Intelligent overhead line fault positioning and monitoring system

A technology of fault location and overhead lines, applied in the direction of fault location, etc., can solve problems such as wrong action information, fault indicator display information is not completely reliable, and reduce the time for fault finding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

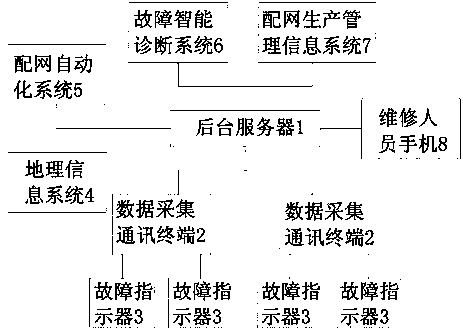

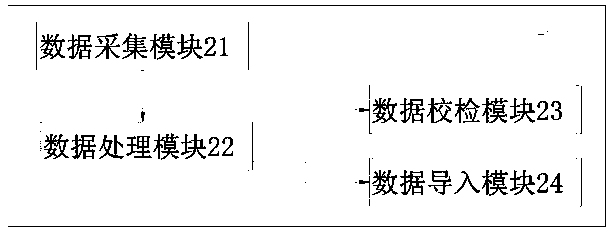

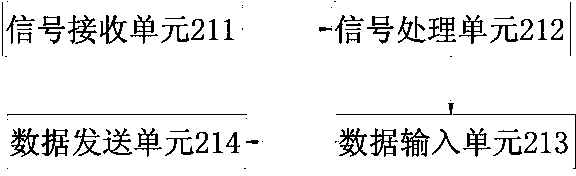

[0018] Such as figure 1 , figure 2 , image 3As shown, the present invention includes a background server 1, a data acquisition communication terminal 2 and a fault indicator 3 installed on the line, and the background server 1 is equipped with a fault location and monitoring platform and communicates with the data acquisition communication terminal through GPRS 2 to realize communication, the data acquisition communication terminal 2 communicates with multiple groups of the fault indicators 3 through radio frequency communication, and the intelligent overhead line fault location and monitoring system also includes Geographic information system 4, fault intelligent diagnosis system 6, distribution network automation system 5, and distribution network production management information system 7, the fault location and monitoring platform accesses the geographic information system after receiving the action message of the fault indicator 3 information system 4, and define all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com