Online fault diagnosis method for hydraulic system

A fault diagnosis and hydraulic system technology, applied in fluid pressure actuation system testing, fluid pressure actuation devices, mechanical equipment, etc., can solve problems such as inability to efficiently diagnose real-time faults, accurate fault location, and maintenance decision-making support gaps, and achieve Good human-computer interaction performance, fault location, and system versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific steps of a hydraulic system online fault diagnosis method are as follows:

[0028] The first step is to build a hydraulic online fault diagnosis system

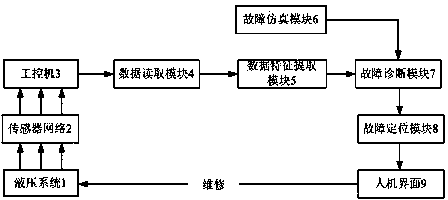

[0029] Hydraulic online fault diagnosis system, including: hydraulic system 1, sensor network 2, industrial computer 3, data reading module 4, data feature extraction module 5, fault simulation module 6, fault diagnosis module 7, fault location module 8 and man-machine interface 9.

[0030] The function of the data reading module 4 is: read the signal data collected by the sensor network 2 through the data acquisition card I / O port installed in the industrial computer 3; the function of the data feature extraction module 5 is: by filtering, read the data The key feature is to prepare for fault diagnosis; the function of the fault simulation module 6 is: perform fault injection simulation through the system model to obtain the fault simulation data of the hydraulic system; the function of the fault diagnos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com