Sample preparation equipment dedicated to triaxial test and capable of preparing high-density disturbed soil sample

A technology of triaxial test and disturbance of soil samples, applied in the preparation of test samples, etc., can solve the problems of high cost of soil samples, cumbersome operation, high experience and technical requirements, etc., and achieve the effect of convenient operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below through examples.

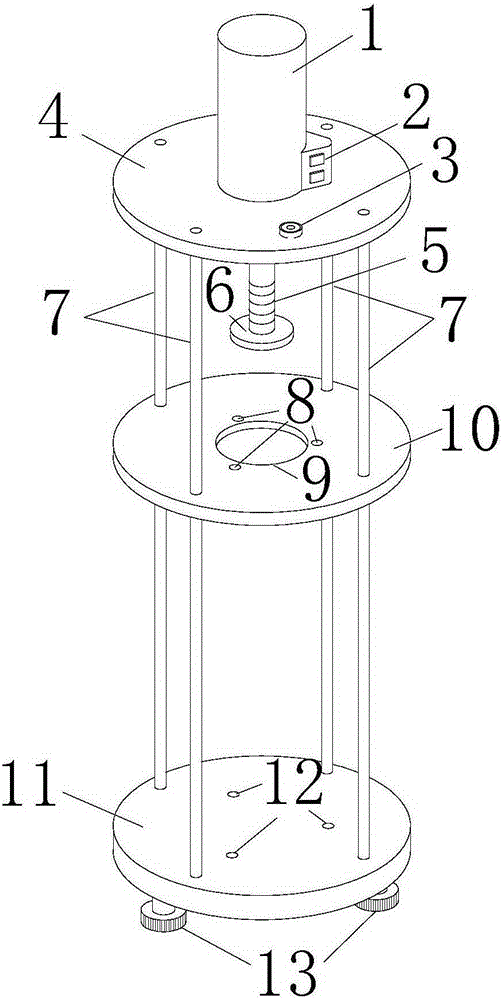

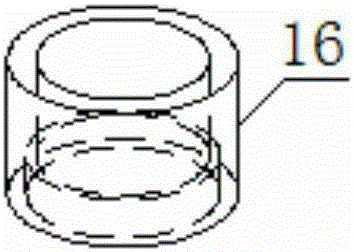

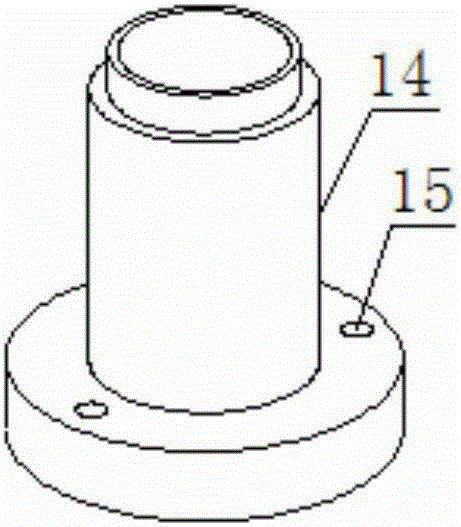

[0028] A special sample preparation device for triaxial testing that can prepare high-density disturbed soil samples, including an electro-hydraulic jack 1, a horizontal air bubble 3, a top plate 4, an extended piston rod 5, a pressed cake 6, a middle plate 10, and a bottom plate 11. The specific structure and The connection relationship is as follows: the electro-hydraulic jack 1 and the horizontal air bubble 3 are installed on the top plate 4, the electro-hydraulic jack 1 is connected with the extended piston rod 5, and the electro-hydraulic jack 1 controls the rising and pressing down of the extended piston rod 5 through the electric switch 2 . The end of the extended piston rod 5 is threaded to the stainless steel press cake 6, and different diameters of the press cake 6 are configured according to different triaxial test specifications. The diameter of the press cake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com