Embedded intelligent monitoring and remote maintenance system of powder forming machine

A powder molding machine, remote maintenance technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., to meet real-time processing needs, improve fault recovery efficiency, and high system configurability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

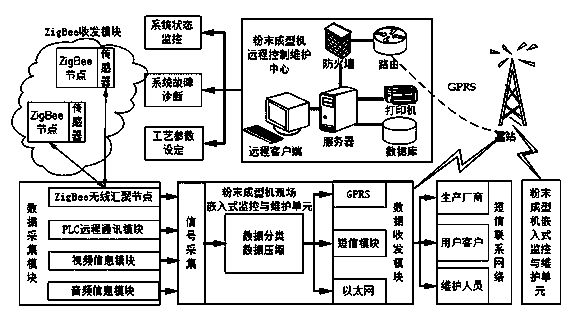

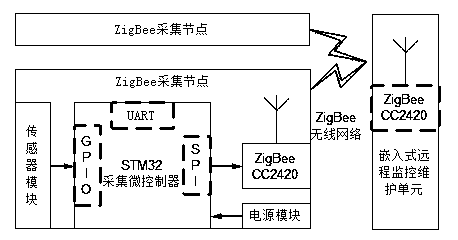

[0022] Combined with Figure 1, the overall composition of the embedded intelligent monitoring and remote maintenance system is illustrated: the network structure model based on the B / S mode of the present invention is mainly composed of three parts, the embedded monitoring and maintenance unit 1, the remote control and maintenance of the powder molding machine manufacturer Center 2 and contact network 3 with those responsible for powder molding machine components. Among them, the embedded monitoring and maintenance unit 1 collects the status parameters and soft component information of the PLC, the on-site picture information of the powder molding machine, and the sound signal of the operation site through the data acquisition module 5, and collects the crankshaft stress, fuel tank temperature, and main slide through the ZigBee transceiver module 15. Block pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com