Blade fault diagnostic method based on strain energy response of wind-driven generator

A fault diagnosis and strain energy technology, which is used in the testing of mechanical components, the testing of machine/structural components, and special data processing applications. problem, to achieve the effect of simple and easy diagnosis method, improve reliability and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

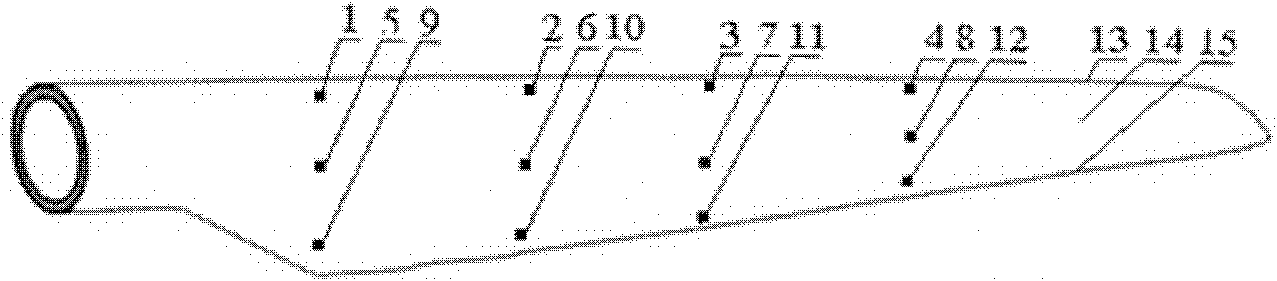

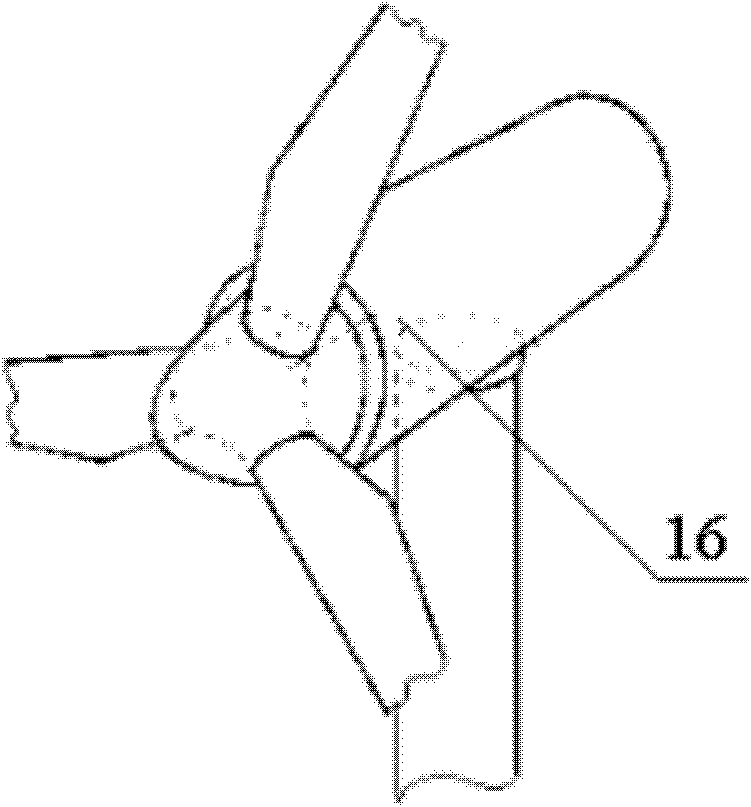

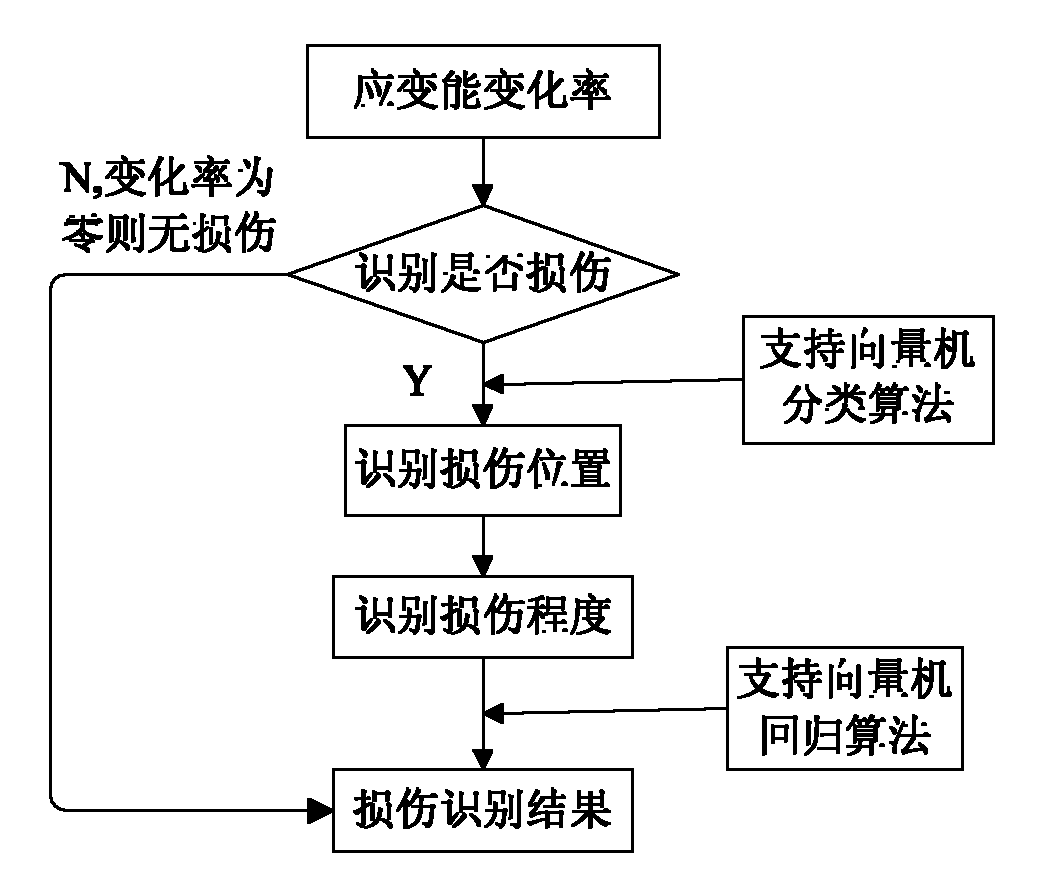

[0044] A blade fault diagnosis method based on wind turbine strain energy response, the wind turbine blade is mainly composed of blade spine 13; leaf cover 14; blade edge 15, the steps of the diagnosis method are:

[0045] (1) Through the dynamic modeling and modal analysis and calculation of the wind turbine, the first M-order natural frequency and mode of the blade of the wind turbine are obtained, 15≤M≤20;

[0046] (2) For wind turbines, simulate blade rotation excitation loading through finite element calculations, and obtain the time-domain response of strain energy corresponding to the setting point 16 of the front M-order nacelle sensor of wind turbine blades, and then calculate the time-domain response of strain energy into Strain en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com