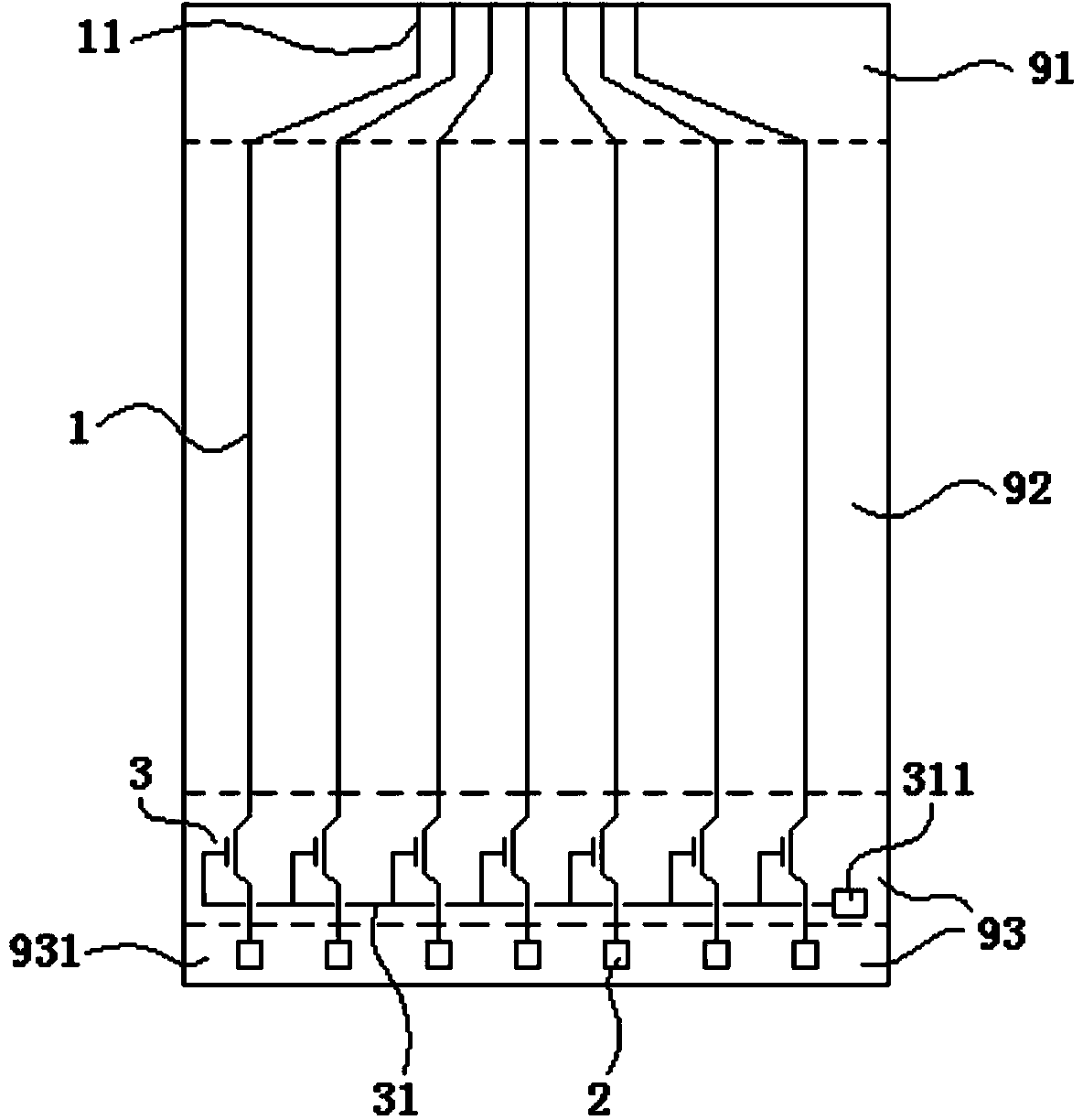

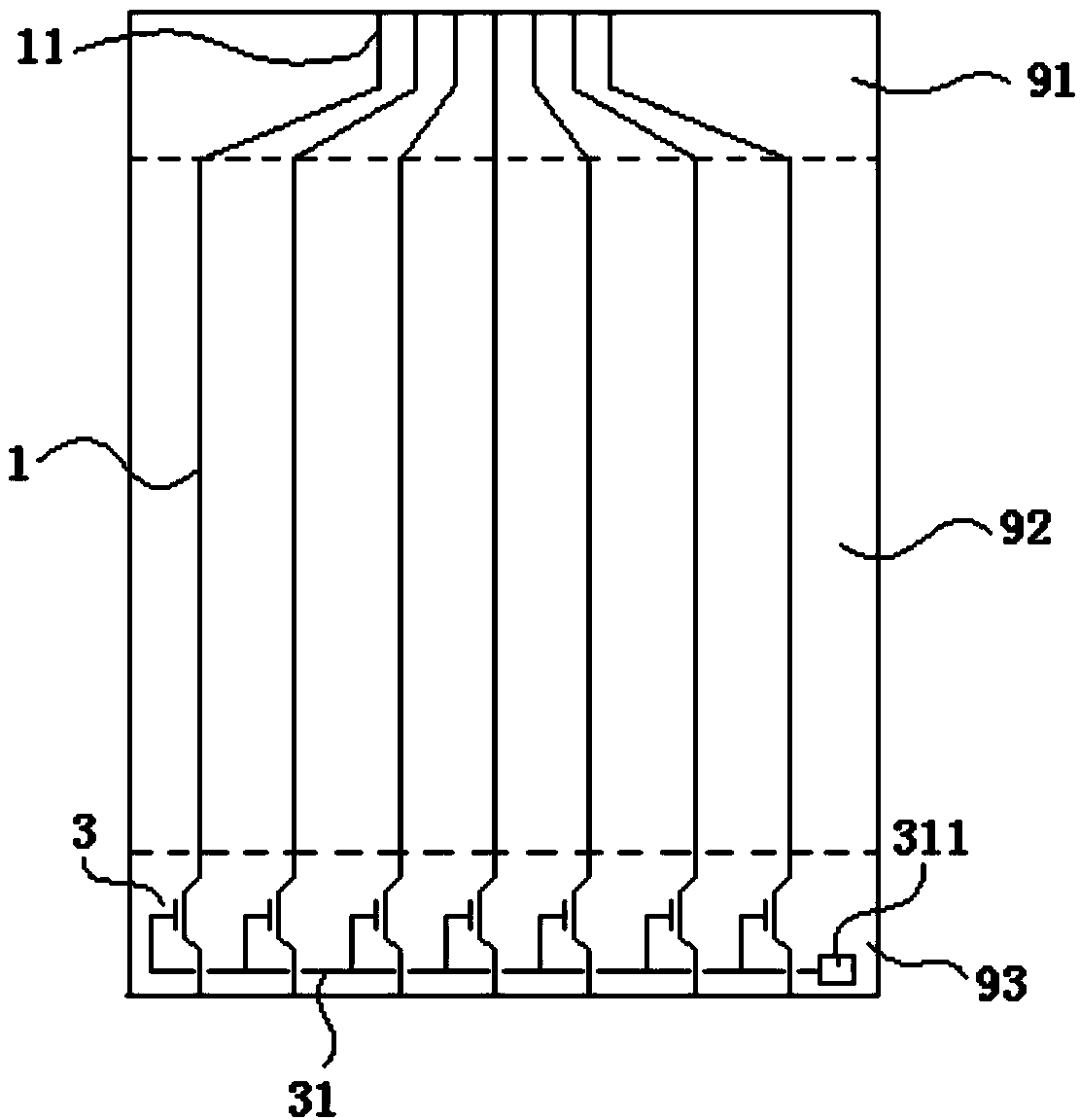

Array substrate and display device

InactiveCN103713410AAccurately locate faultsAccurate fault locationSolid-state devicesElectrical testingDisplay deviceEngineering

The invention provides an array substrate and a display device, and belongs to the technical field of display. The array substrate can solve the problems that an existing array substrate cannot detect leads independently, and the fault positioning is inaccurate. The array substrate comprises an expanding area, an edge area and a display area for performing displaying, and the expanding area and the edge area are connected with the display area and located on the two non-adjacent sides of the display area respectively. A plurality of leads are arranged on the array substrate and penetrate through the display area into the edge area. One end of each lead is an input end for connecting a drive chip, and the input end of each lead is located in the expanding area. The array substrate further comprises connectors which are located on the sides, far away from the input ends, of the leads and used for detecting probe contact, and the connectors are located in the edge area.

Owner:BOE TECH GRP CO LTD

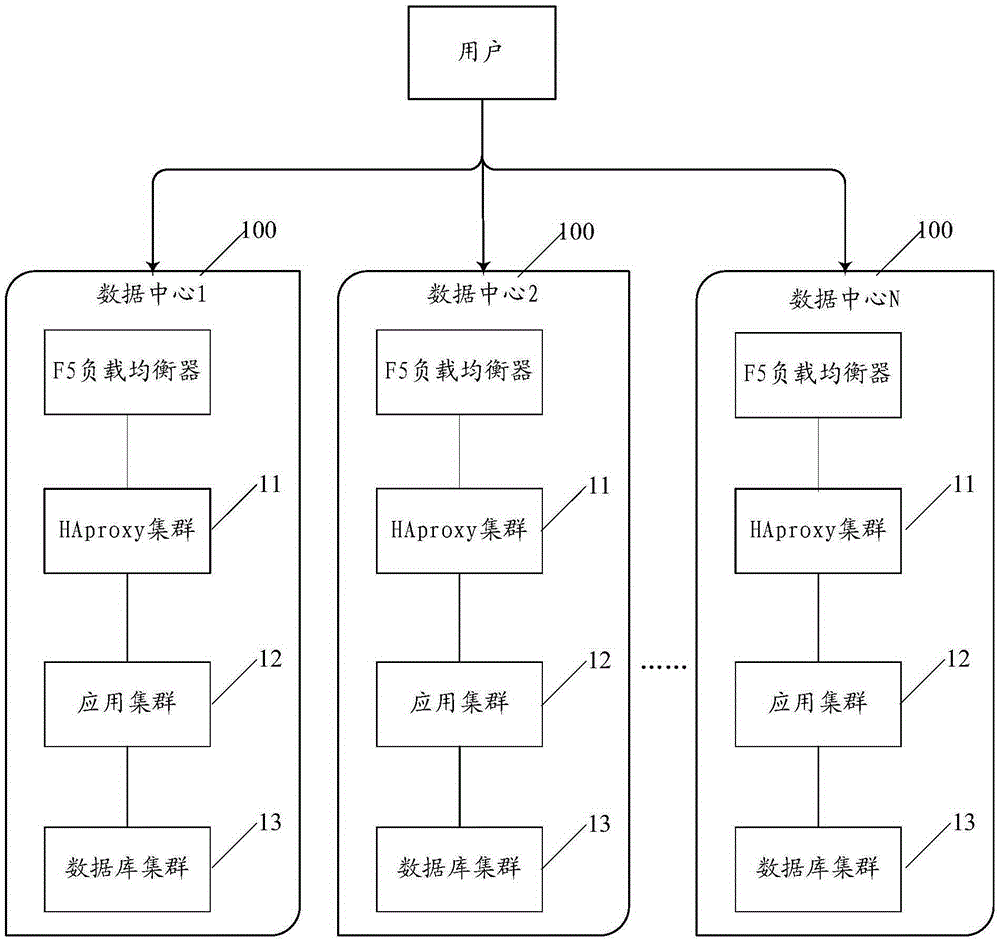

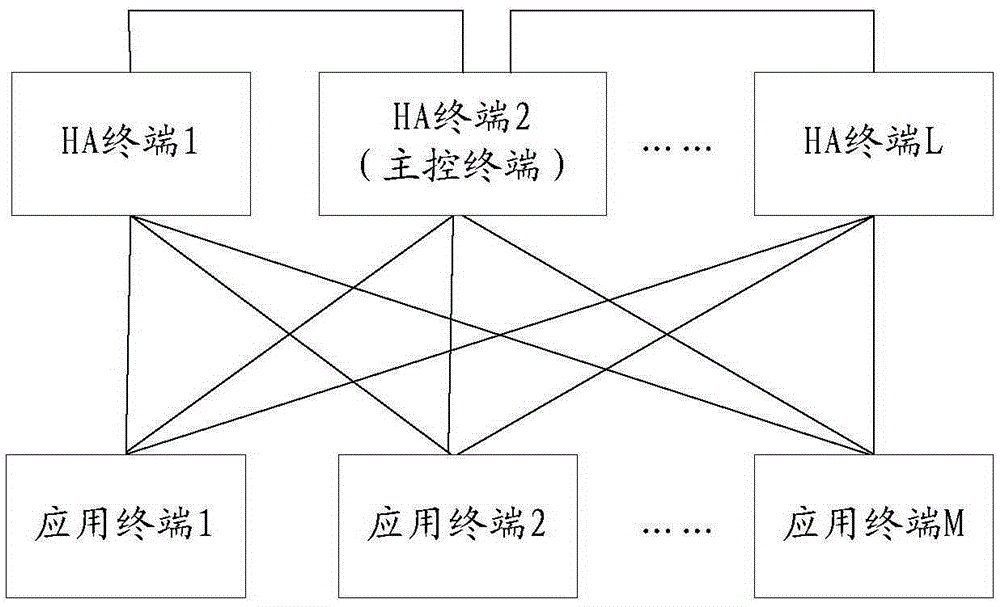

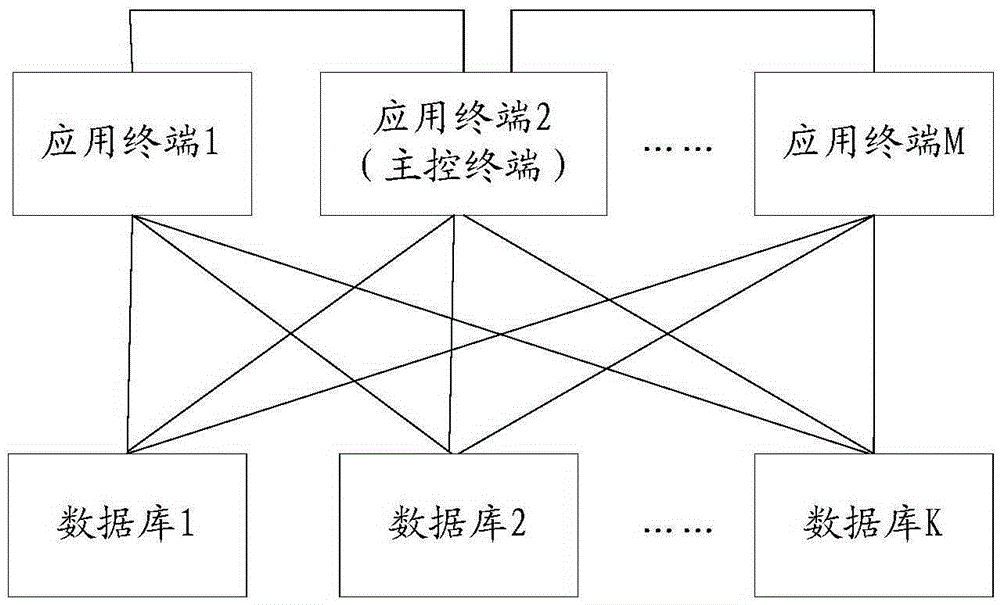

Application-level disaster tolerant method and application-level disaster system

ActiveCN105262633ARealize connection exceptionAccurately determineData switching networksData centerDatabase clustering

The present application provides an application-level disaster tolerant method and an application-level disaster tolerant system. The application-level disaster tolerant method is deployed at each data center, and comprises the steps of: determining that an abnormal connection of an application cluster occurs and pushes a notification that the abnormal connection of the application cluster occurs when a main control terminal of a HAProxy clustered system judges that number of application terminals having abnormal connection in the application cluster is greater than a first preset number; and determining that an abnormal connection of a database cluster occurs and pushes a notification that the abnormal connection of the database cluster occurs when a main control terminal of the application cluster judges that number of databases having abnormal connection in the database cluster is greater than a second preset number. The application-level disaster tolerant method and the application-level disaster tolerant system can achieve the purpose of accurately determining a fault position. Since the application-level disaster tolerant method and the application-level disaster tolerant system can accurately determine the fault position, the switching can be carried out at the fault position when switching the data center without switching the overall data center.

Owner:CHINA CONSTRUCTION BANK

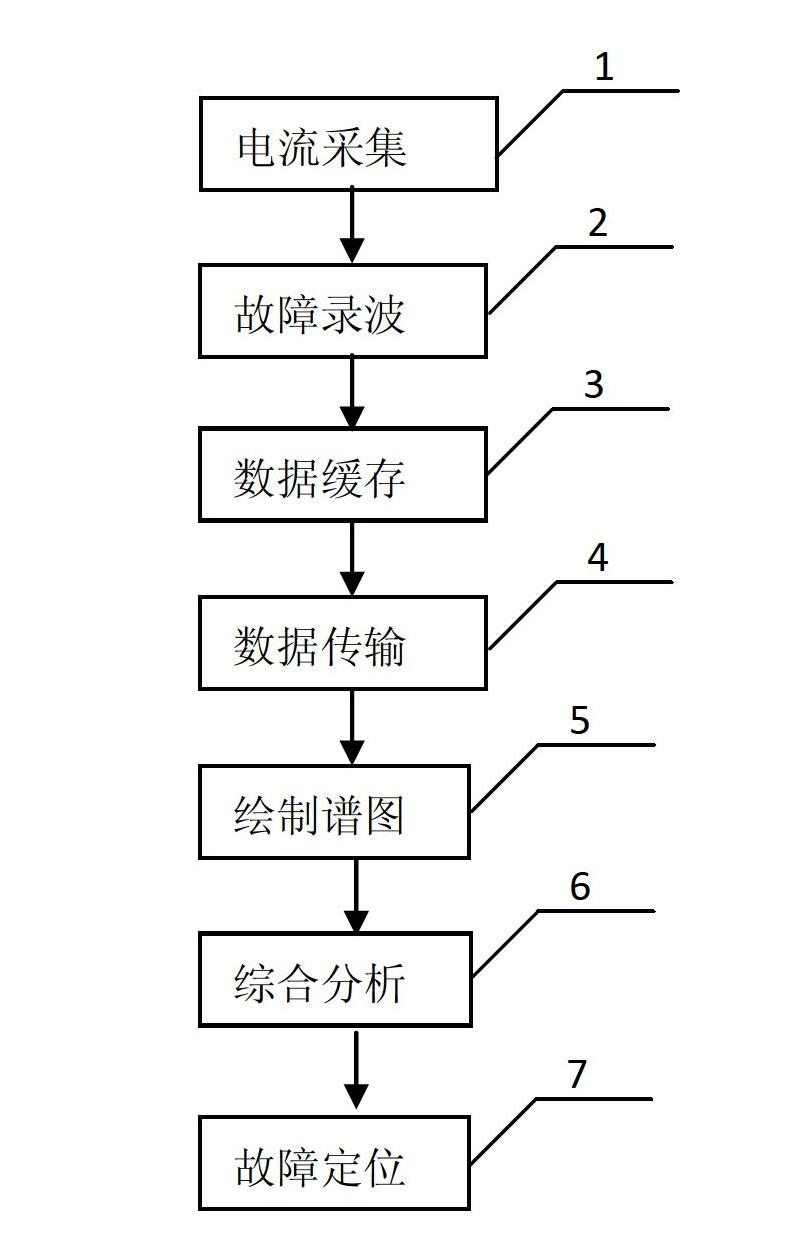

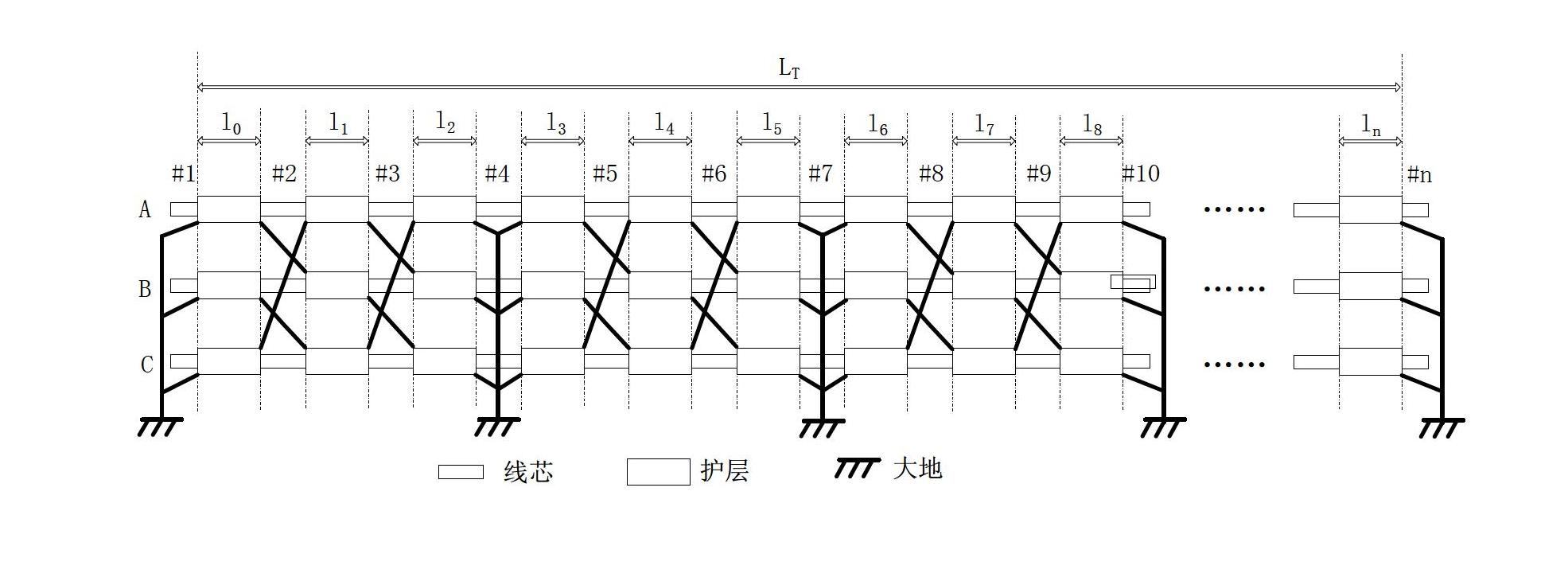

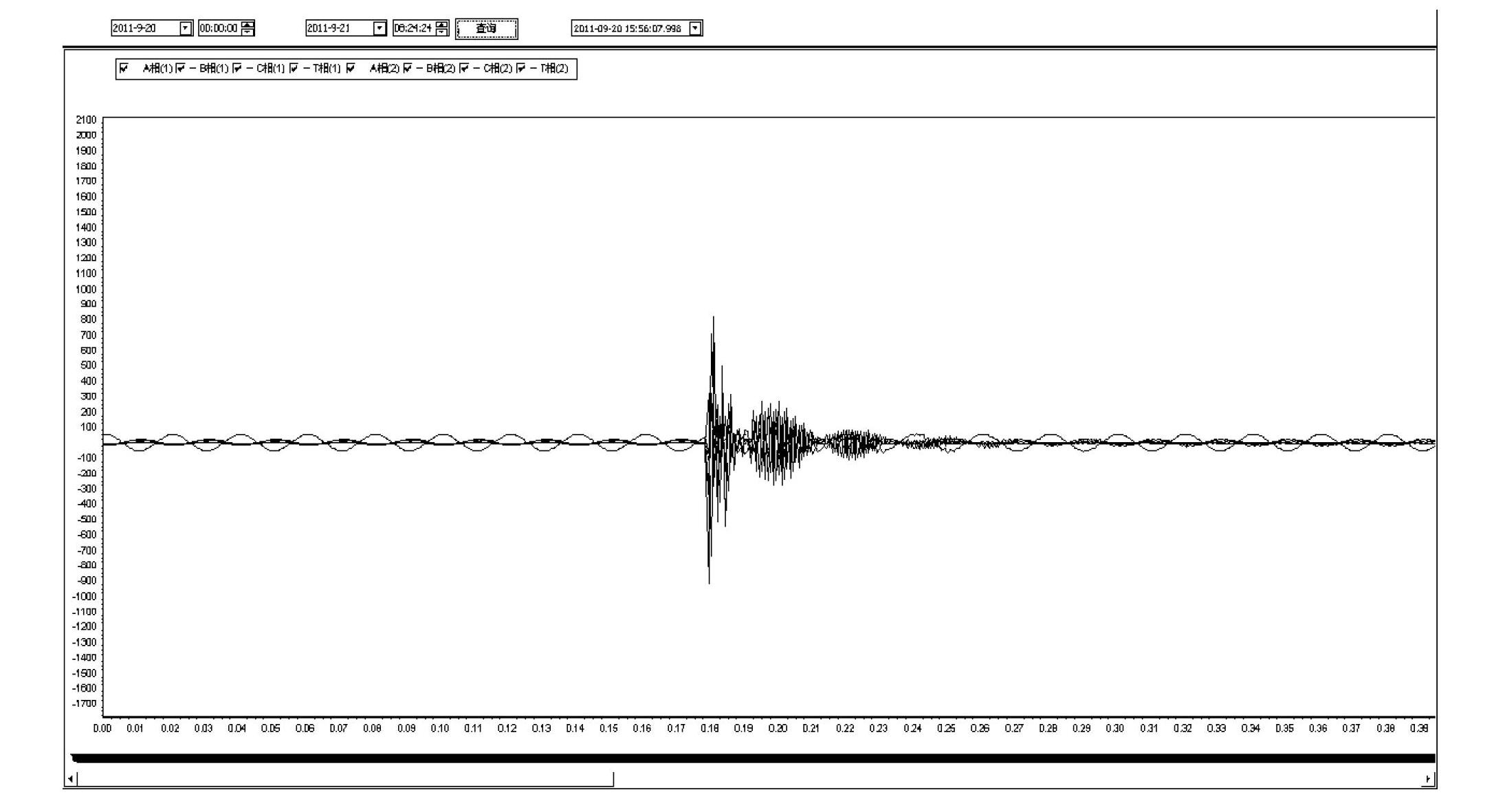

Online monitoring method for covert faults and joint process defects of power cable

The invention discloses an online monitoring method for covert faults and joint process defects of a power cable. The online monitoring method comprises seven steps, namely current acquisition, fault recording, data caching, data transmission, map drawing, comprehensive analysis and fault positioning. The online monitoring method comprises the specific steps of: acquiring transition and mutation of transfinite current of all earthing points in a cable sheath layer by using a current transformer arranged on the cable; uploading the acquired data to a monitoring host by a fault recording device connected with the current transformer; transmitting the received data to a monitoring platform in a TCP / IP (Transmission Control Protocol / Internet Protocol) Ethernet interface manner by the monitoring host; and carrying out comparative judgment, fault reason analysis and fault segment positioning on the acquired transition and mutation data of the transfinite current according to a specific analytic method by a server arranged in the monitoring platform. According to the system, the early finding of the covert faults and the joint process defects of the power cable can be realized and the basis for ensuring long-term normal operation of the power cable is provided; and comprehensive monitoring, accurate fault positioning and early warning can be realized.

Owner:康威通信技术股份有限公司

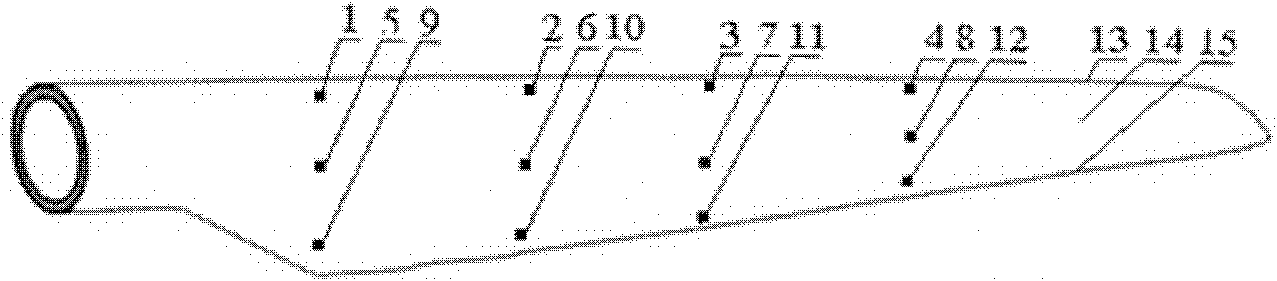

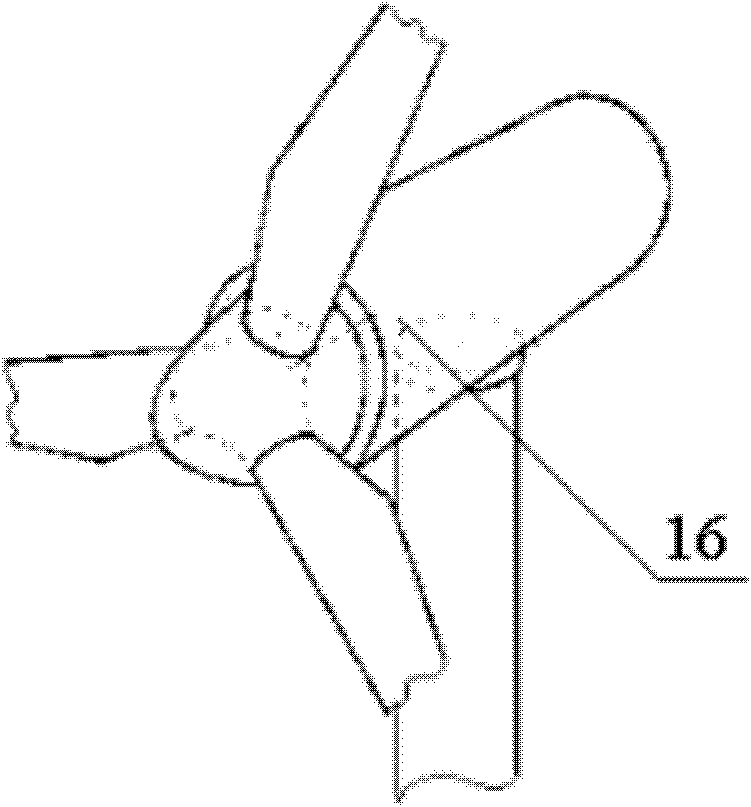

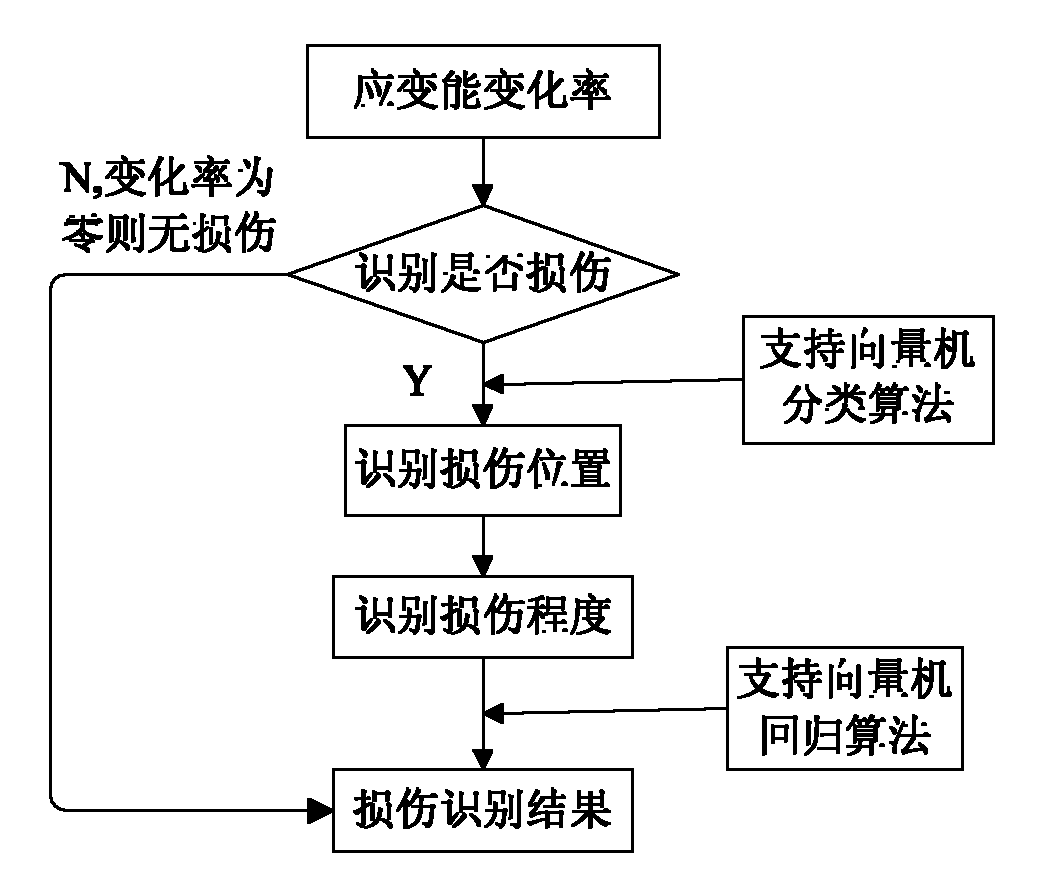

Blade fault diagnostic method based on strain energy response of wind-driven generator

InactiveCN102175449AAccurate diagnosisTimely brakingMachine part testingSubsonic/sonic/ultrasonic wave measurementWind drivenNacelle

The invention relates to a blade fault diagnostic method based on a strain energy response of a wind-driven generator, which comprises the following steps of: (1) obtaining the natural frequencies and the modes of the first M orders of the blade of a wind generator set by performing dynamic modeling and model analytical calculation to the wind generator set; (2) simulating the rotational excitation load of the blade through finite element calculation to the wind generator set to obtain strain energy time domain responses corresponding to the cabin sensor set points of the first M orders of the blade of the wind generator set, and then calculating strain energy frequency domain responses; and (3) obtaining the running state characteristic values of the blade of the wind generator set from the strain energy frequency domain responses corresponding to the cabin sensor set points of the first M orders of the blade of the wind generator set through the strain energy and the rate of change thereof and the method of a support vector machine, and then comparing to obtain a diagnostic result. The blade fault diagnostic method based on the strain energy response of the wind-driven generator related to the invention is simple and easy, high in sensitivity and accuracy and low in diagnostic cost, and can effectively improve the safety and reliability of the blade of the wind generator set and accurately perform fault point positioning, fault qualification and prediction for the blade.

Owner:TIANJIN POLYTECHNIC UNIV

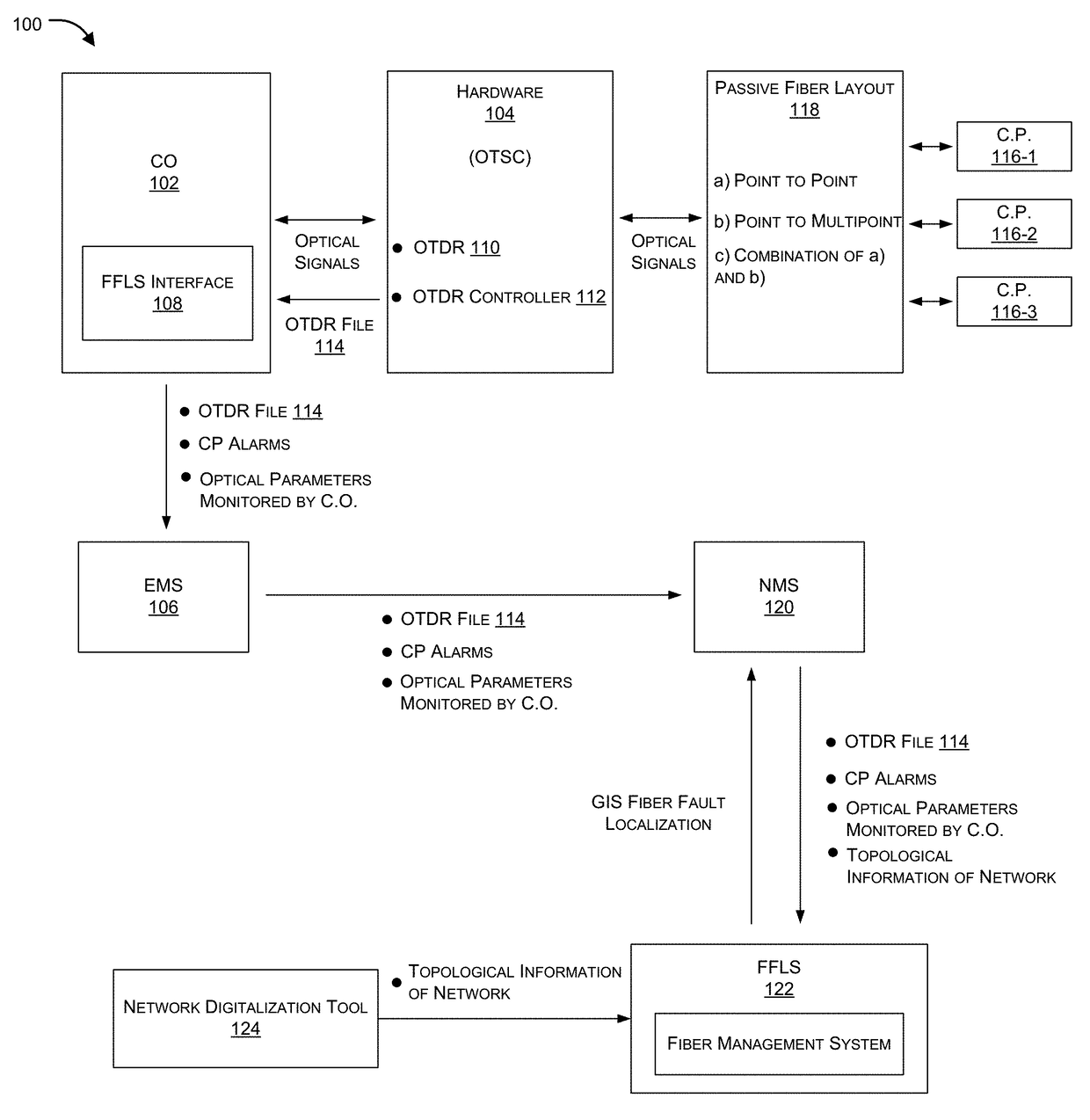

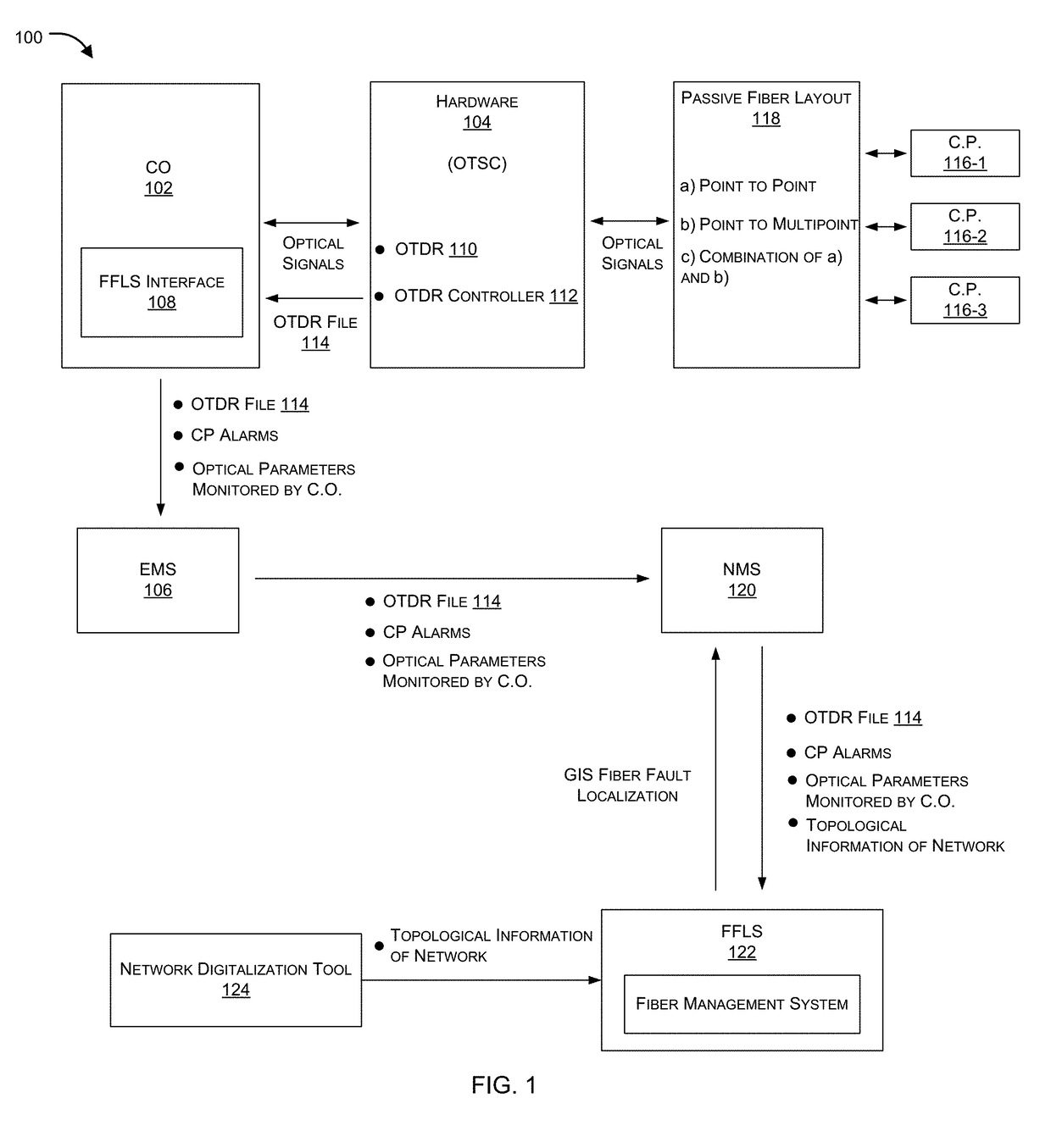

Gis based centralized fiber fault localization system

ActiveUS20180006715A1Accurate fault locationAccurately indicate exact location/position of the faultTransmission monitoring/testing/fault-measurement systemsTime domainFiber

Aspects of the present disclosure aim at configuring an optical time domain reflectometry (OTDR) in a central office such that the OTDR is configured to be operatively coupled with and also configured to periodically poll each fiber at defined intervals and compute / store a reflection signature that can be used to compare with future signatures received from subsequent polls of the fiber to determine a fault (e.g., a fiber cut or breakage) between the central office (CO) and one or more optical network unit (ONU) over GIS.

Owner:CENT FOR DEV OF TELEMATICS

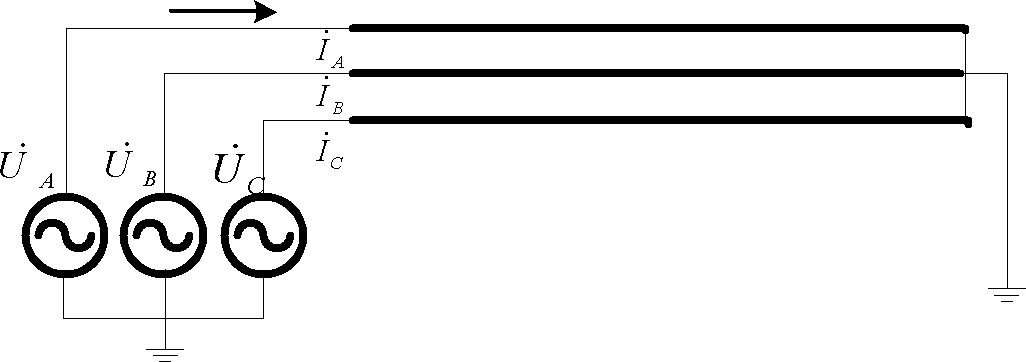

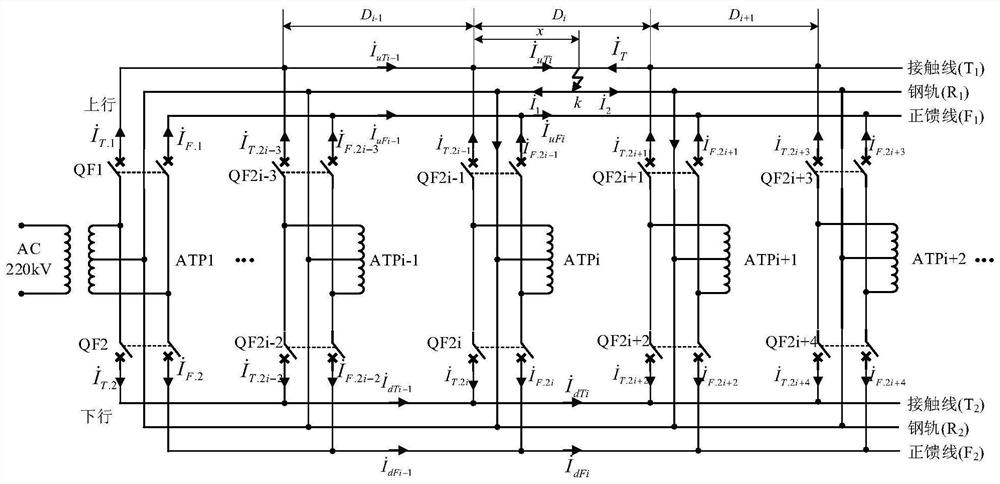

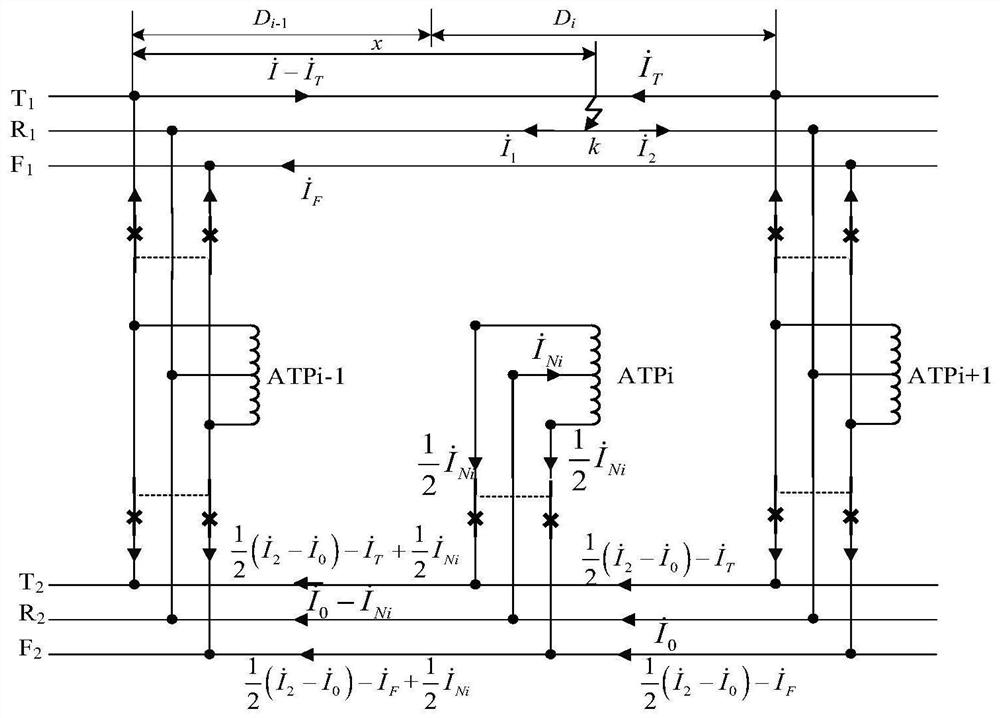

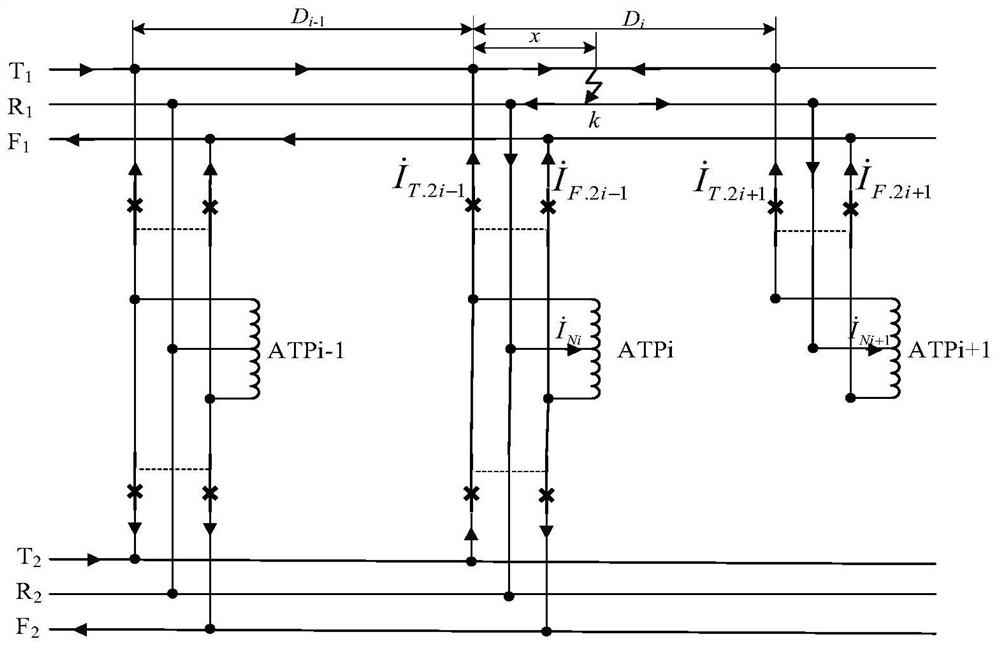

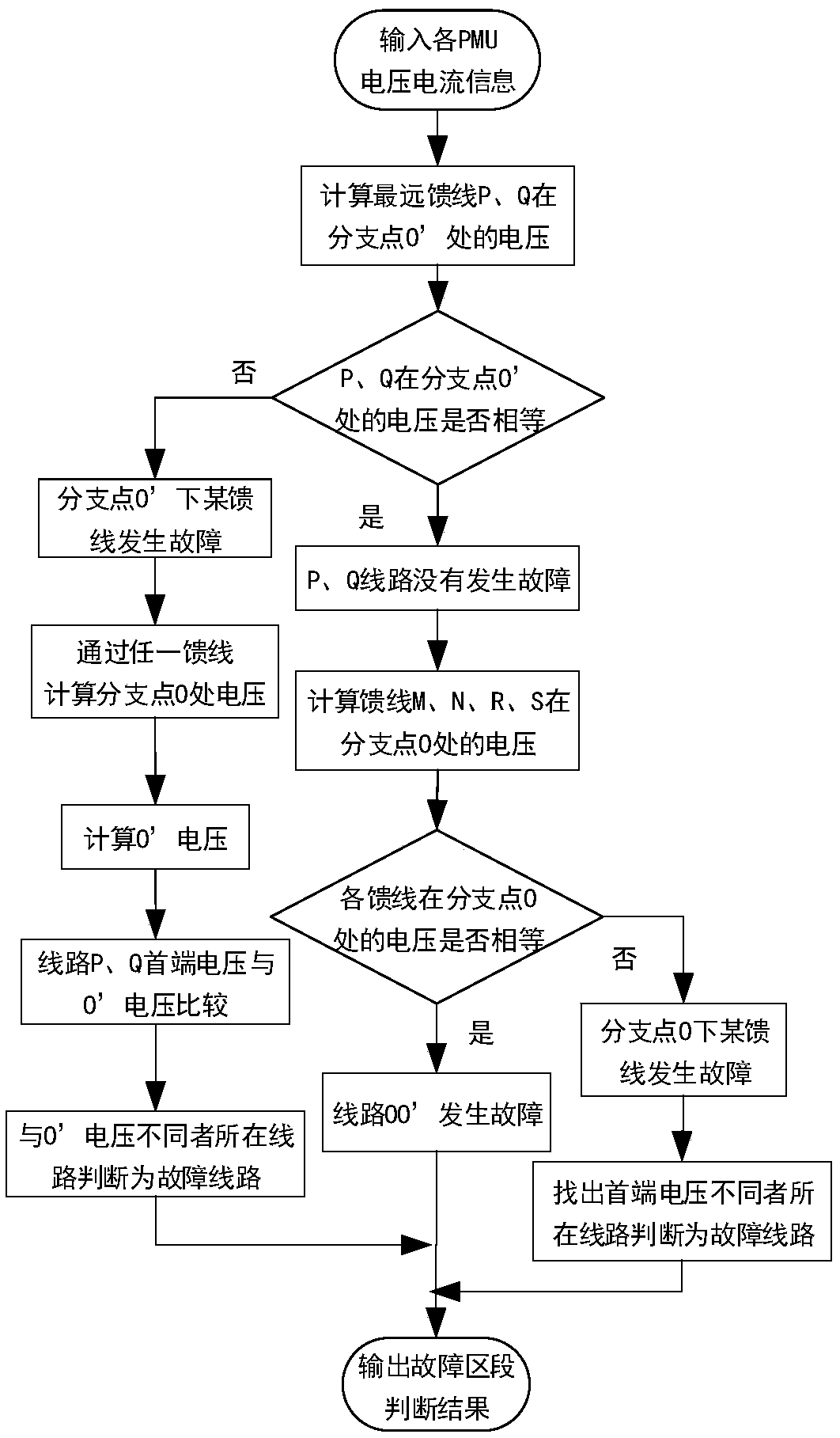

Full-parallel AT traction network fault location method

ActiveCN111796164AAvoid exhaustively enumerating various operating modes for distance measurementEasy to implementCurrent/voltage measurementFault location by conductor typesFeeder lineOvercurrent

The invention discloses a full-parallel AT traction network fault location t method, which comprises the following steps that: when a fault occurs, synchronously acquiring the states of uplink and downlink bipolar feeder circuit breakers of each kiosk and the current flowing through the circuit breakers, and constructing a traction network parallel state matrix and a feeder current matrix; constructing a current state matrix and a fault state matrix; and judging whether the fault section is an uplink and downlink parallel section post-ranging section, or judging whether the fault section is asingle-line AT section post-ranging section, or judging the fault type post-ranging section. The invention has the following beneficial effects: the operation mode of the traction network is characterized by the switch state matrix, the fault section is identified by the current state matrix and the fault state matrix, and finally the fault distance calculation is realized by three classified fault location methods, which can realize the fault location in normal power supply operation mode and various abnormal power supply operation modes. The method has the characteristics of accurate distance measurement, high applicability and the like.

Owner:SOUTHWEST JIAOTONG UNIV

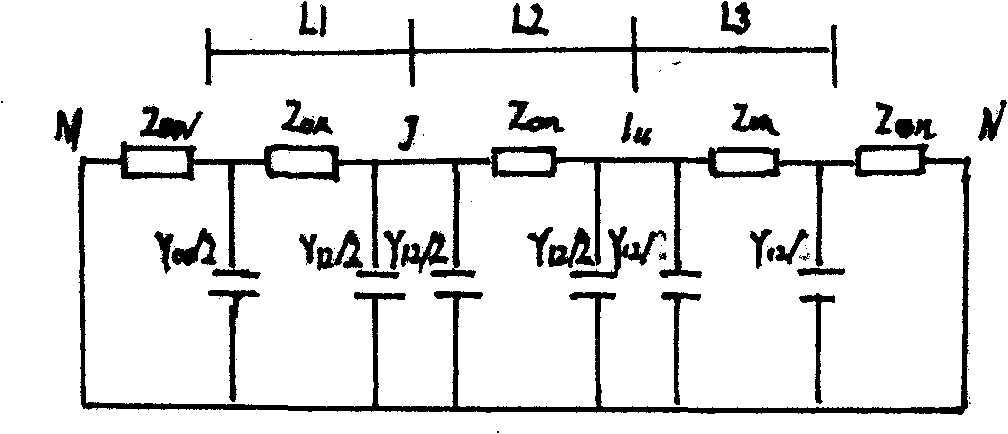

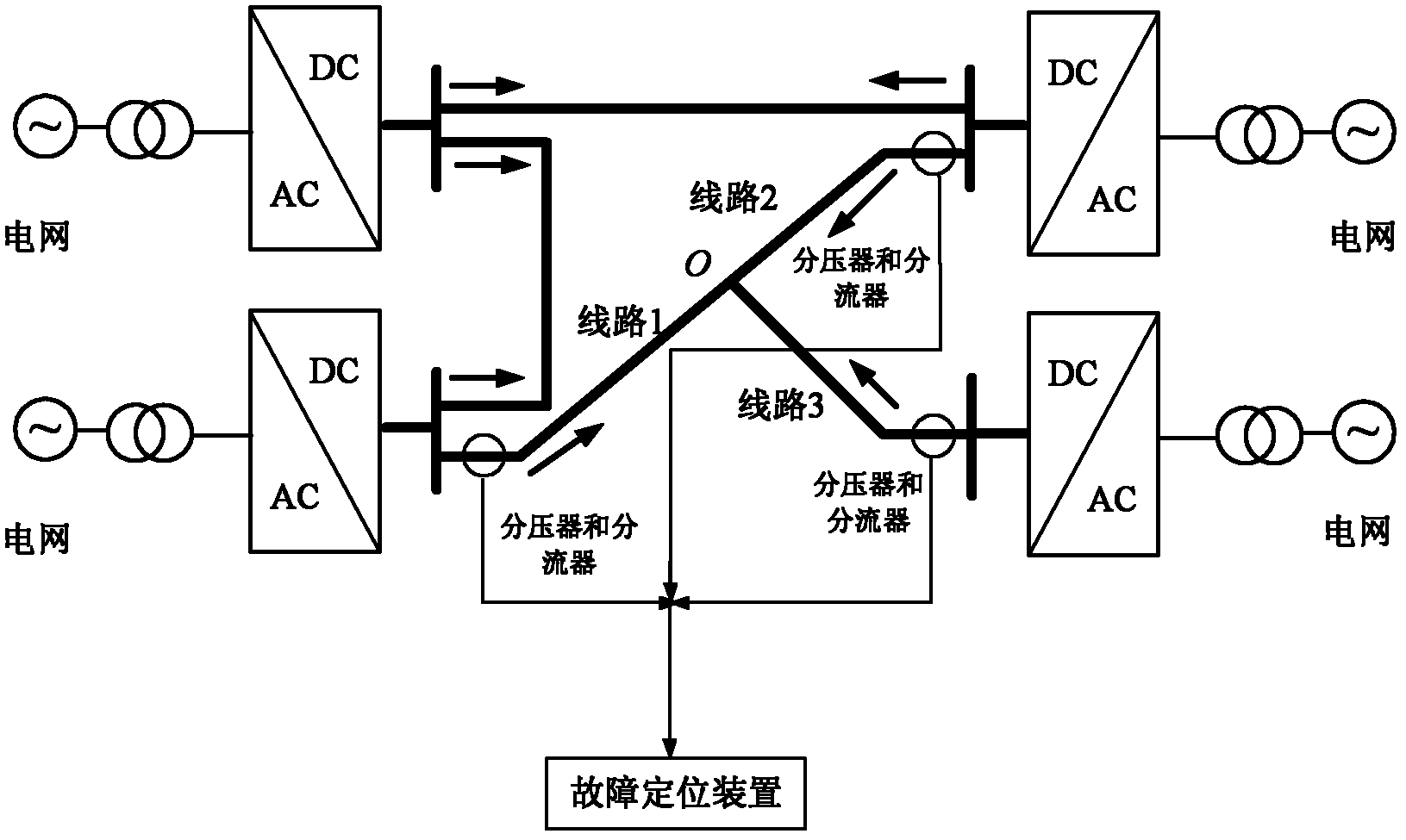

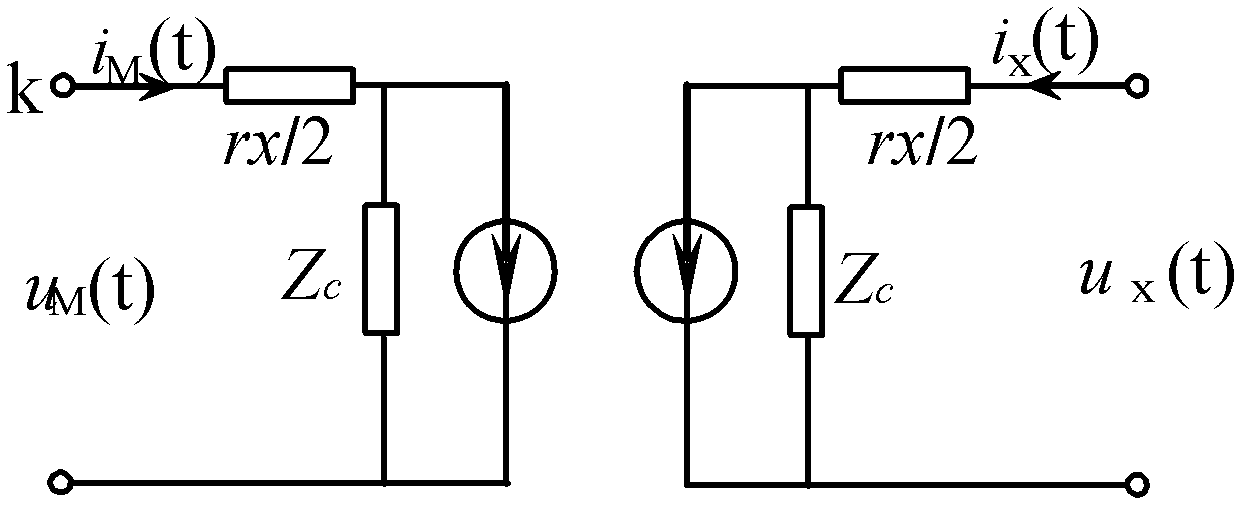

Time-domain fault location method of multibranch direct current line in multiterminal direct current power transmission system

ActiveCN102445638ADistributed parameter characteristics are obviousDownsamplingFault locationTime domainDistributed parameter model

The invention provides a time-domain fault location method of a multibranch direct current line in a multiterminal direct current power transmission system. The method is established on the basis of a distributed parameter model; in a time domain, sampling values of a direct current and a direct current voltage are converted into moduluses by utilizing modular transformation; according to voltages and currents at terminal points of a line, voltages of branch points of the line are calculated; comparison is carried out on voltages that are obtained by calculation of electric quantities at all the terminal points so as to select a fault branch; all good branches are used to calculate a voltage and a current of a branch point, and the electric quantity of the branch point and the electric quantity of the other end of the fault branch form a two-terminal line; and electric quantities of the two terminals are used to respectively calculate voltage distribution along the line, and fault location is realized according to a constant equal situation of voltages calculated at a fault point. According to the invention, a needed sampling rate is low and calculation is simple; and precise fault location with a short data window can be realized. Besides, the fault location method can be applied to a multiterminal direct current system containing branch lines, wherein the multiterminal direct current system can be a parallel system, a tandem type system or a mixing system.

Owner:XI AN JIAOTONG UNIV

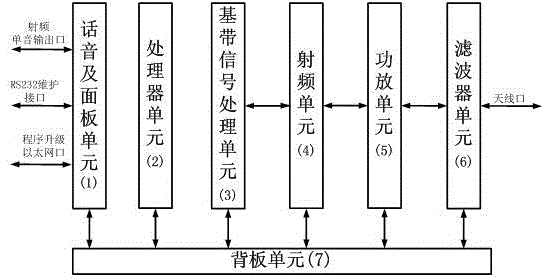

Wireless communication device testability design method

ActiveCN105553754AAchieve control and observabilityAvoid disassembling the whole machine out of the boxData switching networksRadio frequencyUpgrade

The invention discloses a wireless communication device testability design method. The method includes performing functional unit division on a wireless communication device, including a voice and panel unit, a processor unit, a baseband signal processing unit, a radio frequency unit, a power amplifier unit, a filter unit and a backboard unit, wherein the voice and panel unit, the baseband signal processing unit, the radio frequency unit, the power amplifier unit and the filter unit are connected with the processor unit through respective control interfaces and data communication interfaces via the backboard unit, and the voice and panel unit provides a device internal unit program upgrade interface and maintenance interface to the outside. Main faults of each unit are automatically diagnosed when the device is powered on, a test command is input through the maintenance interface when a fault occurs, a test signal passes through each unit inside and realizes loopback gradually, and the faults of each unit are diagnosed automatically. The wireless communication device testability design method has the beneficial effects of utilizing hardware resources of the device itself, increasing test software to realize testability design of the device itself, accurately positioning the faults inside the device, and greatly reducing debugging and testing and maintenance guarantee cost of the device.

Owner:CHONGQING JINMEI COMM

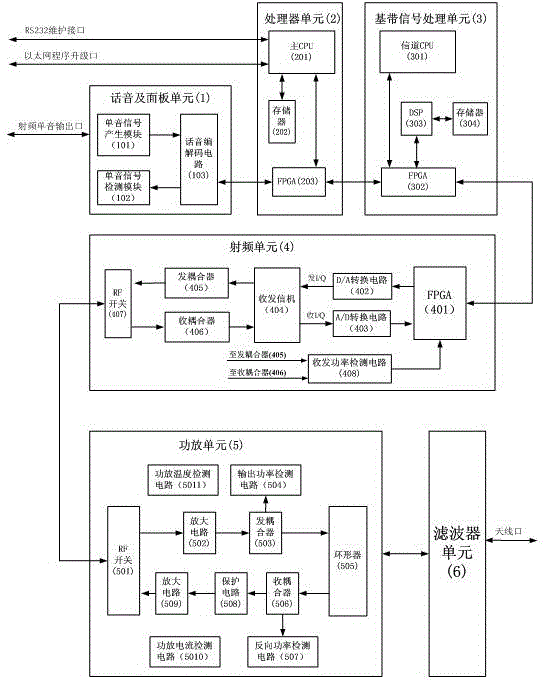

Fault range finding method of power distribution network based on equivalent positive and negative sequence impedance principle

ActiveCN109283429ASolve puzzlesAccurate fault locationFault location by conductor typesSystems intergating technologiesChannel state informationElectrical resistance and conductance

The invention discloses a fault range finding method of a power distribution network based on an equivalent positive and negative sequence impedance principle. According to the method, a PMU is used to obtain line state information in real time, and a fault line is determined by calculating and comparing the head-end line voltages in the same branch point; normal line information is used to calculate the head-end voltage and current of the fault line; and on the basis that electrical quantity of the two ends of the fault line is known, accurate fault locating is realized on the basis of the equivalent positive and negative sequence impedance principle. The difficulty that too many branch lines are included in fault location in the power distribution network via the limited PMU, and accurate fault locating is realized; fault range finding is realized by measurement in the two ends, it is not required to determine the fault type, the method is avoided from influence of transitional resistors or opposite-end feed-in current, and it is not required to consider the change of fault boundary condition or system operation manner, and compared with the single-end measurement method, the range finding precision is higher, fault range finding can be realized rapidly and accurately, the operational reliability, safety and flexibility of the system are improved greatly, and the applicationprospects are better.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +2

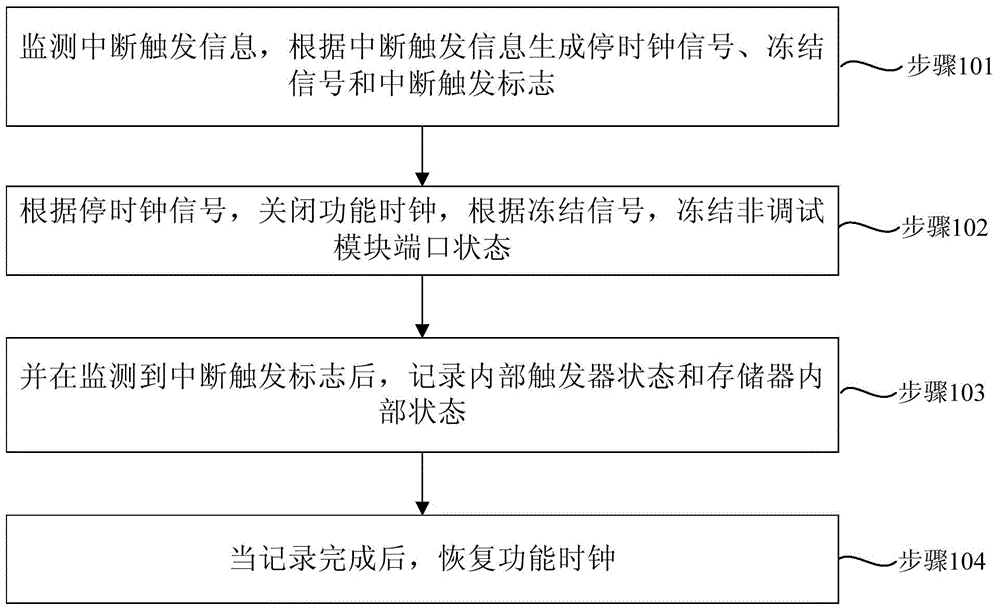

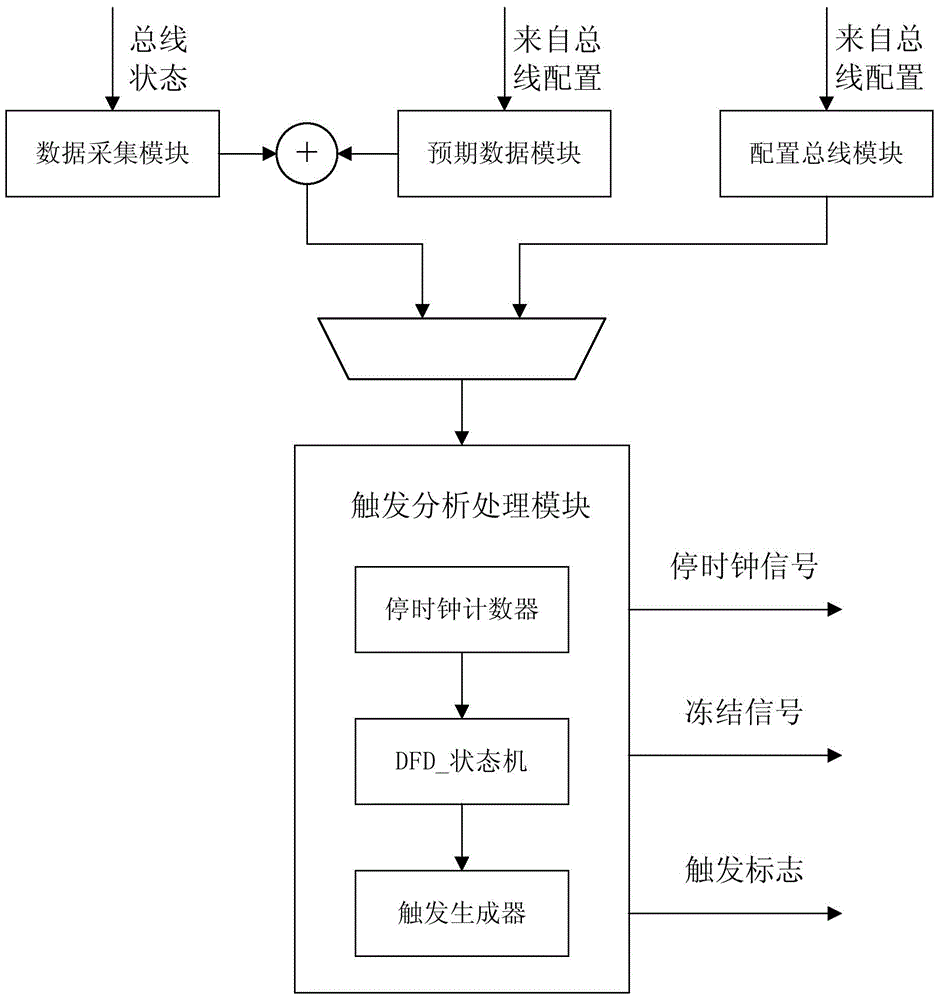

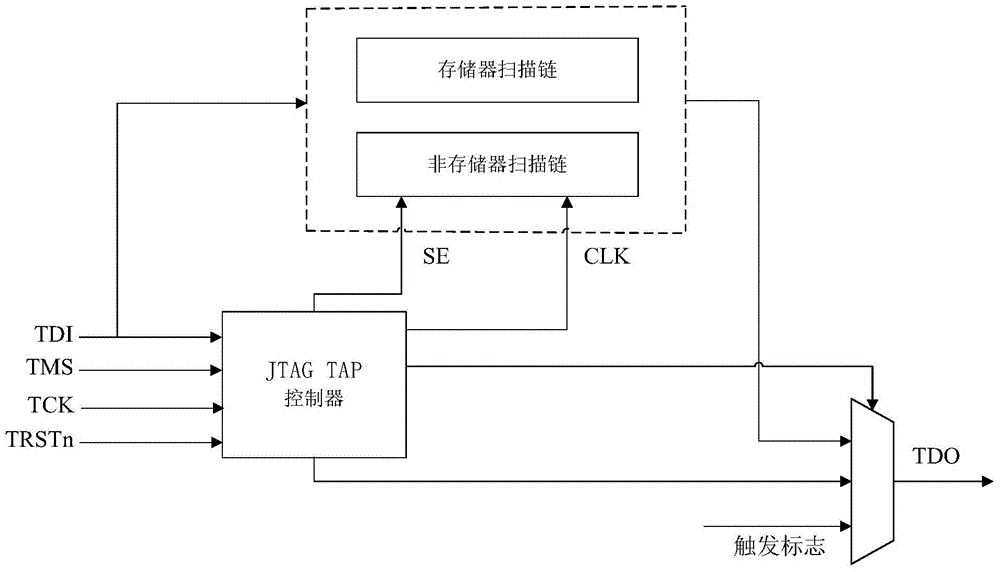

On-chip debug and diagnostic method, device and chip

ActiveCN106324476AImprove debuggabilityQuick TroubleshootingElectronic circuit testingRecovery functionEmbedded system

The present invention provides an on-chip debug and diagnostic method, a device and a chip. The method comprises the steps of monitoring the interrupt trigger information; generating a stop clock signal, a freeze signal and an interrupt trigger flag based on the interrupt trigger information; according to the stop clock signal, closing a functional clock; according to the freeze signal, freezing the state of a non-debug module port; upon monitoring the interrupt trigger flag, recording the state of an internal trigger and the internal state of a memory; after the recording is completed, recovering the function of the clock. Based on the on-chip debug and diagnostic method, the device and the chip, the functional clock can be automatically closed when the chip goes wrong, and the operation of a processor is paused. Meanwhile, the debug and diagnostic function is triggered automatically, so that the internal state of the chip can be quickly and accurately acquired. The debugging capability of the chip is effectively improved. therefore, the fault diagnosis is more rapid and the fault location is more accurate.

Owner:LOONGSON TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com