Patents

Literature

41results about How to "Facilitate division of labor and cooperation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

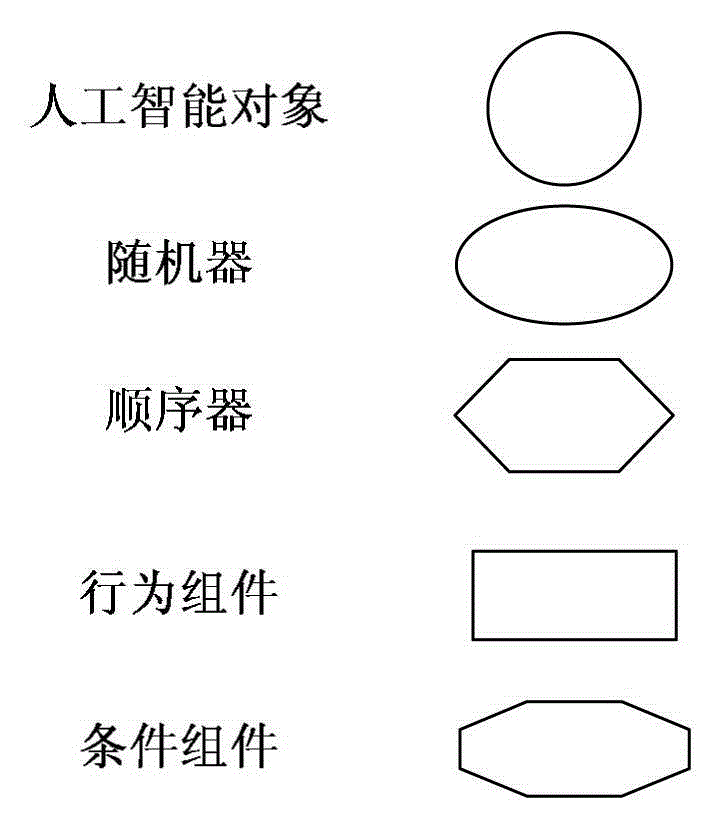

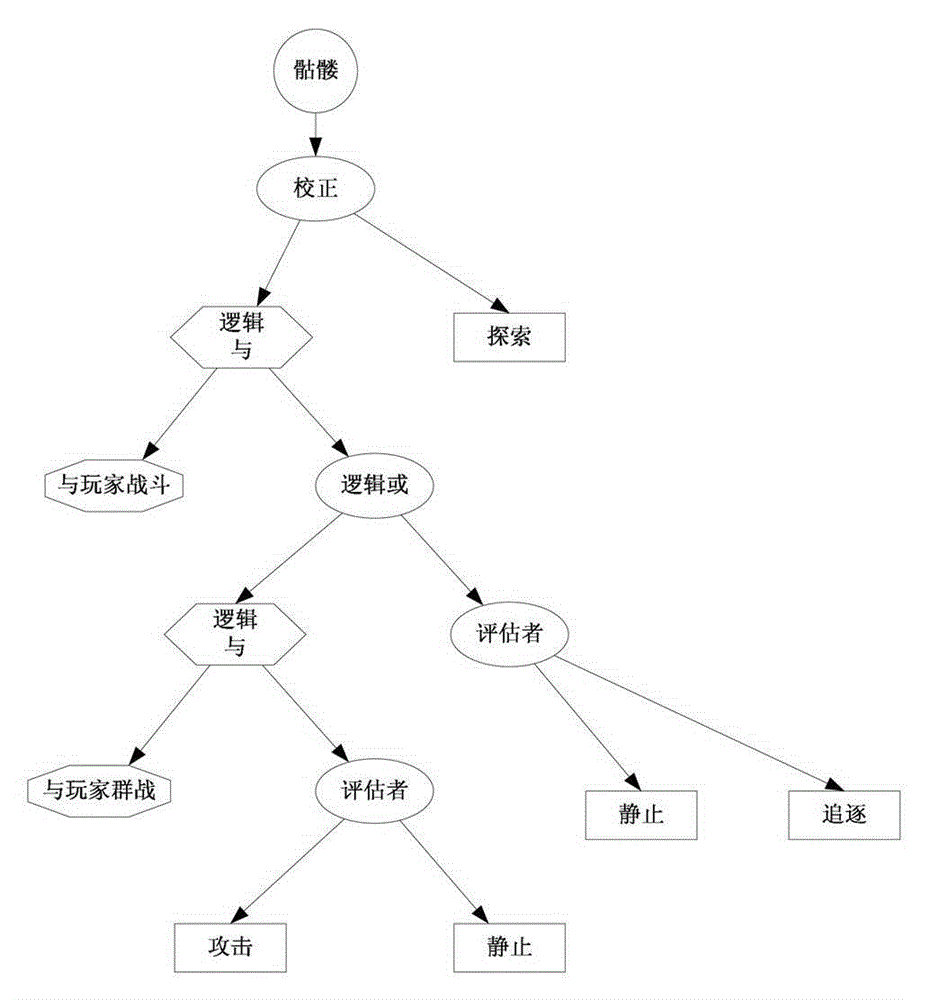

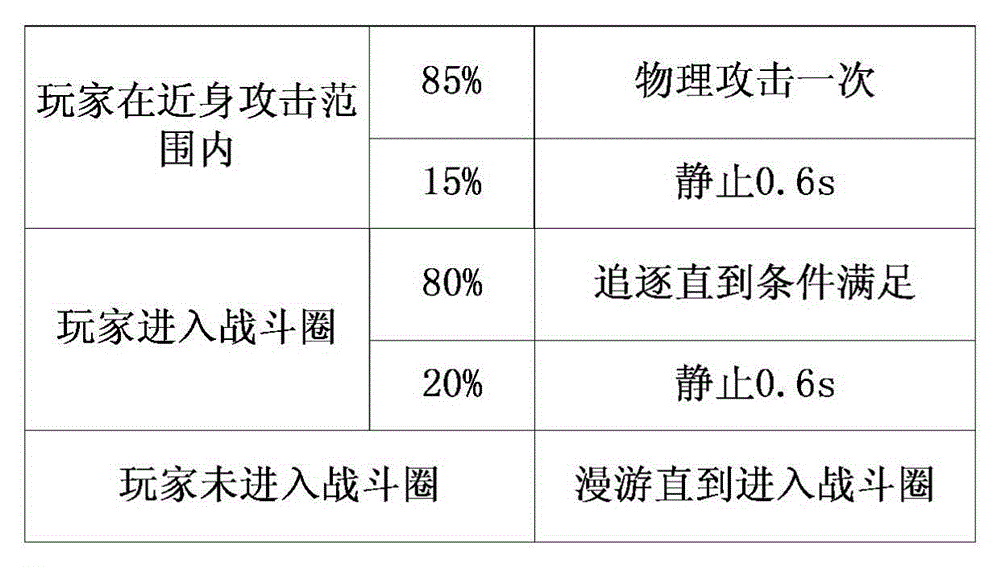

Visual design system of artificial intelligence of game on the basis of XML (Extensive Markup Language)

ActiveCN105183445AShorten the development cycleEasy to editSpecific program execution arrangementsGraphicsMaintainability

The invention discloses a visual design system of the artificial intelligence of a game on the basis of an XML (Extensive Markup Language). The system comprises a system logic device, a graph editor, a function editor, a graph configurator and an integral actuator, wherein the system logic device comprises a connection assembly and a function assembly and is used for describing assembly logics; the graph editor is used for graphically expressing the assemblies and combining the assemblies into an artificial intelligence tree structure; the function editor is used for compiling corresponding attributes and functional interface functions for the assemblies; the graphic configurator is used for configuring the attributes and the functional interface functions to the assemblies; and the integral actuator is used for traversing, backtracking, interrupting and blocking the assemblies of the artificial intelligence tree to cause the artificial intelligence tree structure to own an integrated function. The visual design system has the beneficial effects that a development period of the artificial intelligence is obviously shortened, the maintainability and the reusability of codes are enhanced, game experience is improved, personnel on various posts can work in cooperation with a due division of labor, and a flow is optimized.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

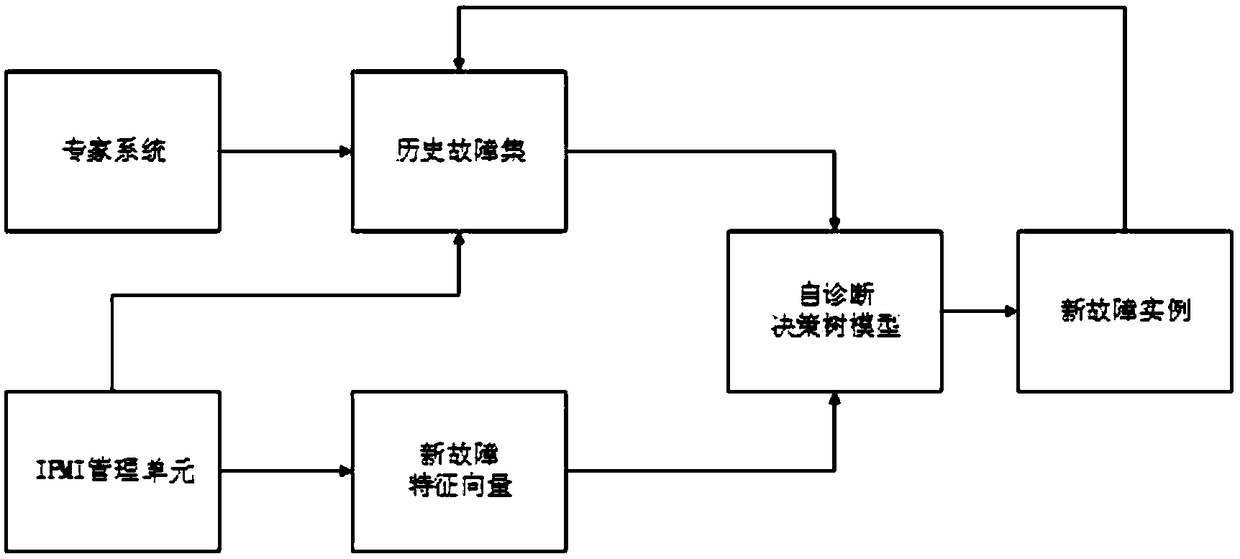

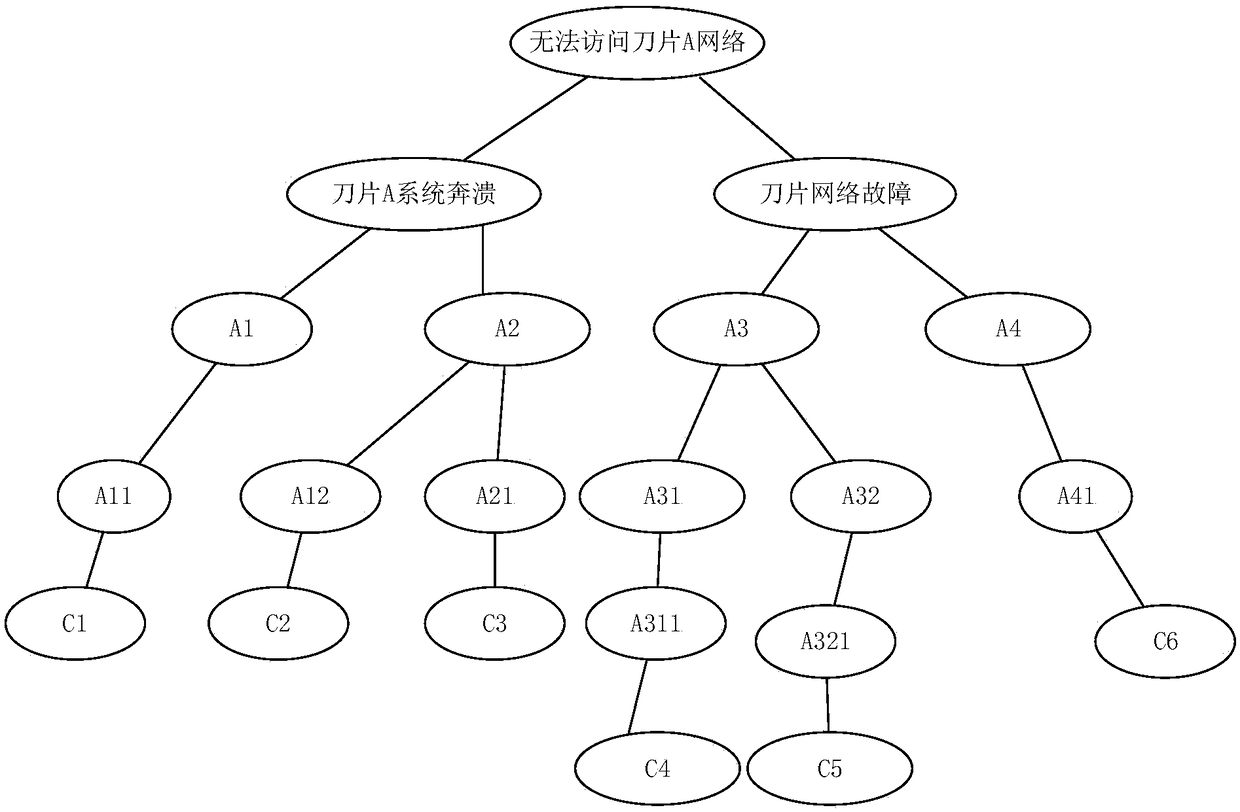

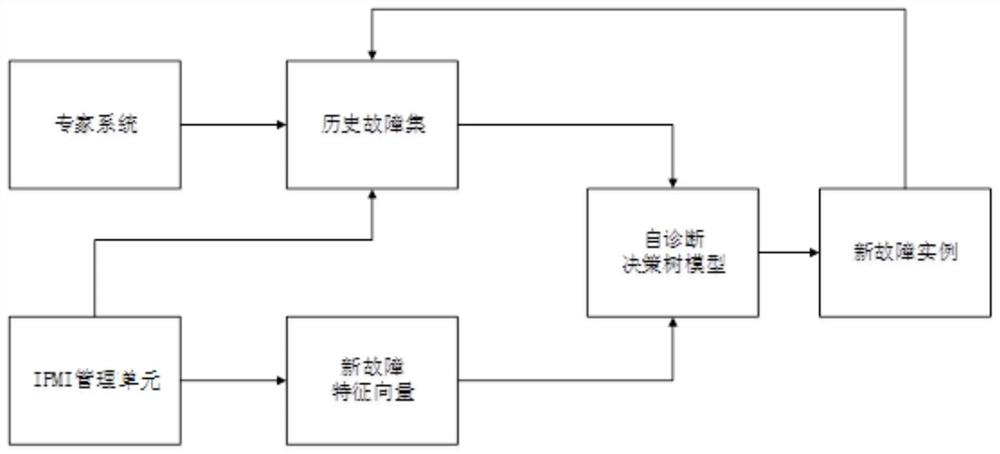

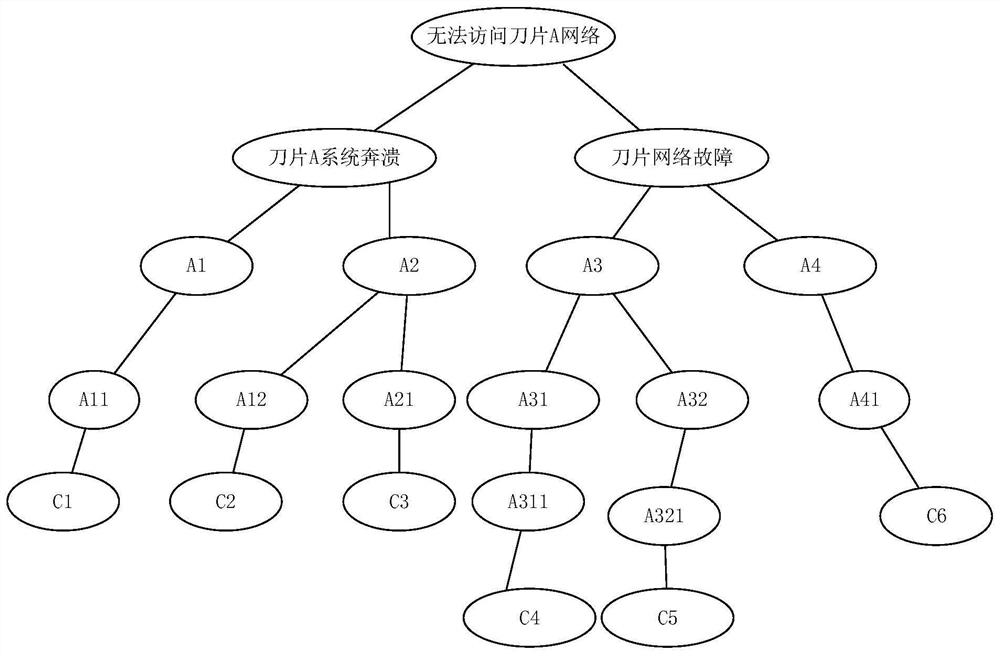

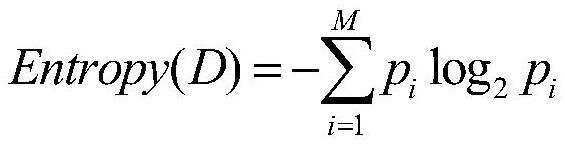

Server fault automatic detection system and detection method based on decision tree

ActiveCN109218114AFacilitate division of labor and cooperationImprove readabilityData switching networksFeature vectorManagement unit

The invention discloses a server fault automatic detection system and a detection method based on a decision tree, which combines an expert system and an IPMI management unit to generate a historicaldata set. The server running state data, i.e. Abnormal data stream, is obtained by IPMI management unit. According to the abnormal data stream, the new fault feature vector is extracted, and the new feature vector and the fault cause relation pair are formed into a fault data set, and the fault data set is trained into a self-diagnosing decision tree model. When the server fails while running, thecorresponding fault feature vectors are extracted, the fault types are automatically judged by the self-diagnostic decision tree model, After the fault is cleared, the fault feature vector and the fault cause relation are updated and the self-diagnosing fault tree model is updated. Therefore, the fault diagnosis system will be more accurate and reliable with the improvement of the history fault set.

Owner:XIAN MICROELECTRONICS TECH INST

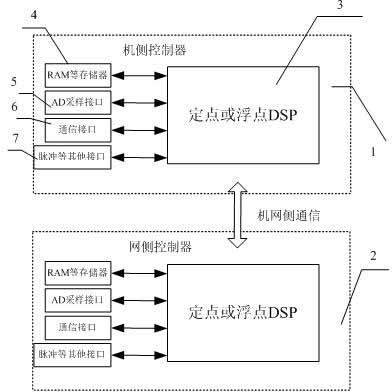

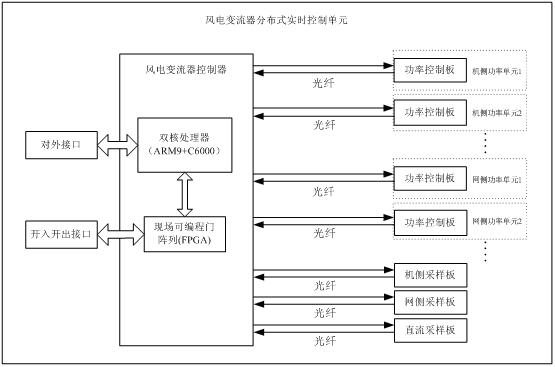

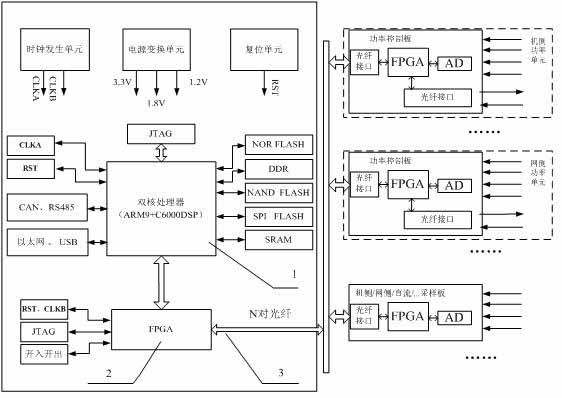

Distributed real-time control unit of wind power converter

InactiveCN102510092AEasy wiringImprove real-time performanceSingle network parallel feeding arrangementsConvertersControl cell

The invention discloses a distributed real-time control unit of a wind power converter. The distributed real-time control unit is characterized in that: a machine side sampling board, a network side sampling board and a DC (direct current) sampling board are mounted at a power loop sampling point nearby so as to realize nearby sampling; an analogue quantity is converted into a digital quantity by an AD (analogue / digital) converter and then transferred to a controller in a serial mode through an optical fiber while a hardware protection threshold value and control command information sent by the controller are received; a power control board mounted on a machine network side power unit receives a pulse signal sent by the controller, performs serial-parallel conversion and pulse protection treatment, and sends the signal to a power element to realize control of the converter; and meanwhile, the phase current and temperature signal of the power unit are sampled in real time and converted into a digital signal through the AD converter to be sent to the controller in a serial mode. Through the invention, the real-time performance and reliability of the system can be effectively improved, the cost is saved, the converter wiring is simplified, and relatively high generality and cuttability are realized.

Owner:STATE GRID ELECTRIC POWER RES INST

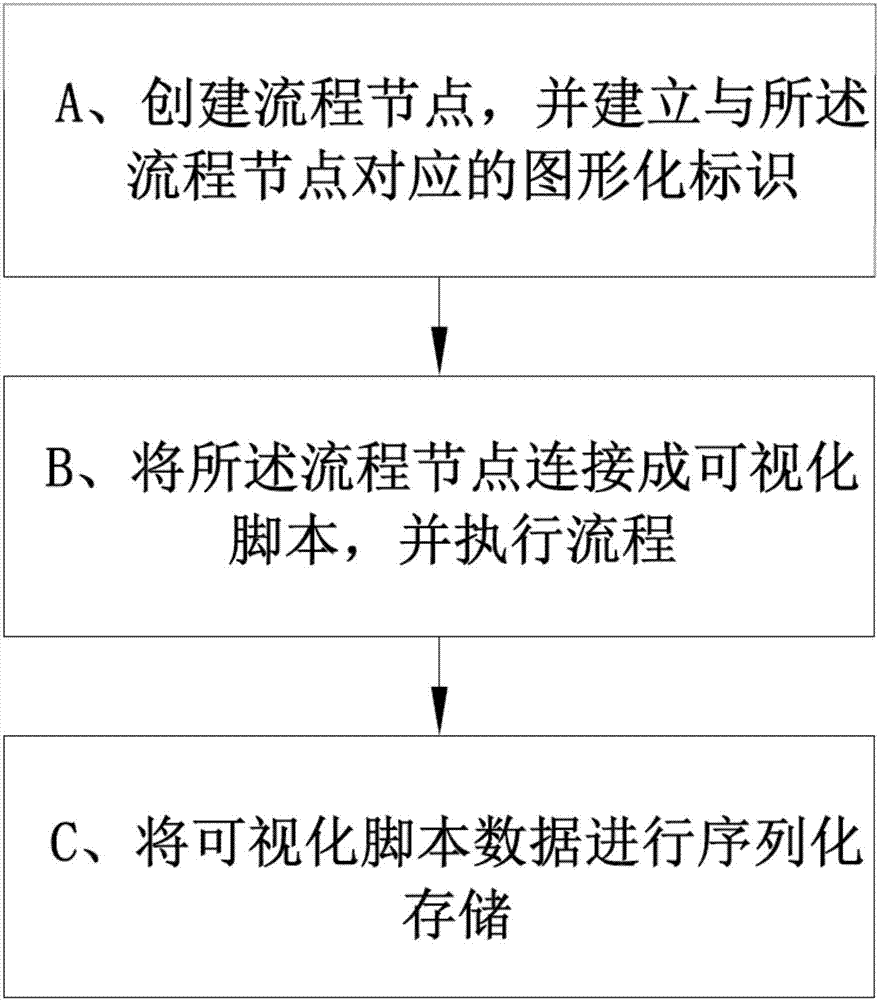

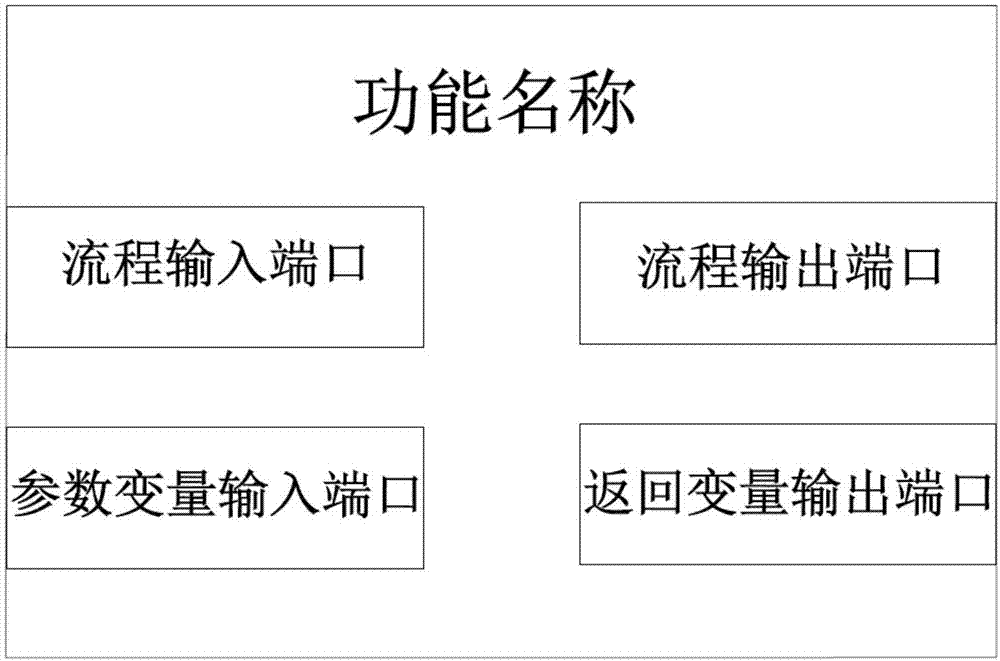

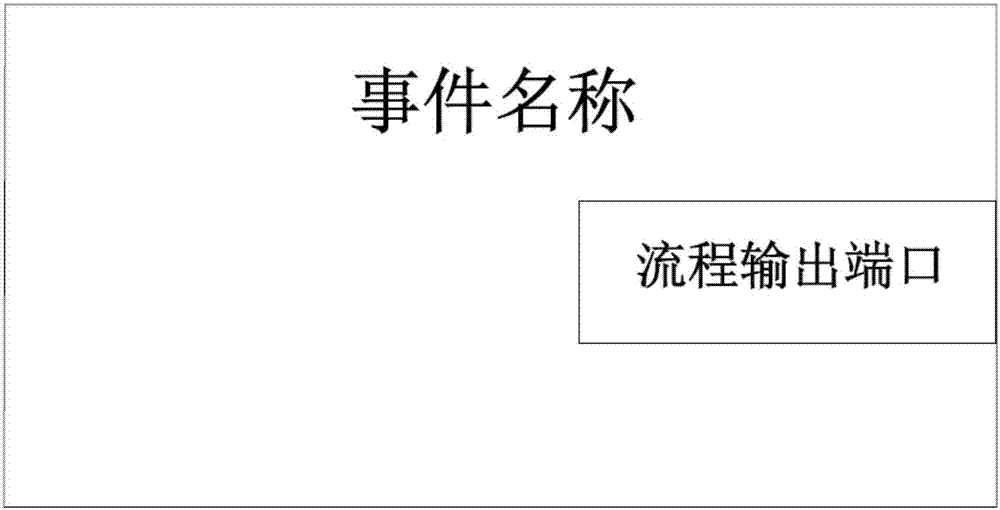

Design system and method of visualization script editor

ActiveCN107357567APromote division of laborShorten the development cycleIntelligent editorsVisual/graphical programmingDesign systemsSerialization

A method for implementing a visualization script editor is provided. The method comprises following steps: A. creating flow nodes and building graphical identifications corresponding to the flow nodes; B. connecting the flow nodes into a visualization script and executing the flow; C. performing serial storage on the visualization script data. The invention also discloses a design system corresponding to the visualization script editor. The method and system of the invention facilitate planning personnel and artists to take part in game development so that they can better share out the work and cooperate with one another; the flow is optimized; the development period is shortened; specific requirements of visual understanding of games are facilitated; reusability and scalability of codes are enhanced.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

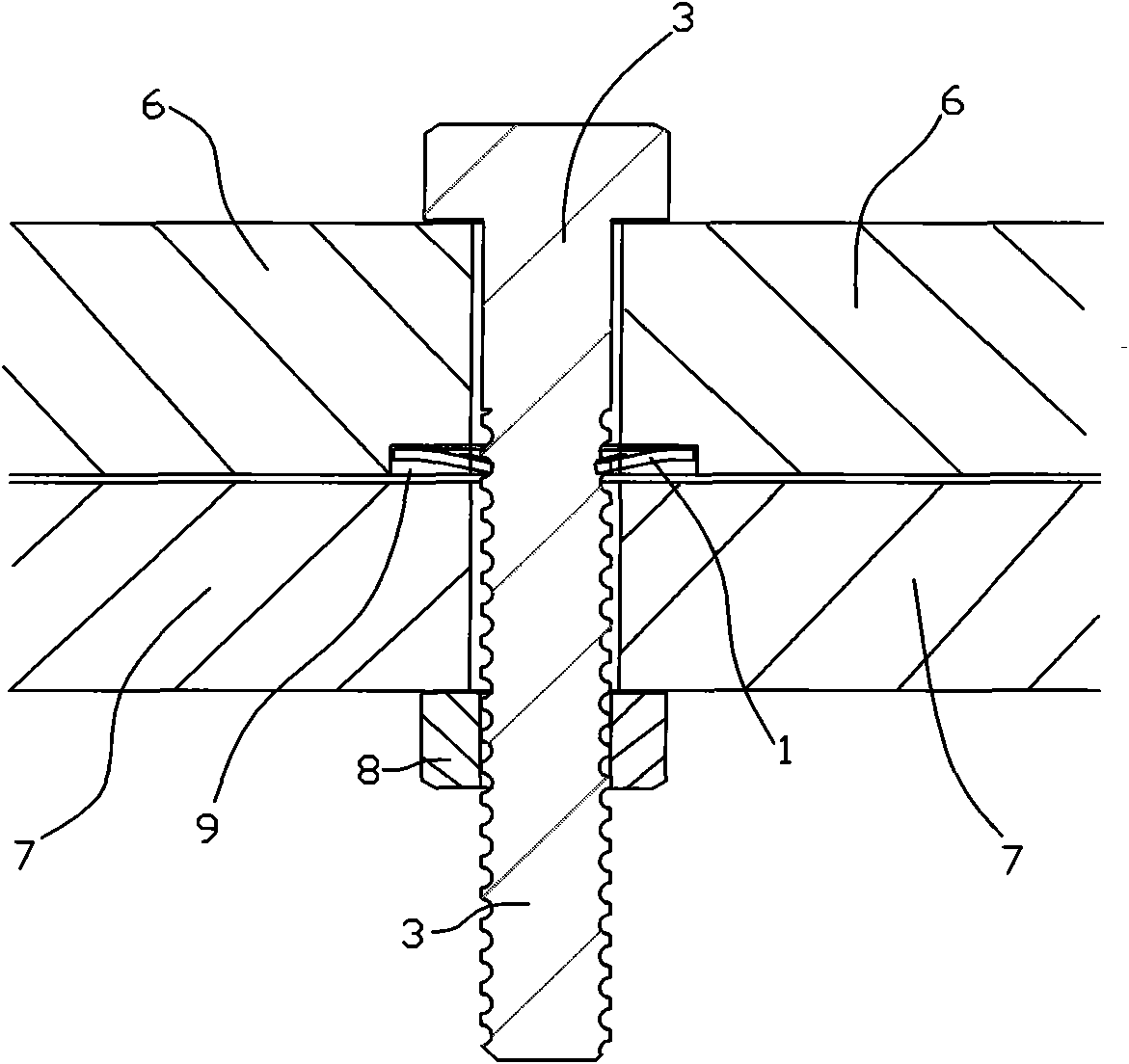

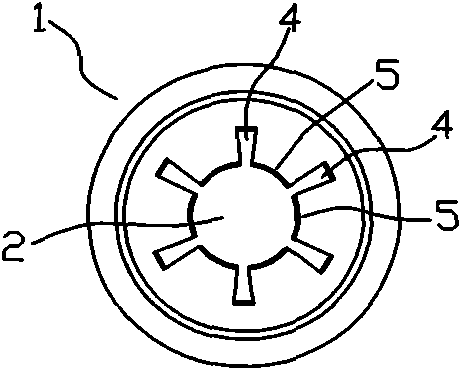

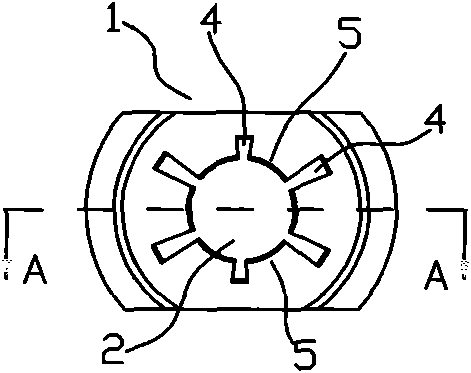

Bolted connection structure and lock washer and luggage rack thereof

The invention provides a bolted connection structure capable of effectively reducing bolt movement and a lock washer thereof, and an automobile luggage rack with the structure. The center of the lock washer (1) is provided with a round hole (2), and the diameter of the round hole (2) is slightly larger than the external diameter of threads of a bolt (3) to be locked by the round hole (2), so thatthe round hole (2) and the bolt (3) are in interference fit after the bolt (3) is screwed in; and the periphery of the round hole (2) is provided with a plurality of grooves (4) among which a plurality of deformation teeth (5) are formed. In the bolted connection structure suitable for the automobile luggage rack, the bolt (3) passes through two connected pieces (6 and 7), the lock washer (1) is screwed in or pressed in the bolt (3), and the deformation teeth (5) are deformed to be embedded into the threads of the bolt (3); or the bolt (3) passes through an upper connected piece (6), the lockwasher (1) is screwed in or pressed in the bolt (3), the bolt (3) passes through a lower connected piece (7), and a nut (8) is screwed in.

Owner:NINGBO XINTAI MACHINERY

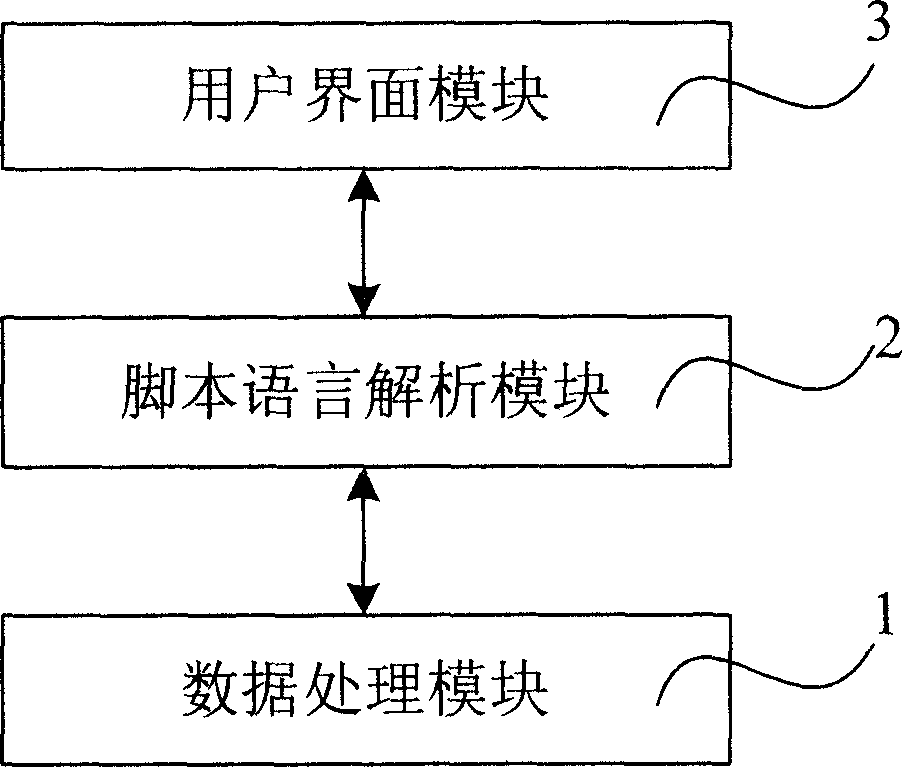

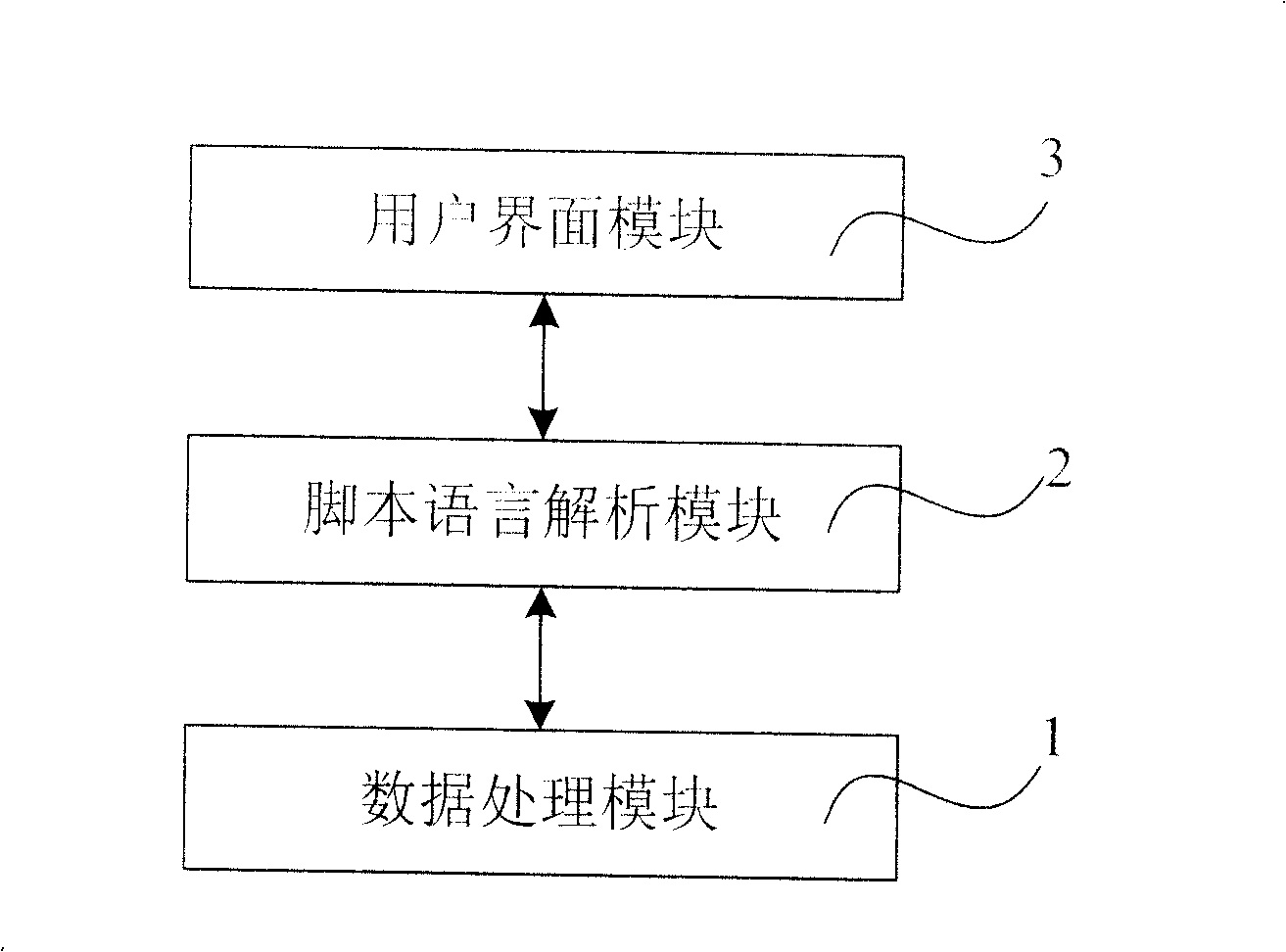

Map browser embedded mobile terminal and mobile phone map mobile terminal platform

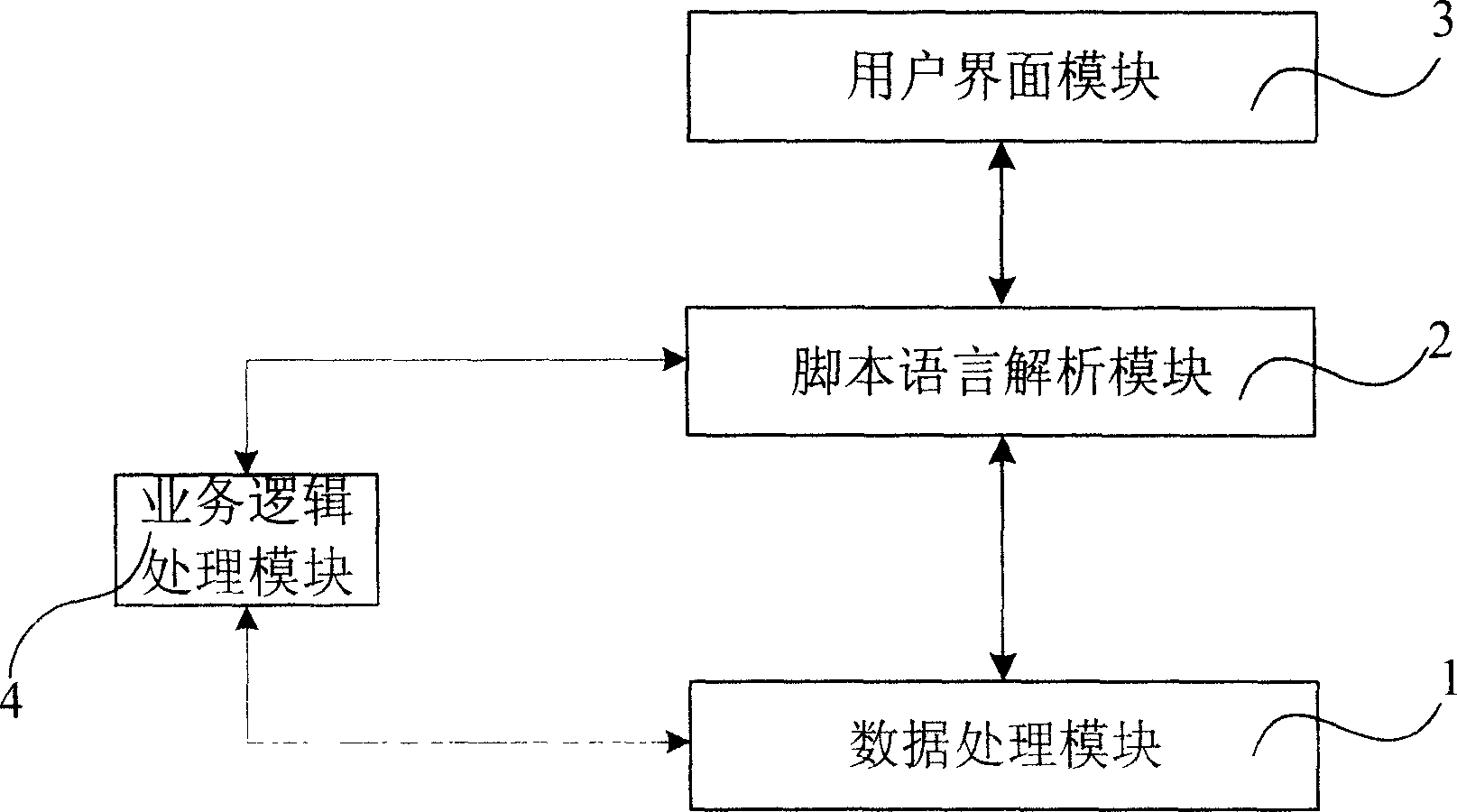

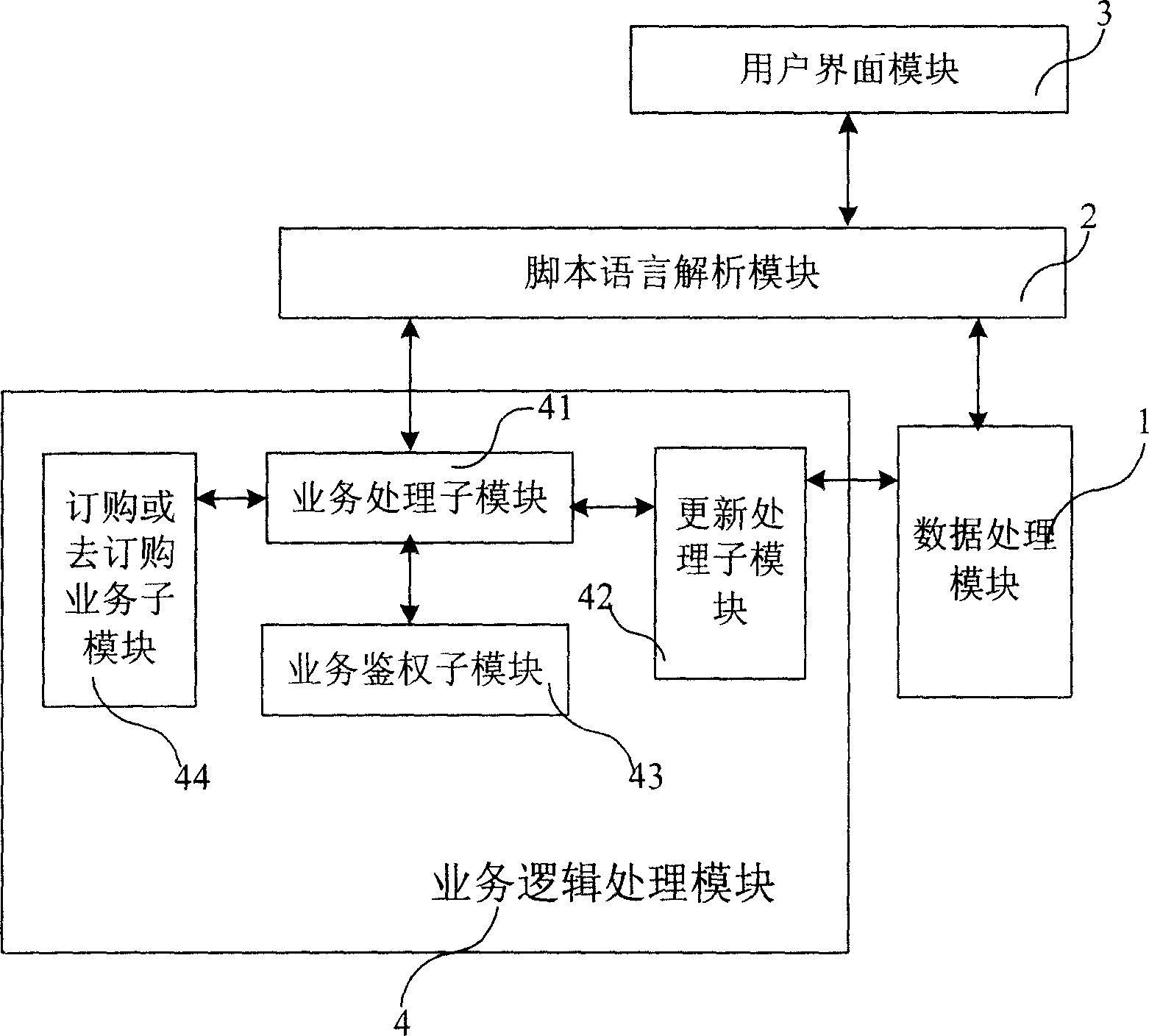

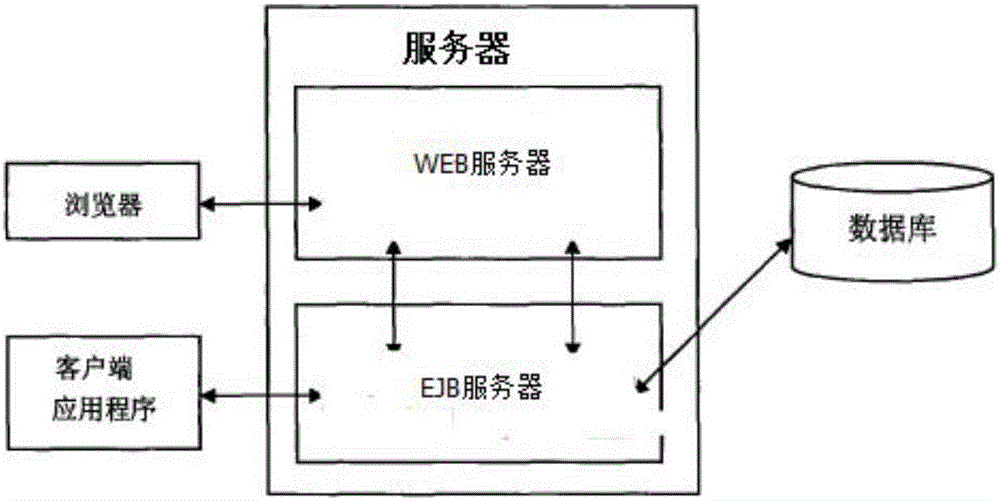

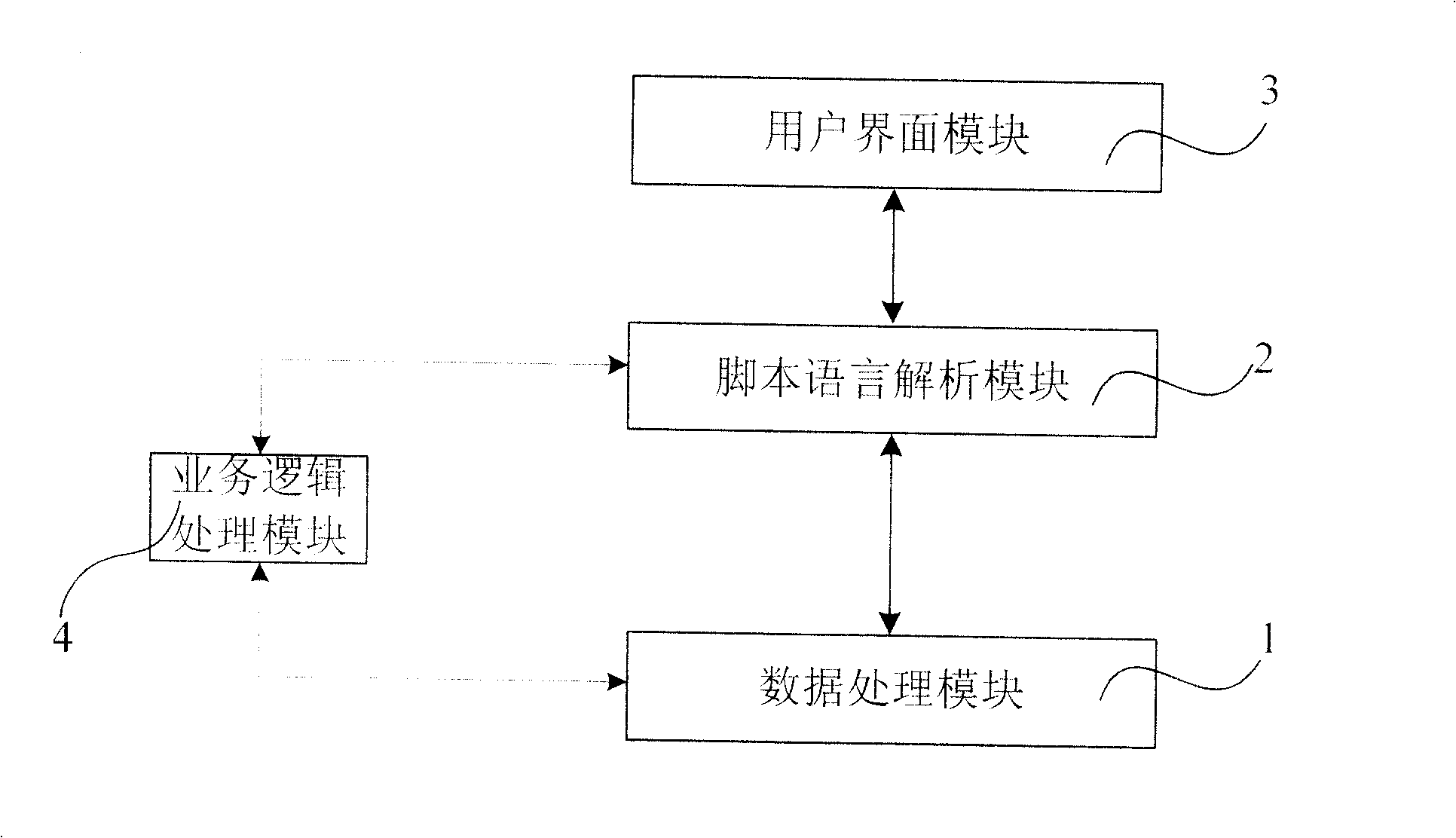

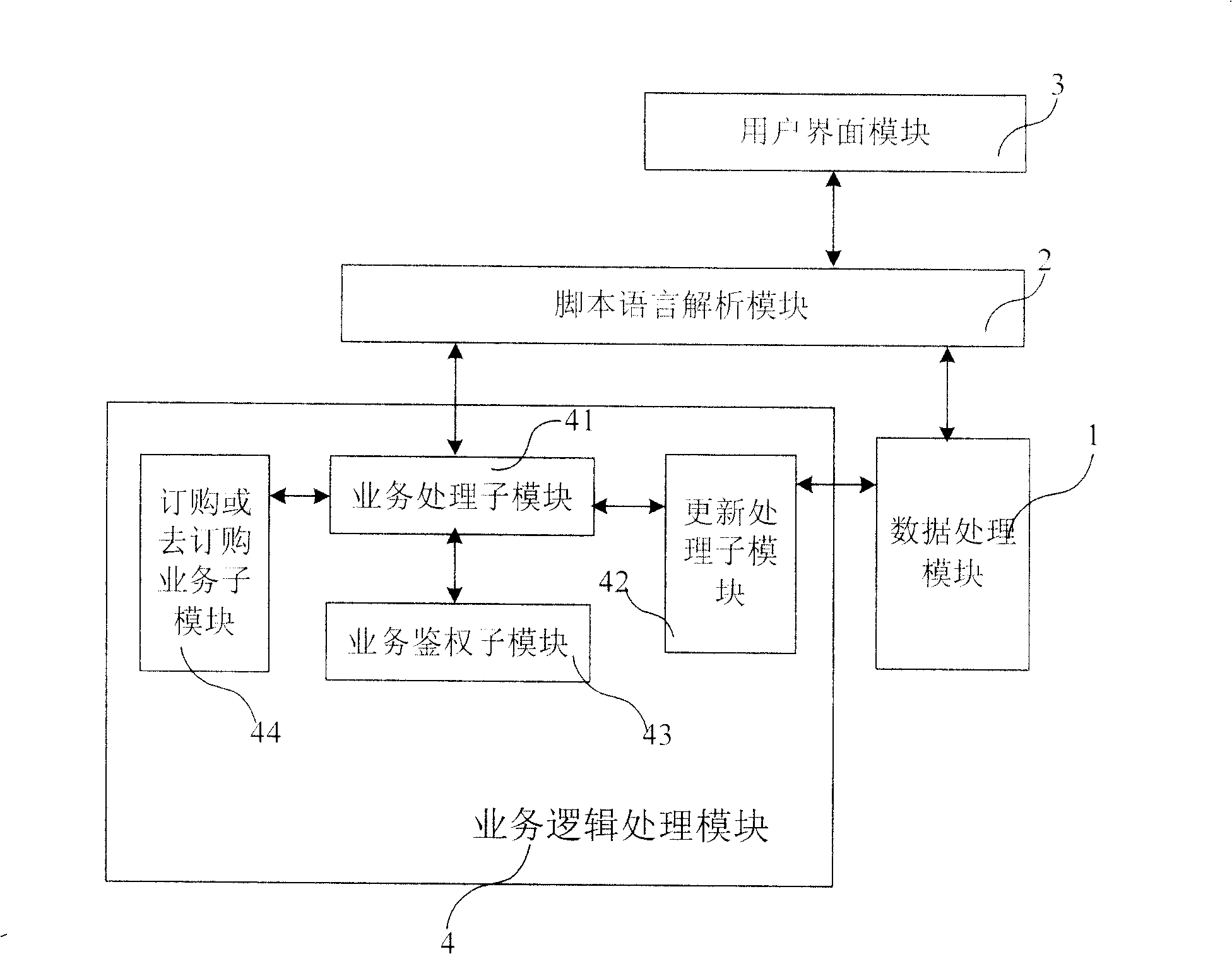

ActiveCN1867144AEasy to buildSimplified splitting modelSpecial service for subscribersSubstation equipmentScripting languageComputer module

The invention relates to a map browser embedded in the mobile terminal, which comprises: a data processing module; a script language analyze module connected to the data processing module; and a user interface module connected to the script language analyze module. With said invention, each node of LBS service chain can work independently. And it also provides a mobile phone map mobile terminal platform, which comprises a map browser, an interface module connected to the map browser, a local map database, and a map engine connected to the interface module. Via said platform, increment services based on position information can be supplied to mobile terminal user, to effective combine the data and map, to support map service in the mobile communication network.

Owner:CHINA MOBILE COMM GRP CO LTD +1

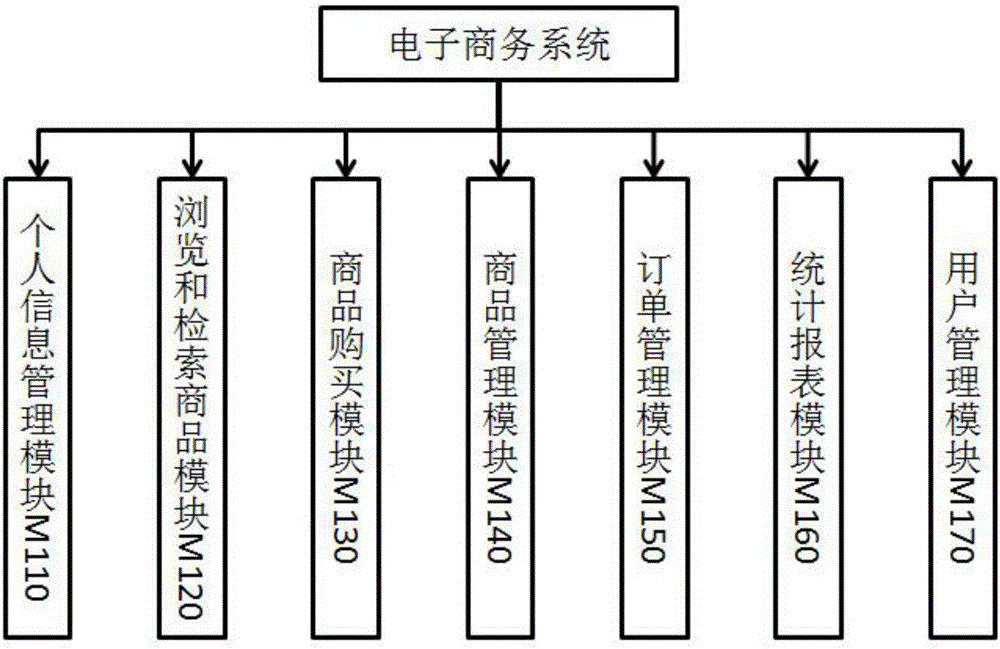

Electronic commerce system

InactiveCN106408397AMeet industry needsEasy to modifySoftware designBuying/selling/leasing transactionsOpen sourceStatistical Report

The invention discloses an electronic commerce system which comprises a personal information management module, a commodity browsing and searching module, a commodity purchasing module, a commodity managing module, an order managing module, a statistical report module and a user management module. Starting from the characteristics of electronic commerce, the invention analyzes and does research on the background for an enterprise to develop such a system so that the system can meet the industrial requirement more. As key technologies for developing and designing the electronic commerce system for an enterprise are analyzed, a free open source based PHP+MySQL development program is determined. Through the use of an increment development model, the system's security, flexibility, and operational feasibility are improved and developers can correct the system, expand the system and cooperate with each other more conveniently.

Owner:合肥红珊瑚软件服务有限公司

Brocade texture, embroidery stitch and drawing principle combined process

InactiveCN106087298AHave superiorityShow style charmDecorative surface effectsSwivel-woven fabricsYarnEngineering

A brocade texture, embroidery stitch and drawing principle combined process includes steps of drawing, brocading and embroidering. An integral pattern drawn at the drawing step comprises a transparent pattern portion with distinct line contours and unpigmented areas enclosed by the line contours; in the brocading step, the integral pattern is taken as a pattern for brocading, but the transparent pattern portion is not brocaded or only mark lines are brocaded; in the embroidering step, using a yarn needle for embroidering the line contours of the transparent pattern portion of the integral pattern. Content presentation and drawing technique selection of paintings are realized, different portions of a complete painting are shown through brocade texture and embroidery respectively, artistic expression of original paintings is well duplicated, and obtained brocade products can better show styles and lingering charm of the paintings.

Owner:四川蜀菁文化传播有限公司

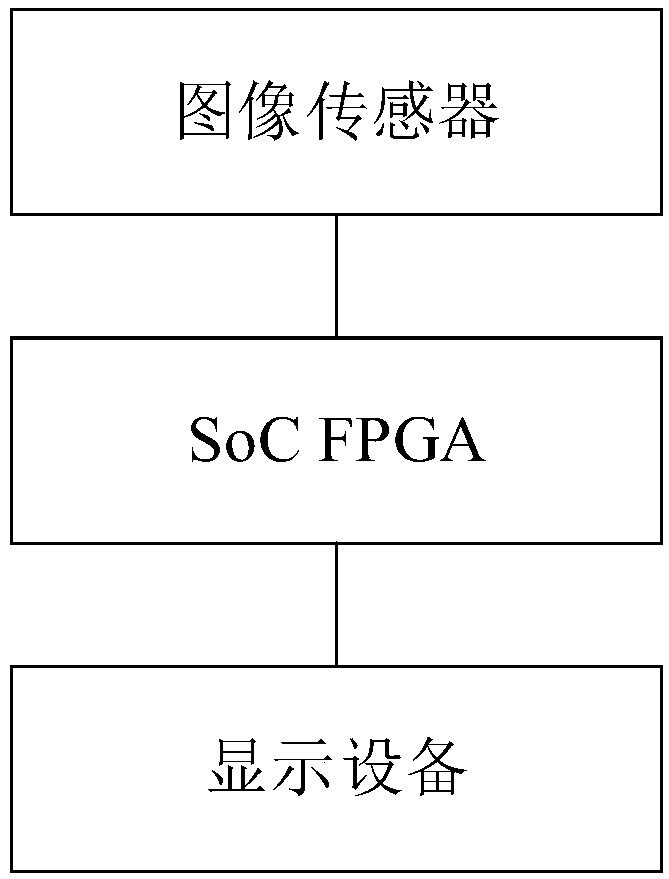

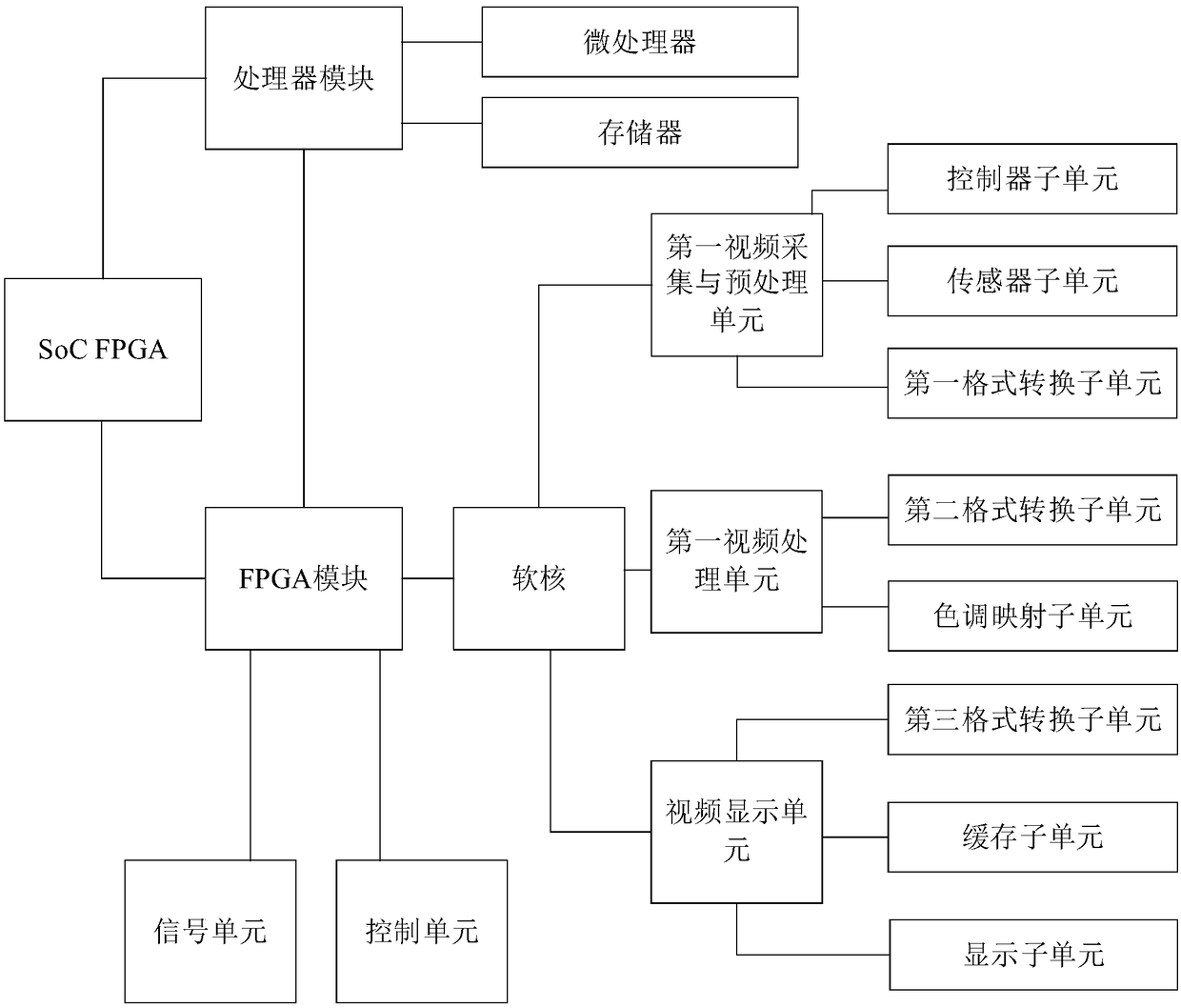

High dynamic video processing system based on SoC FPGA

ActiveCN108632505AHighly integratedReduce design difficultyTelevision system detailsColor signal processing circuitsSystems designImaging processing

The invention relates to a high dynamic video processing system based on a SoC FPGA. The system comprises an image sensor, the SoC FPGA and display equipment, wherein the image sensor is used for collecting and outputting first video data; the SoC FPGA is connected to the image sensor and is used for configuring the image sensor, simultaneously receiving and processing the first video data to formsecond video data and outputting the second video data; and the display equipment is connected to the SoC FPGA and is used for receiving and displaying the second video data. In the invention, a SoCPGA platform is adopted, an integrated level is further increased, the advantages of various chips are performed, and system design difficulty brought by inter-chip data exchange is reduced through astandard bus protocol. Software program exploitation is flexible and convenient and can be transplanted to different hardware platforms. Through a software and hardware cooperation design, hardware system resources can be flexibly used. The FPGA is used for real-time image processing, and calculating performance and real-time performance are effectively increased.

Owner:XIDIAN UNIV

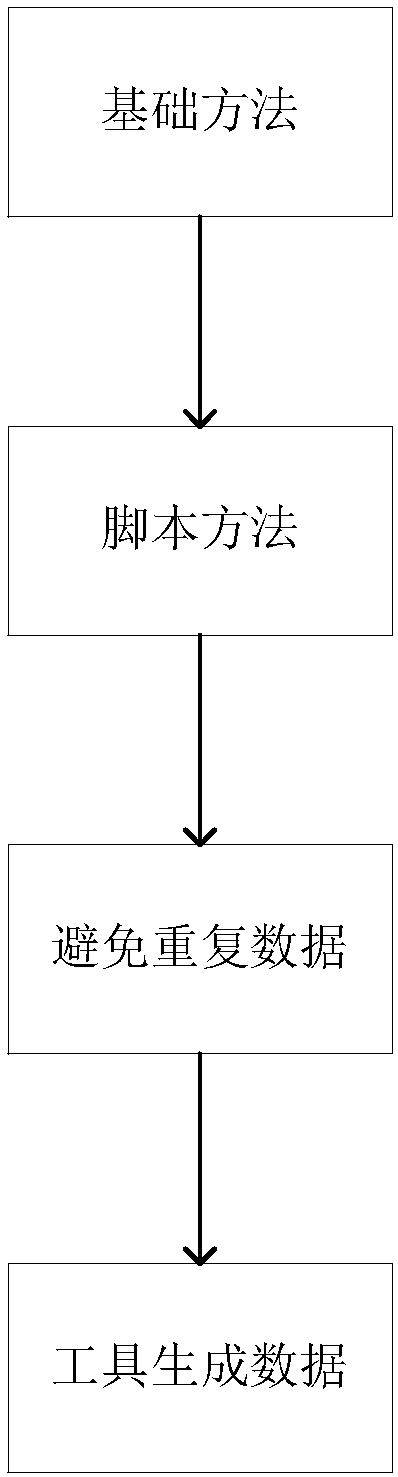

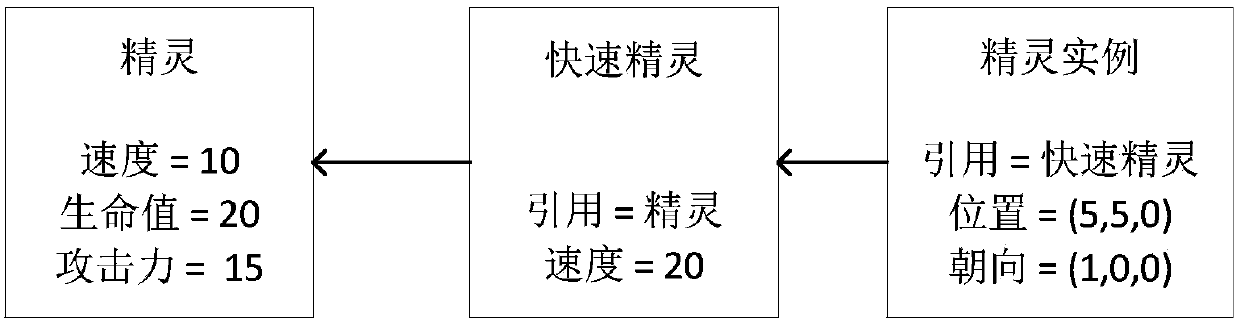

Data driving design method of game system

InactiveCN107754314AShorten the development cycleImprove experienceVideo gamesMaintainabilityData-driven

The invention discloses a data driving design method of a game system. The method comprises the steps of creating a file analysis system to be used for analyzing a text file in a game program, whereinthe text file is used for storing constant data of an abstract functional assembly in the game program; creating a script to define a logic code in the game program, wherein the script comprises constant data of the logic code; using multiple data blocks capable of being globally cited to constitute functional assemblies and / or game data; creating a corresponding editor to be used for custom-editing the text file, the script and the data blocks. The data driving design method has the advantages of greatly shortening the game system development cycle, improving maintainability and reusabilityof the code, improving the experience and expression of a game, facilitating personnel labor division and cooperation of all positions and optimizing the procedure.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

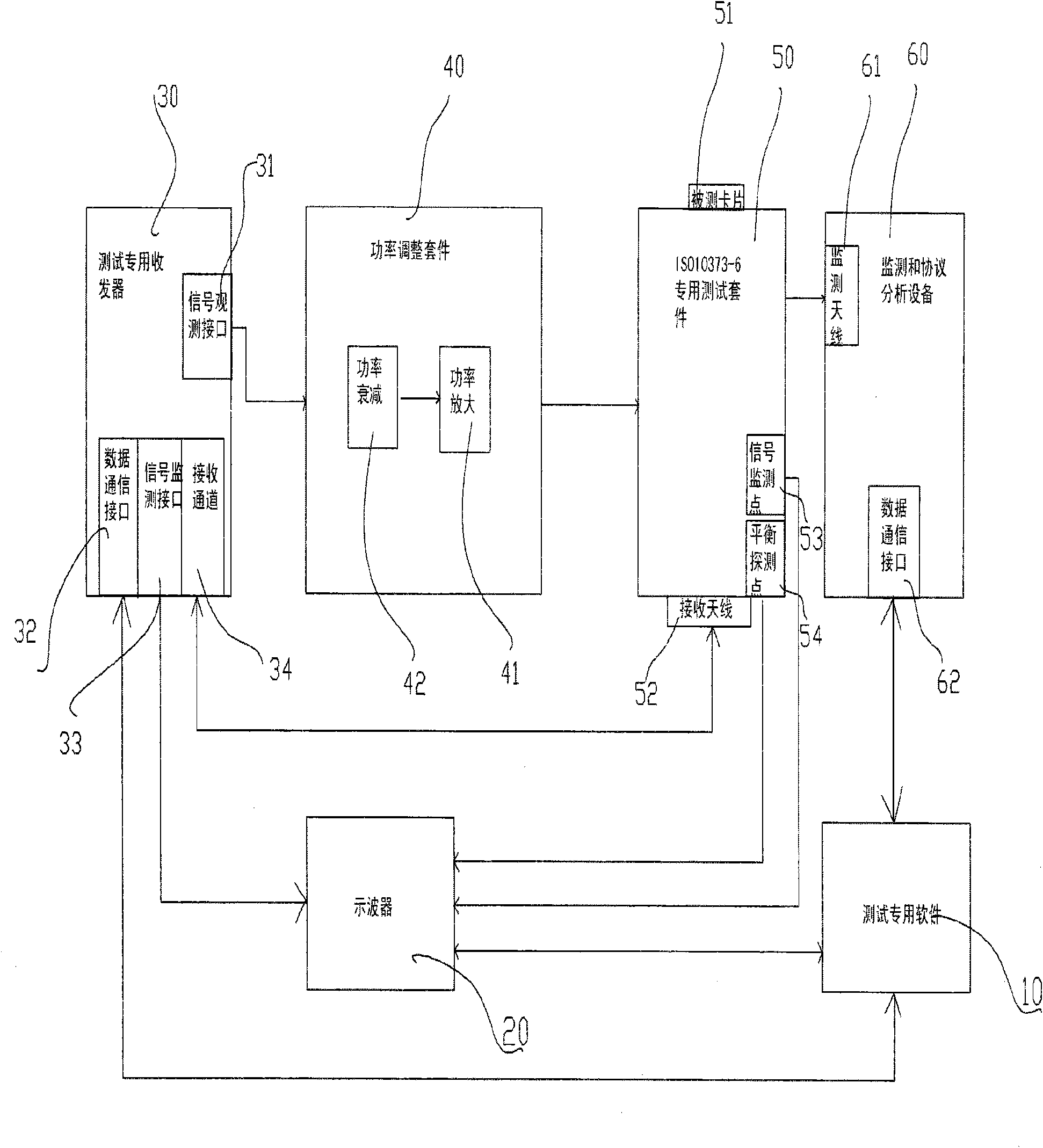

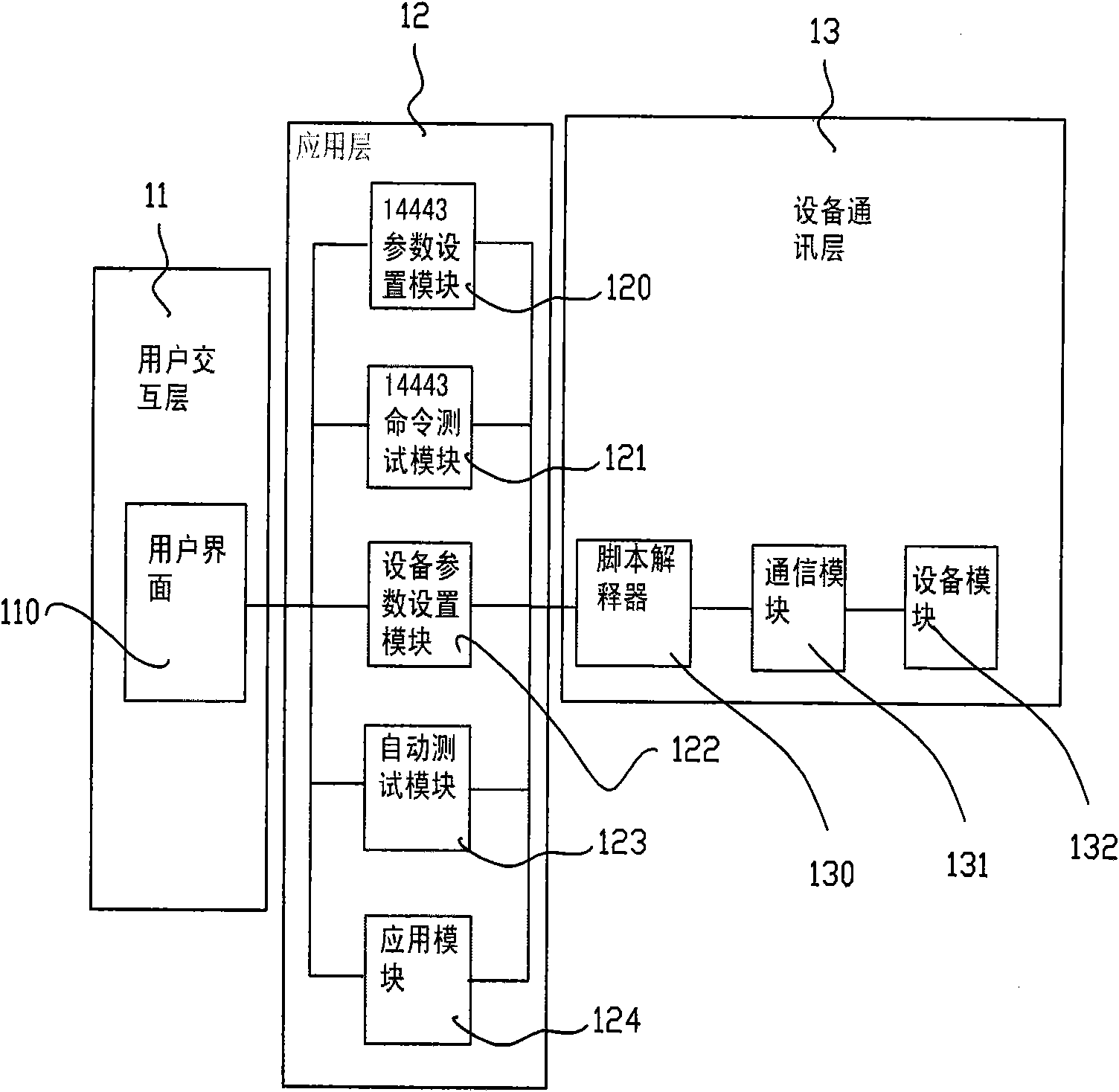

Non-contact IC card radio frequency protocol and application testing method

ActiveCN101661552AGuaranteed uptimeEasy and flexible updatesSensing record carriersTransceiverRadio frequency

The invention discloses a non-contact IC card radio frequency protocol and an application testing method, comprising screening interoperability key parameter, constructing a testing system, calibrating the testing system and testing, wherein screening is carried out according to the influence of the parameters to the interoperability, and the key parameter influencing the interoperability of a non-contact IC card can be found out in the parameters, so that the testing method is the only way for solving the problem of interoperability; and the testing system comprises professional testing software, a transceiver specially used for testing, an ISO 10373-6 test suite, a power regulating suite, a monitoring and protocol analyzing device, an oscilloscope and a connecting line used for testing.The invention has the advantages that by adopting multi-loop synchronous verification technique, working mode which can be used for completing every test scene based on script and modular software layered design technology, the invention effectively ensures the stability of the testing system as well as the authenticity and the recurrence of the test result, leads the test content to be updated and the problem analysis to be simple and flexible, and guarantees the function of the testing software to be expandable and the maintenance to be convenient and easy.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

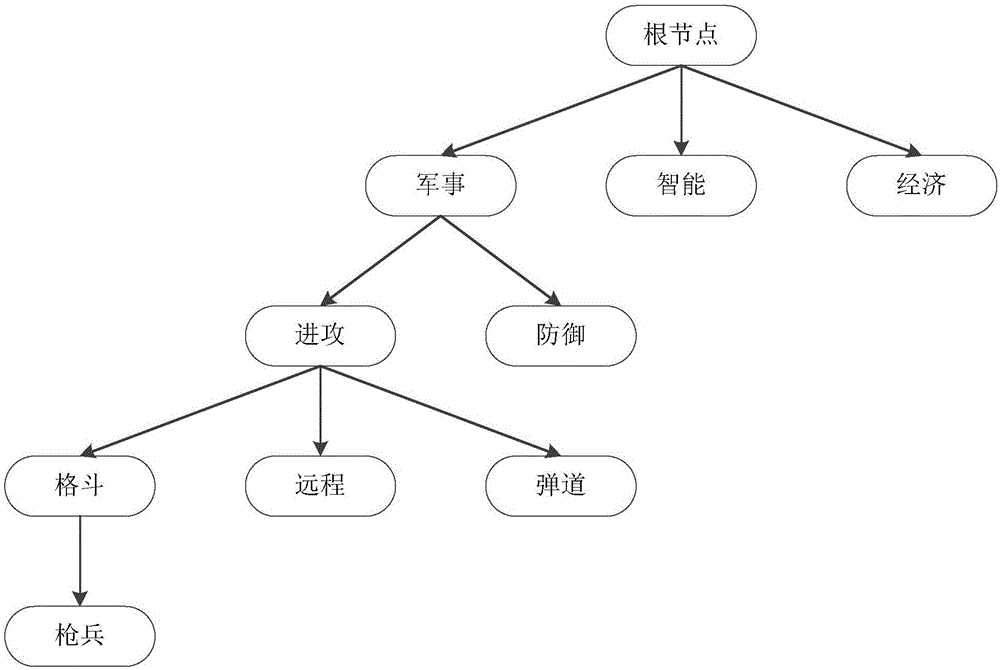

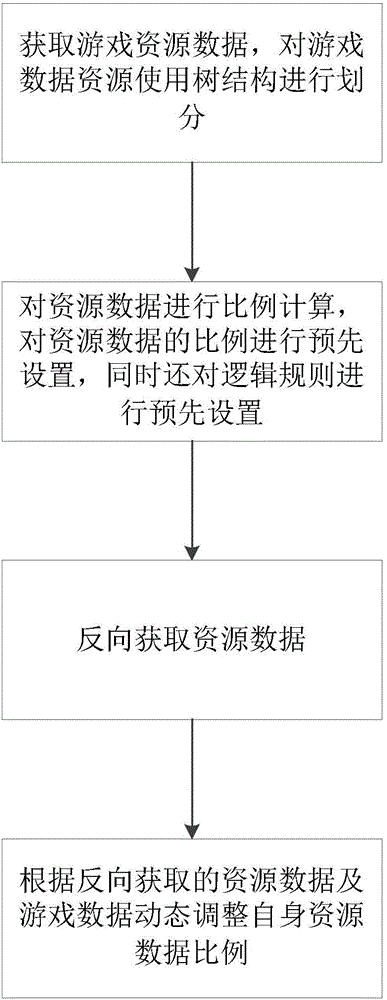

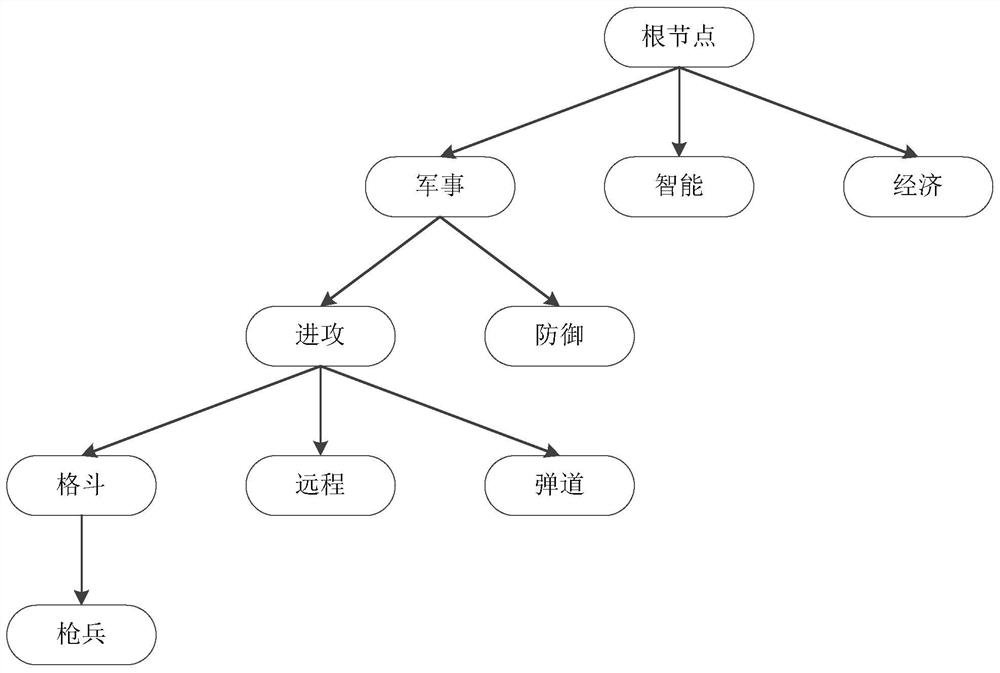

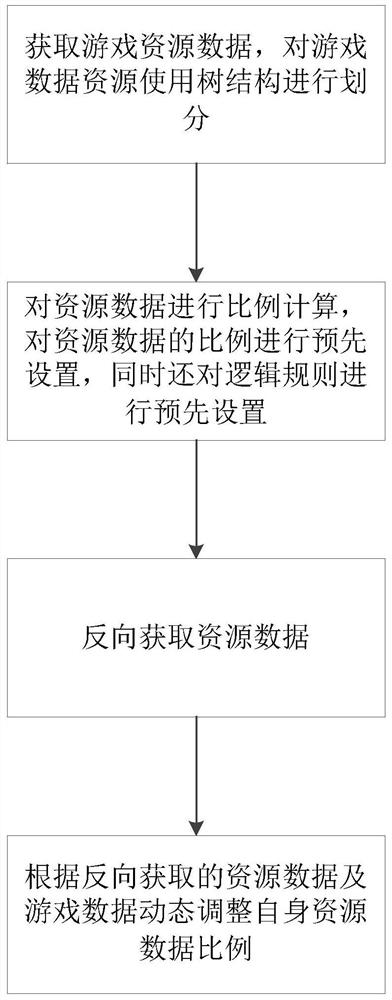

System and method for resource distribution of strategy game

InactiveCN106669145AShorten the development cycleImprove experienceVideo gamesMaintainabilityReusability

According to the technical scheme, the invention provides a system for resource distribution of a strategy game. The system comprises a resource partitioning module, a resource setting module, a resource judgment module and a resource adjustment module, wherein the resource partitioning module divides resource data by using a tree structure; the resource setting module presets resource data proportion and logic; the resource judgment module traverses and obtains all resource data and performs calculation; and the resource adjustment module dynamically adjusts resource data proportion. According to the technical scheme, the invention provides a method for resource distribution of the strategy game. The method comprises the steps of dividing the resource data by using the tree structure; presetting the resource data proportion and logic; traversing and obtaining all the resource data and performing calculation; and dynamically adjusting the resource data proportion. The system and method for resource distribution of the strategy game have the advantages that the development cycle of the strategy game is greatly shortened; code maintainability and reusability are enhanced; game experience and expression are enhanced; workers at various posts can share out the work and cooperate with one another conveniently, and flow is optimized.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

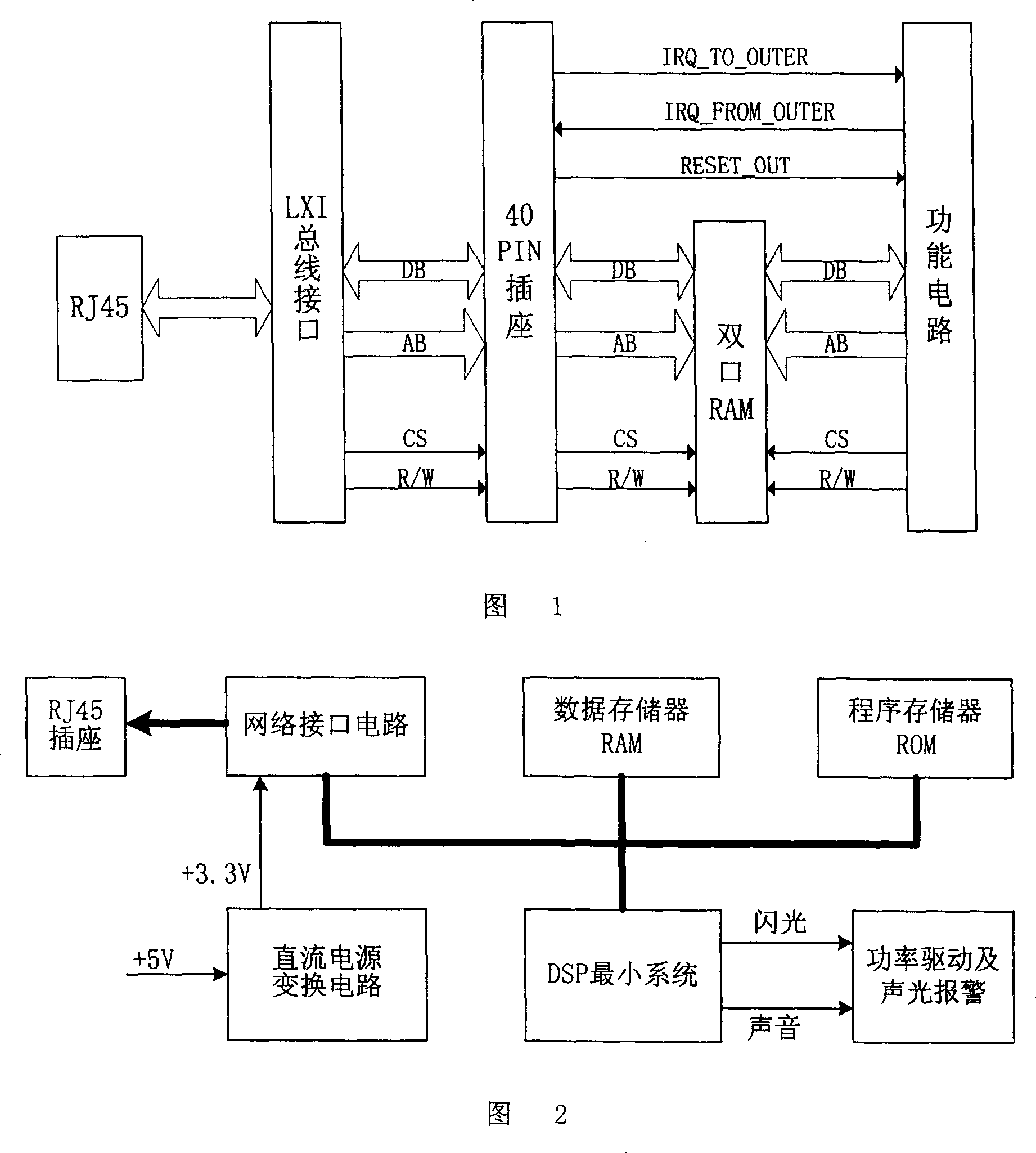

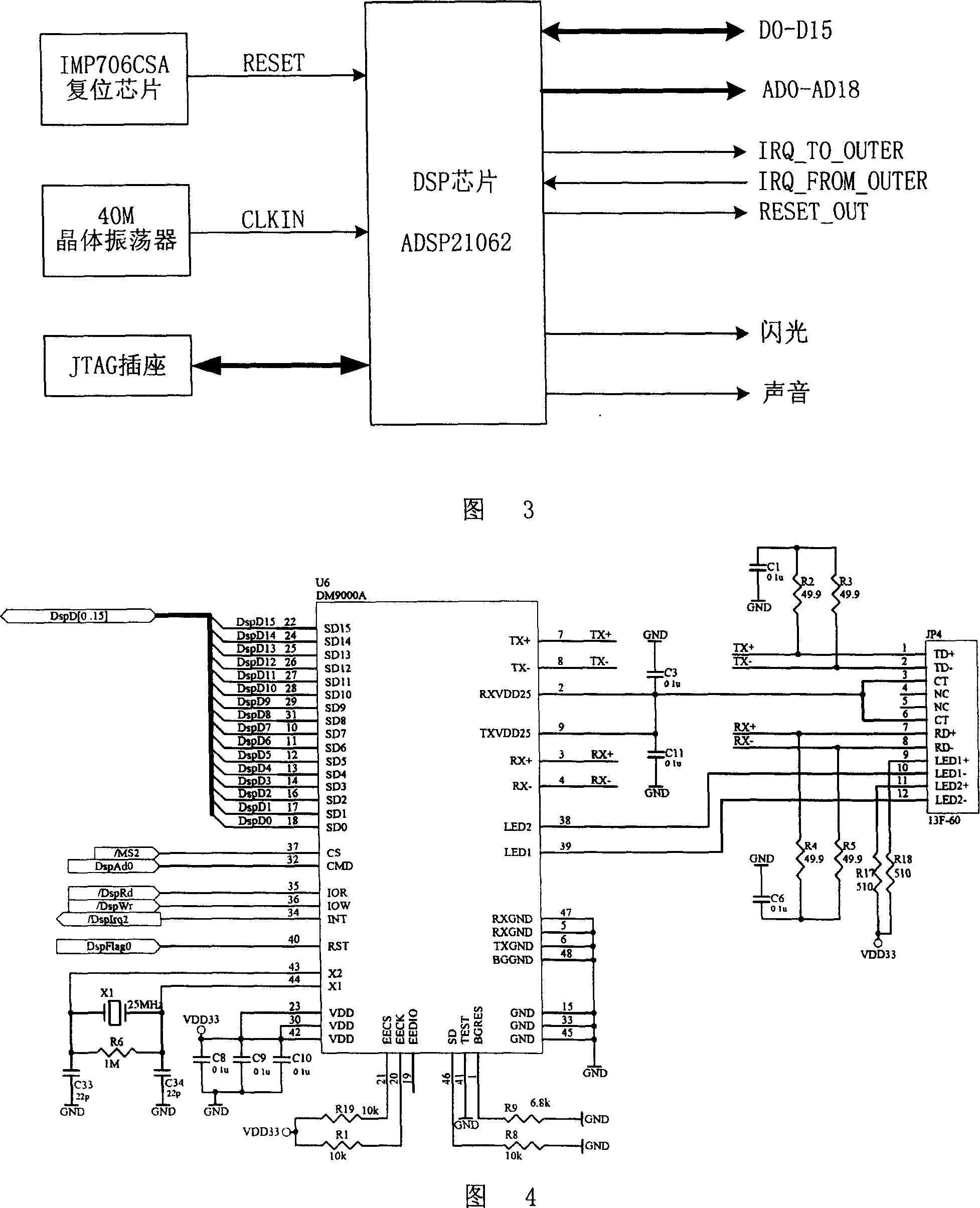

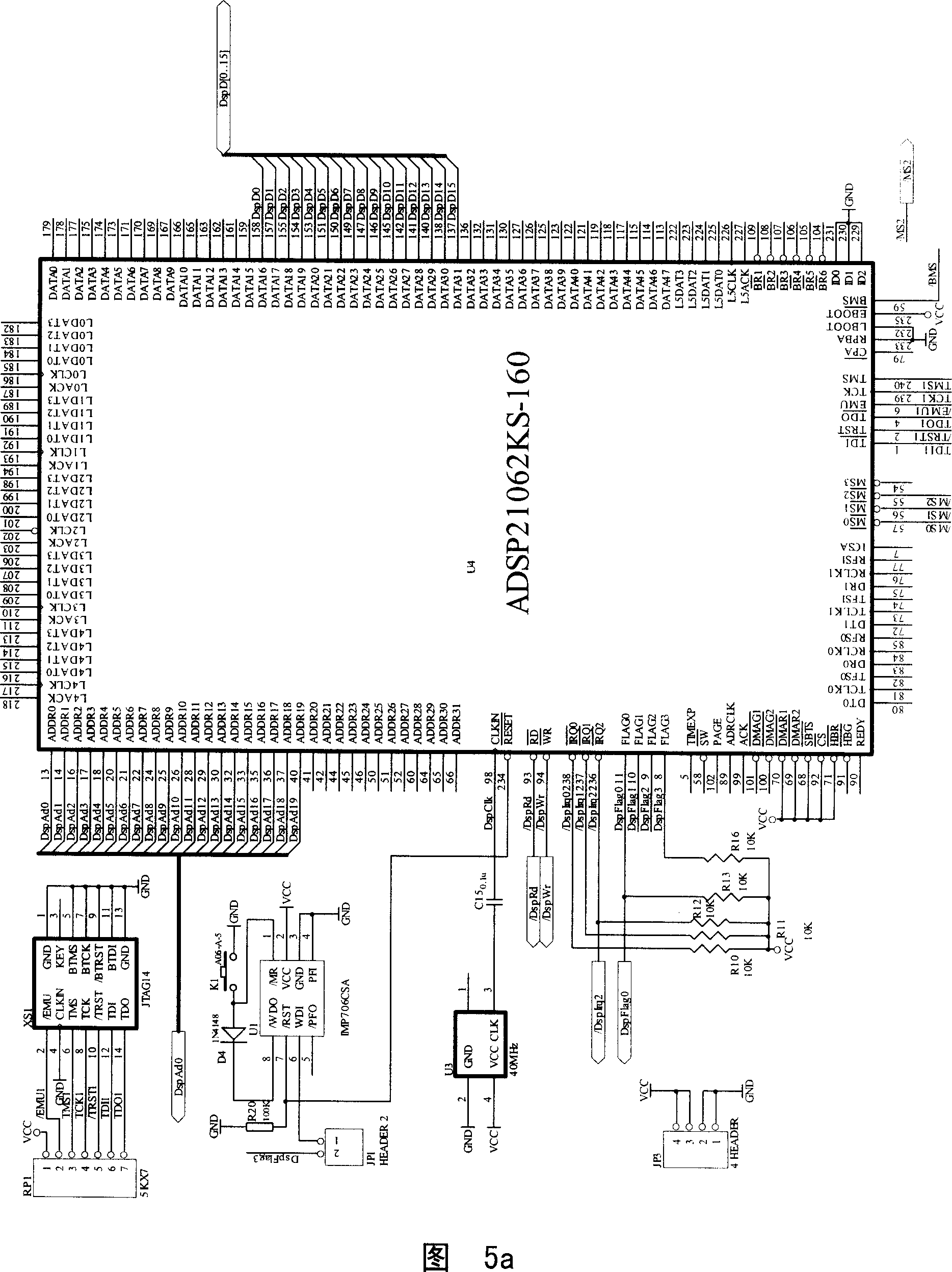

A LXI bus interface

InactiveCN101087313AFacilitate division of labor and cooperationImprove versatilityBus networksDigital signal processingSpecific function

The invention relates to LXI bus interface which includes digital signal processing chip, network interface circuit which is used to be connected with computer, faucet which is used to be connected with function circuit of radar monitoring equipment. The digital signal processing chip possesses data memory, program memory; the interrupt output, interrupt input, reposition output of the digital signal processing chip are separately connected with the interrupt input, interrupt output, reposition input of the function circuit; the data bus, address bus, piece-selecting line, reading and writing line of the digital signal processing chip are separately used to be connected with the data bus, address bus, piece-selecting line, reading and writing line of function circuit double data memory. The invention possesses perfect currency, and fits for circuit with any concrete function; the flexibility is high, fits for cooperation of researching personnel.

Owner:WUHAN UNIV

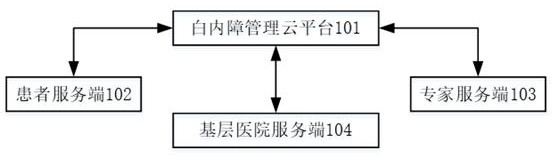

Control system and method for cataract patient in medical consortium

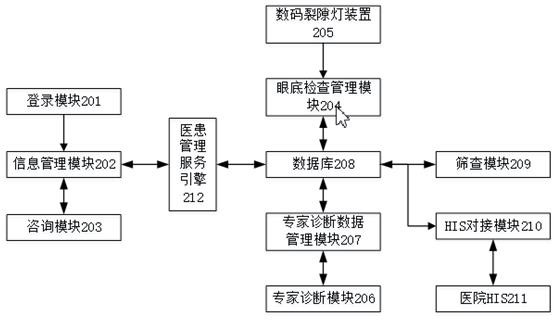

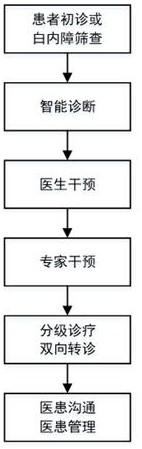

PendingCN111710396AShorten the timeRealize refined managementMedical communicationHealthcare resources and facilitiesPatient managementCataract screening

The invention discloses a control system and method for a cataract patient in a medical consortium. The control system comprises a cataract management cloud platform, a patient server, an expert server and a primary hospital server, wherein the cataract management cloud platform is connected with the patient server, the expert server and the primary hospital server to realize data interaction, thecataract management cloud platform comprises a doctor-patient management service engine, a screening module, an HIS docking module and a database, the primary hospital server comprises an eyeground examination management module and a digital slit lamp device used for shooting eyeground imaging pictures of a patient, the expert server comprises an expert diagnosis module and an expert diagnosis data management module, and the patient server comprises a login module, an information management module and a consultation module. The management method of a cataract patient in a medical consortium comprises: 1, carrying out primary diagnosis or cataract screening on a patient; 2, carrying out intelligent diagnosis; and 3, intervening by doctors.

Owner:武汉华瓴医疗科技有限公司

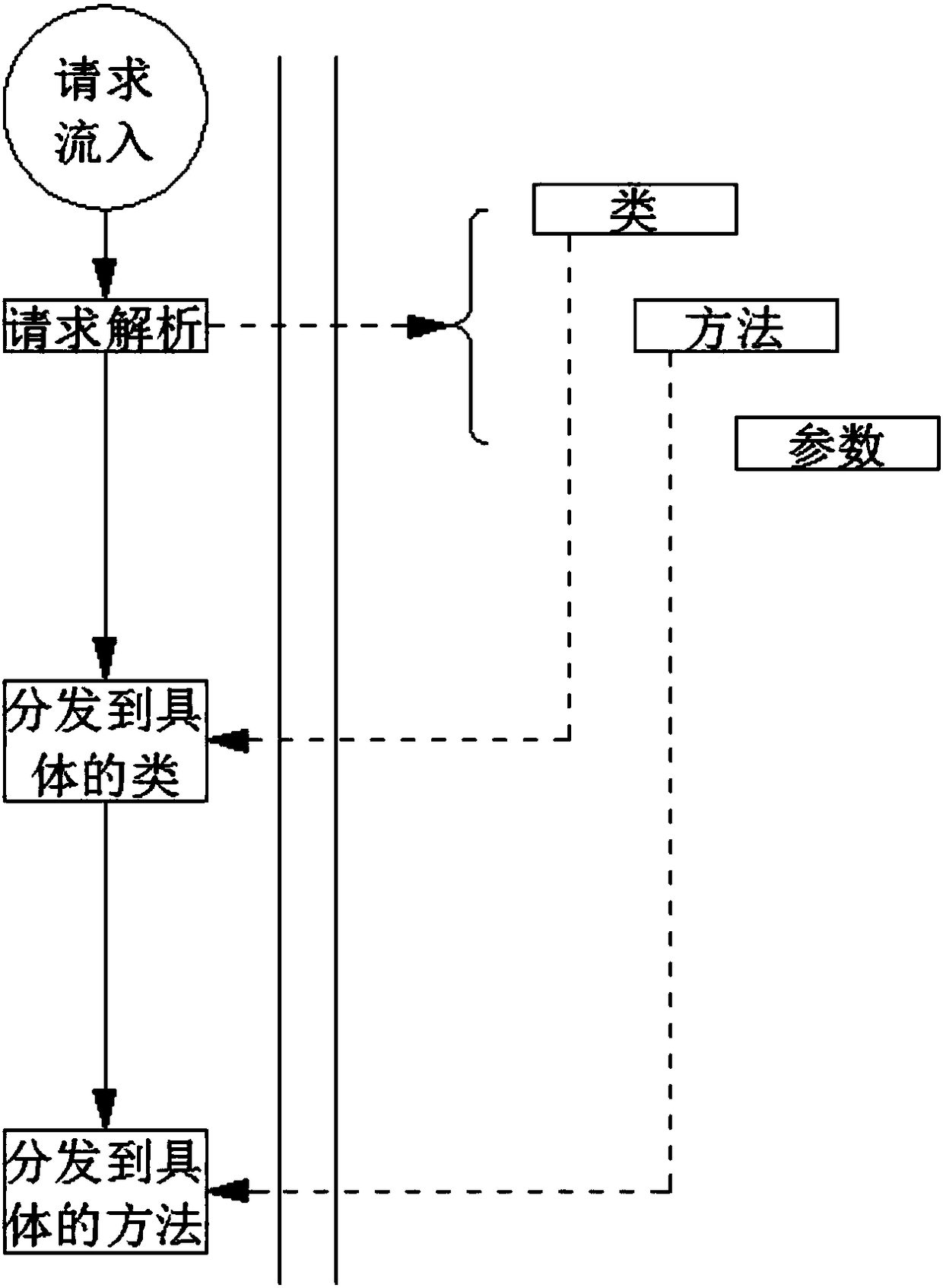

Web request processing method based on uniform web portal

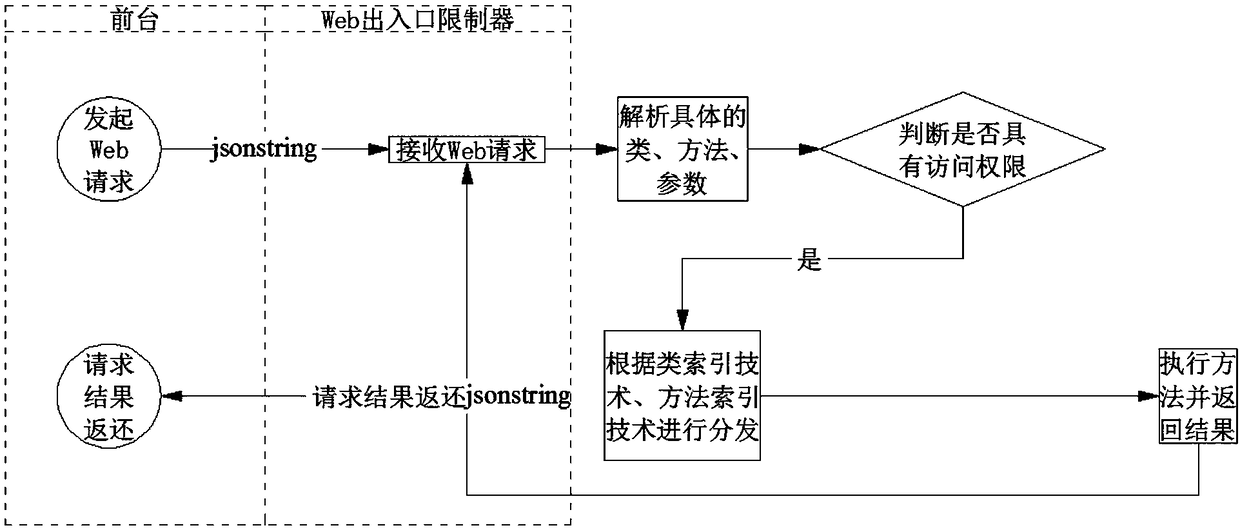

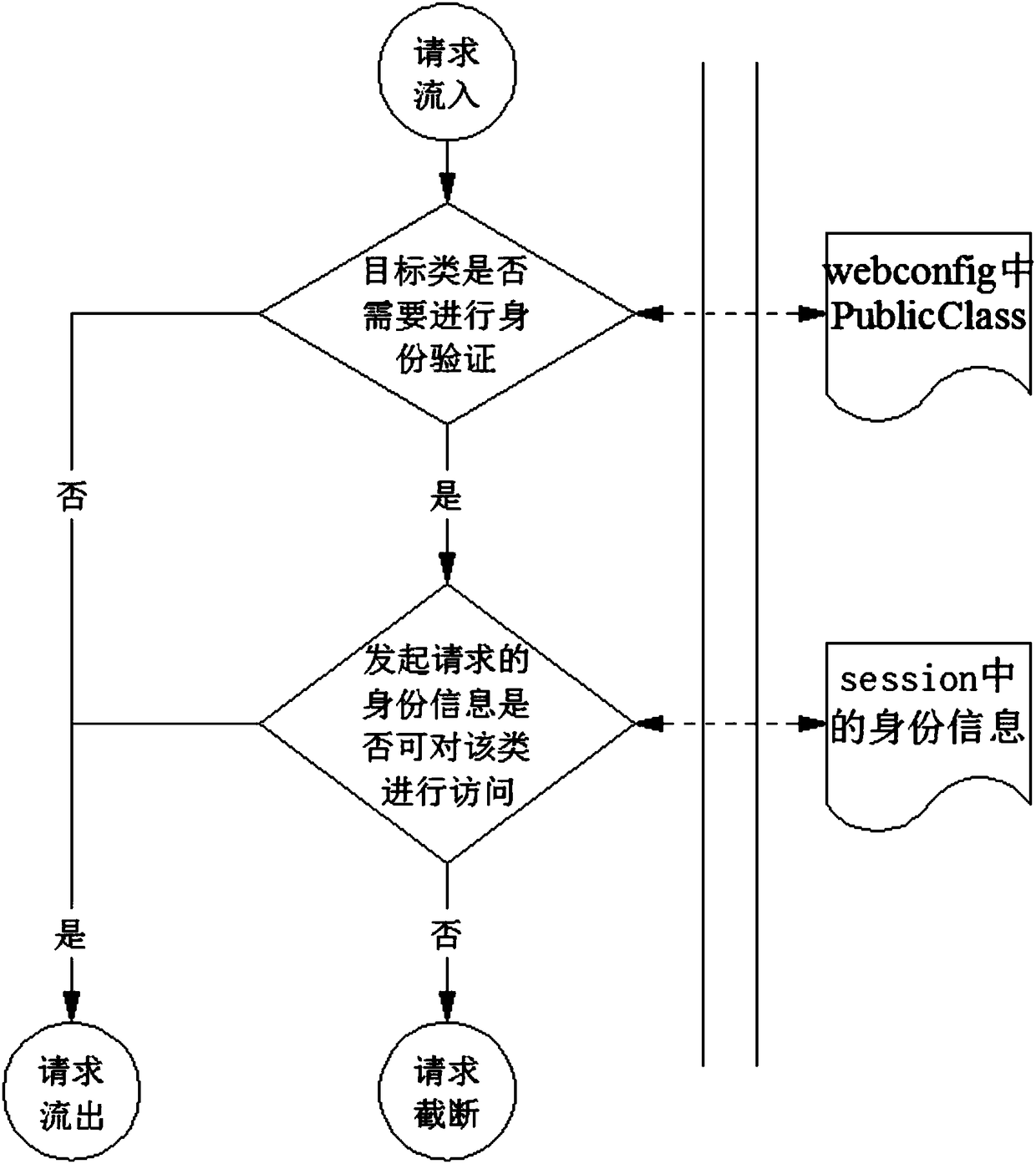

ActiveCN108595479AFacilitate division of labor and cooperationBalance work pressureSoftware engineeringSpecial data processing applicationsWeb applicationComputer science

The invention discloses a Web request processing method based on uniform web portal in c#, comprising the steps of: for any Web request, firstly receiving through a Web portal restrictor as a front-end data-only interactive interface of the Web application; parsing the Web request, generating the class name, method name, and carried parameters to be accessed by the Web request; determining whetherthe background class involved in the Web request needs to be authenticated and verifying whether the user has an accessible identity; if the authentication successes, shifting into S4, if the authentication fails, feeding back the information to the foreground through the Web portal restrictor; using the class index and the method index to distribute the Web request to the specific background method by using the class and method name parsed in S2, and assigning the parameters parsed in S2; executing the web request in the background and returning the running result to the foreground through the Web portal restrictor.

Owner:泰安协同软件有限公司

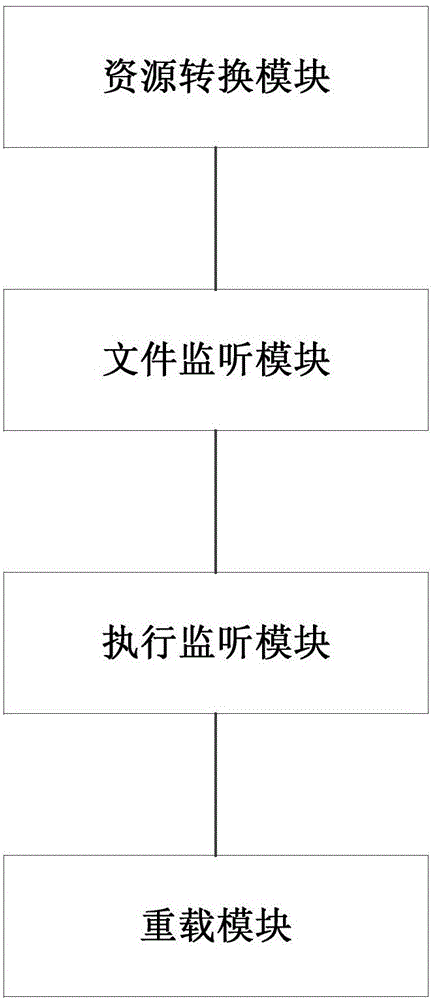

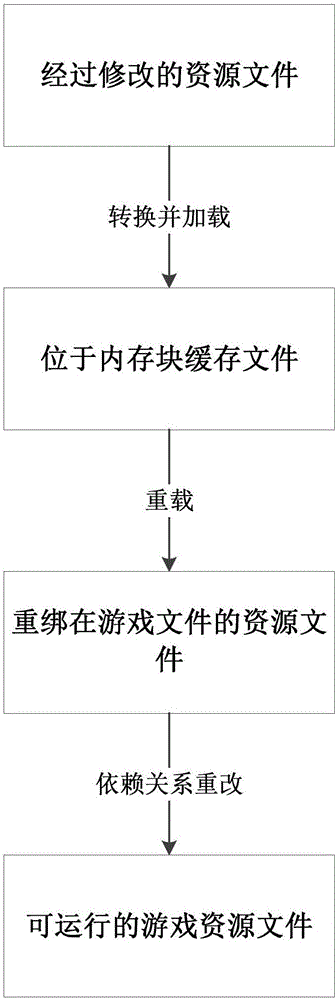

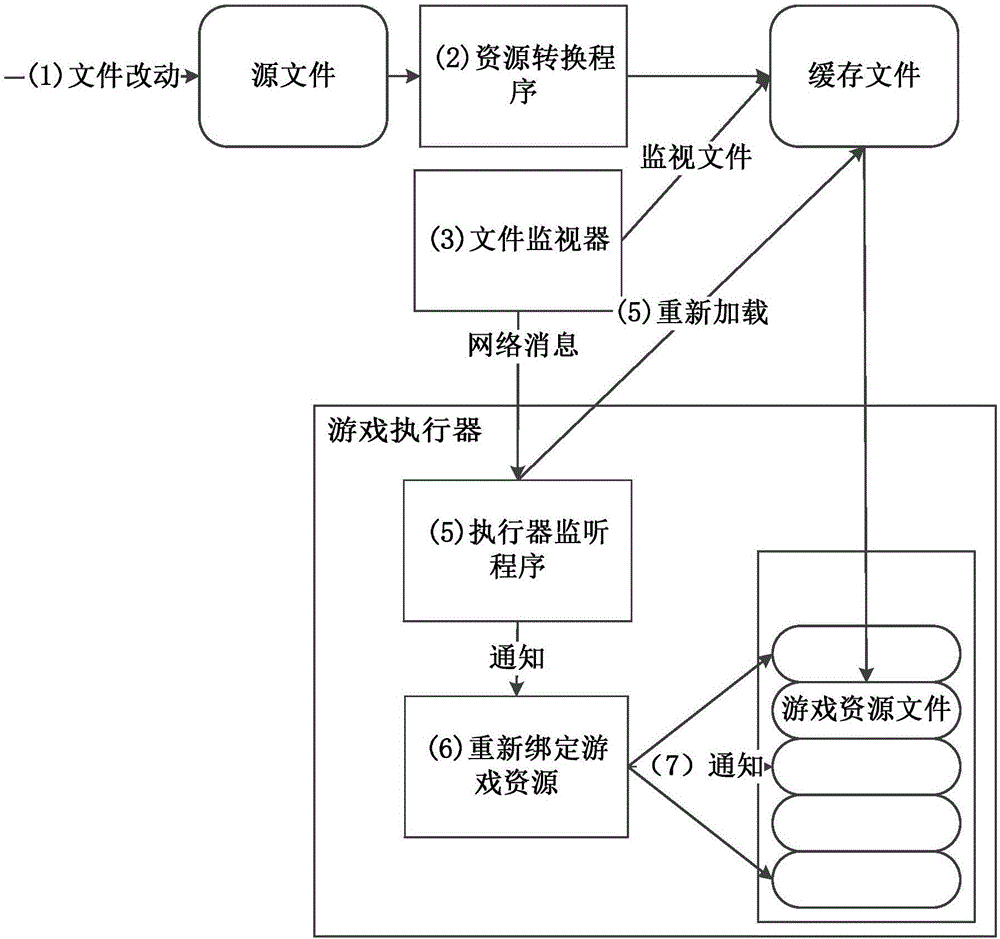

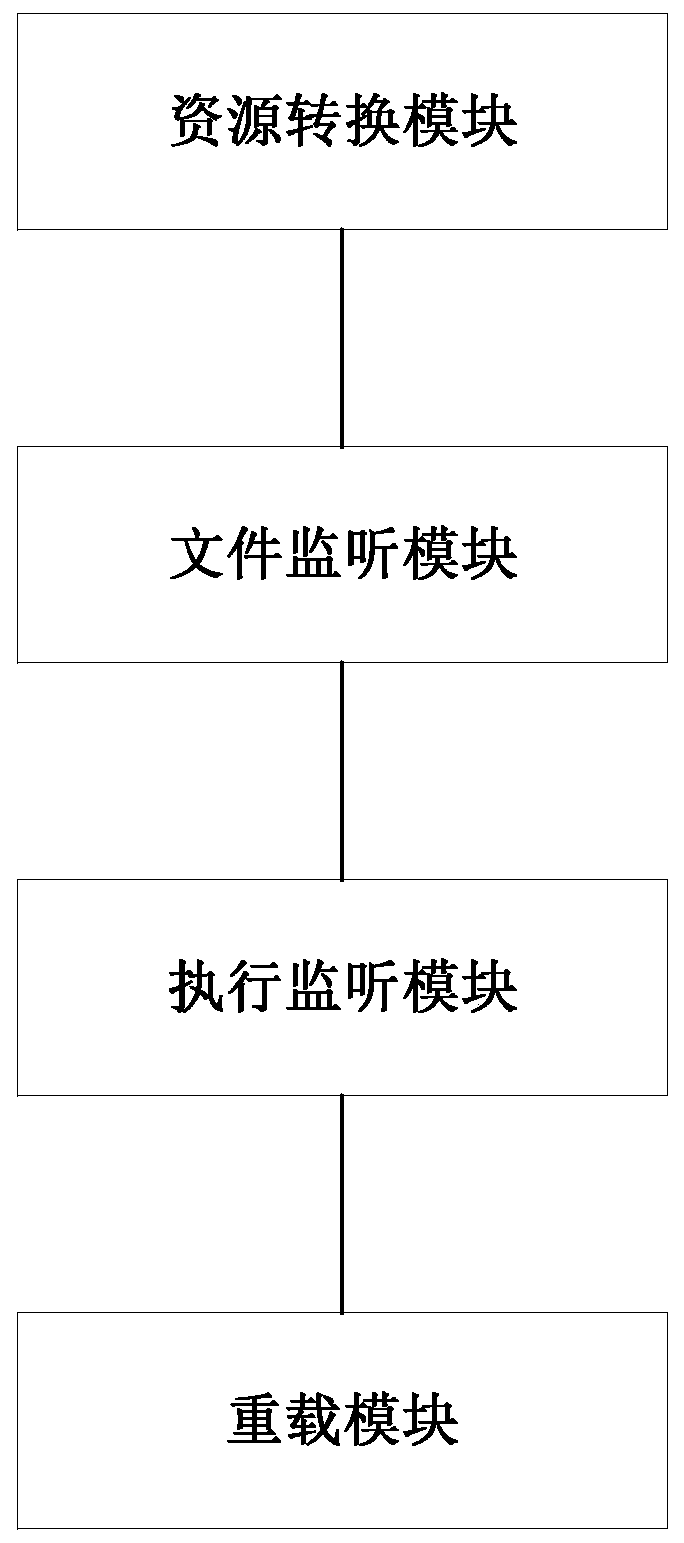

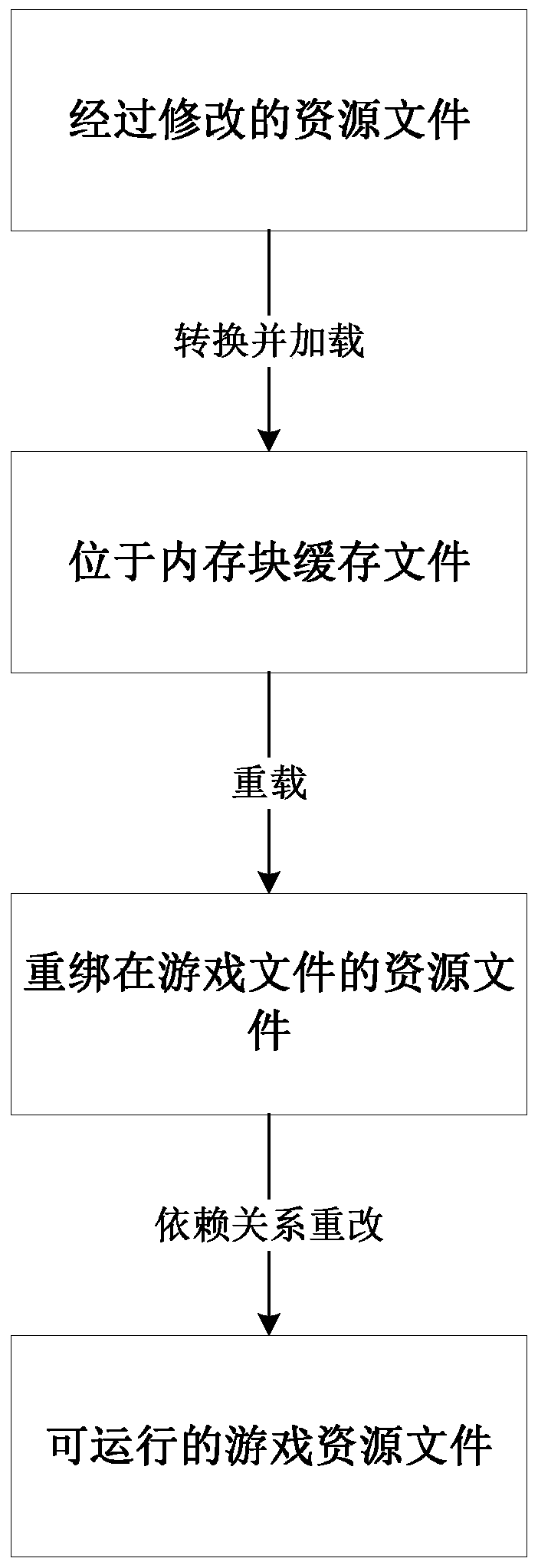

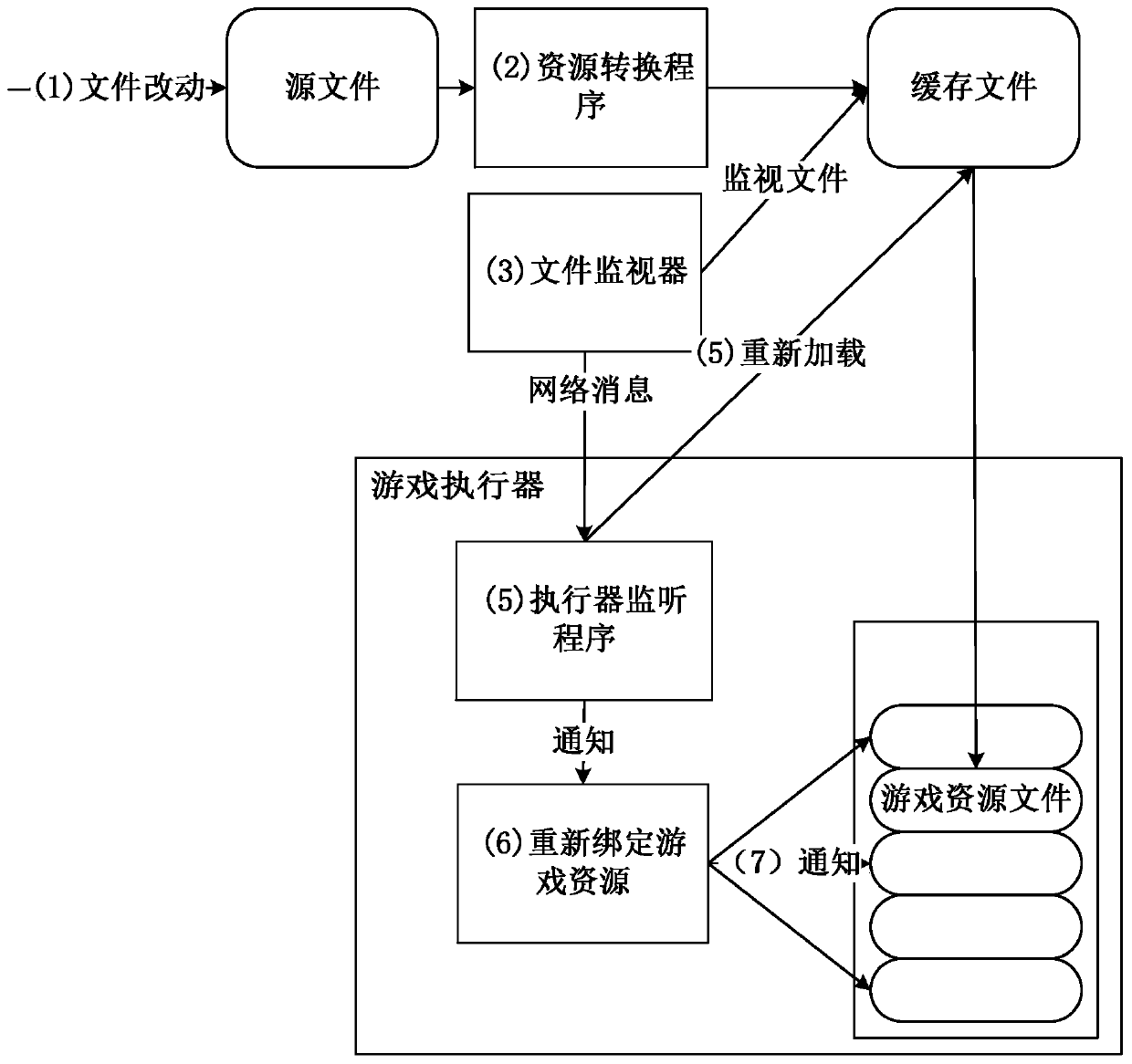

Resource hot-loading rapid iteration game making system and method

ActiveCN106371880AShorten the development cycleImprove experienceSoftware engineeringProgram loading/initiatingData fileUnique identifier

The technical scheme of the invention discloses a resource hot-loading rapid iteration game making system and method. The method comprises the following steps: identifying and converting a source file provided by a game developer, and loading identified and converted file data into a memory block; representing the file data loaded into the memory block by a file list, performing real-time monitoring, acquiring change information when the file list changes, and transmitting the change information; producing a mapping table for the monitored data file and unique identifiers of the data file, receiving the change information, acquiring the changed data file through the mapping table, reloading the data file into the memory block, and issuing a reloading instruction; receiving and executing a reloading instruction issued by a monitoring module, acquiring a new data file, and rebinding file resources included in the data file into a game system. The resource hot-loading rapid iteration game making system and method have the beneficial effects that the game development period is shortened greatly, the experience and performance of a game are improved, personnel in various positions can share out the work and cooperate with one another conveniently, and the flow is optimized.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

Ougu mobile health counseling system

InactiveCN101533430AEnsure safetyGuaranteed operating efficiencyAutomatic exchangesSpecial data processing applicationsThe InternetBase function

The invention relates to an Ougu mobile health counseling system, which is a mobile health counseling system allowing groups concerning health to perform health counseling and health promotion guidance at all times and places through mobile phones. The mobile health counseling system is characterized in that a three-dimensional internet developed by Xphant Digital Media consists of a network information service center platform and a Chinatown three-dimensional browser; and a small-size search engine specialized in inquiring health contents is used for searching health counseling contents and health promotion counseling contents embodied in a database of a health counseling system, and embodying detailed principles of the generations of various diseases and therapy methods thereof. A 3G network is used for updating the database of the health counseling system periodically; besides, system software is burnt to a mobile phone chip directly so that the security and the operating efficiency of the system are guaranteed. Furthermore, the mobile health counseling system sufficiently digests a GSM protocol and integrally achieves all items of basic functions required by the protocol. Thus, the mobile health counseling system is convenient and fast health counseling software with a stable system.

Owner:唐世勇

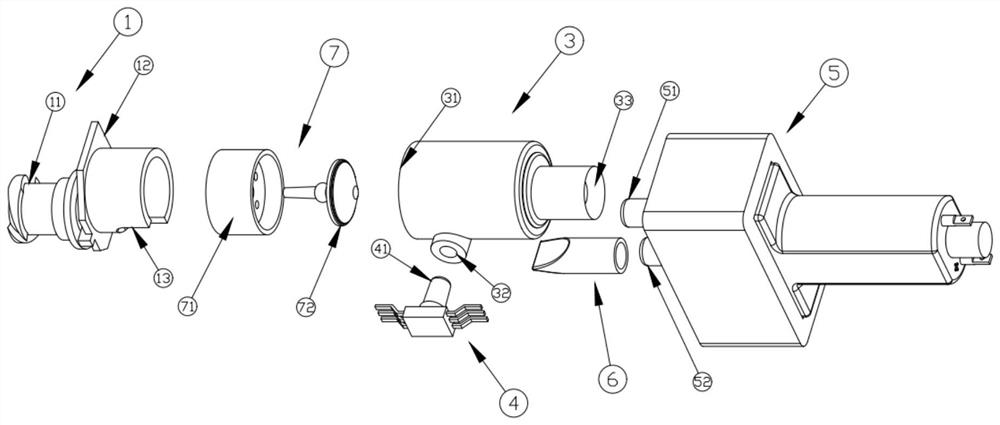

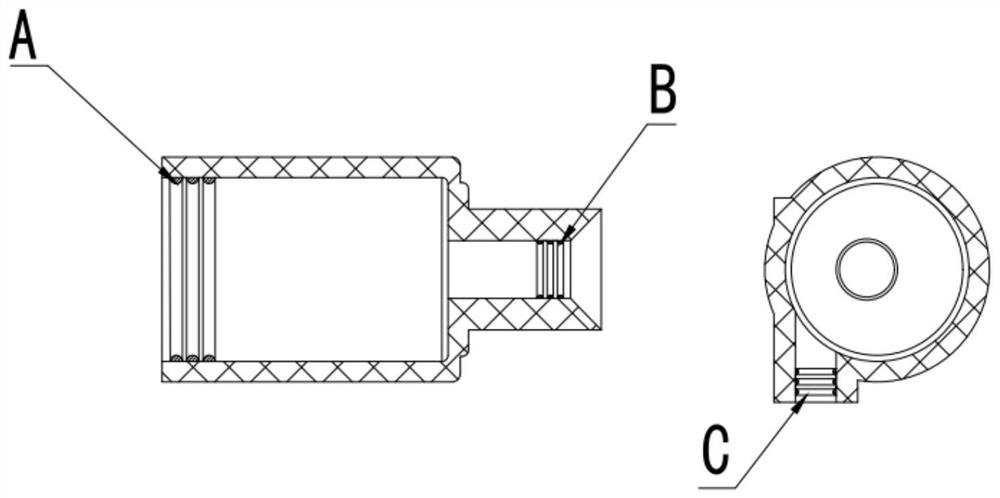

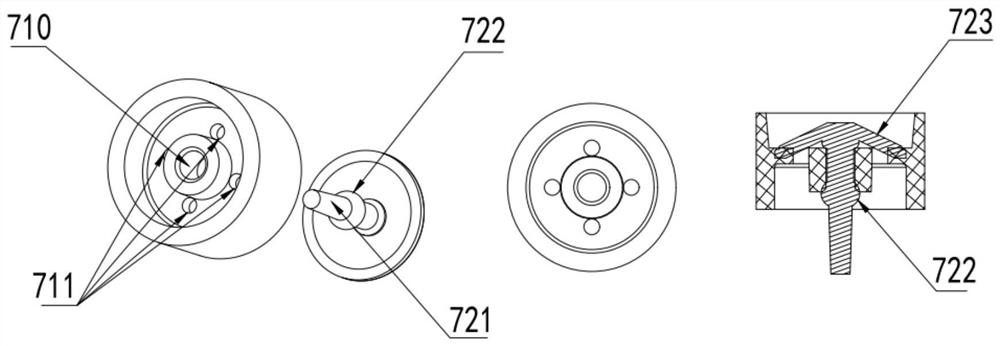

One-way valve system for medical vacuum negative pressure machine

ActiveCN113521527AImprove air tightnessUniform air pressureSuction devicesValvesInterference fitEngineering

The invention discloses a one-way valve system used for a medical vacuum negative pressure machine, the one-way valve system comprises an adapter, a one-way valve, an air nozzle and a negative pressure pump which are connected in sequence, the adapter and the air nozzle, the one-way valve and the air nozzle, and the air nozzle and the negative pressure pump are assembled in an interference fit mode, and the interior of the one-way valve is of an interference fit structure. Flow holes are evenly distributed in the end face. According to the one-way valve system, only one-way circulation of air can be achieved; meanwhile, the external air leakage amount is small, the air tightness of the one-way valve system can be effectively improved, the air tightness of the whole medical vacuum negative pressure machine system is ensured, so that the power consumption of a medical vacuum negative pressure machine is reduced, the control precision is improved, noise is reduced, and better user experience is brought.

Owner:SUZHONG PHARMA GRP MEDICAL EQUIP CO LTD

Map browser embedded mobile terminal and mobile phone map mobile terminal platform

ActiveCN100442895CEasy to buildSimplified splitting modelSpecial service for subscribersSubstation equipmentEngineeringHuman–computer interaction

The invention relates to a map browser embedded in a mobile terminal, comprising: a data processing module; a script language analysis module connected with the data processing module; a user interface module connected with the script language analysis module connect. The map browser embedded in the mobile terminal realizes that each link in the middle of the LBS service chain performs its duties and cooperates with division of labor; it is conducive to simplifying the division mode of the mobile phone map service chain. At the same time, the present invention also relates to a mobile phone map mobile terminal system, including a map browser; an interface module connected with the map browser; a local map database; a map engine connected with the interface module. Through this system, various value-added services based on location information are provided to mobile terminal users, the effective combination of data and maps is realized, and map-based information services are established on the mobile communication network.

Owner:CHINA MOBILE COMM GRP CO LTD +1

System and method for implementing game strategy dependencies

ActiveCN107633302BShorten the development cycleImprove experienceVideo gamesInference methodsDatasheetHuman–computer interaction

The technical scheme of the invention comprises a dependency implementation system and method of a game strategy. The system comprises an interface behavior description module, an interface configuration file generator, an interface object loader, an interface data processor and an interface manager, wherein the interface behavior description module provides stored and customized-editing interfaceattributes and interface behavior related data; the interface configuration file generator carries out parameterization on the interface attributes and interface behavior related data of the interface behavior description module and packages the interface attributes and interface behavior related data into a configuration file; the interface object loader is used for creating a new interface object, loading and storing data resources and analyzing the configuration file; the interface data processor is used for identifying and classifying the data resources and recording a relevant interfacebehavior; and the interface manager is used for executing all interface behaviors. The technical scheme of the invention also comprises a dependency implementation system and method of the game strategy. The system and the method have the beneficial effects that resources, logic and data are separated, a structure is simplified, the complexity degree of development is greatly lowered, code repeatability is reduced, meanwhile, interface behaviors are on the same data table, and people who can not understand programs can carry out revision.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

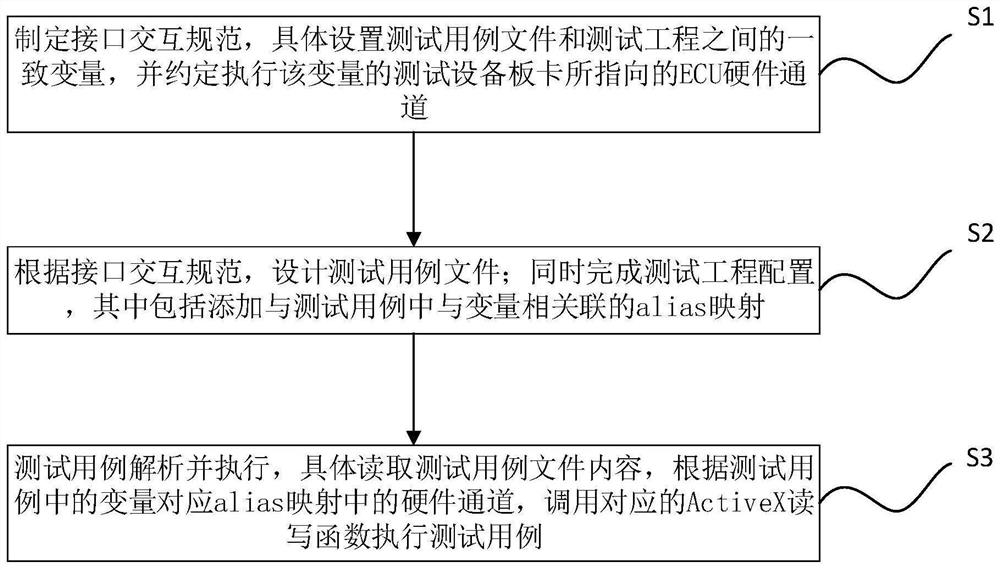

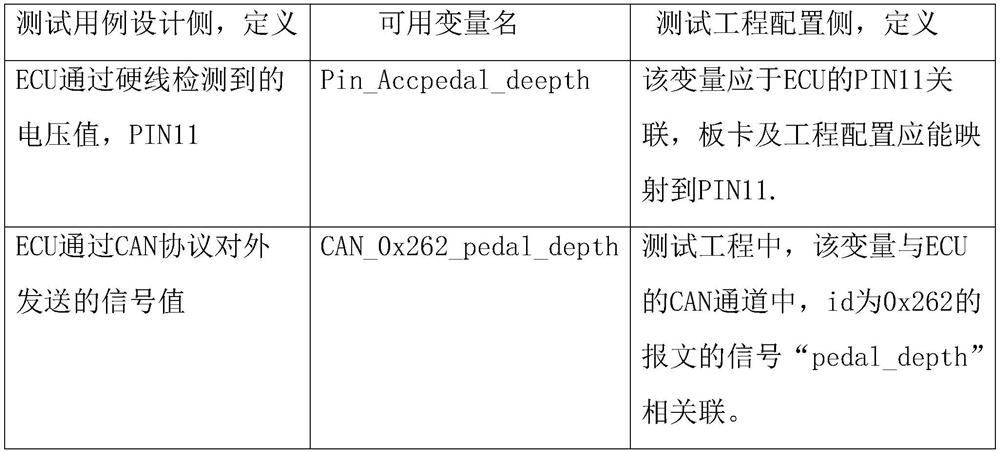

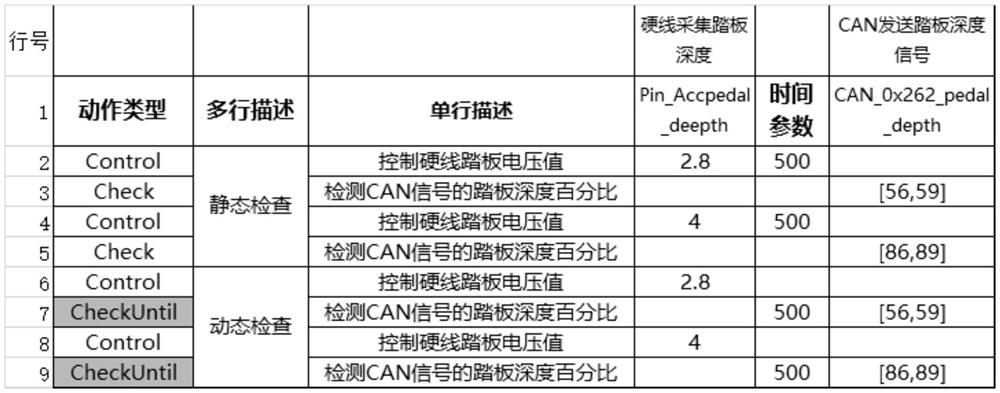

HIL test automatic execution method

PendingCN114816999AFacilitate division of labor and cooperationImprove efficiencySoftware testing/debuggingProgramming languageTest equipment

The invention discloses an automatic execution method for an HIL test, which comprises the following steps of: formulating an interface interaction specification, specifically setting a consistent variable between a test case file and a test project, and appointing an ECU hardware channel pointed by a test equipment board card for executing the variable; according to the interface interaction specification, a test case file is designed, and the test case file comprises an action type and specific execution content corresponding to a variable in the interface interaction specification; test engineering configuration is completed at the same time, namely, alias mapping associated with the variables in the test case is added, and the alias mapping comprises variable names and hardware channels in the corresponding test engineering; and analyzing and executing the test case, specifically reading the file content of the test case, and calling a corresponding ActiveX read-write function to execute the test case according to the hardware channel in the alias mapping corresponding to the variable in the test case. According to the method, the configuration debugging work and the test case design work of the test equipment can be separated, so that the efficiency is improved.

Owner:DONGFENG MOTOR GRP

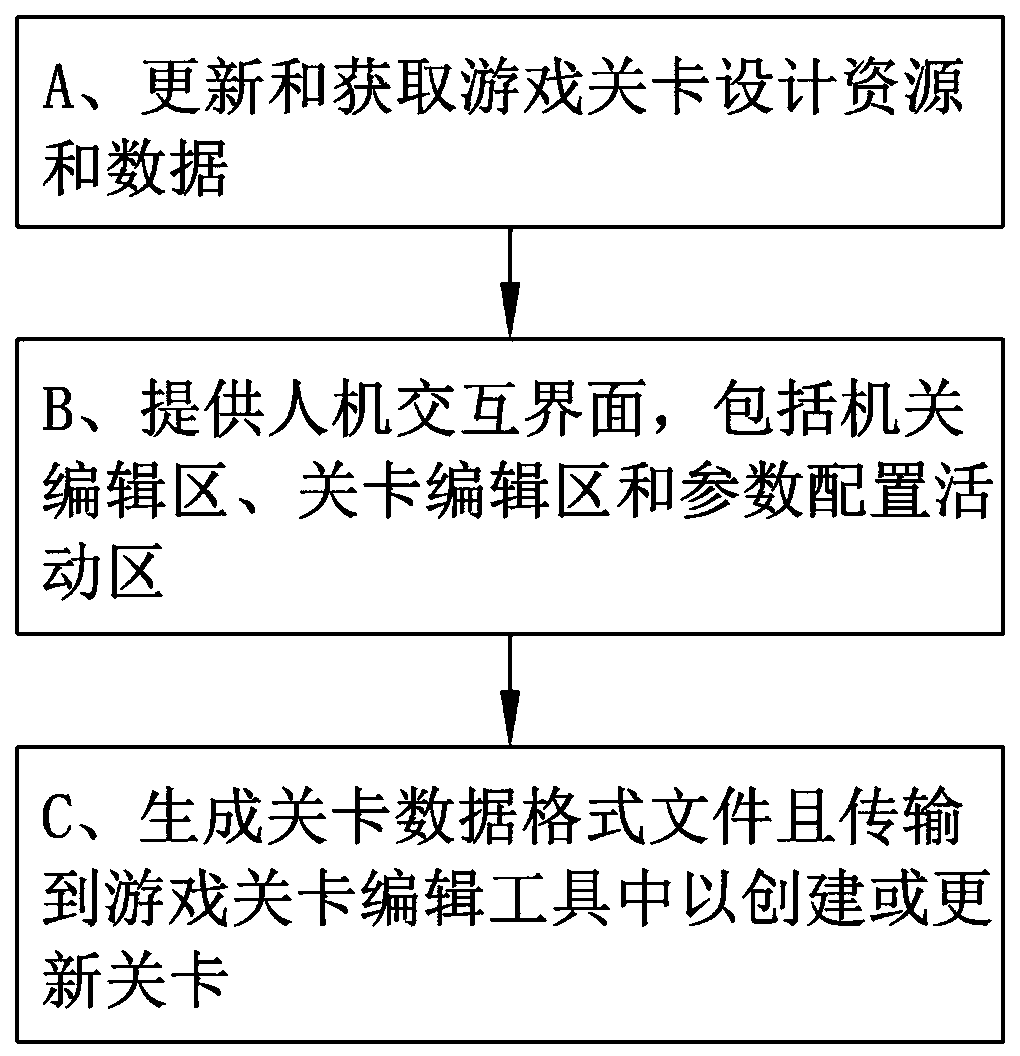

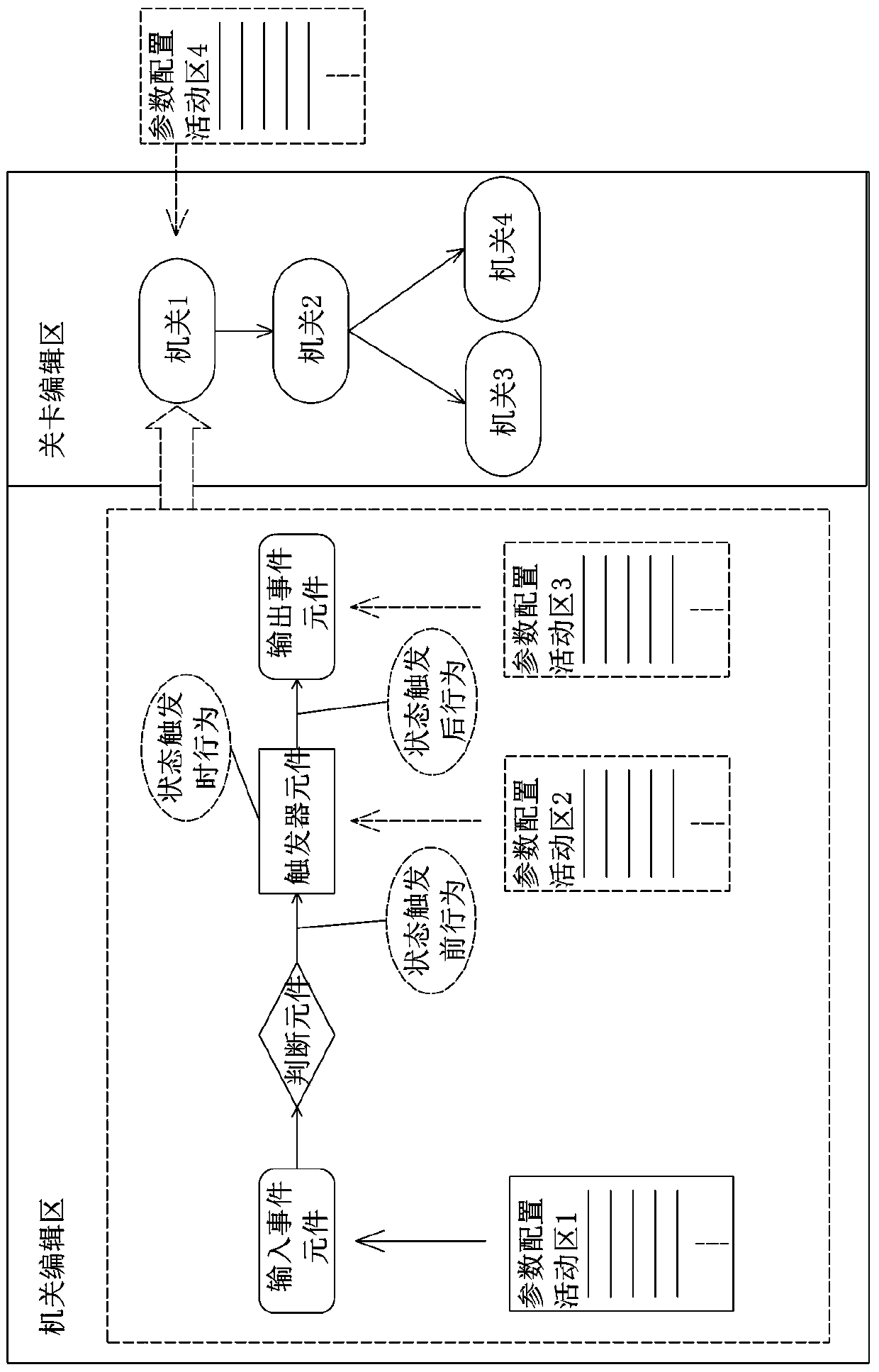

A trigger-based visual game level editing method and system

ActiveCN105653274BShorten development timeImprove maintainabilityVisual/graphical programmingVideo gamesMaintainabilityInteraction interface

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

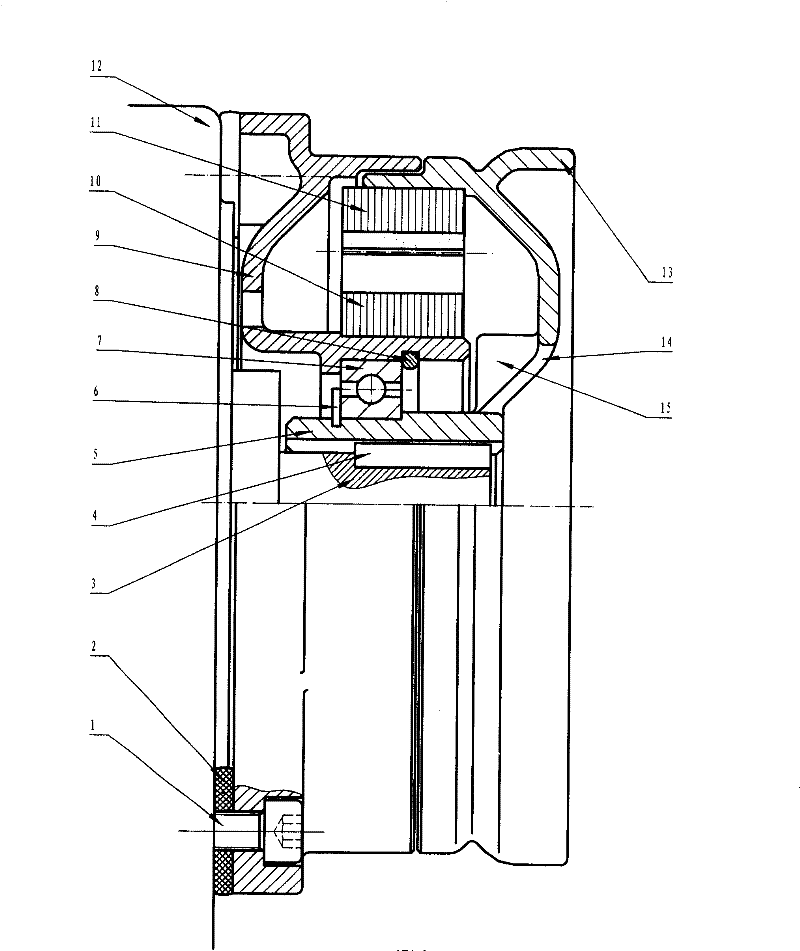

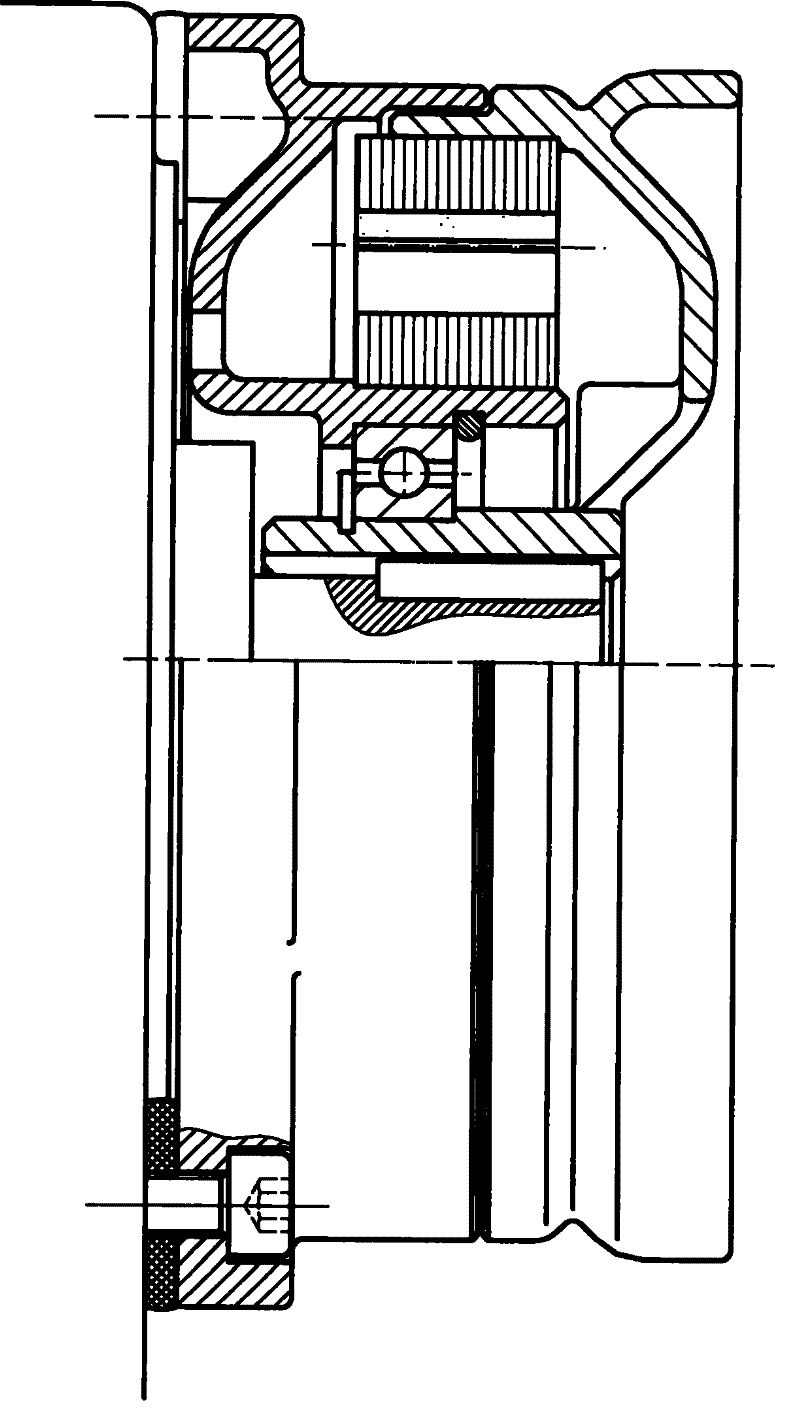

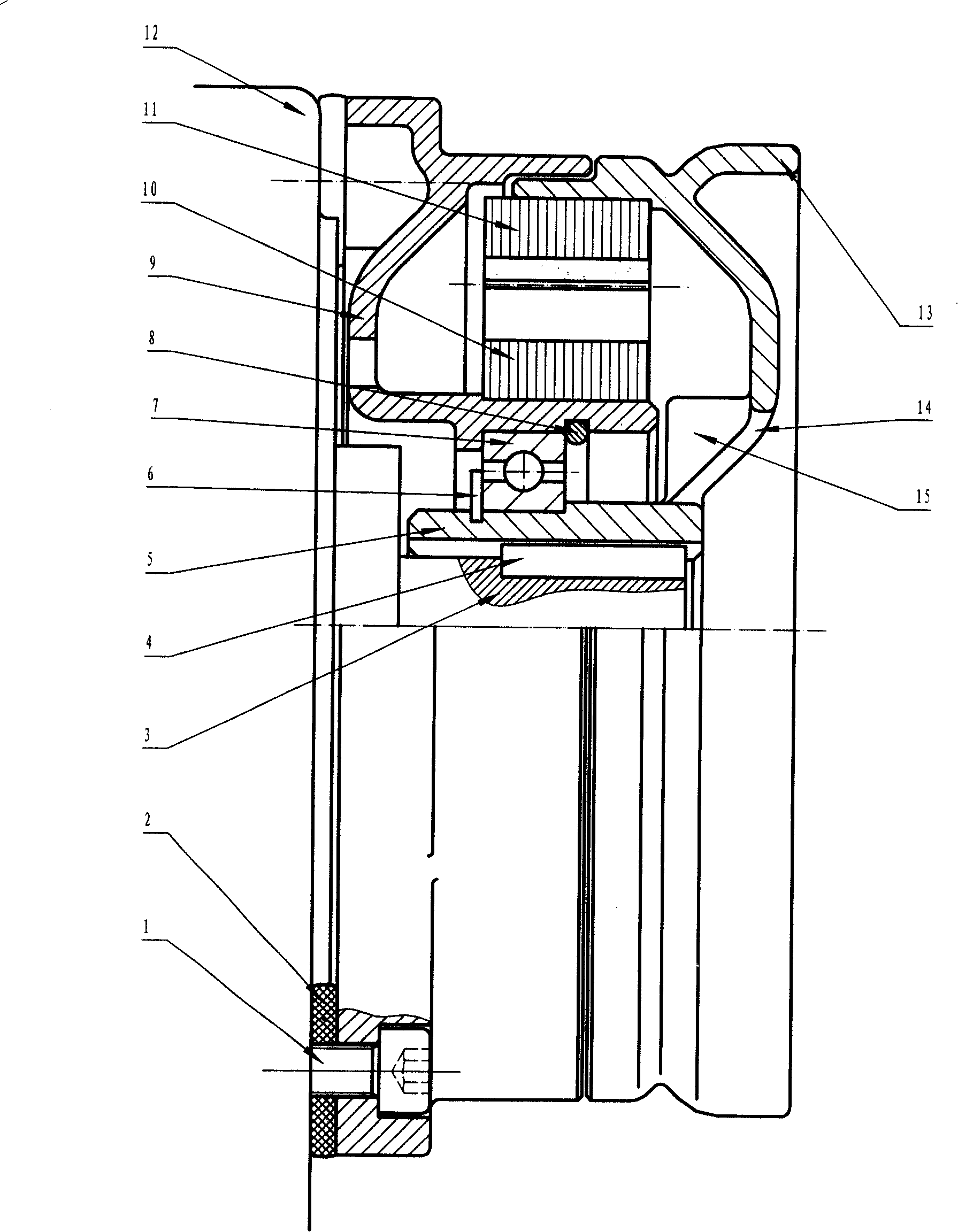

Novel suspended type permanent magnetism velocity modulation electric engine structure

InactiveCN101232210BReasonable designSimple structureMagnetic circuit stationary partsMechanical energy handlingCouplingElectric machine

The invention provides a novel suspended permanent magnet speed regulating motor structure with direct driving instead of conventional belt driving after studying the scheme of how to achieve optimal driving between a novel speed regulating motor and a work machine, which aims to design a novel suspended permanent magnet speed regulating motor compatible to the prior structure without couplings, convenient installation and debugging, good appearance and practical use. The technical scheme of the invention is characterized in that the motor has a short and thick structure, a stator iron core is directly arranged on a pedestal, only one bearing is arranged between a rotor and the pedestal to limit the degree of freedom in radial movement, the rotor is tightly sheathed on an input shaft of the working machine during operation of the motor, and the limitation in other degrees of freedom of the rotor can be achieved by using the shaft and the bearing of the work machine.

Owner:苏州扬名机电有限公司 +1

Novel suspended type permanent magnetism velocity modulation electric engine structure

InactiveCN101232210AReasonable designSimple structureMagnetic circuit stationary partsMechanical energy handlingVelocity modulationMagnet

The invention provides a novel suspended permanent magnet speed regulating motor structure with direct driving instead of conventional belt driving after studying the scheme of how to achieve optimal driving between a novel speed regulating motor and a work machine, which aims to design a novel suspended permanent magnet speed regulating motor compatible to the prior structure without couplings, convenient installation and debugging, good appearance and practical use. The technical scheme of the invention is characterized in that the motor has a short and thick structure, a stator iron core is directly arranged on a pedestal, only one bearing is arranged between a rotor and the pedestal to limit the degree of freedom in radial movement, the rotor is tightly sheathed on an input shaft of the working machine during operation of the motor, and the limitation in other degrees of freedom of the rotor can be achieved by using the shaft and the bearing of the work machine.

Owner:苏州扬名机电有限公司 +1

A system and method for resource hot loading and fast iterative game production

ActiveCN106371880BShorten the development cycleImprove experienceSoftware engineeringData fileUnique identifier

The technical scheme of the invention discloses a resource hot-loading rapid iteration game making system and method. The method comprises the following steps: identifying and converting a source file provided by a game developer, and loading identified and converted file data into a memory block; representing the file data loaded into the memory block by a file list, performing real-time monitoring, acquiring change information when the file list changes, and transmitting the change information; producing a mapping table for the monitored data file and unique identifiers of the data file, receiving the change information, acquiring the changed data file through the mapping table, reloading the data file into the memory block, and issuing a reloading instruction; receiving and executing a reloading instruction issued by a monitoring module, acquiring a new data file, and rebinding file resources included in the data file into a game system. The resource hot-loading rapid iteration game making system and method have the beneficial effects that the game development period is shortened greatly, the experience and performance of a game are improved, personnel in various positions can share out the work and cooperate with one another conveniently, and the flow is optimized.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

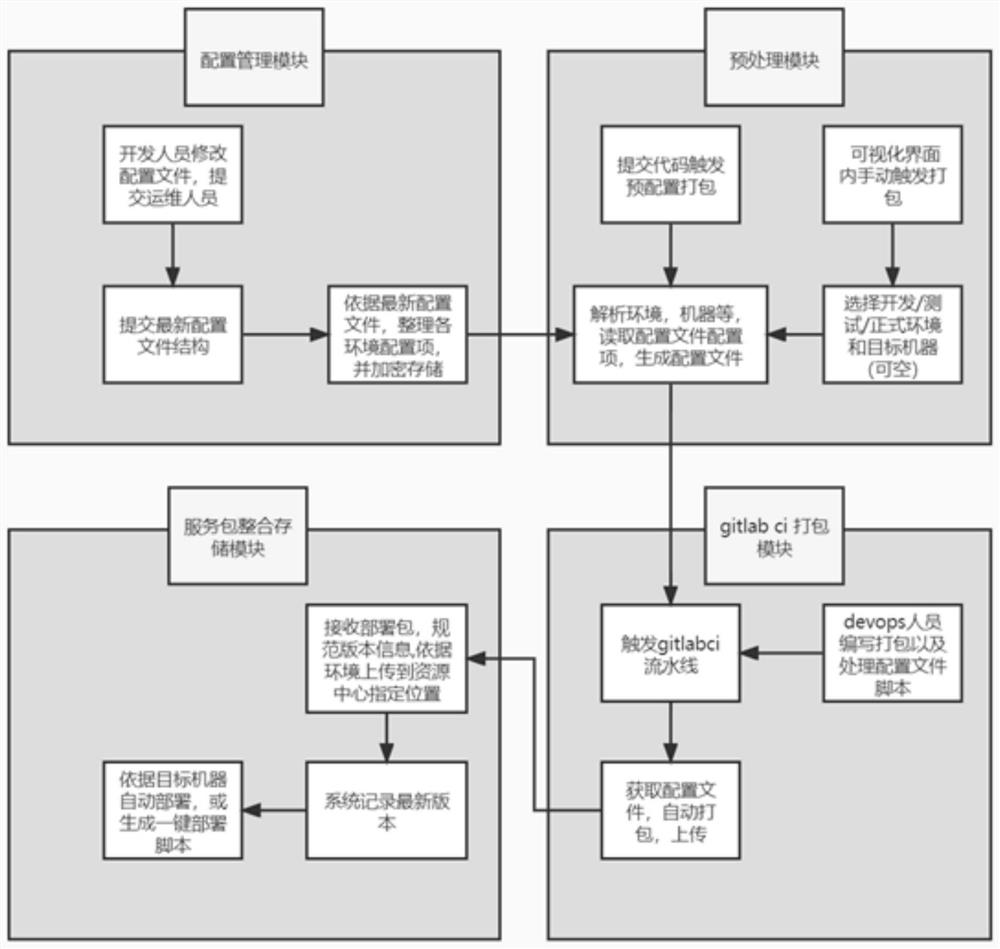

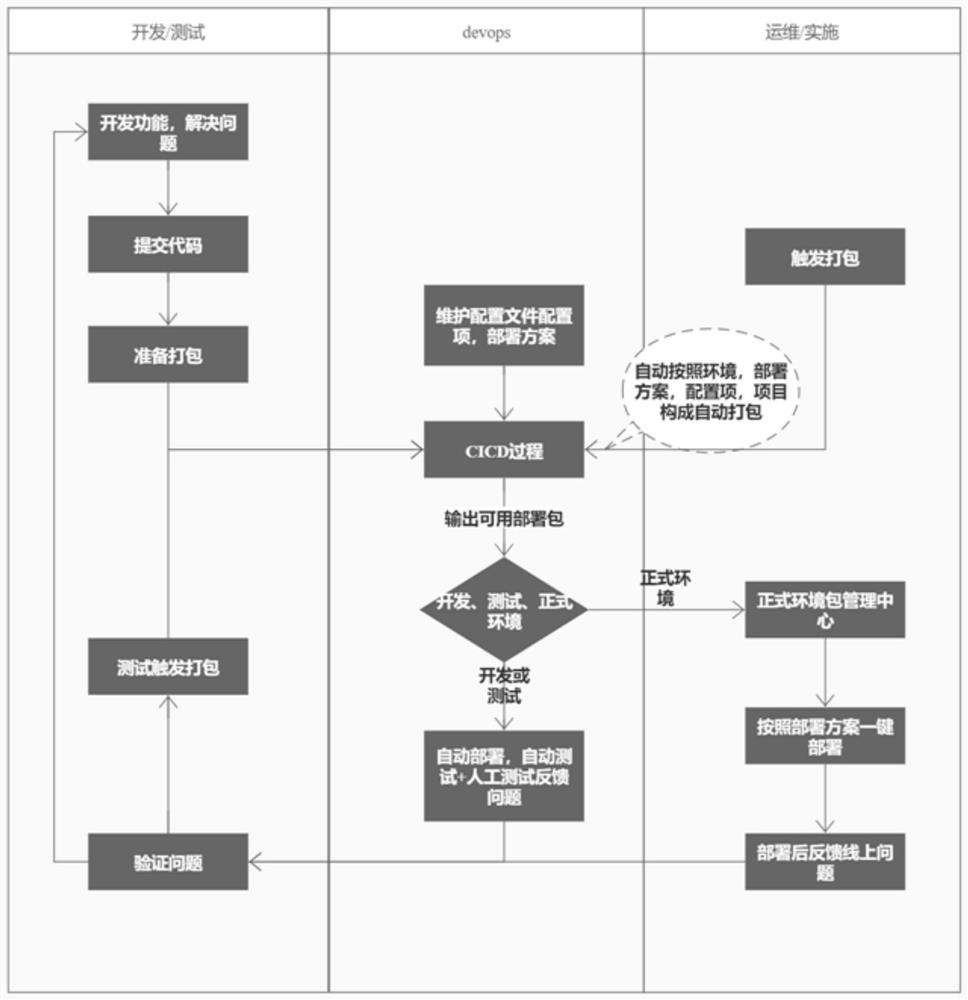

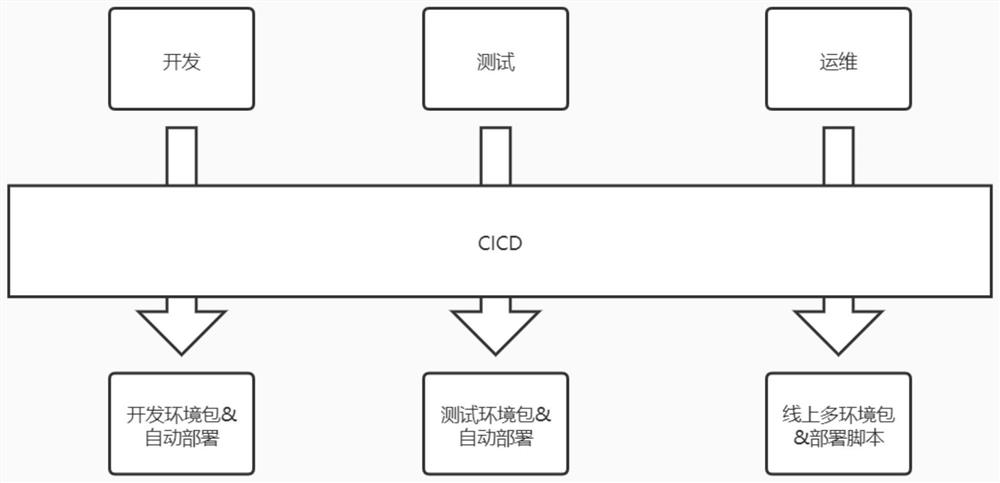

Gitlab-ci-based flexible and safe CI/CD service deployment system and method

PendingCN114371881AIncrease flexibilityMeet environmental needsDigital data protectionProgram loading/initiatingConfiguration itemProject management

The invention discloses a flexible and safe CI / CD service deployment system and method based on gitlab-ci, belongs to the field of operation and maintenance deployment, and aims to solve the technical problem of how to realize that a service deployment packet adapts to various deployment schemes and network environments, improve the security of configuration items and improve the efficiency of continuous integration and continuous deployment at the same time. According to the technical scheme, the system comprises a configuration management module used for project management, configuration file structure management and configuration item encryption management; the preprocessing module is used for triggering packaging and analyzing an environment and a machine to generate a corresponding configuration file; the gilab-ci packaging module is used for starting a gilab-ci assembly line after triggering the CI / CD, reading parameters of a scheduling system and a configuration file assembled by the scheduling system, and pushing a task to a gilab run queue; and the service package integration module is used for storing the service package and automatically deploying the service package.

Owner:INSPUR SOFTWARE CO LTD

A Decision Tree-Based Automatic Server Fault Detection System and Detection Method

ActiveCN109218114BFacilitate division of labor and cooperationImprove readabilityData switching networksFeature vectorData set

The invention discloses an automatic detection system and detection method for server faults based on a decision tree, combined with an expert system and an IPMI management unit to generate a historical data set; through the IPMI management unit to obtain the server operation status data at the time of failure, that is, the abnormal data flow, according to The abnormal data flow extracts new fault feature vectors, and the fault data set is composed of new feature vectors and fault cause relationship pairs, and is trained into a self-diagnosis decision tree model; when a fault occurs during server operation, the corresponding fault feature vector is extracted, The self-diagnosis decision tree model automatically judges the fault type, cause and treatment method and notifies the technicians. After the fault is cleared, the fault feature vector and fault cause relationship are added to the historical fault set to complete the update, and the self-diagnosis fault tree model is updated. , so with the continuous improvement of the historical fault set, the fault diagnosis system will be more accurate and reliable.

Owner:XIAN MICROELECTRONICS TECH INST

Extraction technology of crude heparin sodium

The invention relates to an extraction technology of crude heparin sodium. The extraction technology comprises the following steps: hydrolysis: putting broken raw materials into a reaction kettle, adding a hydrolysis liquid into the reaction kettle, adding resin into filtrate, stirring, siphoning the supernatant liquid, collecting the resin, washing the resin in clean water till the resin is neutral, and draining; desorption: soaking the resin with dilute saline water, discarding the soaking solution, adding concentrated saline water into the resin twice, stirring, washing, filtering, and keeping the washing liquid; alcohol precipitation: adding ethyl alcohol into the washing liquid, stirring, carrying out standing, discarding the supernatant liquid, keeping the bottom sediment, draining the sediment, adding ethyl alcohol, washing, unwatering, and collecting dehydrated heparin sodium sediment; drying: drying the heparin sodium sediment in vacuum. The extraction technology of crude heparin sodium provided by the invention has the following advantages: all the steps are clear, so that labor division and cooperation are facilitated; the contents of various important additives have quantitative marks and are authenticated through tests, and the sequence among the additives is clear.

Owner:JIANGSU LIANZHONG CASING

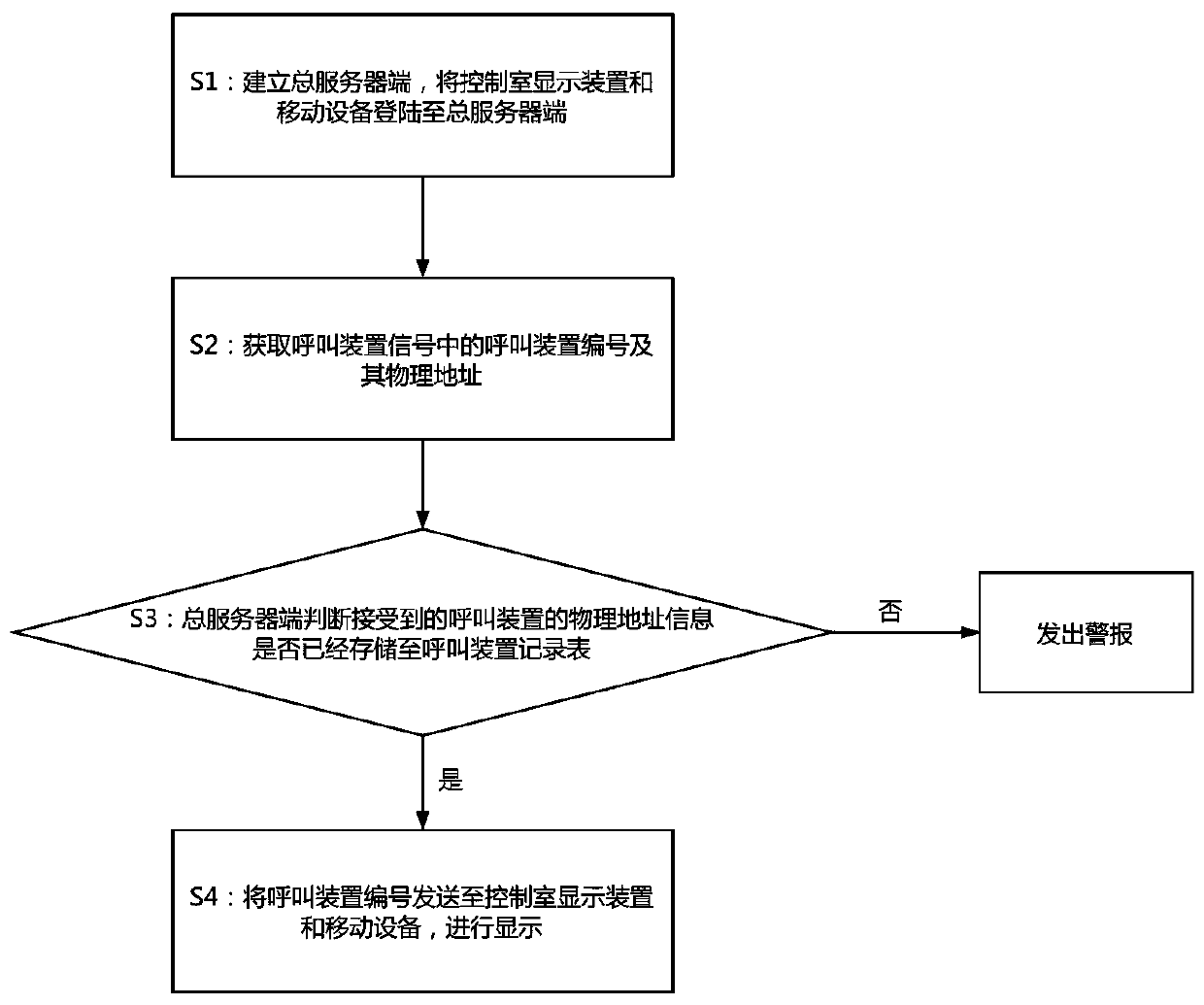

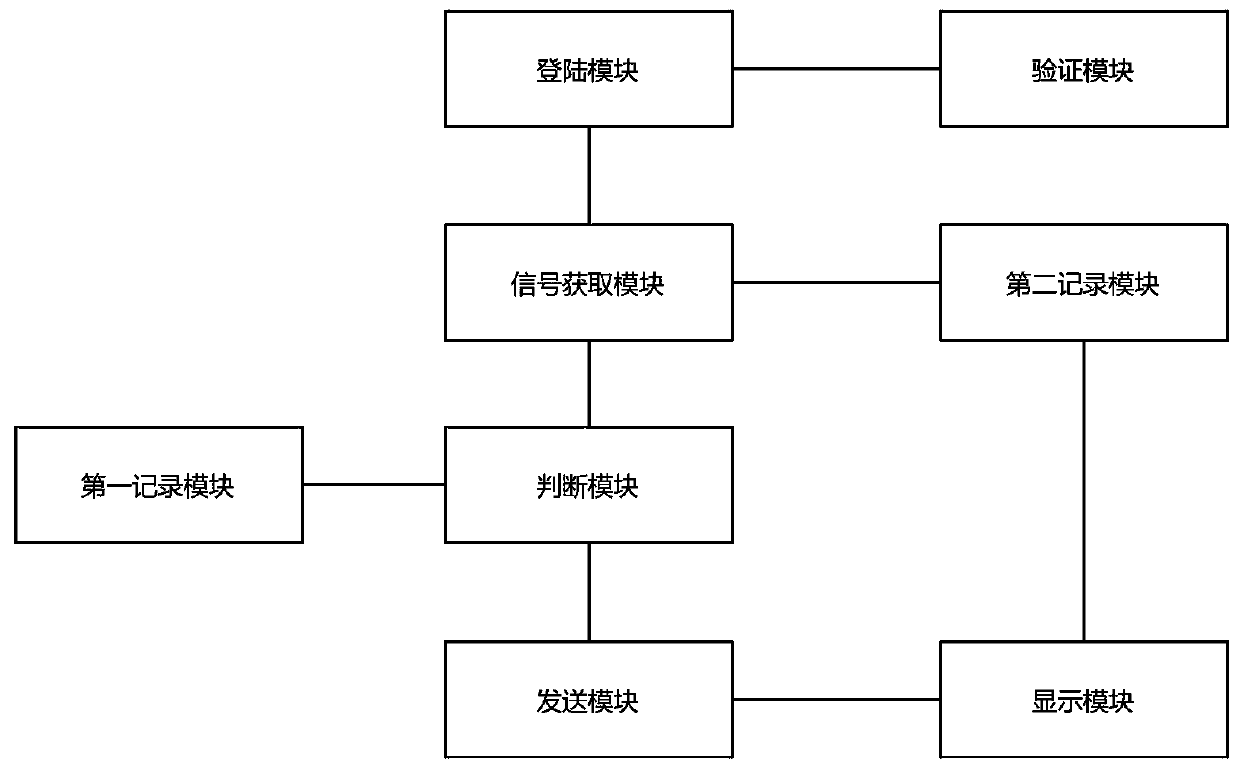

An electric power capital construction on-site communication calling method and system

InactiveCN109818947AFacilitate division of labor and cooperationFacilitate communicationTelephonic communicationTransmissionPhysical addressDisplay device

The invention provides an electric power capital construction field communication calling method and system, and relates to the technical field of field communication, the electric power capital construction field communication calling method comprises the following steps: S1, establishing a total server side, and logging in a control room display device and mobile equipment to the total server side; S2, acquiring a calling device number and a physical address of the calling device number in the calling device signal; S3, enabling the master server to judge whether the received physical address information of the calling device is stored in a calling device record table, and if the received physical address information of the calling device is stored in the calling device record table, executing the step S4; And S4, sending the calling device number to a control room display device and mobile equipment for display. The electric power capital construction site communication calling method and system are simple, practical and convenient to communicate, one person is required to know multiple persons, the two receivers are independent of each other and do not interfere with each other, workers can cooperate with each other conveniently, and the response efficiency of temporary power utilization requests of the capital construction site is improved.

Owner:黄冈东源电业集团有限公司建设分公司 +1

Industrial construction method of "square hole and round patch" on asphalt concrete pavement

Owner:ANHUI KAIYUAN HIGHWAY & BRIDGE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com