Patents

Literature

33results about How to "Promote division of labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

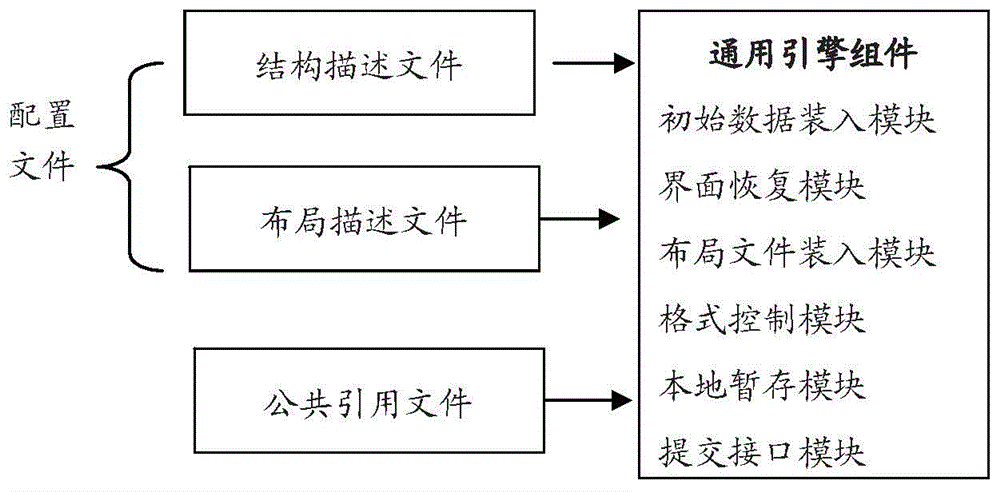

System and method for achieving general data form inputting through configuration files

InactiveCN104375818ALower requirementSpeed up developmentSpecific program execution arrangementsDatabaseCommon Data Format

The invention discloses a system and method for achieving general data form inputting through configuration files. The system comprises a general engine component for reading all the configuration files and finishing form interface display and data inputting and submitting according to the contents described by the read configuration files; the configuration files comprise structure description files for describing various structure attributes of forms. The method includes the steps that S1, the structure description files for describing various structure attributes of the forms are created; S2, the general engine component is started, all the configuration files including the structure description files are read, and form interface display and data inputting, verifying and submitting are finished according to the contents described by all the read configuration files, so that for different forms, no programming is needed for programmers, general inputting can be achieved just by modifying the related configuration files simply, and meanwhile, better user experience can be achieved as well.

Owner:北京金辉东方科技有限公司

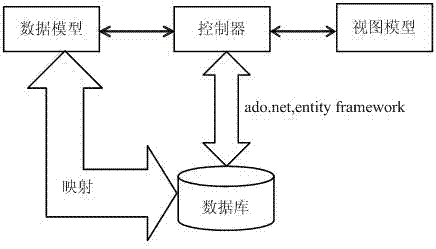

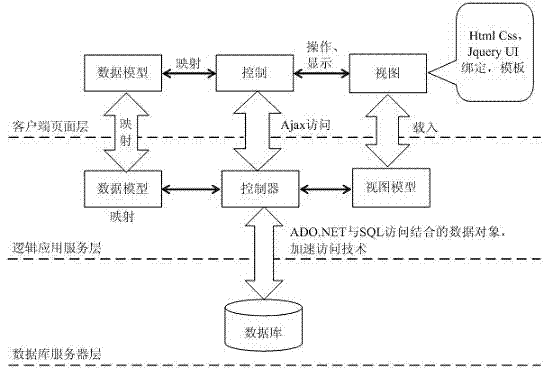

Method and layered structure for double-layer MVC (model, view and controller) developed by Web application with mass data

InactiveCN102830973AImprove experience praiseImprove experienceSpecific program execution arrangementsSpecial data processing applicationsWeb applicationDatabase server

The invention discloses a method and a layered structure for double-layer MVC (model, view and controller) developed by a Web application with mass data. The method includes: sequentially and transversely dividing a development mode of the Web application from a body into a client page layer, a logical application service layer and a database server layer from top to bottom; and executing corresponding model, view and controller processing on the client page layer, the logical application service layer and the database server layer. The method and the layered structure can overcome the defects of data structure disorderliness, high processing and maintaining difficulty, high error rate, low processing speed, poor user experience and the like in the prior art, and have the advantages of clear data structure, low processing and maintaining difficulty, low error rate, high processing speed and fine user experience.

Owner:WUXI ZHEQIN TECH

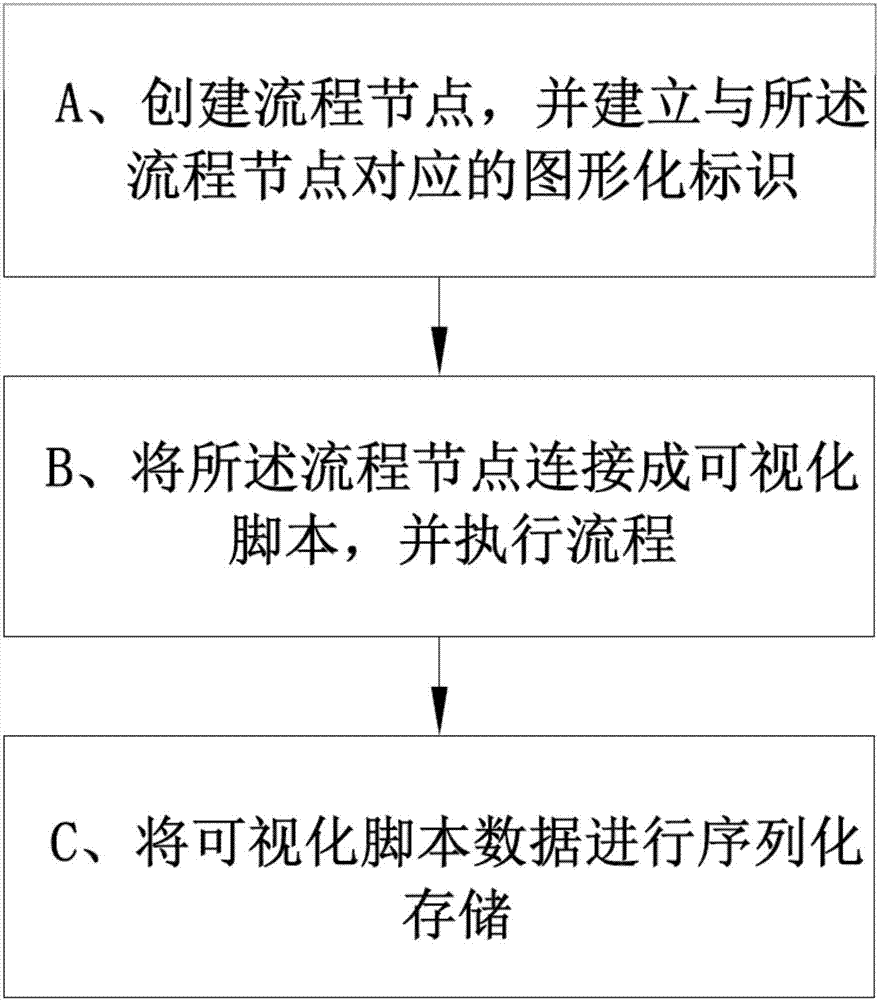

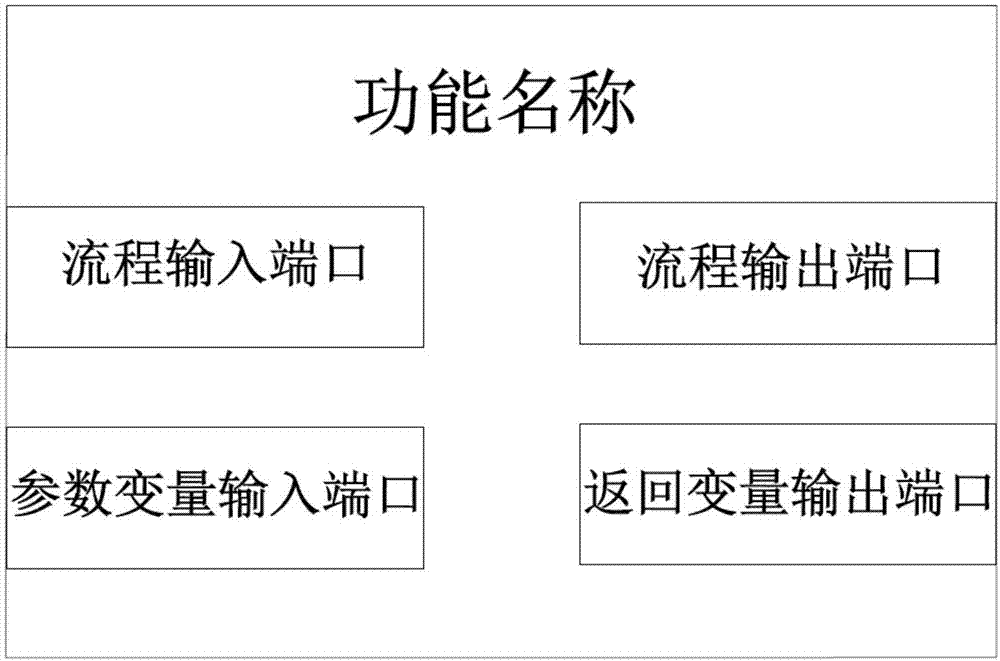

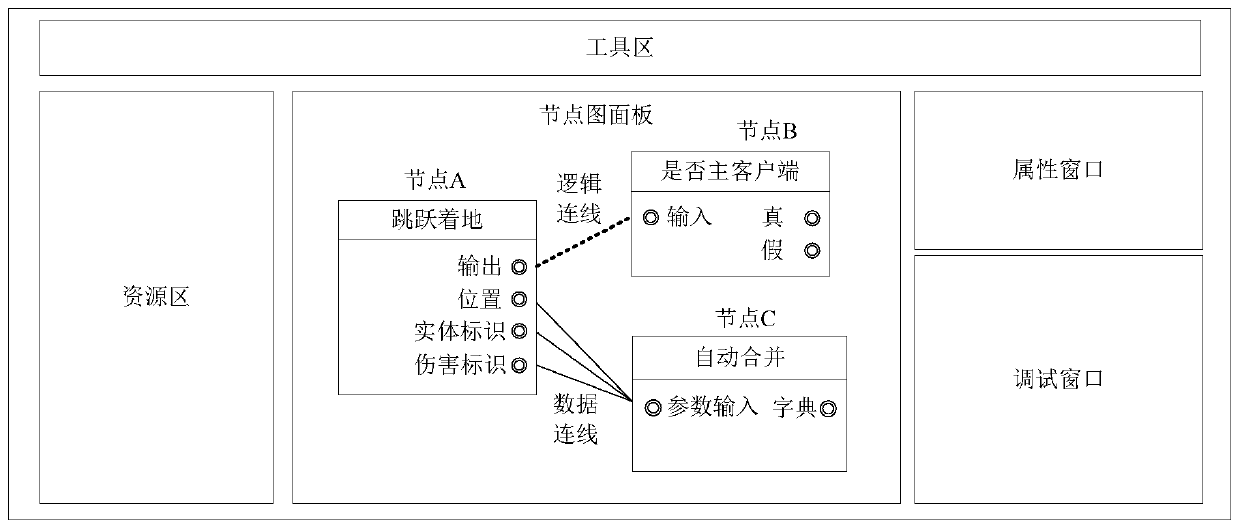

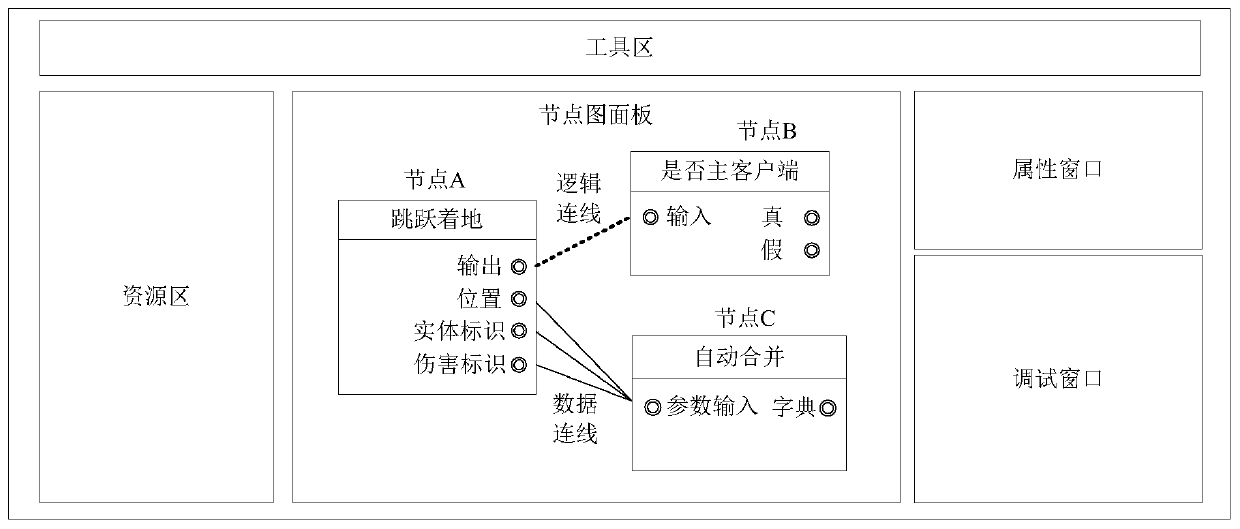

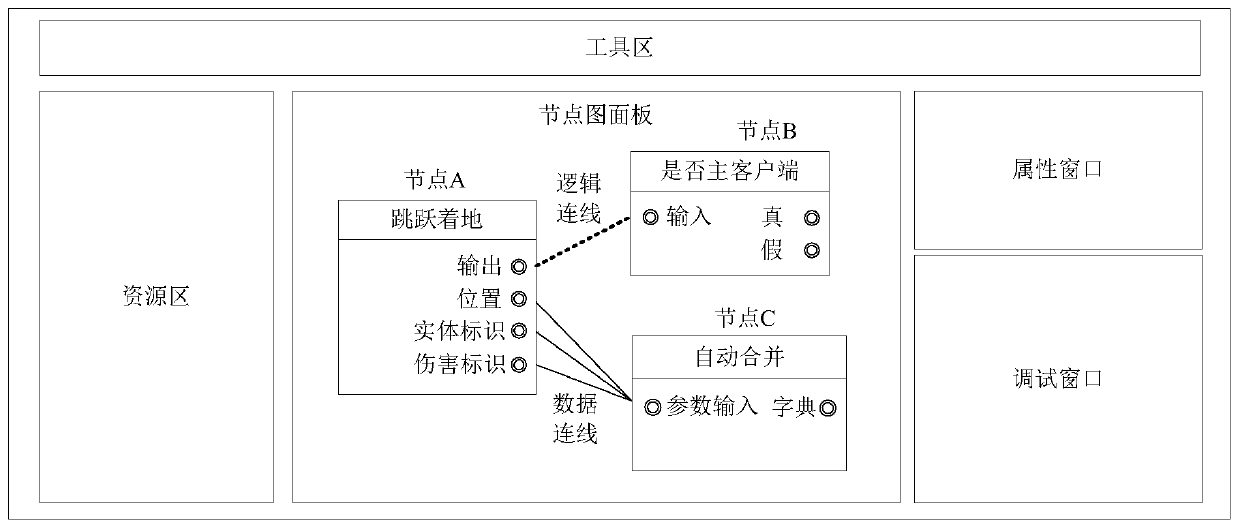

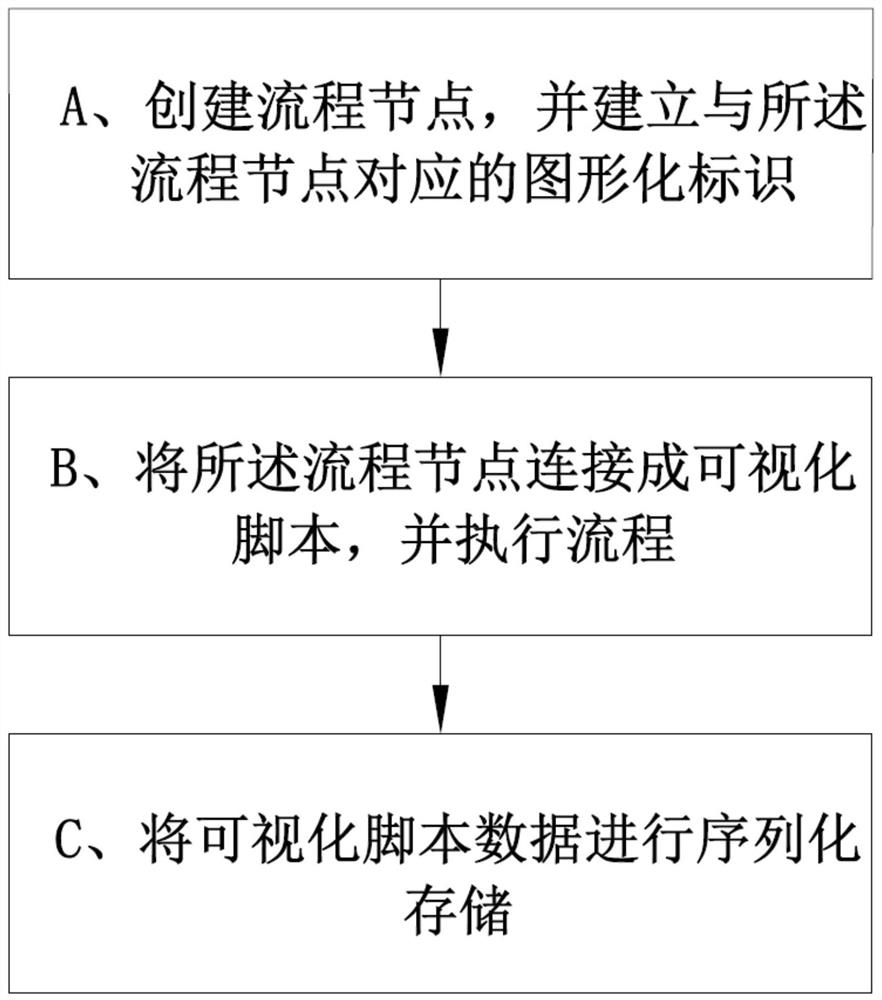

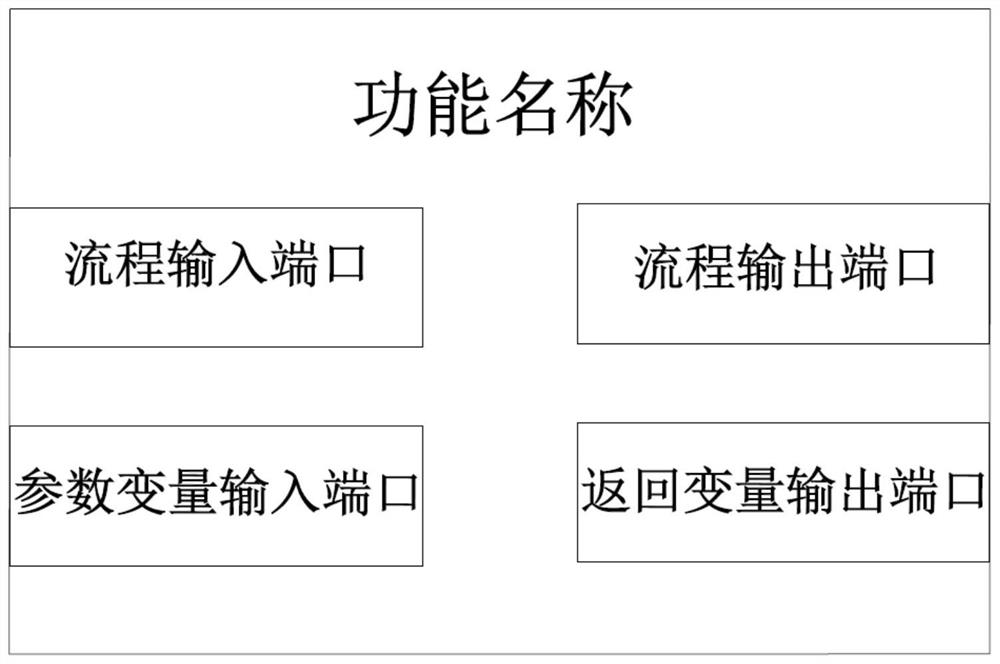

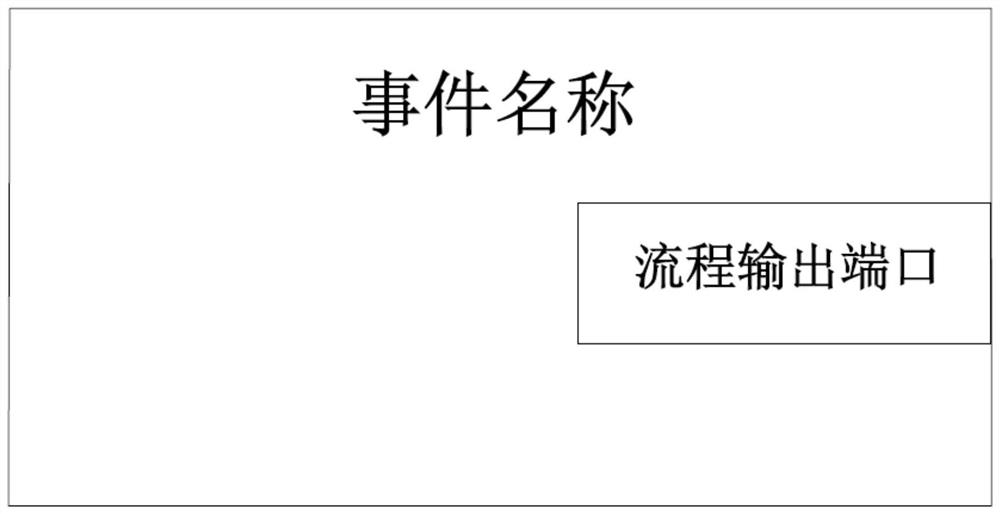

Design system and method of visualization script editor

ActiveCN107357567APromote division of laborShorten the development cycleIntelligent editorsVisual/graphical programmingDesign systemsSerialization

A method for implementing a visualization script editor is provided. The method comprises following steps: A. creating flow nodes and building graphical identifications corresponding to the flow nodes; B. connecting the flow nodes into a visualization script and executing the flow; C. performing serial storage on the visualization script data. The invention also discloses a design system corresponding to the visualization script editor. The method and system of the invention facilitate planning personnel and artists to take part in game development so that they can better share out the work and cooperate with one another; the flow is optimized; the development period is shortened; specific requirements of visual understanding of games are facilitated; reusability and scalability of codes are enhanced.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

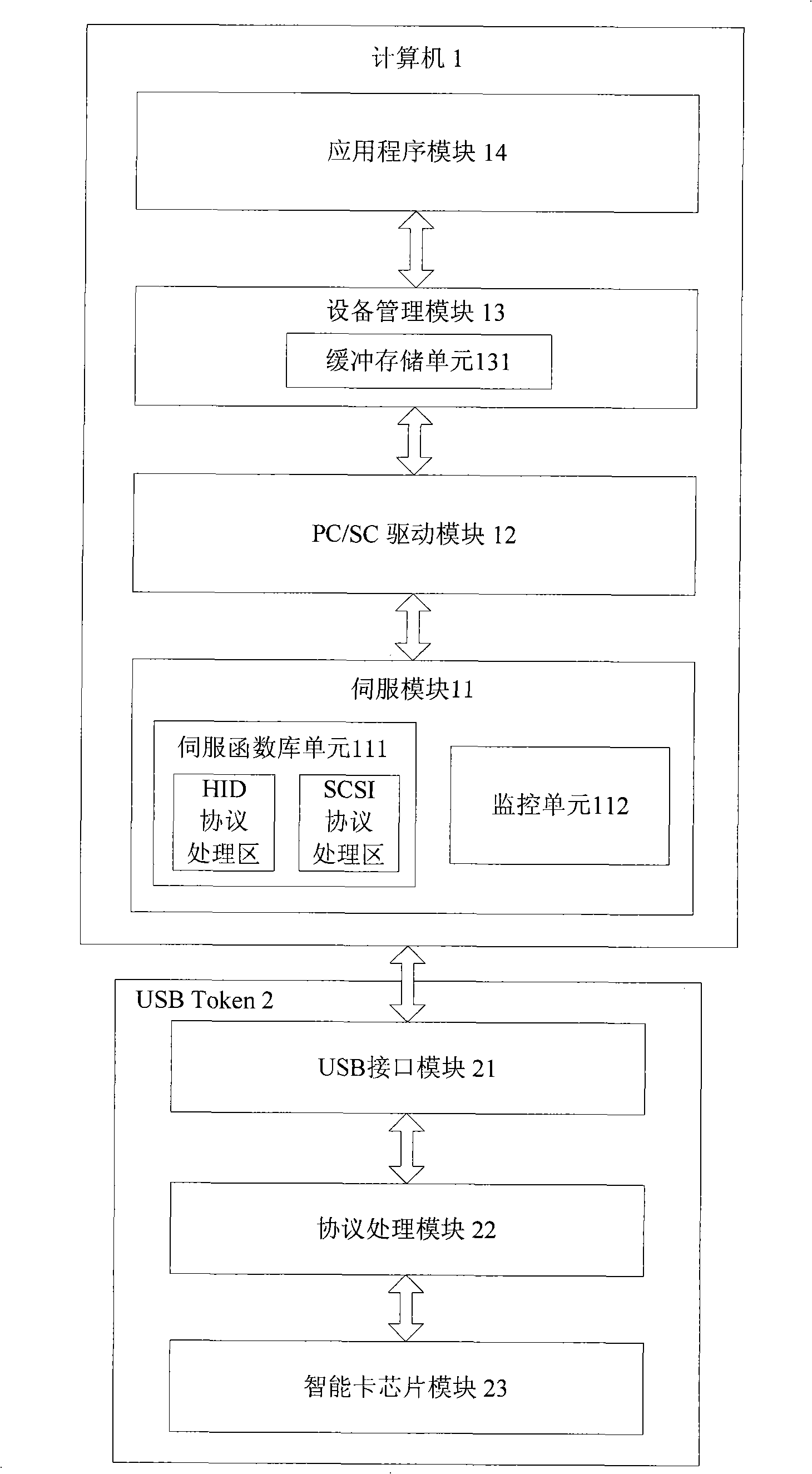

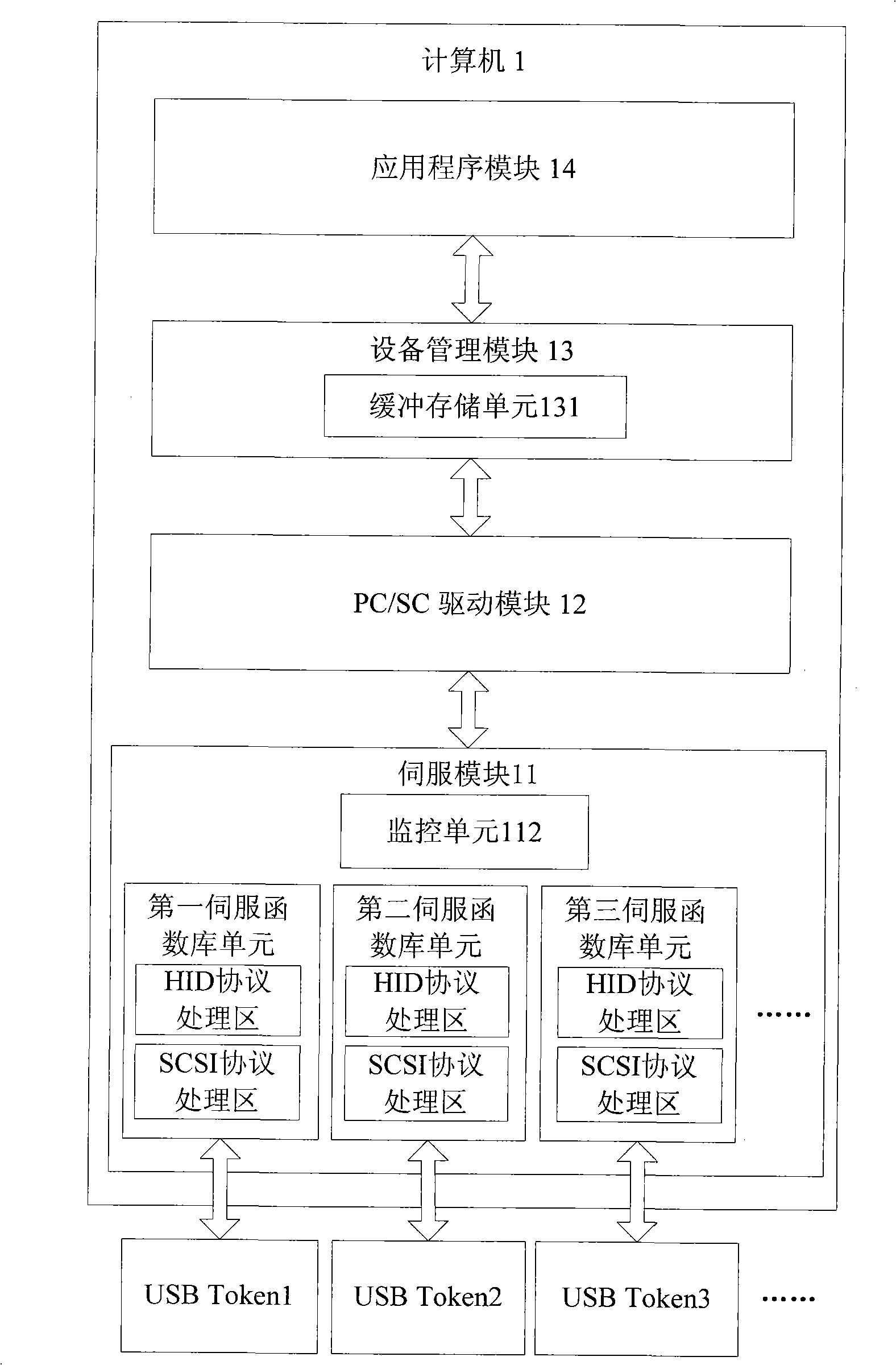

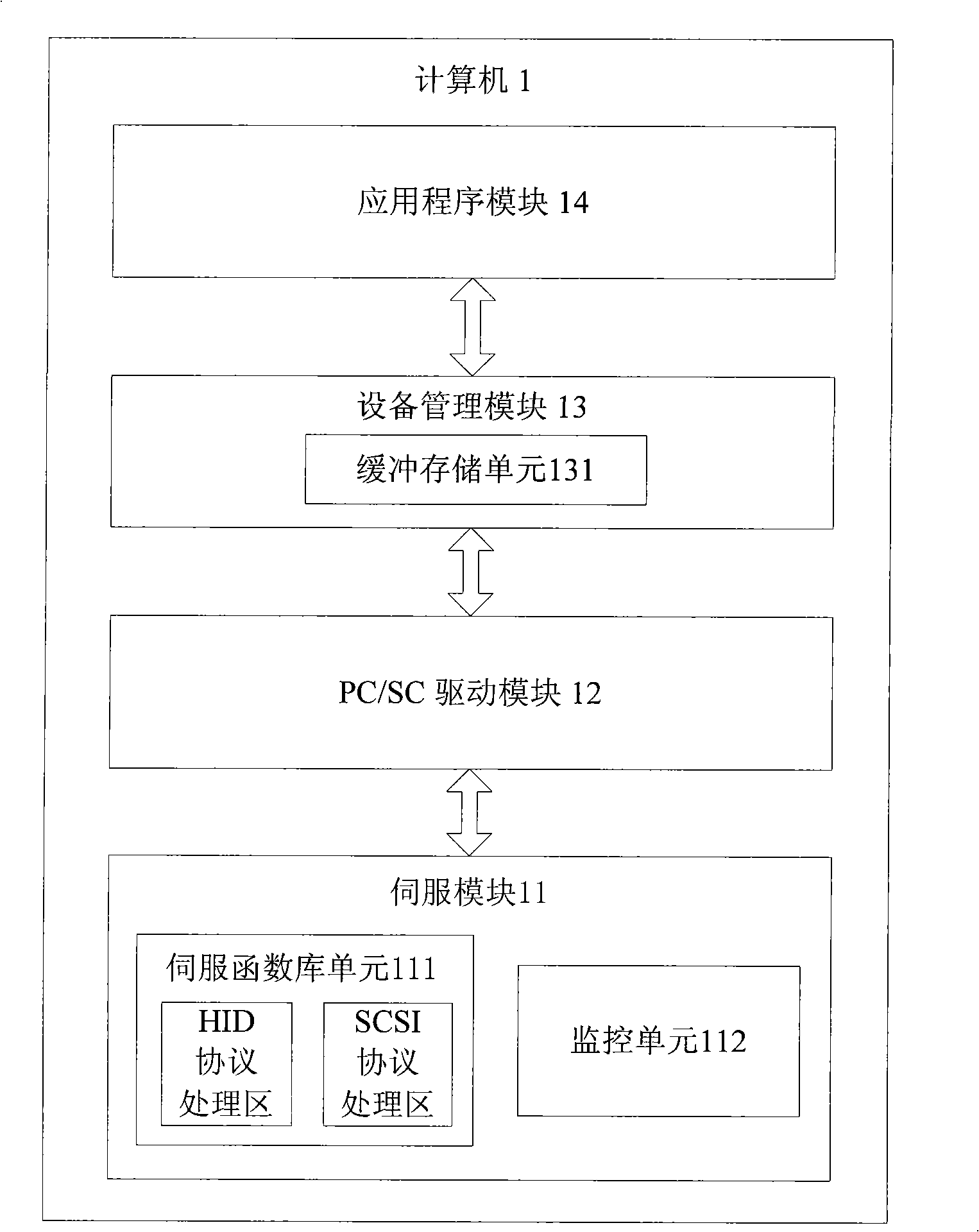

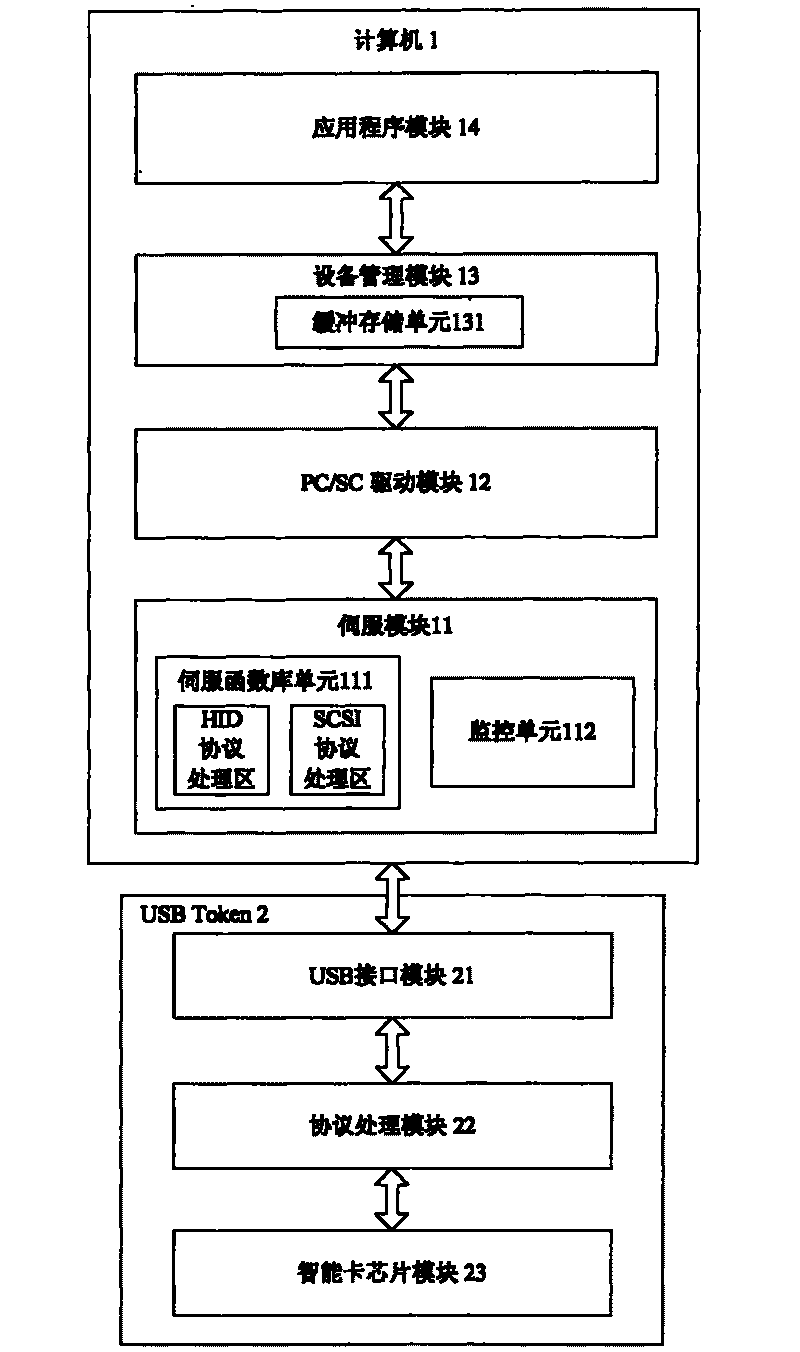

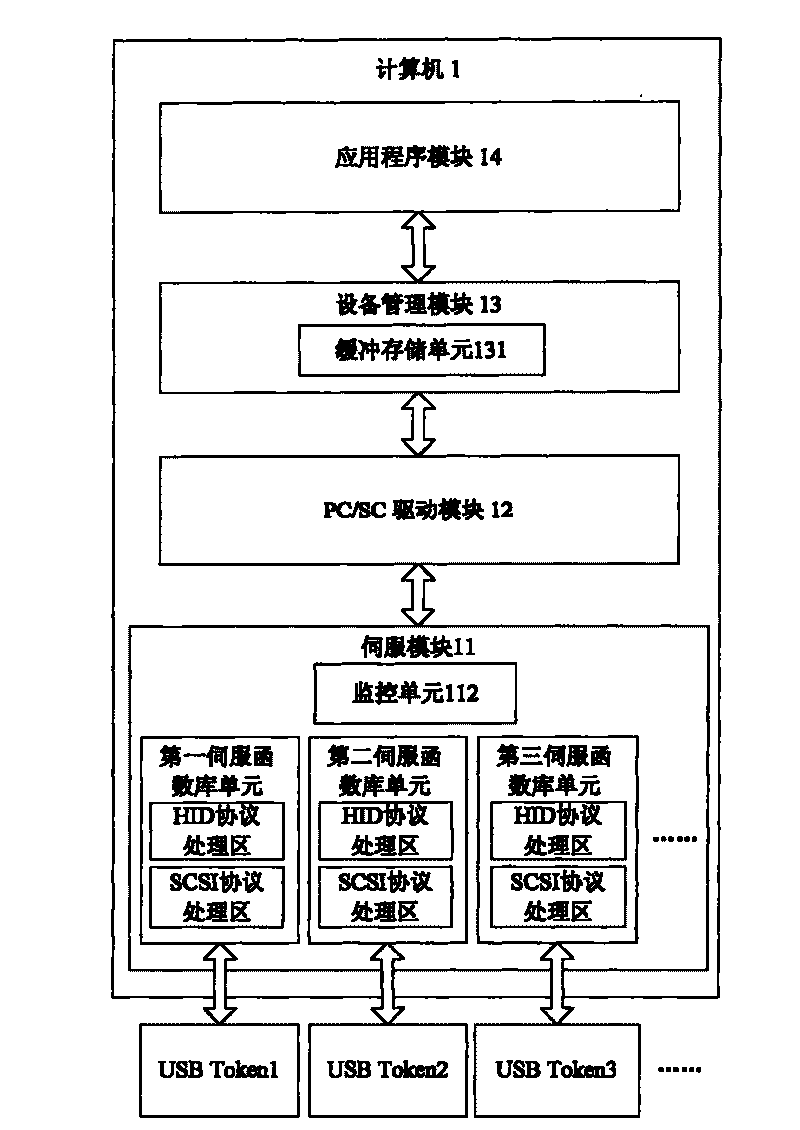

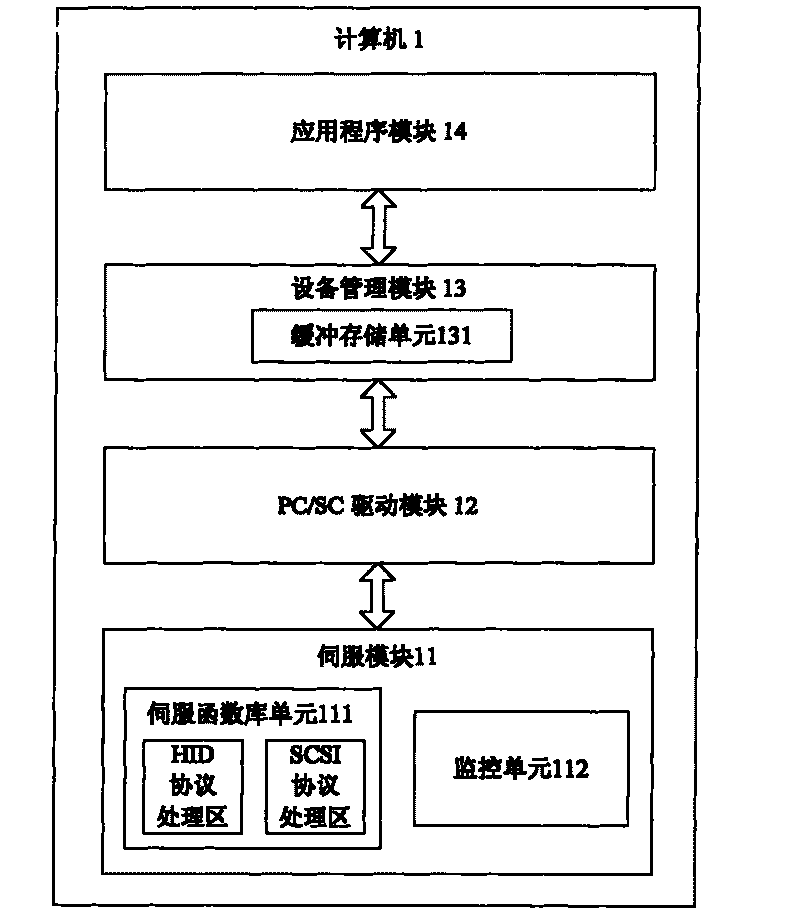

System and method for implementing PC / SC interface of HID / SCSI apparatus

ActiveCN101329661ASimplify writingEasy to modifyElectric digital data processingCommunications securitySCSI

The invention discloses a system for realizing a PC / SC interface of HID / SCSI equipment and a method thereof, which pertain to the field of communication safety. The method comprises the steps that: a servo program establishes a kernel object and uploads a servo function library, send the kernel object to a PC / SC driver program; the servo program submits the information of the HID / SCSI equipment to a computer equipment management program by the PC / SC driver program; the PC / SC driver program sends a received instruction for accessing the HID / SCSI equipment to the servo program by the kernel object; the servo program receives the instruction for accessing and obtains the code information of an instruction for calling the HID / SCSI interface from the servo function library; by the PC / SC driver program and the servo program, an application program accesses the HID / SCSI equipment through the PC / SC interface. As carrying out operation in an application layer of a system, the servo program has simple writing, modification and maintenance, and can not cause the whole system to crash when mistakes are made during operation process; when the support of new HID / SCSI equipment is required, replacing the servo program is only required to realize compatibility of the new equipment, thus enhancing the flexibility and expansibility of the system.

Owner:FEITIAN TECHNOLOGIES

Large-scale sintering project BIM model construction method

ActiveCN110222374AImplement the buildHighly integratedGeometric CADDesign optimisation/simulationElement modelGraphics workstation

The invention relates to a large-scale sintering project BIM model construction method. The method comprises the following steps of carrying out total plane layout; carrying out construction element model modeling; performing professional module modeling; performing professional model positioning conversion; carrying out regional module modeling; and carrying out overall model construction. According to the present invention, the large-scale sintering engineering BIM overall model is constructed, the integration level is high, the light weight processing of the model is achieved, the degree ofdependence on the computer hardware can be reduced, the constraint that a high-performance graphic workstation needs by the existing large-scale complex engineering modeling is avoided, and the modeling efficiency can be effectively improved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

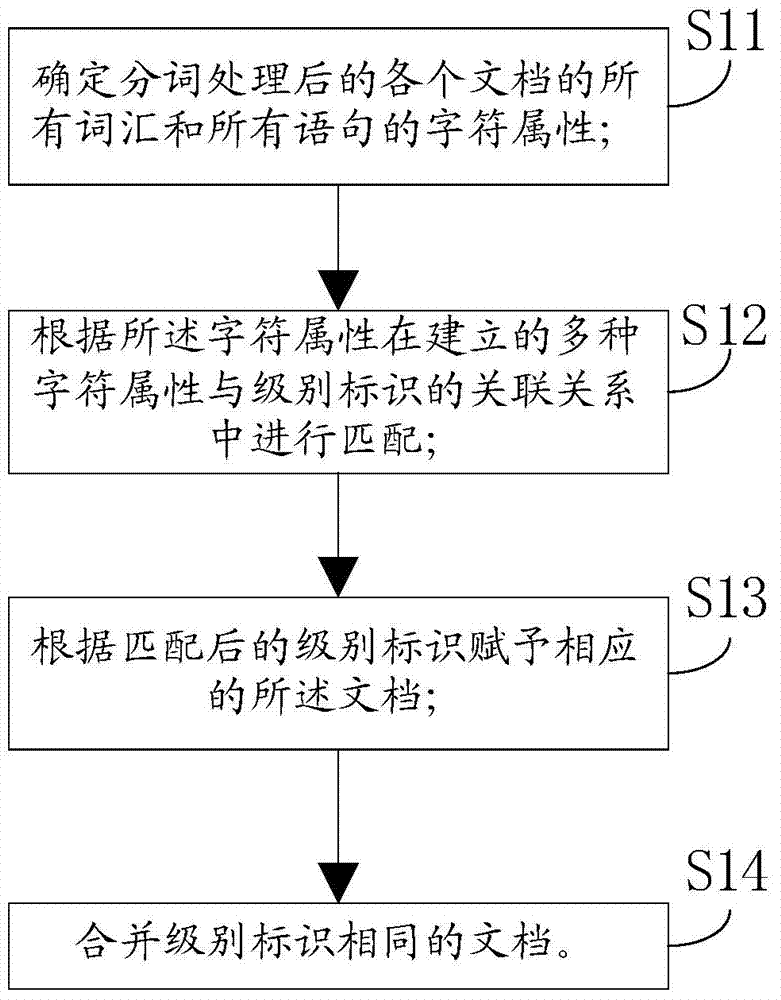

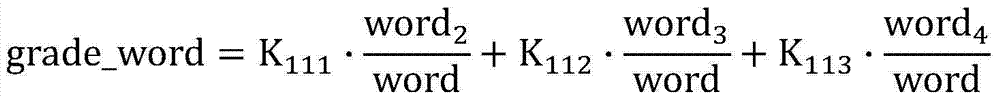

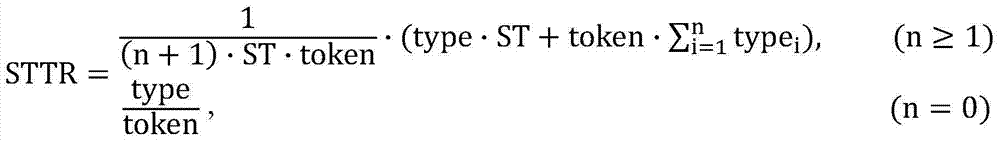

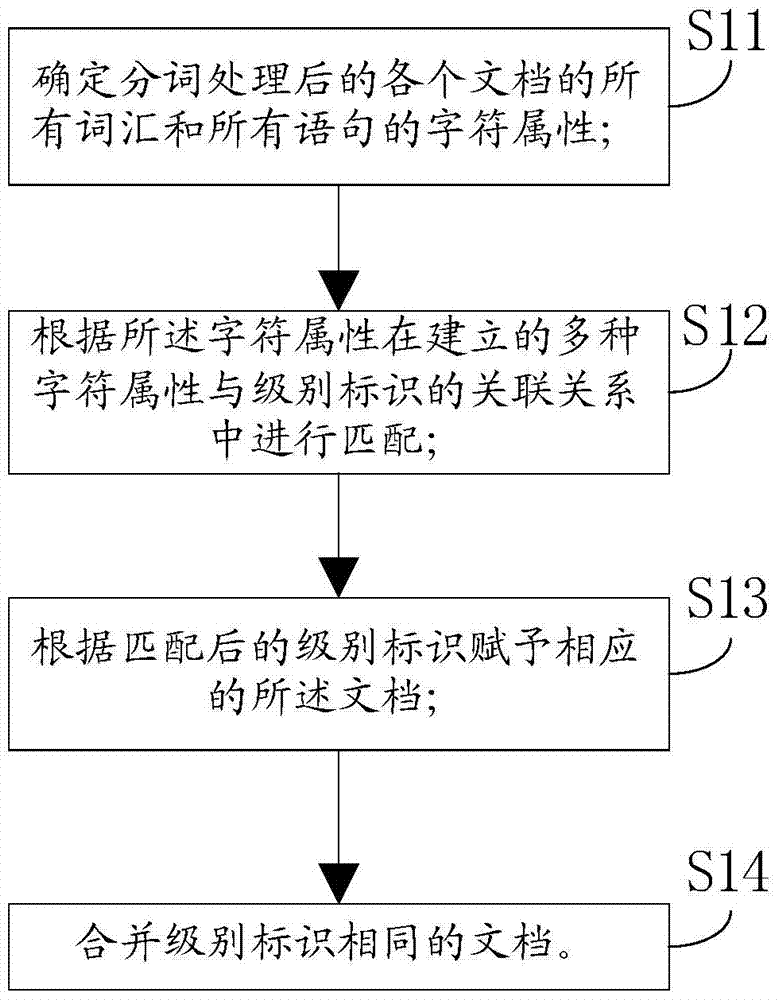

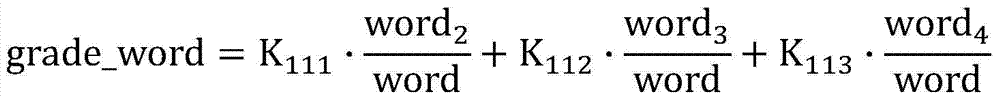

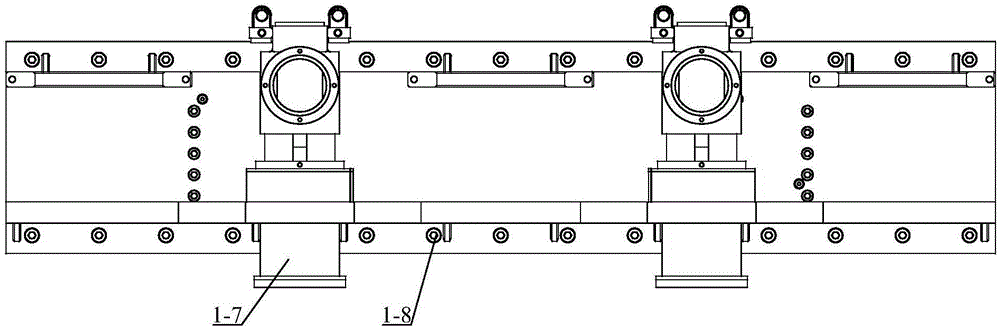

Method for fragmenting according to character attributes of documents

ActiveCN103761226AImprove accuracyImprove translation efficiencySpecial data processing applicationsNatural language processingArtificial intelligence

Owner:IOL WUHAN INFORMATION TECH CO LTD

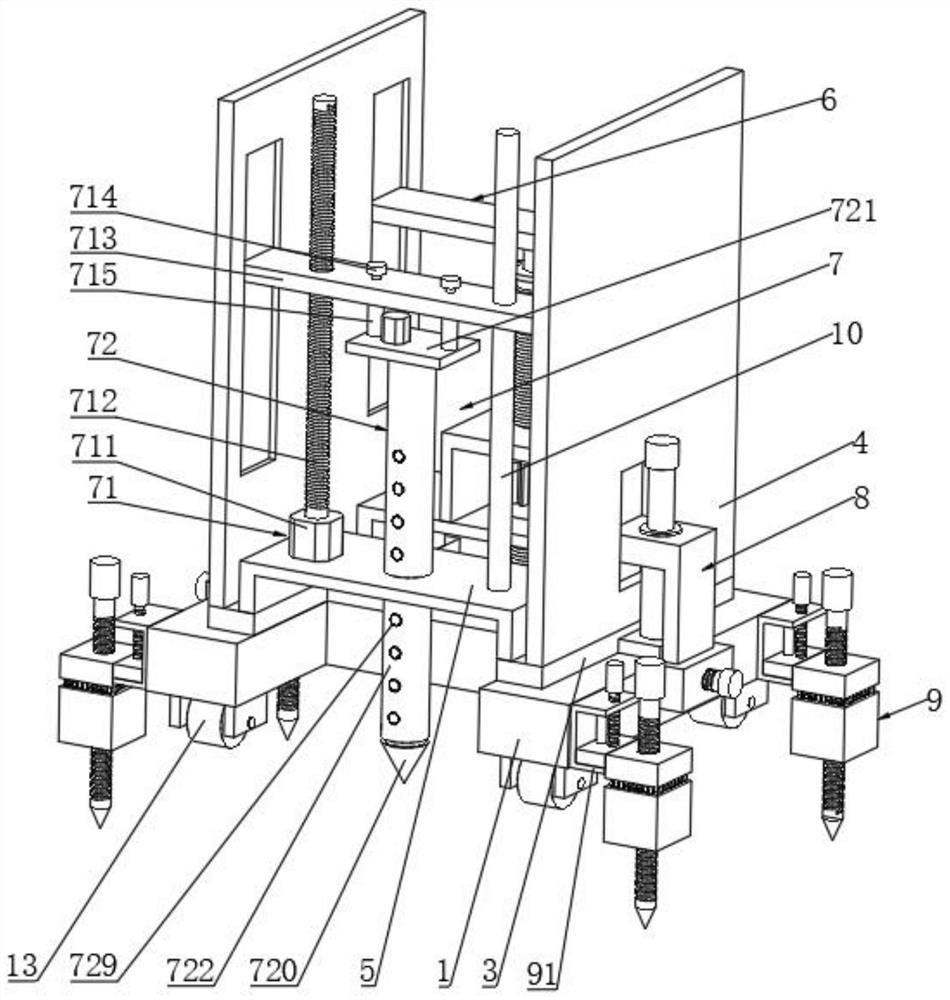

Geological mineral exploration device for layered storage of ore beds with different depths

The invention discloses a geological mineral exploration device for layered storage of ore beds with different depths, and relates to the technical field of mineral exploration devices. The device includes a base, the base is connected with a rotating shaft assembly, the side wall of the rotating shaft assembly is rotationally connected with a conversion plate, the two opposite sides of the conversion plate are both fixedly connected with supporting plates, two oppositely-arranged U-shaped frames are arranged between the two supporting plates, the U-shaped frames are fixedly connected with the conversion plate, one U-shaped frame is connected with a drilling assembly, and the other U-shaped frame is connected with a sampling assembly. The drilling assembly and the sampling assembly are oppositely arranged, the sampling assembly comprises a lifting mechanism and a sampling mechanism, the side walls, away from each other, of the two supporting plates are connected with locking assemblies, and the base is connected with a positioning assembly; therefore, transverse sampling can be carried out on different ore beds of an exploration hole, extracted samples can be independently stored, the sample extraction precision is effectively improved, meanwhile, repeated sampling of workers in different times and groups is avoided, waste of manpower resources is reduced, and the sampling efficiency is improved.

Owner:秦光平

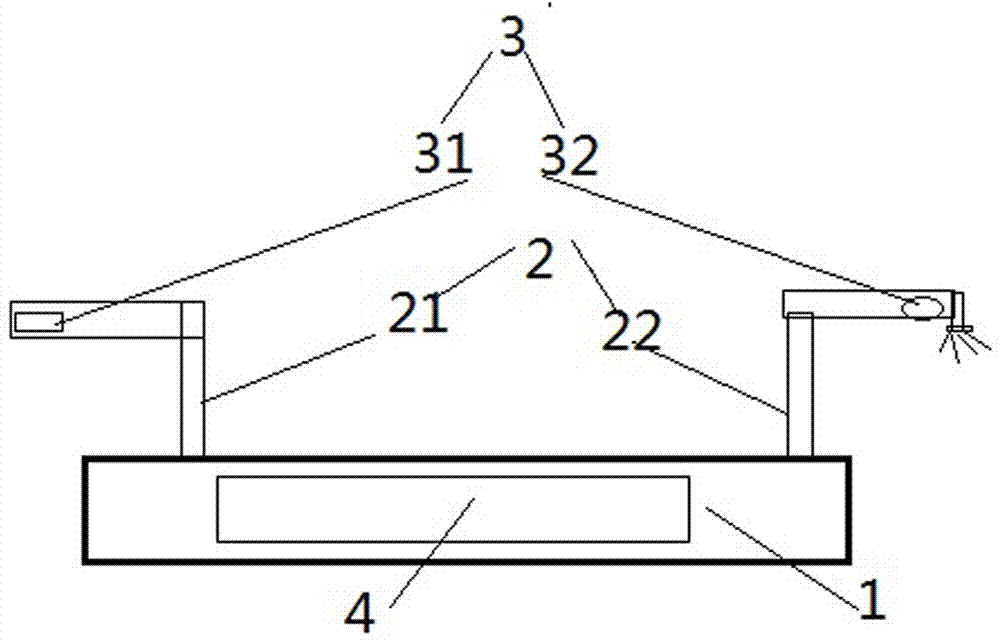

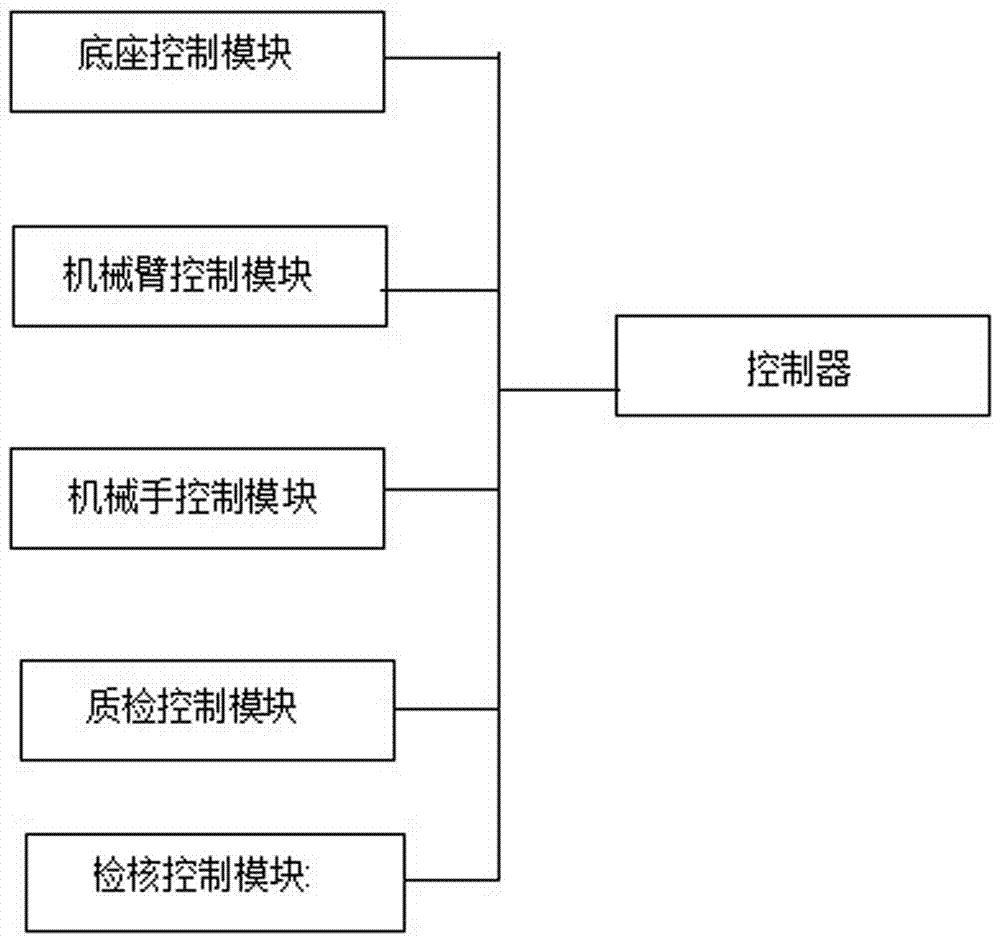

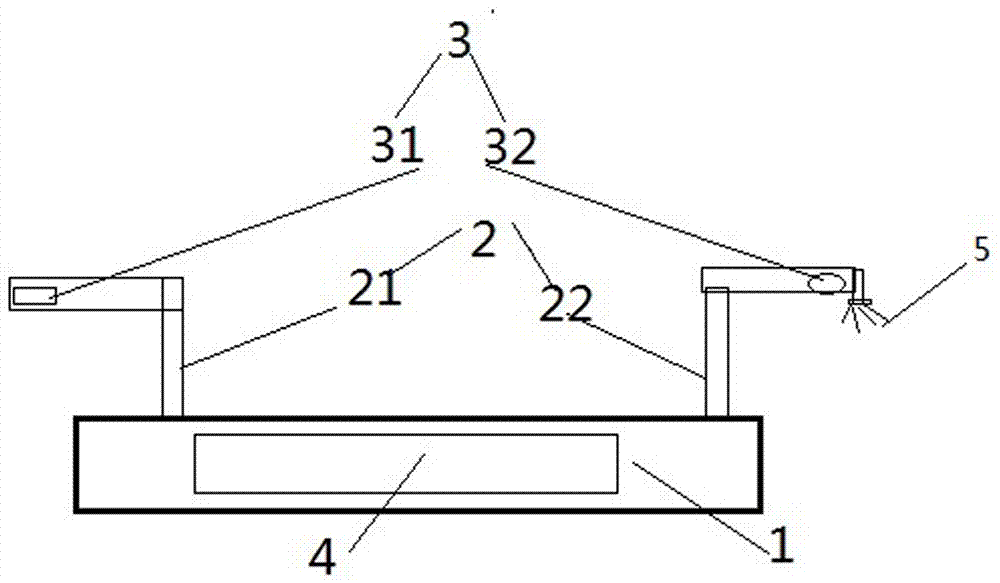

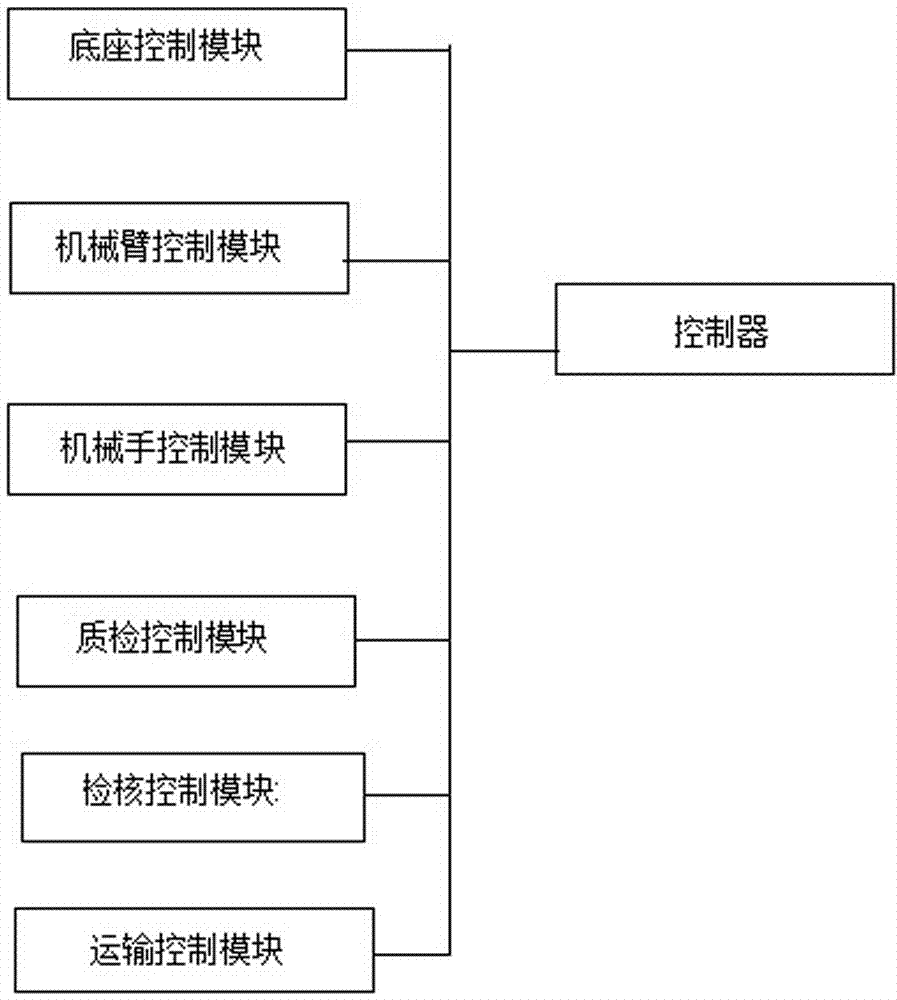

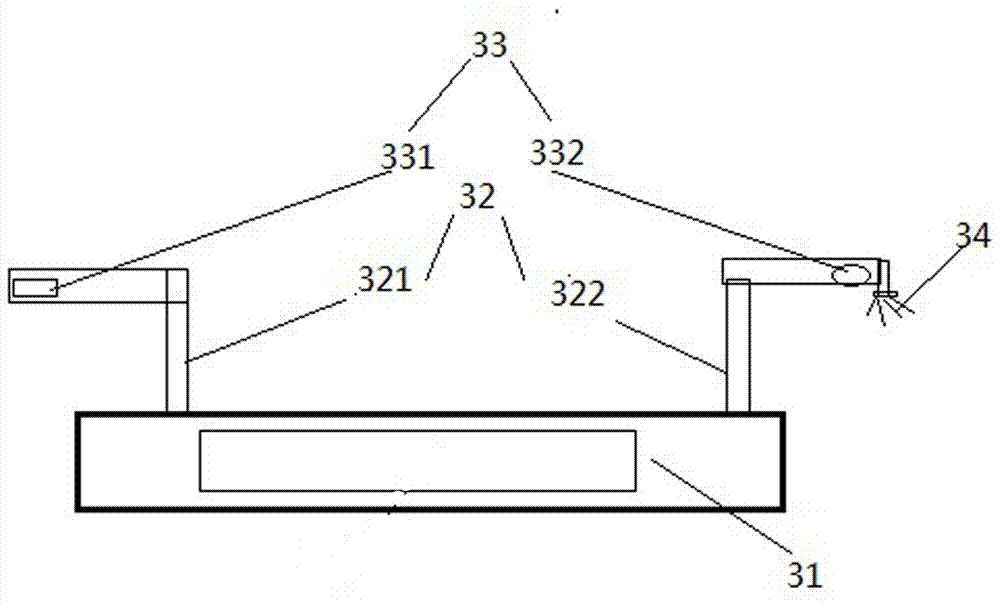

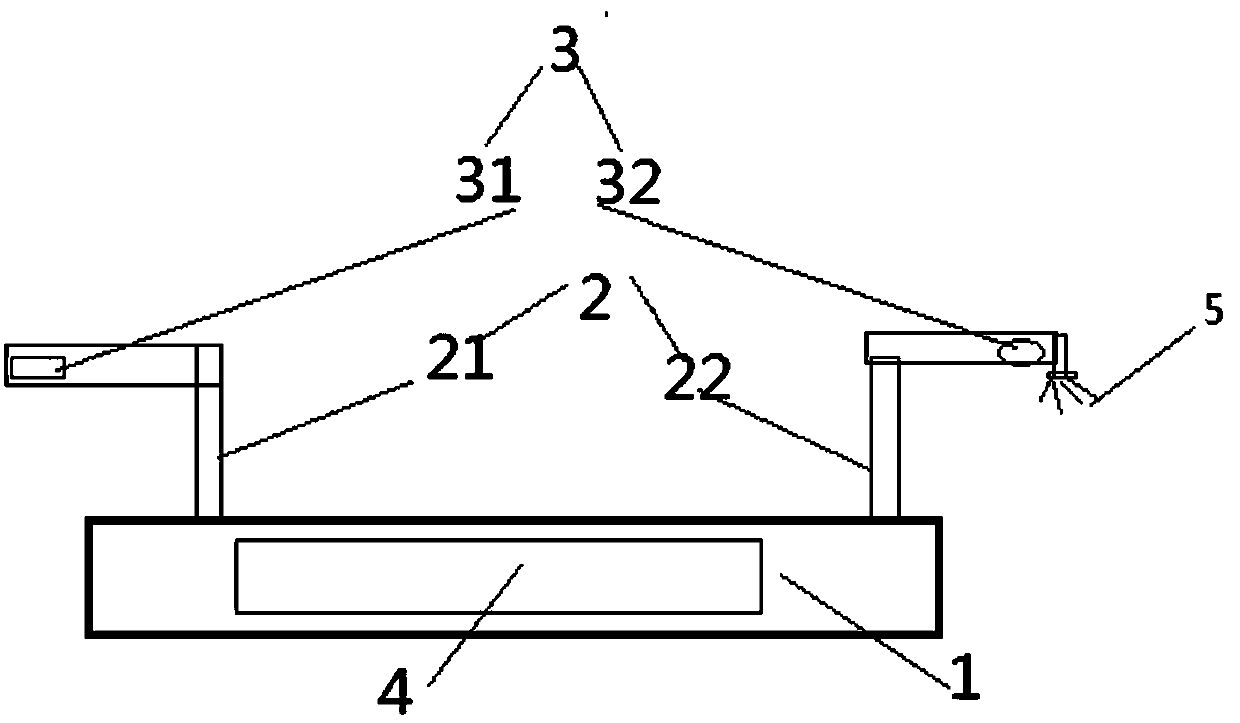

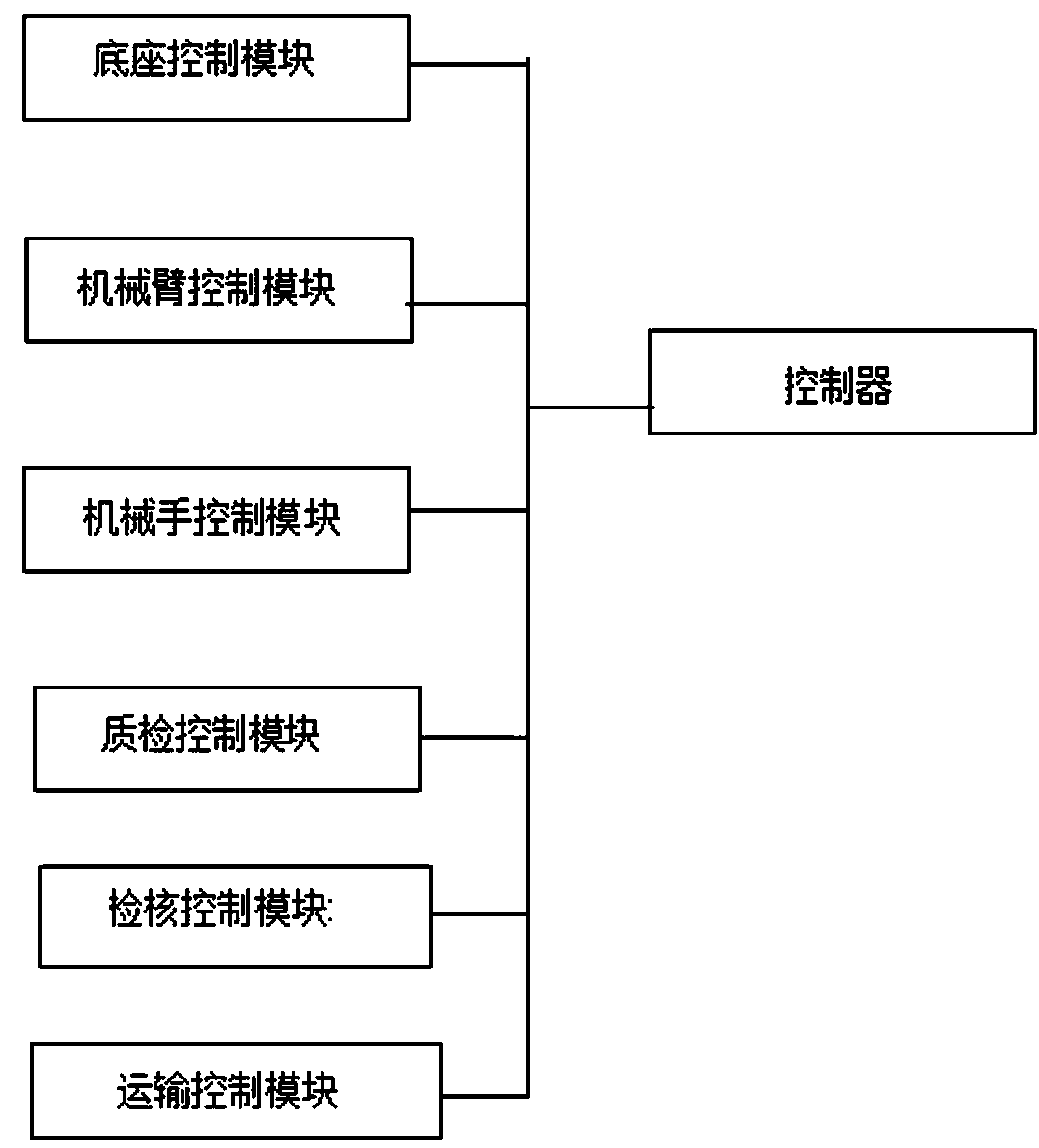

Discharging robot with quality detection function and working method thereof

InactiveCN107309180AReduce equipmentMeet production needsSortingManipulatorPerformance indexEngineering

The invention discloses a discharging robot with a quality detection function. The discharging robot with the quality detection function comprises a base, a mechanical arm, a quality detection mechanism and a control device, wherein the mechanical arm is arranged on the base, the quality detection mechanism is arranged at the end of the mechanical arm, a discharging manipulator is further arranged at the end of the mechanical arm, and the quality detection mechanism and the discharging manipulator are connected with the control device. According to the discharging robot with the quality detection function, in the operation process, products are detected by the quality detection mechanism, and the quality detection mechanism detects the appearances of the products at first and then detects the performance indexes of the products, so that the appearances and the performance of the products are both detected, and good products can be separated from poor products; intellectualization and automation are achieved, the workload is greatly reduced, personnel allocation is also reduced, and by replacing manpower with the robot, the detection accuracy of the robot is improved; and meanwhile all the produced products can be detected, and later product tracking is facilitated.

Owner:SUZHOU CHENGSHENG INFORMATION TECH

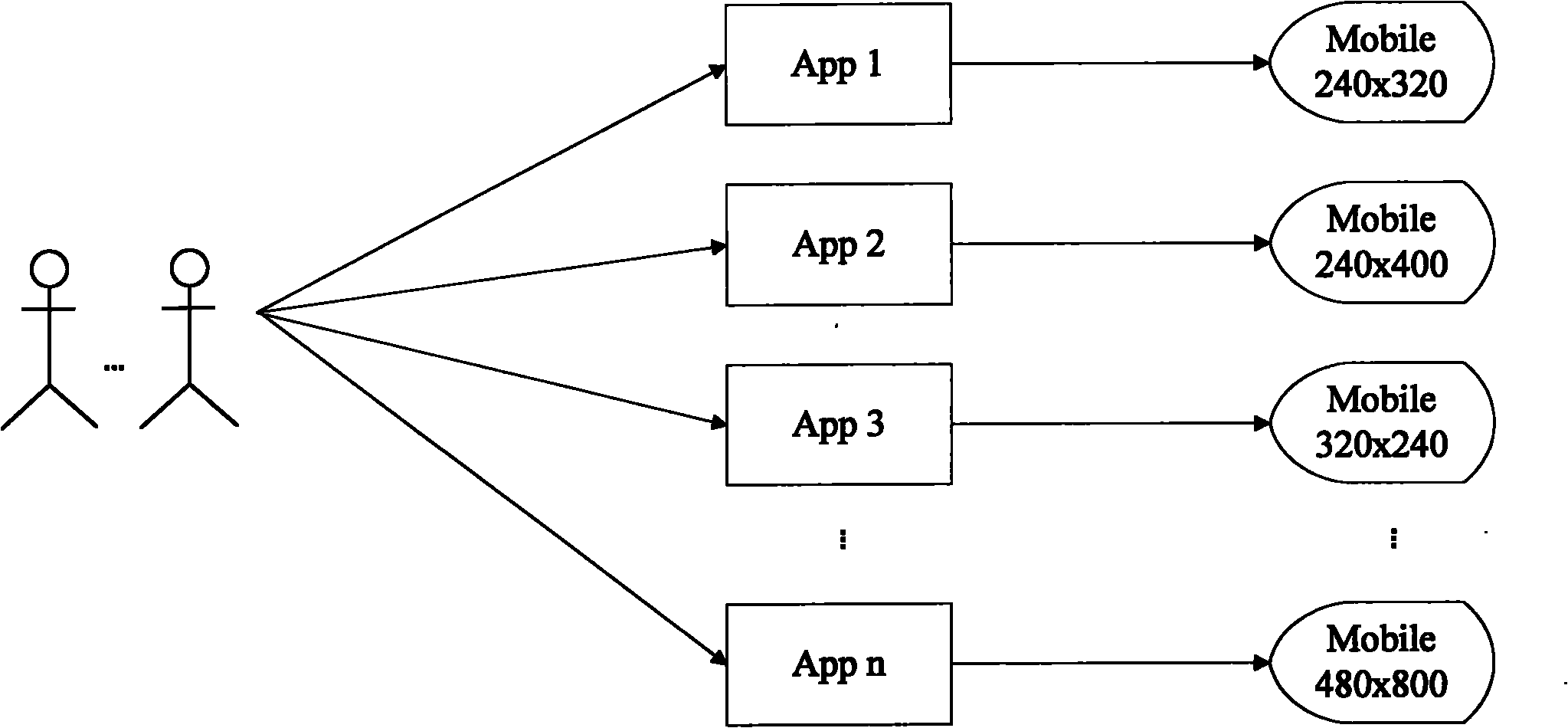

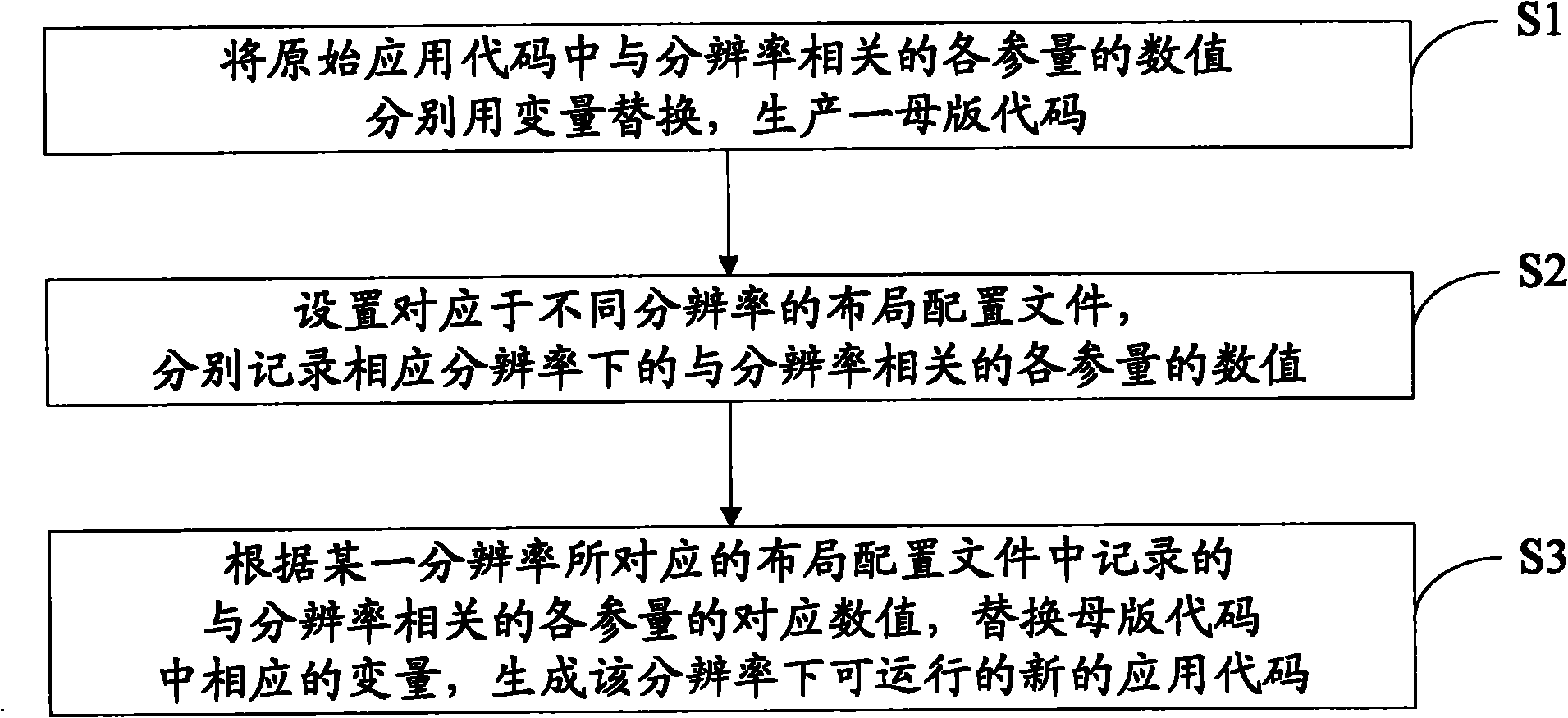

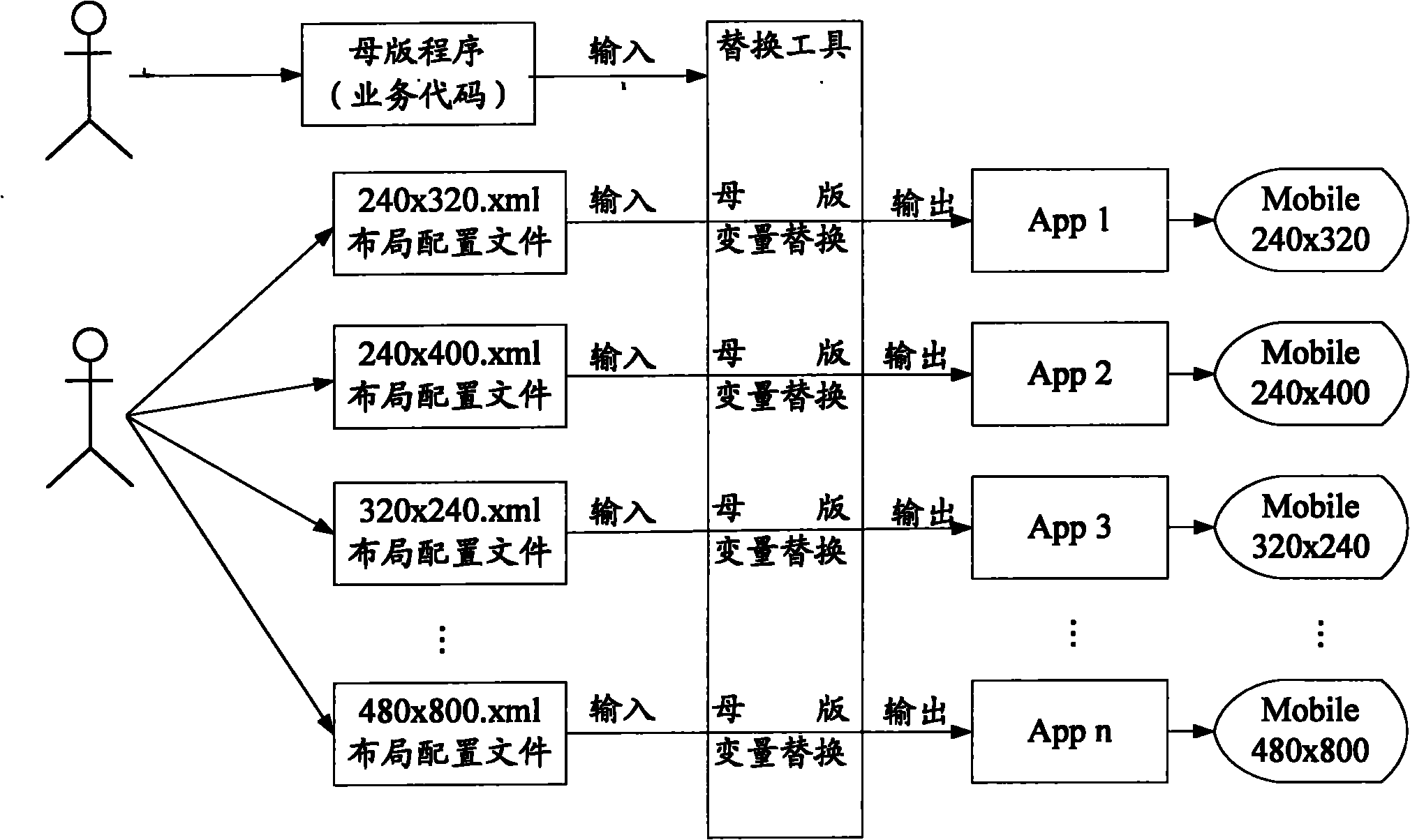

Method for building middleware multi-resolution version codes by configuration files

InactiveCN102033754APromote division of laborReduce riskSpecific program execution arrangementsImage resolutionMulti resolution

The invention discloses a method for building middleware multi-resolution version codes by configuration files, which comprises the steps of: replacing the values of all parameters related to resolutions in original application codes with variables to generate a master codes; setting layout configuration files corresponding to different resolutions, and respectively recording corresponding values of parameters related to a corresponding resolution under the resolution; and replacing corresponding variables in the master codes according to corresponding values of all parameters which are recorded in the layout configuration file corresponding to a certain resolution and related to the resolution, and generating a new application code which can run in the resolution. The method can reduce the amount of codes in development process and lower the adaptation working threshold, the division of labor can be more reasonable, the project is easy to maintain, and the labor cost can be saved at the same time.

Owner:上海网达软件股份有限公司

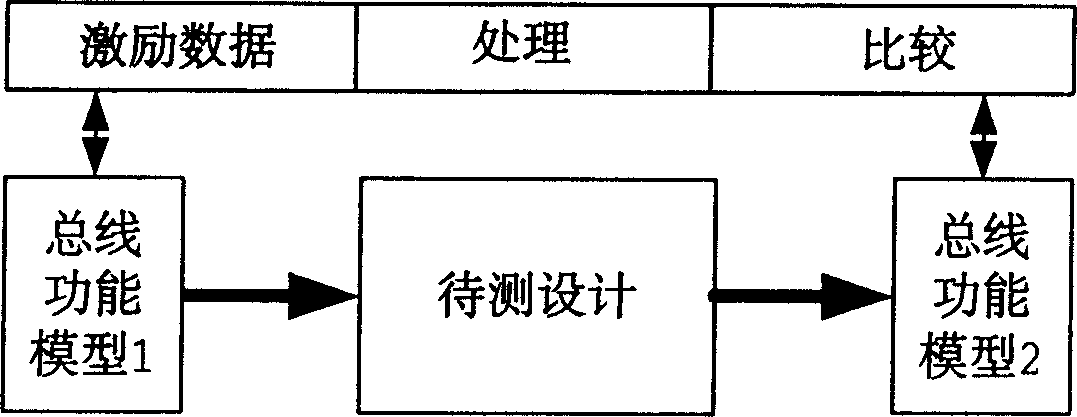

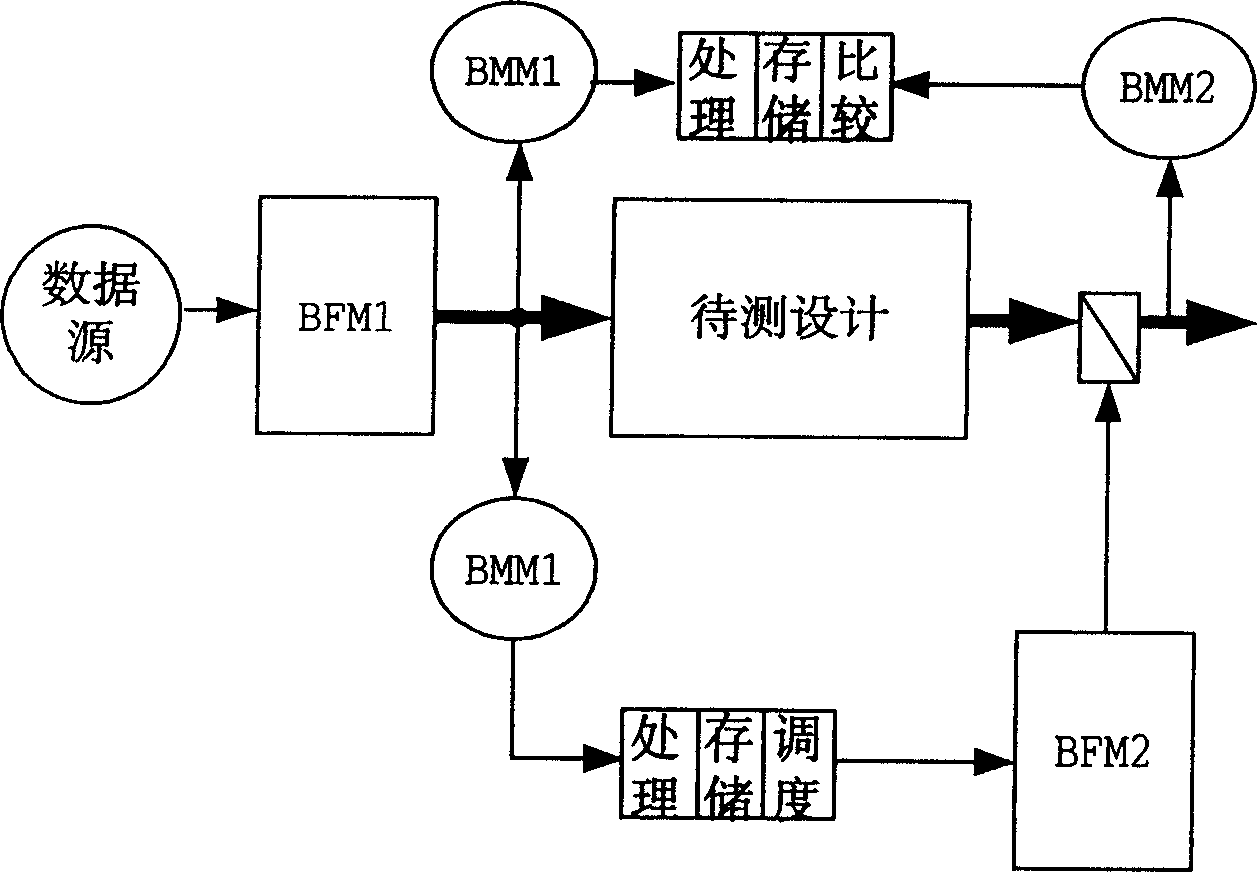

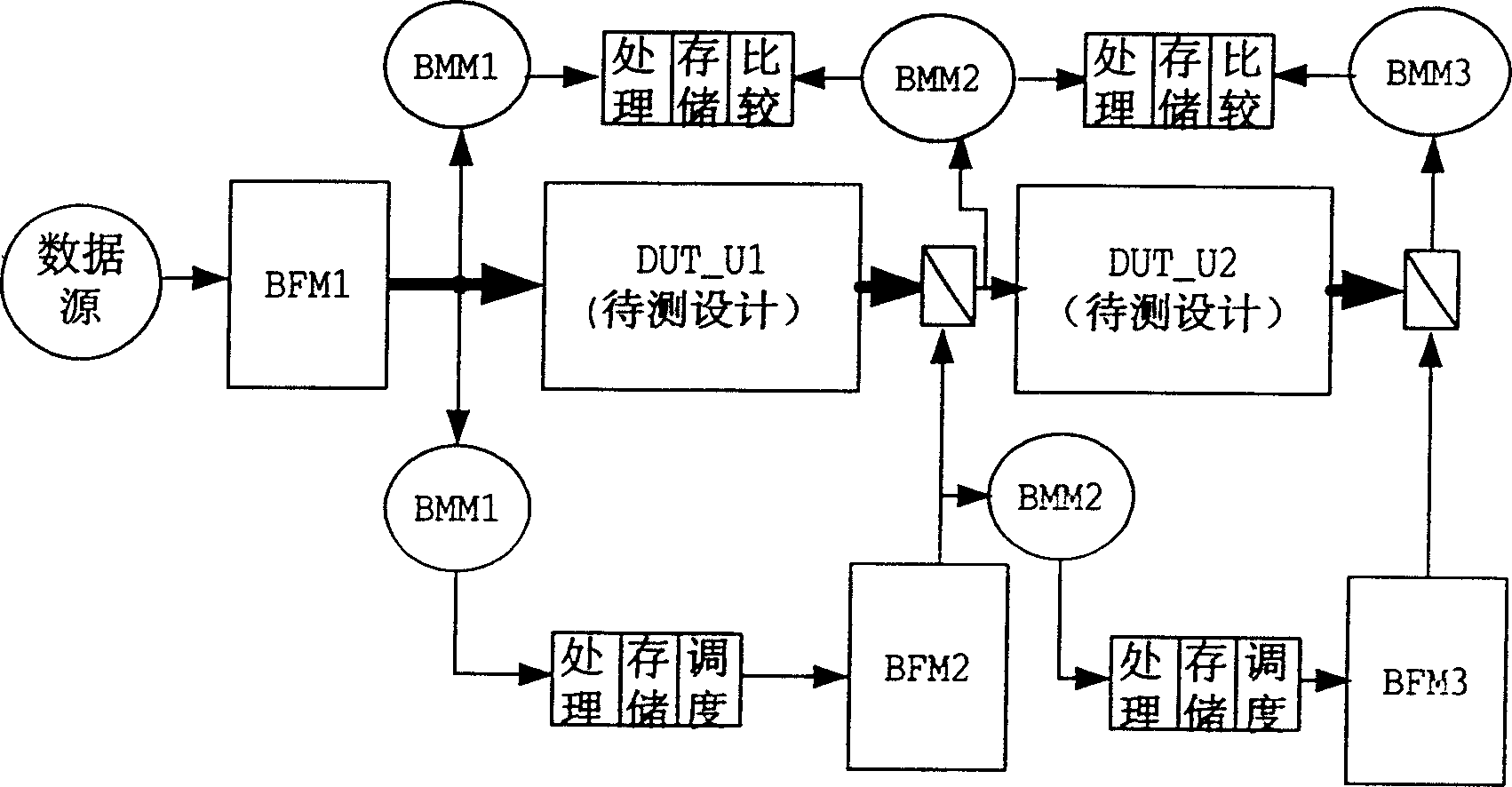

Emulate testing system and testing method for universal digital circuit

InactiveCN1235278CEasy to shareSpeed up testingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTest designGeneral purpose

The invention discloses a general purpose digital circuit simulated test system and test method thereof, wherein the system comprises a data source for generating test excitation data, a bus functional module BFM for mapping the excitation data into time sequence in accordance with the bus standard, and at least a two-way measurement unit, while the corresponding method comprises sending the time sequence of the excitation data to the test design, and performing two-way test in parallel, thus enhancing the versatility of the simulation test and improving the code multiplexing ratio and expandability.

Owner:HUAWEI TECH CO LTD

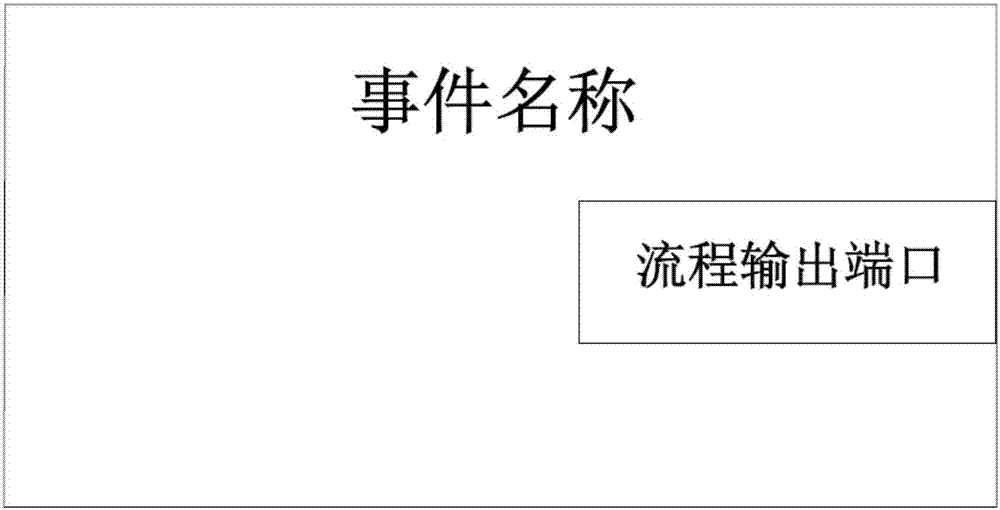

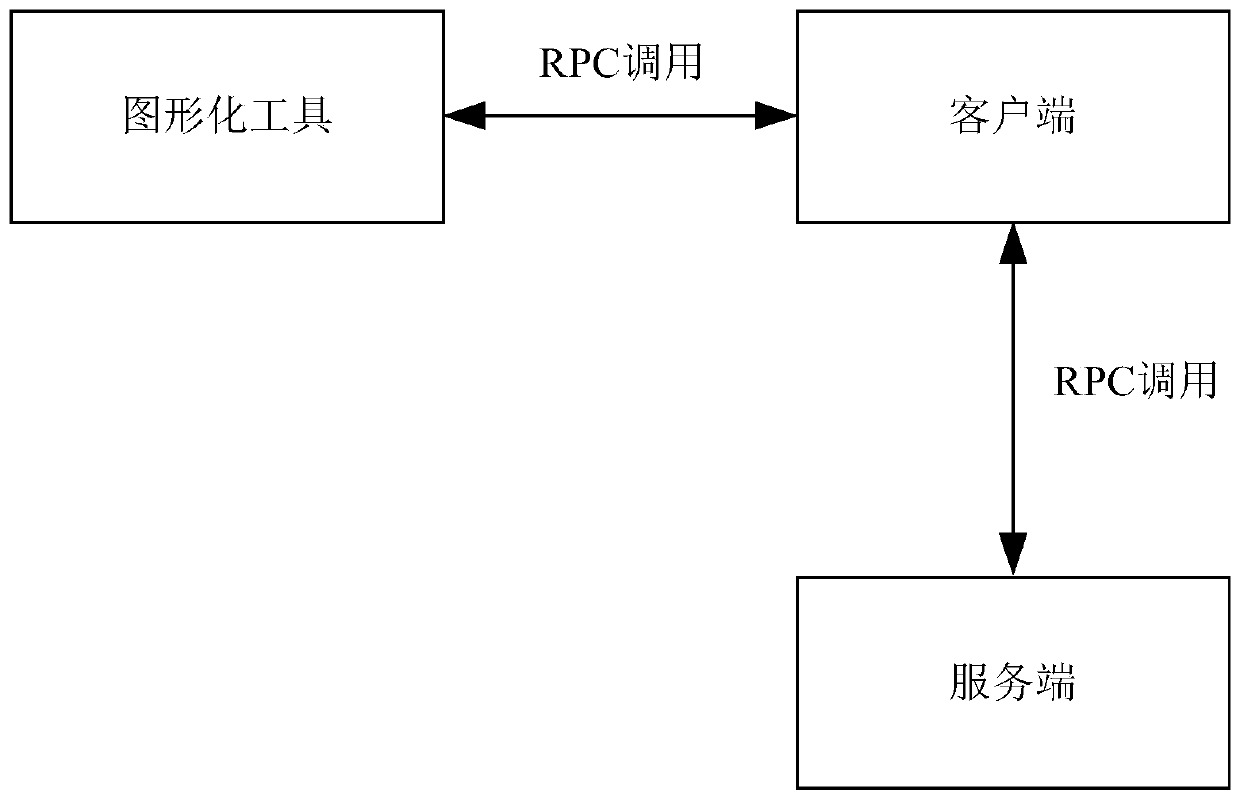

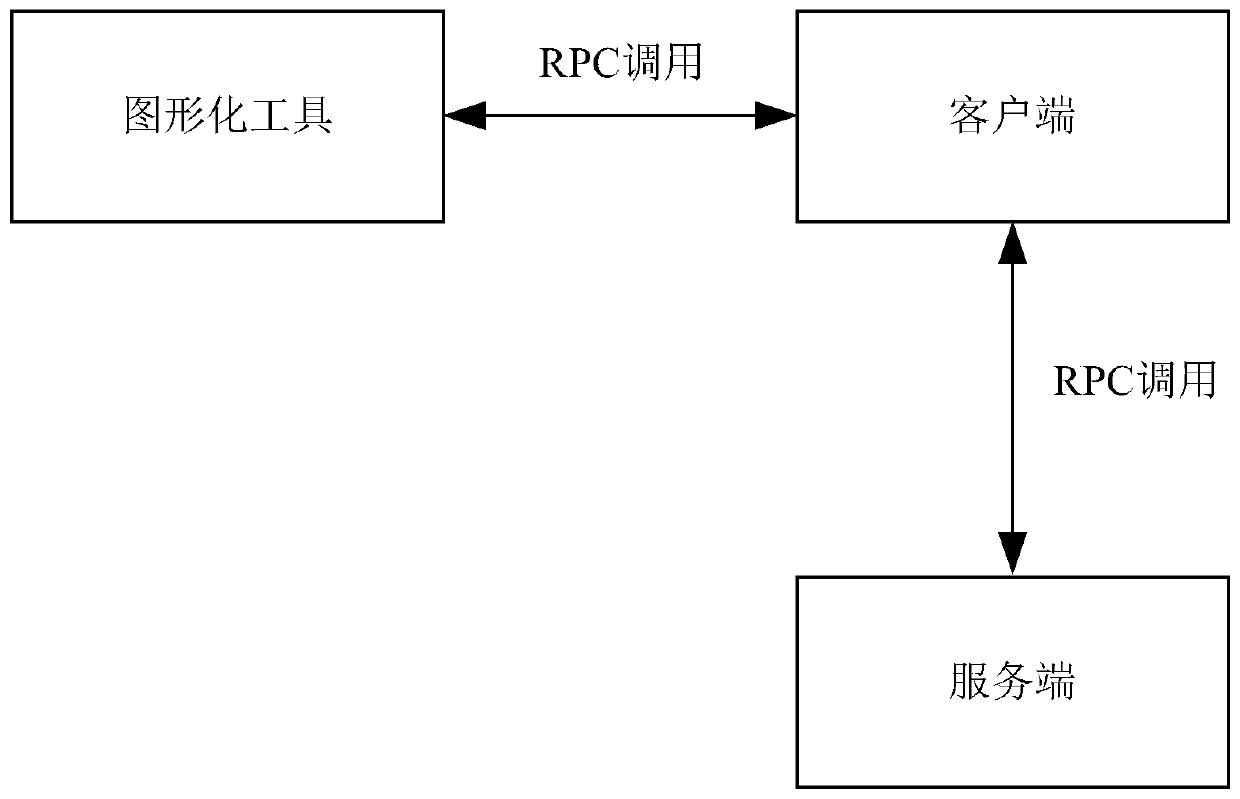

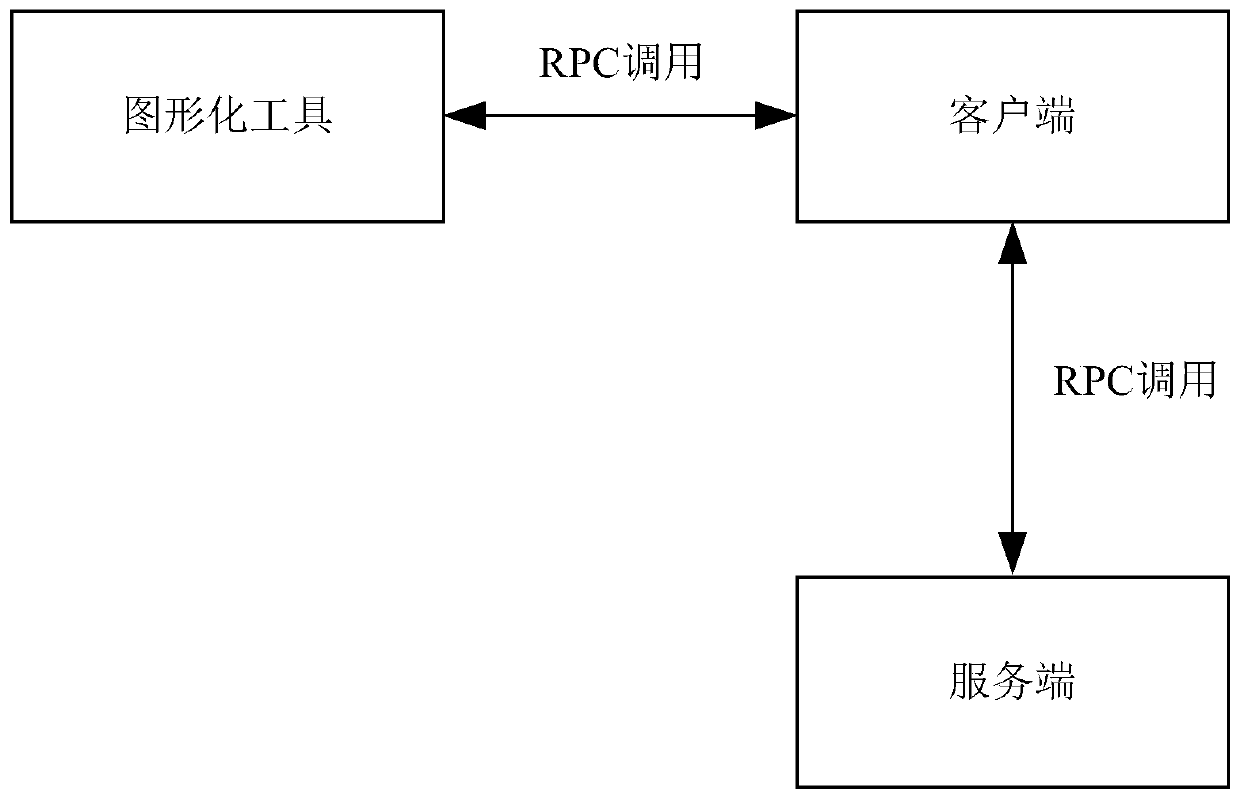

Event processing method and device, storage medium, processor and electronic device

PendingCN111581114APromote division of laborPromote collaborationSoftware engineeringInterprogram communicationSoftware engineeringSystem call

The invention discloses an event processing method and device, a storage medium, a processor and an electronic device. The method comprises the steps of acquiring a predefined event to be executed, wherein the predefined event is used for responding to external system calling and triggering a graphical tool process; initiating a graphical tool flow based on the predefined event, and executing logic corresponding to the predefined event; in the process of executing the logic corresponding to the predefined event, obtaining a first custom event to be sent, with the first custom event being usedfor communicating with at least one client; and sending the first custom event to the at least one client, so that the at least one client executes logic corresponding to the first custom event. The technical problem that logic process control cannot be performed on the client model and the server model through a visual graphical tool in related technologies is solved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

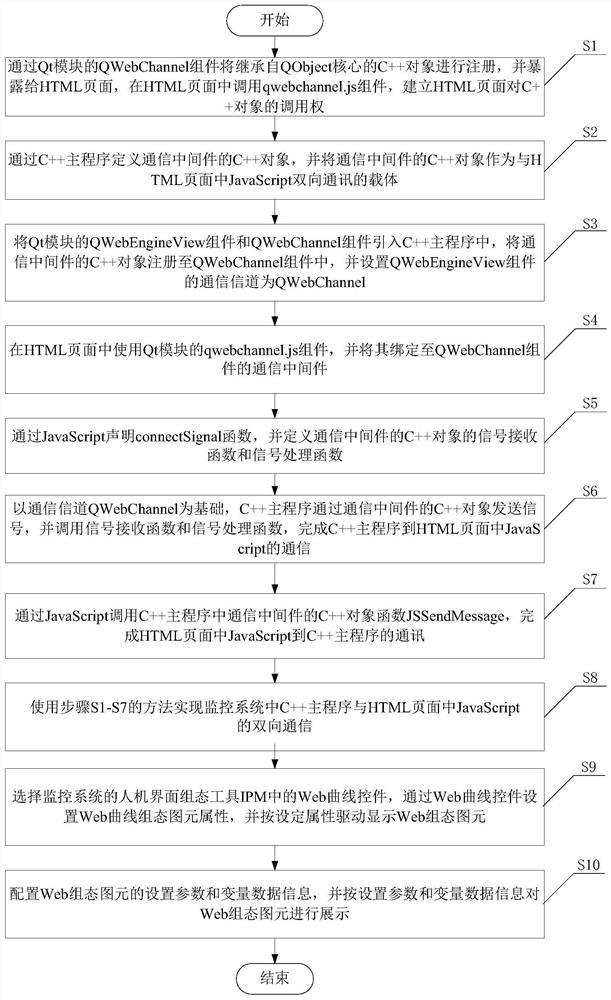

Implementation method of embedded Web configuration primitive

ActiveCN112231608AImprove experienceBeautiful interface interaction effectWebsite content managementSpecial data processing applicationsGraphicsThird party

The invention discloses an implementation method of an embedded Web configuration primitive, which achieves the establishment of the configuration primitive by establishing bidirectional communicationbetween a monitoring system C + + main program and a Javascript in an HTML (Hypertext Markup Language) page, and introduces primitive setting parameters and variable information in real time, so thatthe attribute of the primitive can be dynamically configured and analyzed, and can adapt to a production system in which front-end display information needs to be frequently updated; dynamic attribute variable data is flexible, any third-party data in a Json format is supported, and various graphic component libraries in Internet resources can be adopted. Moreover, the method is implemented basedon Javascript and HTML Canvas technologies, has an attractive interface interaction effect and powerful functions, and can construct a high-experience configuration interface.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

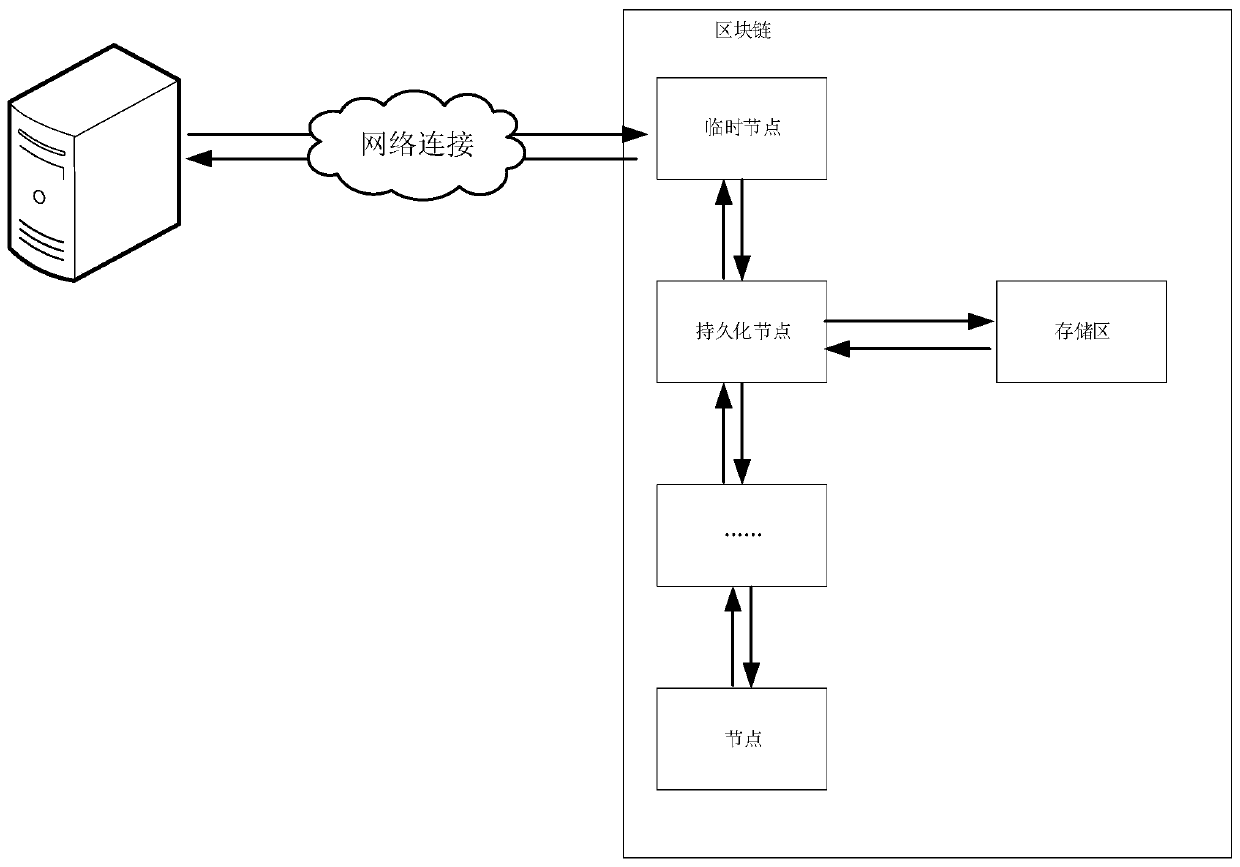

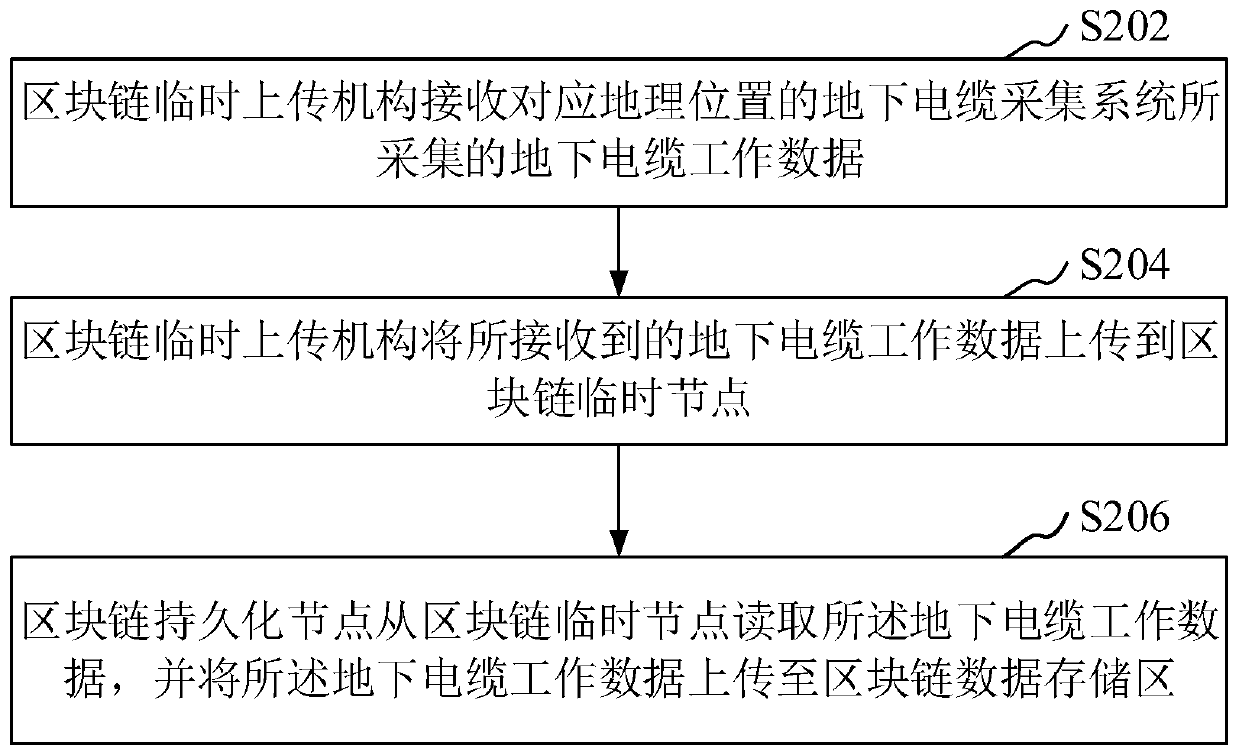

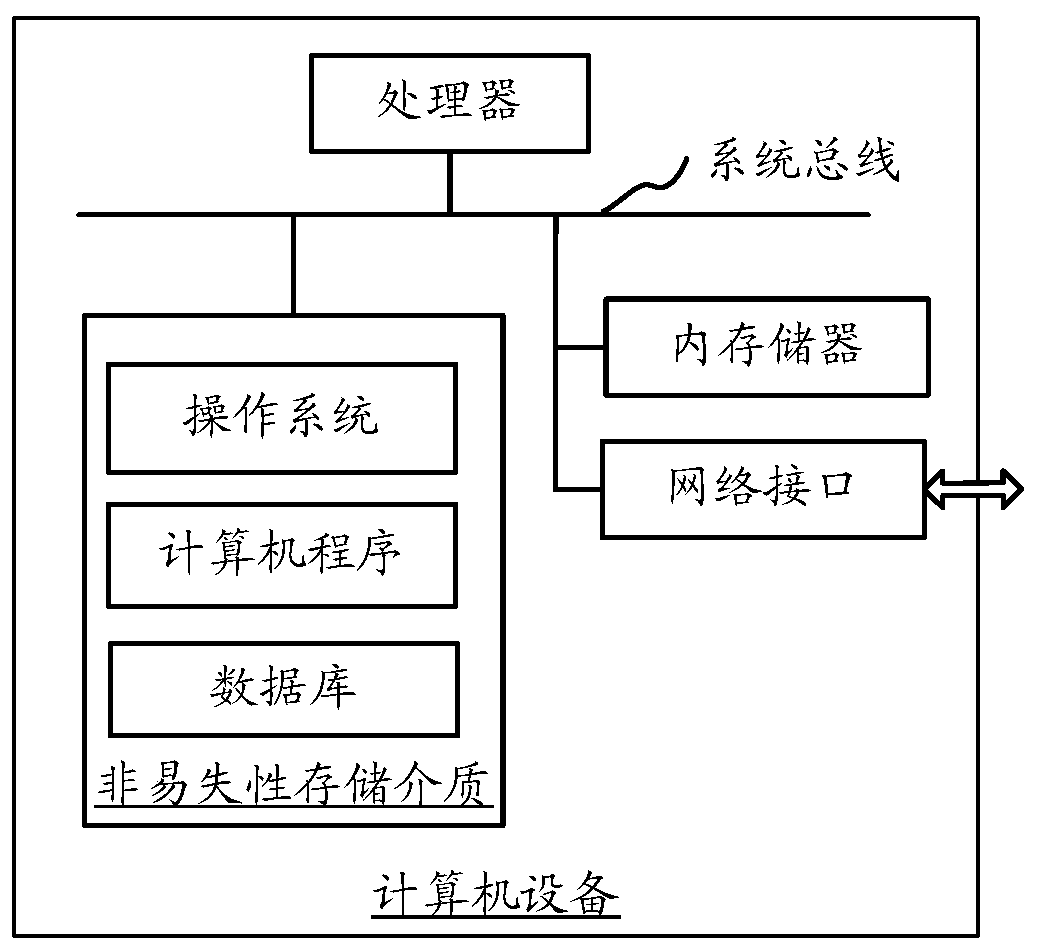

Underground cable collection data uploading method and system based on block chain

ActiveCN110995837AEnsure safetyImprove efficiencyDistributed architecture usageTransmissionCollection systemElectric cables

The invention relates to an underground cable collection data uploading method and system based on a block chain. The method comprises the following steps: a block chain temporary uploading mechanismreceives underground cable working data acquired by an underground cable collection system at a corresponding geographic position; the block chain temporary uploading mechanism uploads the received underground cable working data to a block chain temporary node; and the block chain persistence node reads the underground cable working data from the block chain temporary node and uploads the underground cable working data to a block chain data storage area. By adopting the method, the data safety can be ensured.

Owner:HUNAN GUOAO POWER EQUIP +1

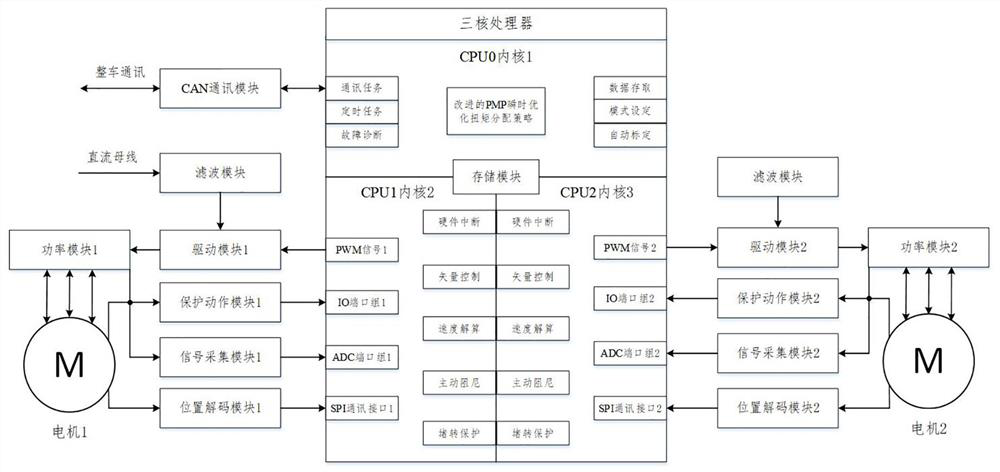

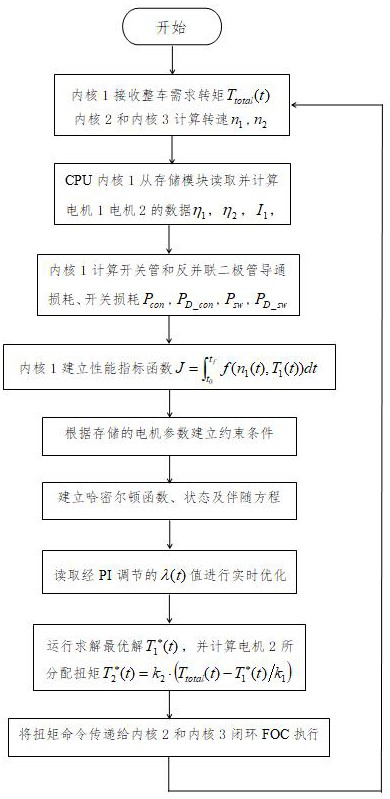

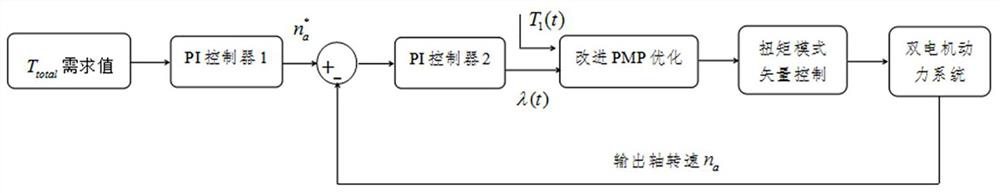

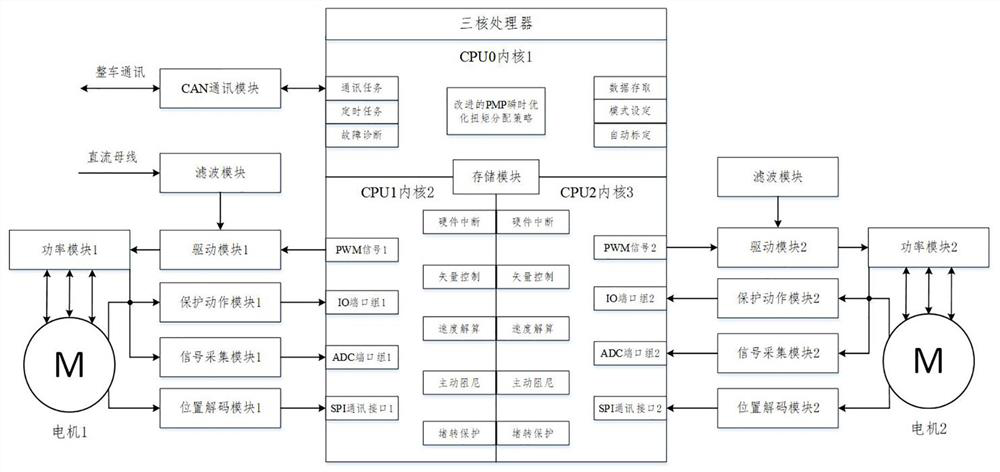

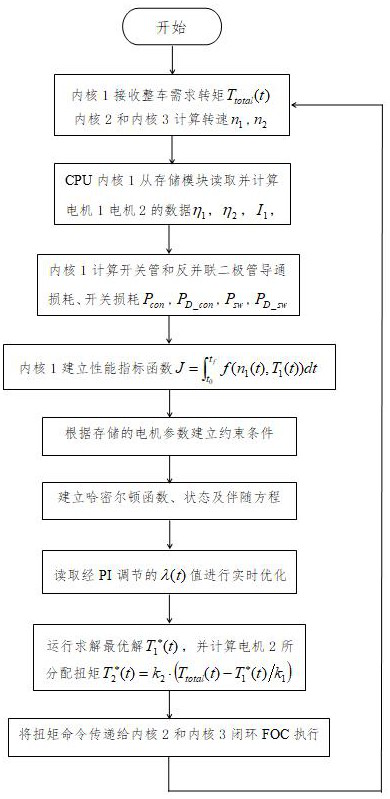

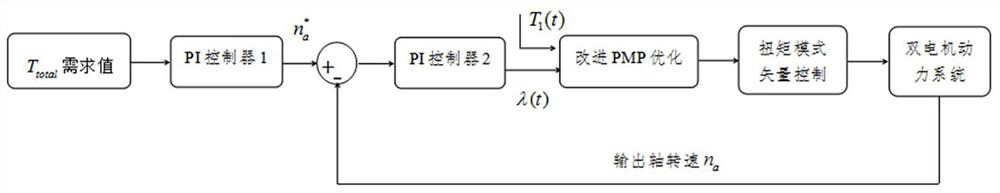

Dual-motor control system and control method of dual-motor combined driving system

ActiveCN113442737AReduced responsiveness variesSave resourcesAC motor controlVector control systemsControl systemControl engineering

The invention discloses a dual-motor control system and a control method of a dual-motor combined driving system, which adopt the dual-motor control system of a multi-core single processor to respectively control the operation of two motors with different characteristics, save resources such as communication, storage and peripheral circuits, and reduce the influences that motor response speeds are different and the effective cooperation is not realized caused by communication time difference. Meanwhile, light weight, low cost and high reliability are realized. The three cores execute different tasks according to task properties so as to optimize division of labor and improve the operation efficiency. The kernel 1 receives a whole vehicle demand torque command and optimizes torque distribution in real time according to different characteristics and data of the two motors, the kernel 2 and the kernel 3 carry out vector control on the two motors respectively to output corresponding torques, co-state variables are dynamically adjusted according to road conditions to be suitable for various road conditions, torque distribution is optimized in real time, and therefore, the loss of the controller and the dual-motor coupling driving system is minimized so as to achieve efficient operation.

Owner:SINO TRUK JINAN POWER

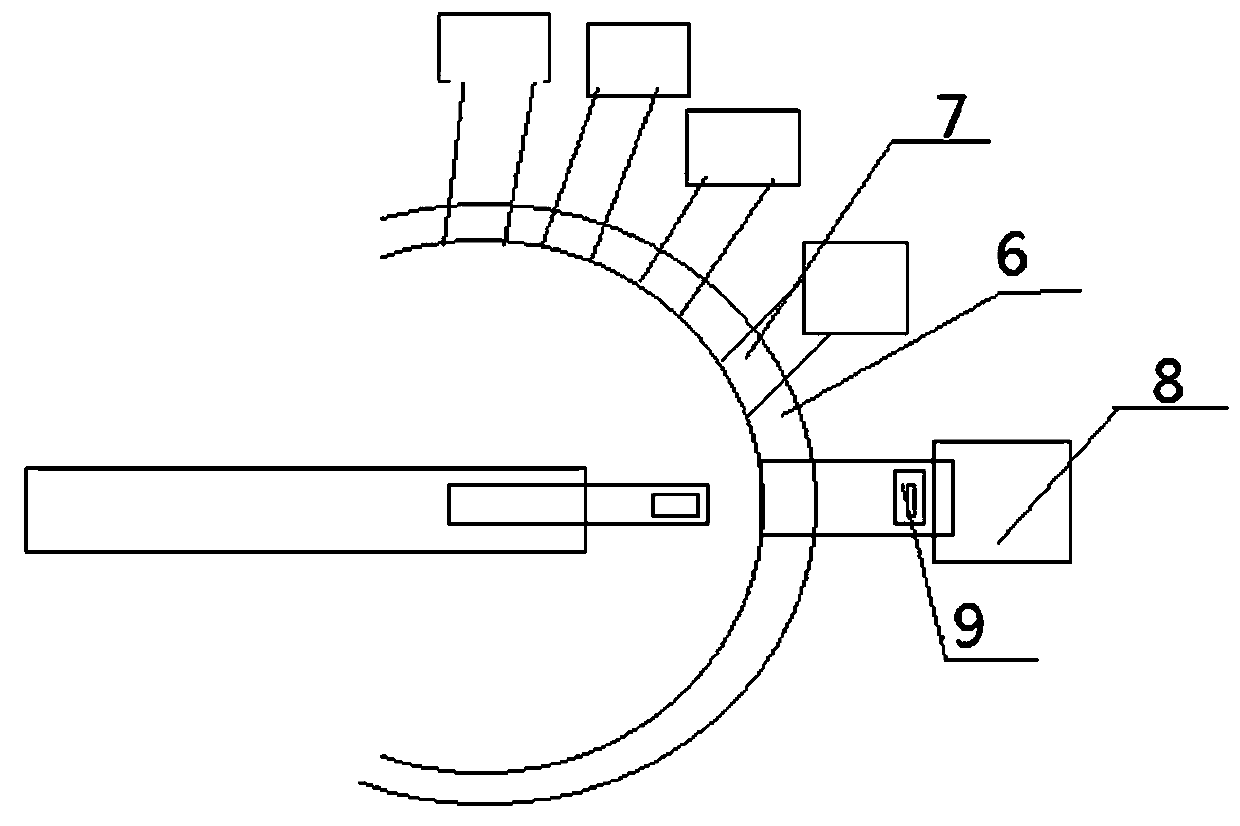

Intelligent robot with grading quality inspection function

InactiveCN107377402AFully automatedRealize intelligenceProgramme-controlled manipulatorSortingPerformance indexEngineering

The invention discloses an intelligent robot with a grading quality inspection function. The intelligent robot comprises a base, a mechanical arm, a quality detecting mechanism and a control device, wherein the mechanical arm is arranged on the base, the quality detecting mechanism is arranged at the end of the mechanical arm, the end of the mechanical arm is provided with a discharging manipulator, a product grade database is arranged in the quality detecting mechanism, and the quality detecting mechanism and the discharging manipulator are both connected with the control device. According to the intelligent robot with the grading quality inspection function, during working, the quality detecting mechanism detects products, the appearances of the products are detected firstly, then performance indexes of the products are detected, the control device classifies the products according to detecting results of the quality detecting mechanism, then the products of different grades are grabbed to designated positions through the discharging manipulator, the whole discharging process is automatic and intelligent, the subsequent quality inspection work is omitted at the same time, and the production efficiency of the intelligent robot is greatly improved.

Owner:TAICANG HONGSHAN ENVIRONMENTAL PROTECTION TECH CO LTD

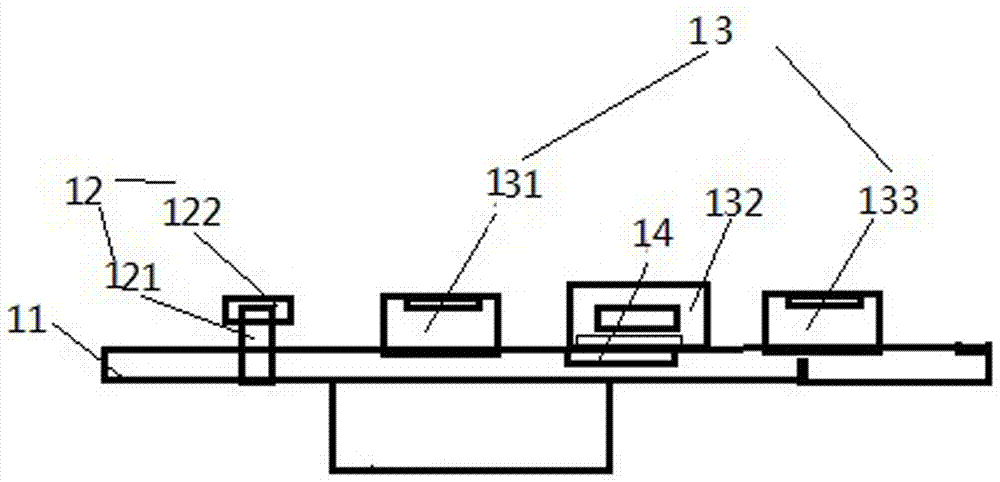

Intelligentized machining system

ActiveCN107096727AAvoid misalignmentEliminate manual quality inspectionSortingEngineeringMachining system

The invention discloses an intelligentized machining system. The intelligentized machining system comprises an automatic feeding mechanism, a production line and an automatic discharging mechanism. The automatic feeding mechanism and the automatic discharging mechanism are arranged at the two ends of the production line and are both connected with a control device of the production line. In the intelligentized machining system, the automatic feeding mechanism and the automatic discharging mechanism are arranged at the front end and the rear end of the production line, a position adjusting mechanism is arranged in the automatic feeding mechanism to monitor and adjust the positions of products on a conveying line, and the dislocation problem is avoided; and meanwhile, a quality testing mechanism is arranged in the automatic discharging mechanism to test the production quality of the products and distinguish the products, manual quality testing is omitted, and the production efficiency of the intelligentized machining system is greatly improved.

Owner:苏州圣典企业管理咨询有限公司 +1

Example creation method and device, storage medium, processor and electronic device

PendingCN111581111AReduce work stressEfficient developmentSoftware engineeringInterprogram communicationProgramming languageSoftware engineering

The invention discloses an instance creation method and device, a storage medium, a processor and an electronic device. The method comprises the steps of obtaining a file identifier of a to-be-operated graphical tool file; determining a logic object and a data object corresponding to the to-be-operated graphical tool file based on the file identifier, with the logic object being used for controlling execution logic of the graphical tool, and the data object being used for providing required data for the execution logic; and creating a graphical tool instance by adopting the logic object and the data object. The technical problem that logic process control cannot be performed on the client model and the server model through a visual graphical tool in related technologies is solved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Methods for Fragmentation by Character Attributes of Documents

ActiveCN103761226BImprove accuracyImprove translation efficiencySpecial data processing applicationsAlgorithmDocument Identifier

Owner:IOL WUHAN INFORMATION TECH CO LTD

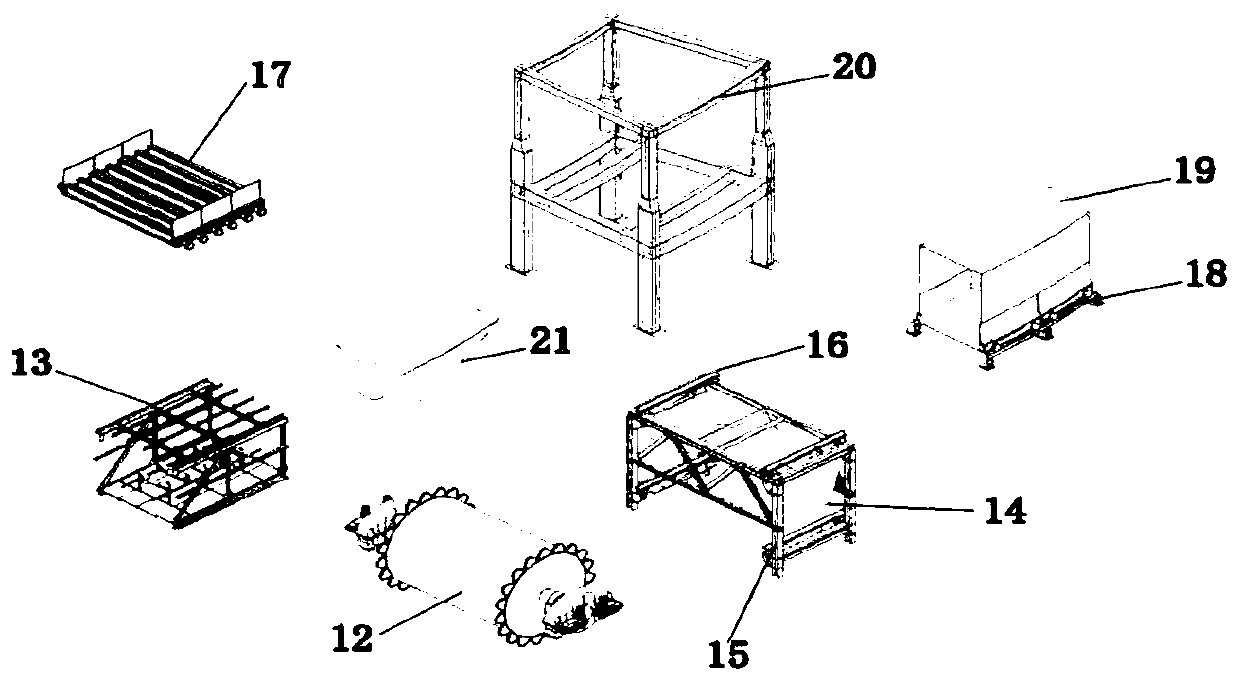

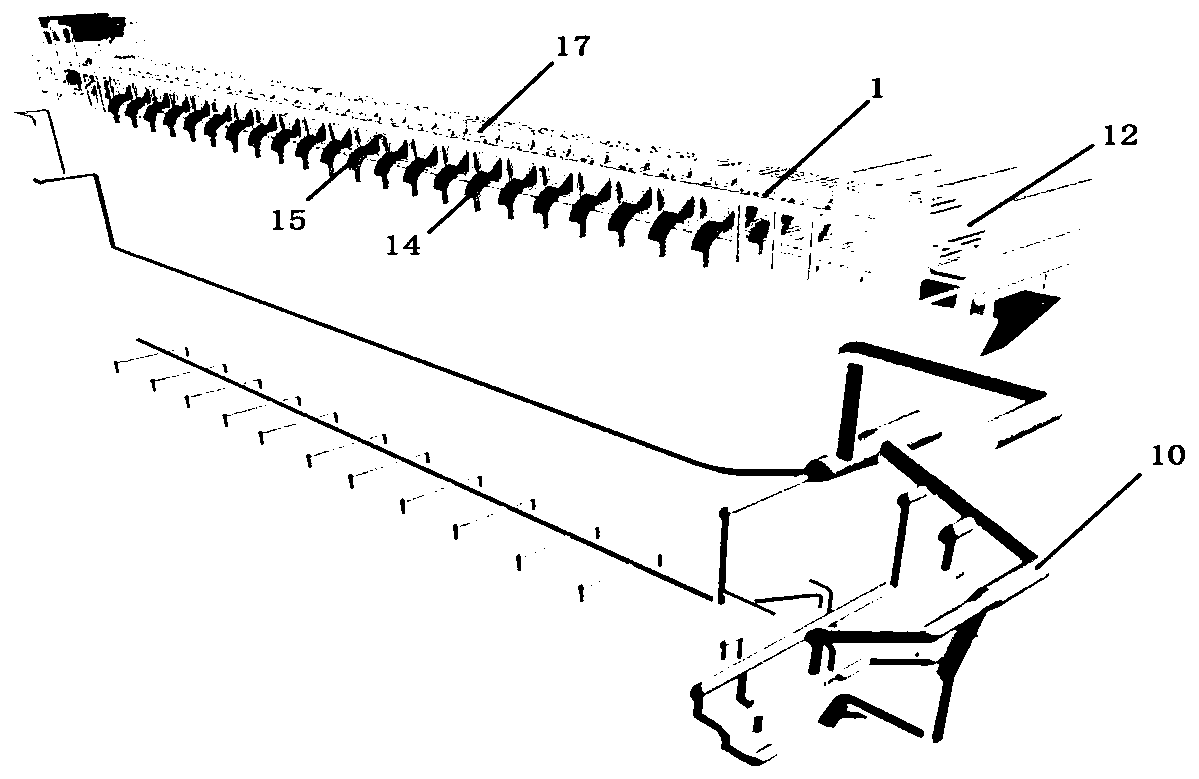

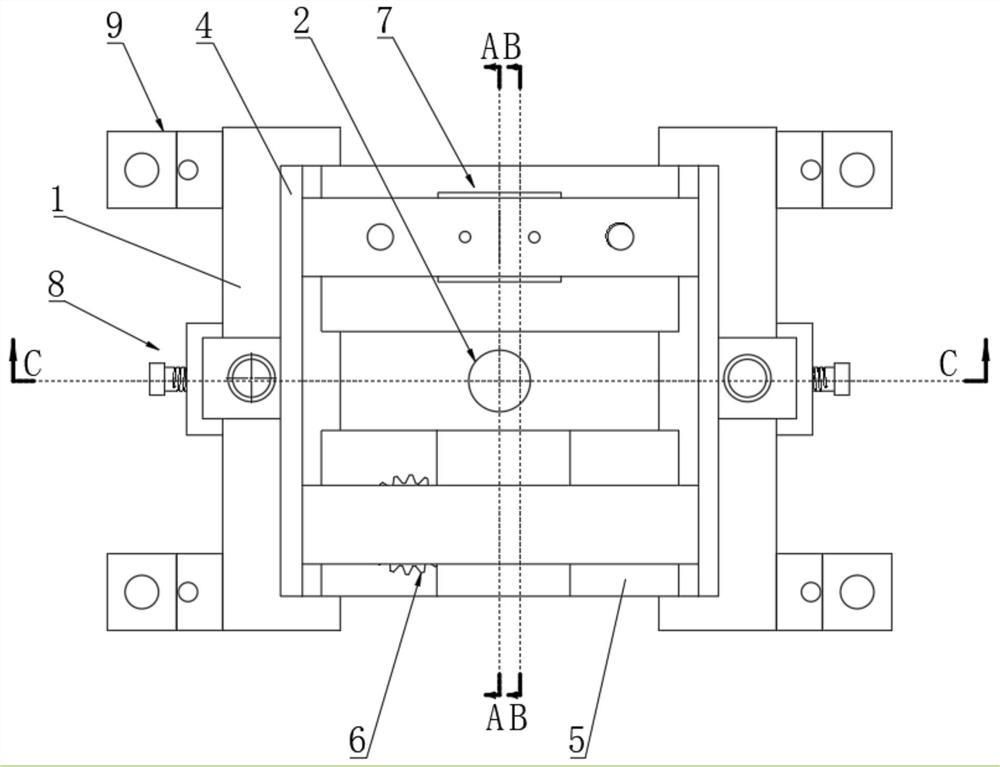

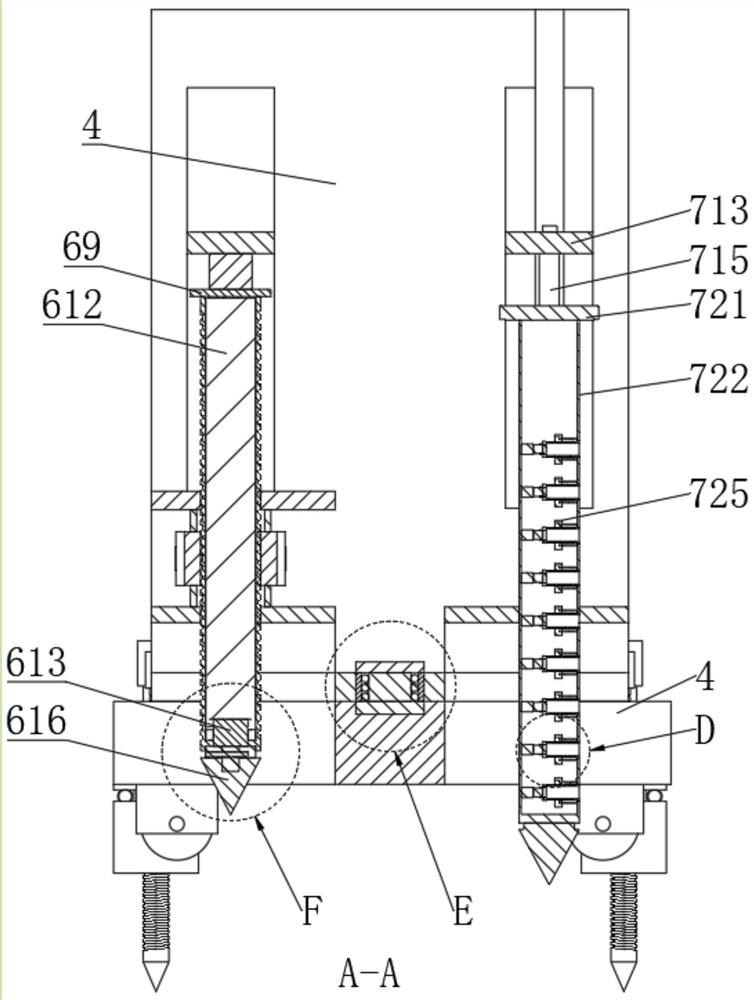

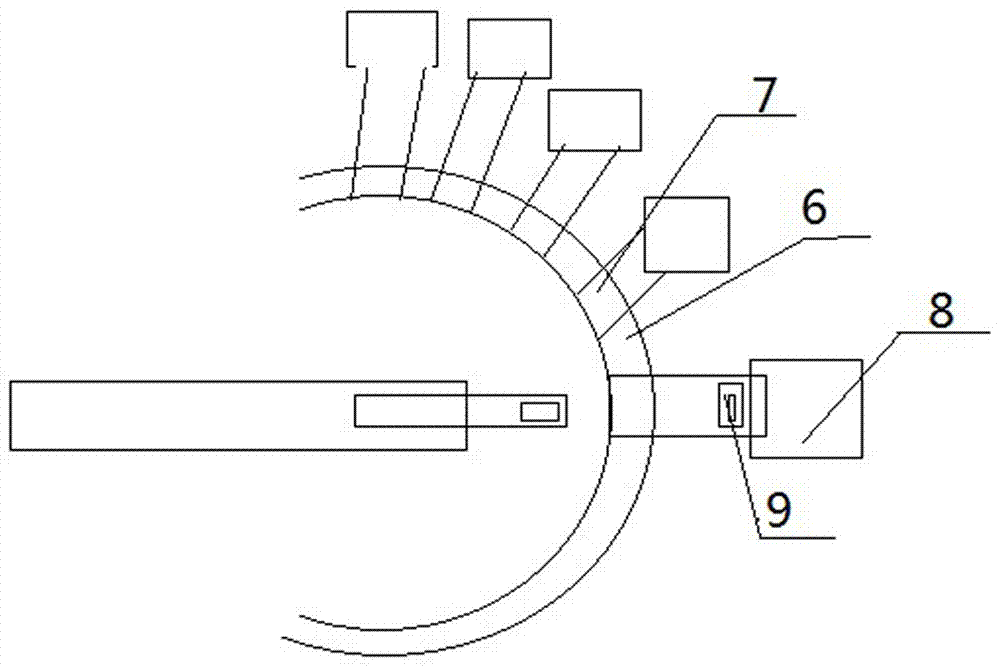

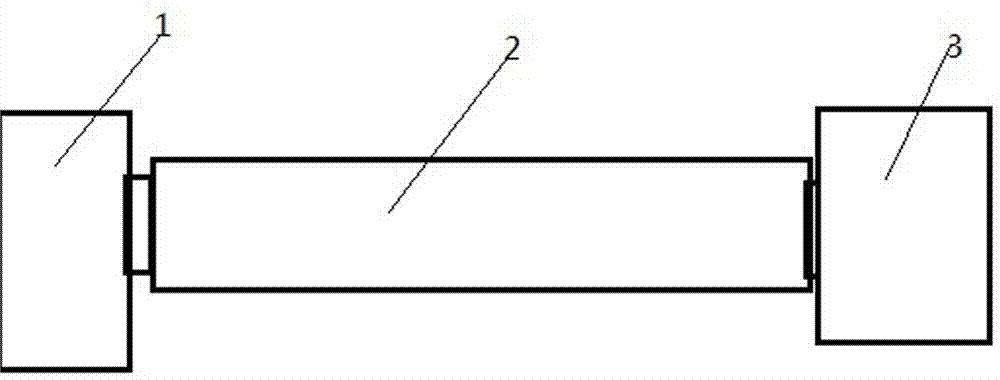

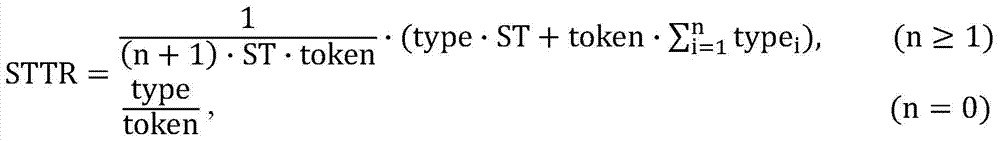

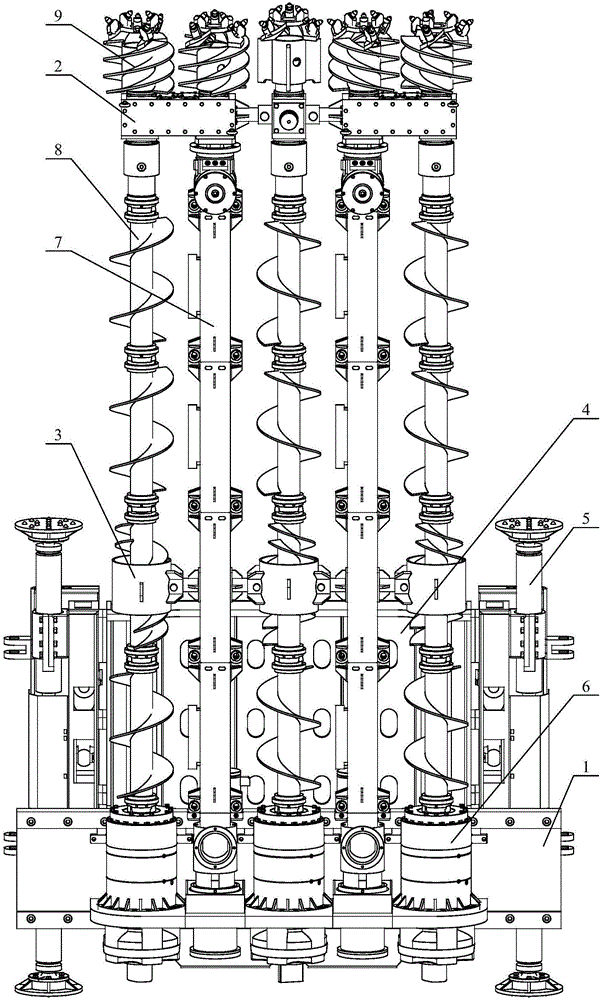

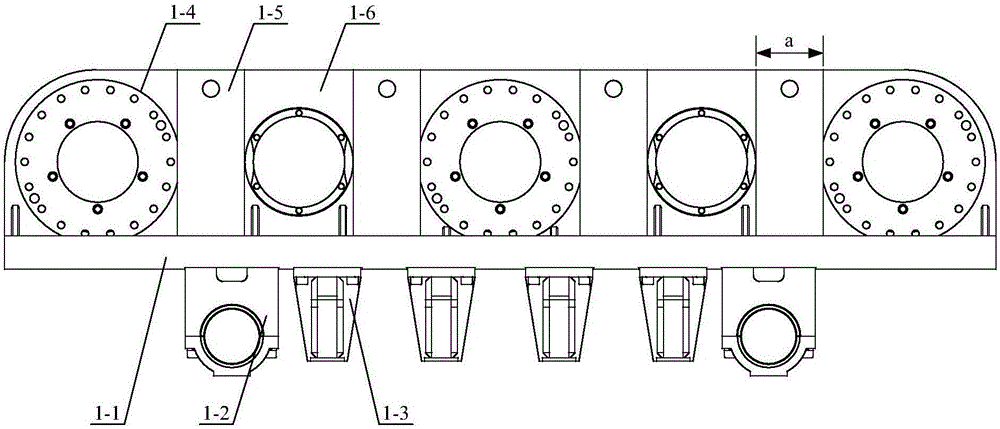

A multi-drill bit exchange device and method on a drilling shearer

InactiveCN104747070BImprove mining efficiencyPromote division of laborDrilling rodsConstructionsHydraulic motorEngineering

The invention disclose multi-drill-bit interchangeable equipment and a method for an auger-type coal cutter. The equipment is mainly composed of a drive frame, interchangeable insertion blocks, interchangeable transmission cases and interchangeable stabilizers. On a same main machine of an auger-type coal cutter, according to mining working conditions of a drilling and mining working surface and the requirement of the needed drill bit number, a three-drill-bit auger-type coal cutter can be changed to be a four-drill-bit or five-drill-bit coal cutter by changing positions and the numbers of hydraulic motor supports, air duct supports and the interchangeable insertion blocks on the drive frame and choosing types of the interchangeable transmission cases and the interchangeable stabilizers in a matched mode. By means of the multi-drill-bit interchangeable equipment and method for the auger-type coal cutter, interchanging of three drill bits, four drill bits and five drill bits can be achieved on a machine body of the same auger-type coal cutter according to actual working conditions under a thin seam coal mine, the multi-drill-bit interchangeable equipment and method for the auger-type coal cutter are suitable for cutting conditions of different thin seams, the adaptability to changes of thicknesses of coal seams and conditions of bottom and top beds is strong, the mining efficiency of thin and extra-thin seams can be improved, and the mining cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

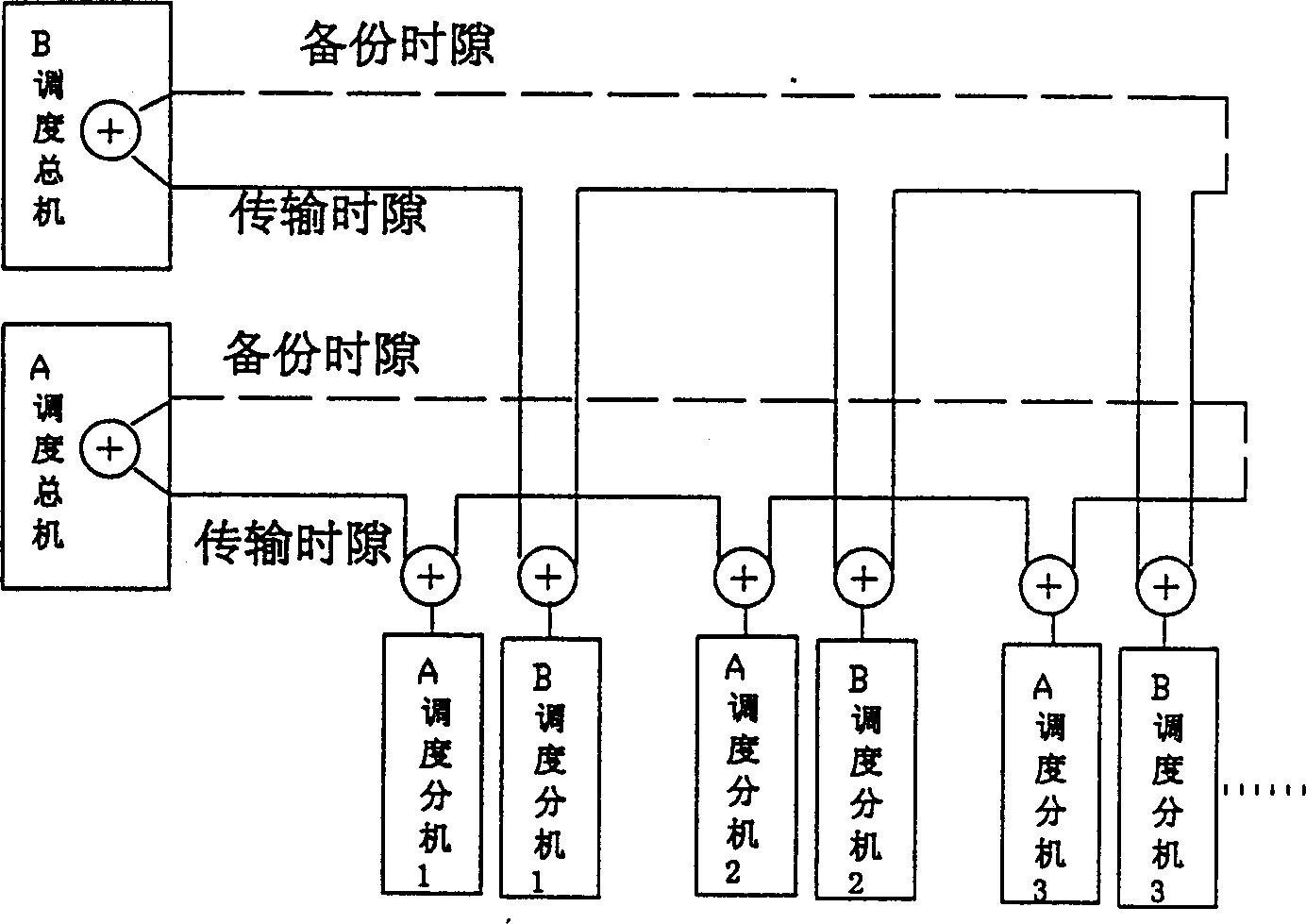

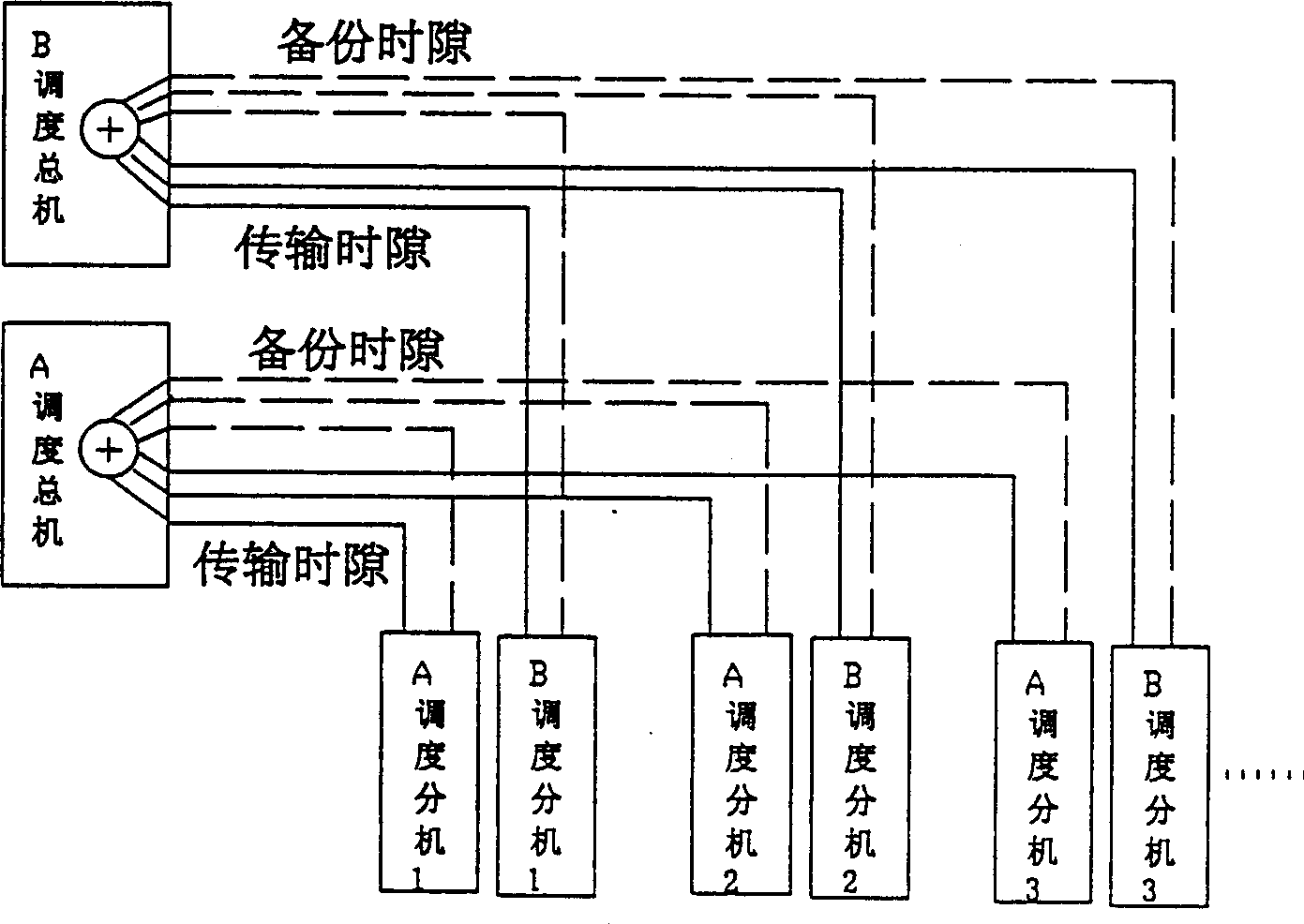

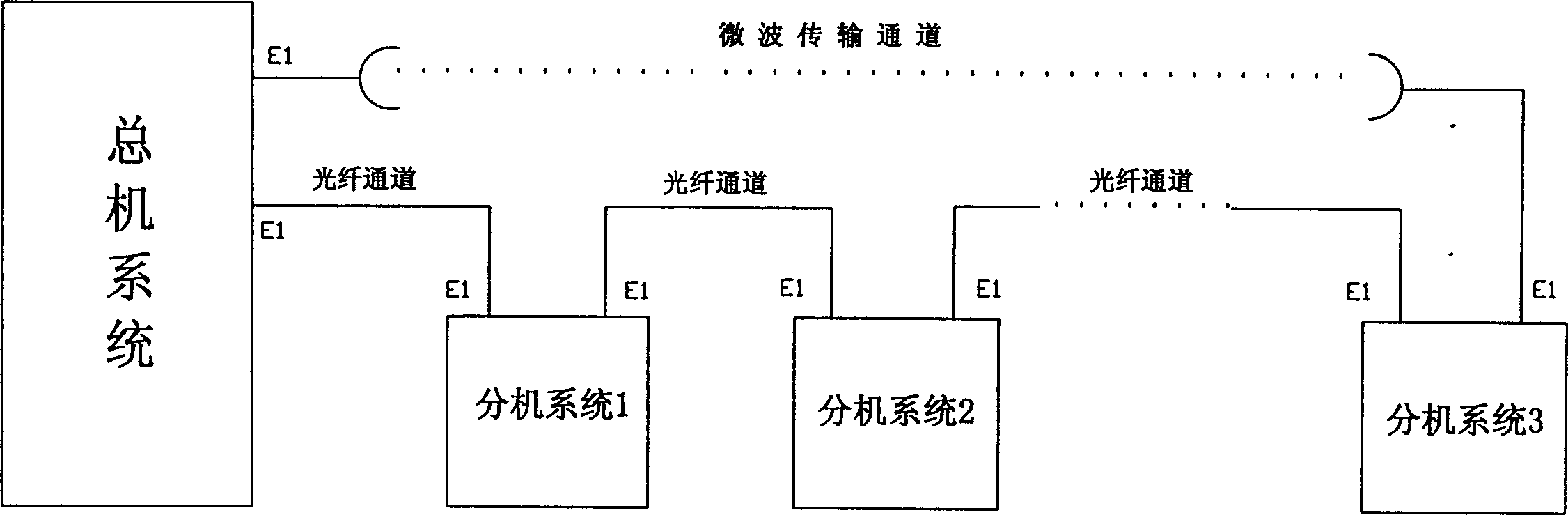

Digital dispatching communication system

InactiveCN1136699CSave resourcesPromote division of laborLoop networksMicrowaveCommunications system

The present invention discloses a digital dispatching communication system, and is characterized by that in every sub-system of said system the main station and extension connected with said main station are sequentially series-connected by means of respective digital adder, and formed into a loop network by utilizing alternate channel time slot, the main station and extension share one time slot, so the occupied time slot is small, it can greatly save transmission system resource and is favourable for selecting one proper channel from digital transmission channels of microwave communication, satellite communication, optical fibre and copper cable as alternate time slot and only need to increase less cost, at the same time it is favourable for time slot management and transimission management of said system.

Owner:BEIJING JIAXUN FEIHONG ELECTRIC CO LTD

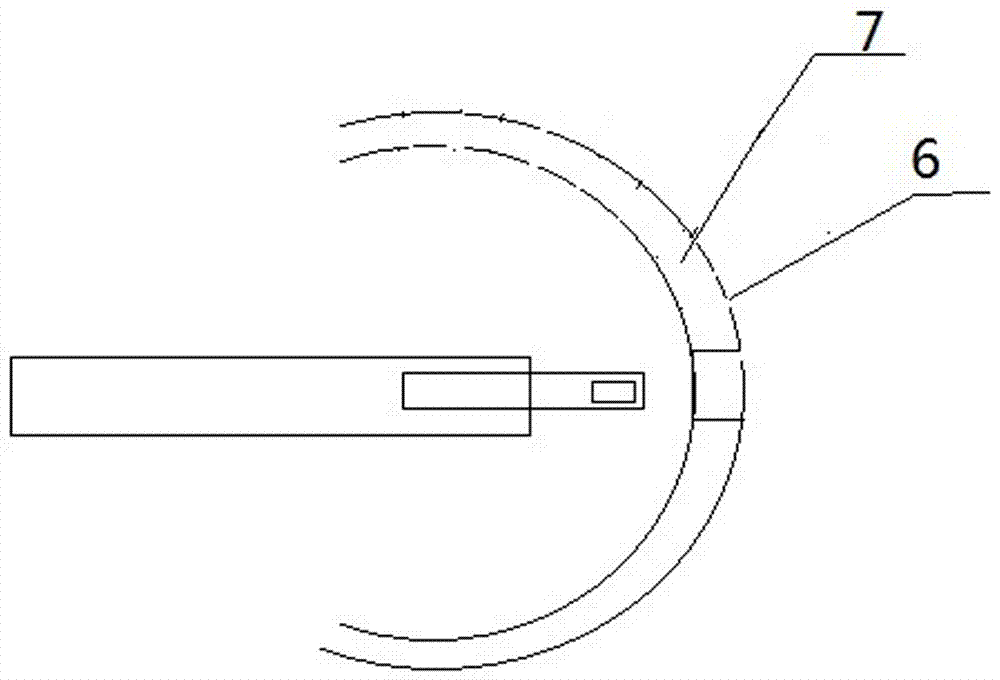

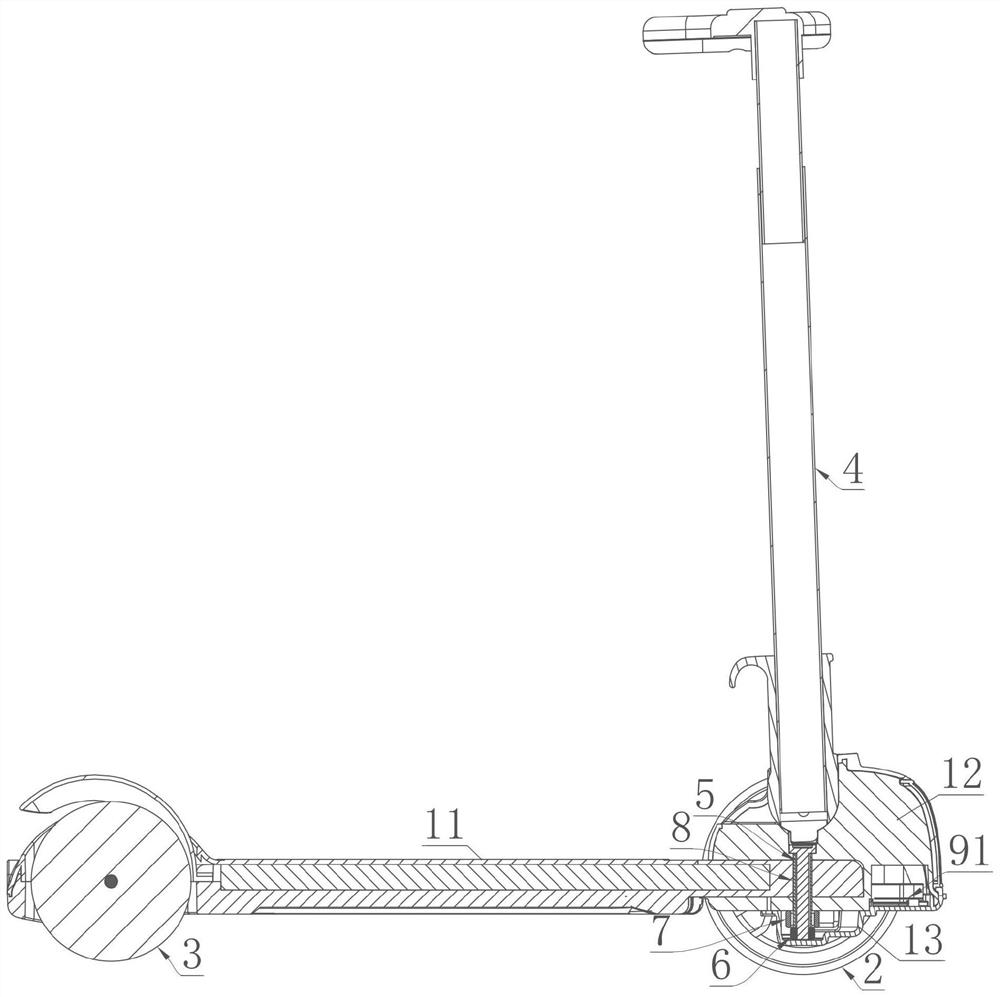

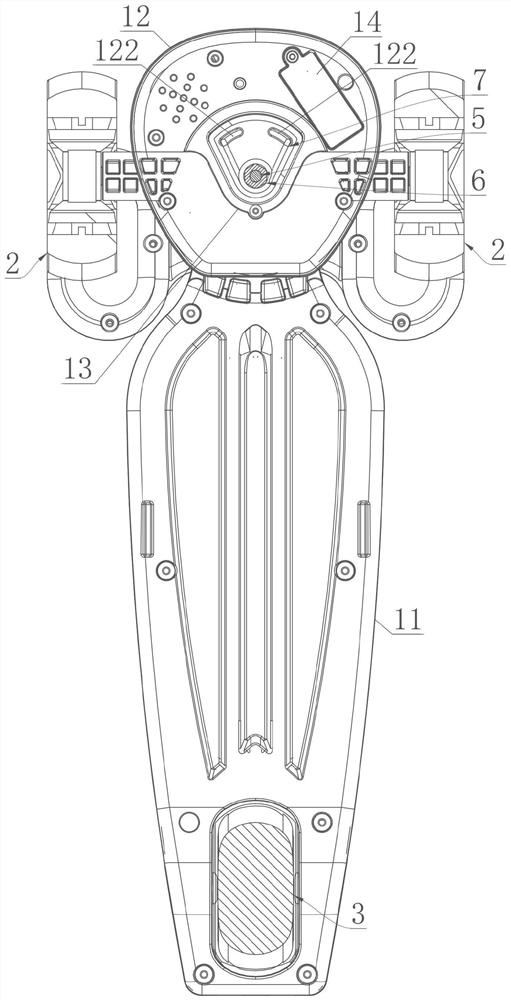

Scooter steering structure

The invention discloses a scooter steering structure , which aims to solve problems of complex structure, inconvenience in assembly and inflexible steering in the prior art. The steering structure comprises a scooter body, the scooter body comprises a mounting seat and a pedal, a handle rod and a rotatable front wheel are arranged on the mounting seat, a rotatable rear wheel is arranged on the pedal, and the mounting seat is hinged on the pedal. A rotating shaft is detachably arranged on the mounting seat, a first shaft hole is formed in the pedal, the rotating shaft penetrates through the first shaft hole, the scooter body is of a split structure and comprises the mounting seat and the pedal, the rotating shaft is detachably arranged on the mounting seat, the mounting seat and the pedal are hinged together through the rotating shaft, and disassembly and assembly between the pedal and the mounting seat can be completed by disassembling and assembling the rotating shaft.

Owner:徐闯

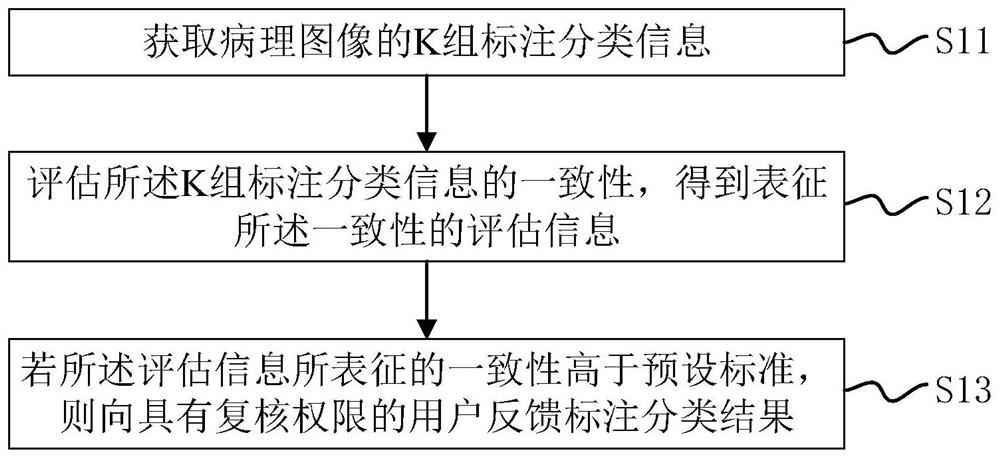

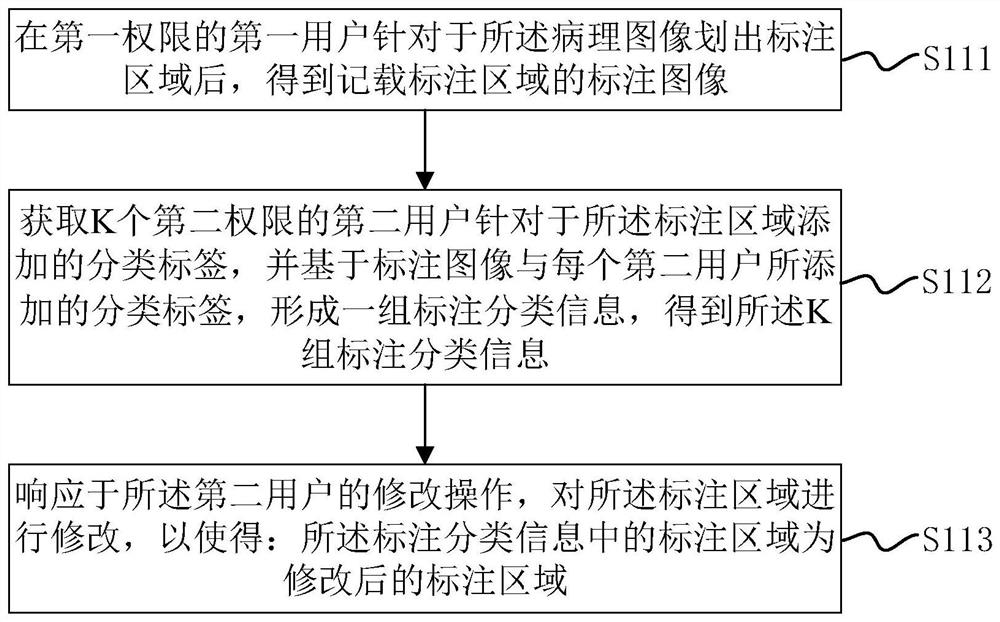

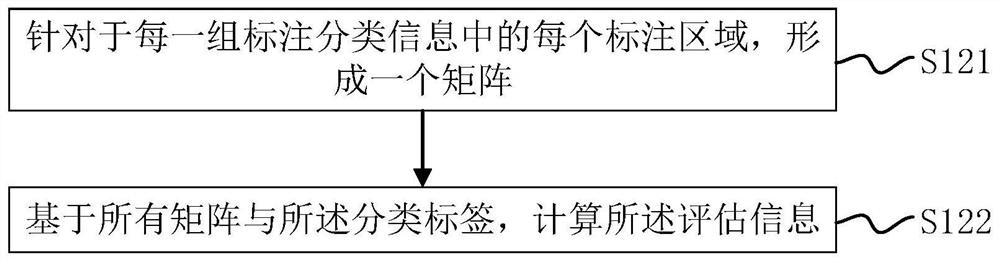

Pathological image processing method and device, electronic equipment and storage medium

PendingCN113764077AAvoid management chaosGuarantee qualityImage enhancementImage analysisImage recordingClassification result

The invention provides a pathological image processing method and device, electronic equipment and a storage medium, and the method comprises the steps: obtaining K groups of annotation classification information of a pathological image, wherein the annotation classification information represents an annotation image recording at least one annotation region, and a classification label added to each annotation region, and the annotation area is marked out for the pathological image; evaluating the consistency of the K groups of annotation classification information to obtain evaluation information representing the consistency; and if the consistency represented by the evaluation information is higher than a preset standard, feeding back the annotation classification result to the user with the rechecking permission, wherein the annotation classification result is determined according to the K groups of annotation classification information.

Owner:3D BIOMEDICINE SCI & TECH CO LTD

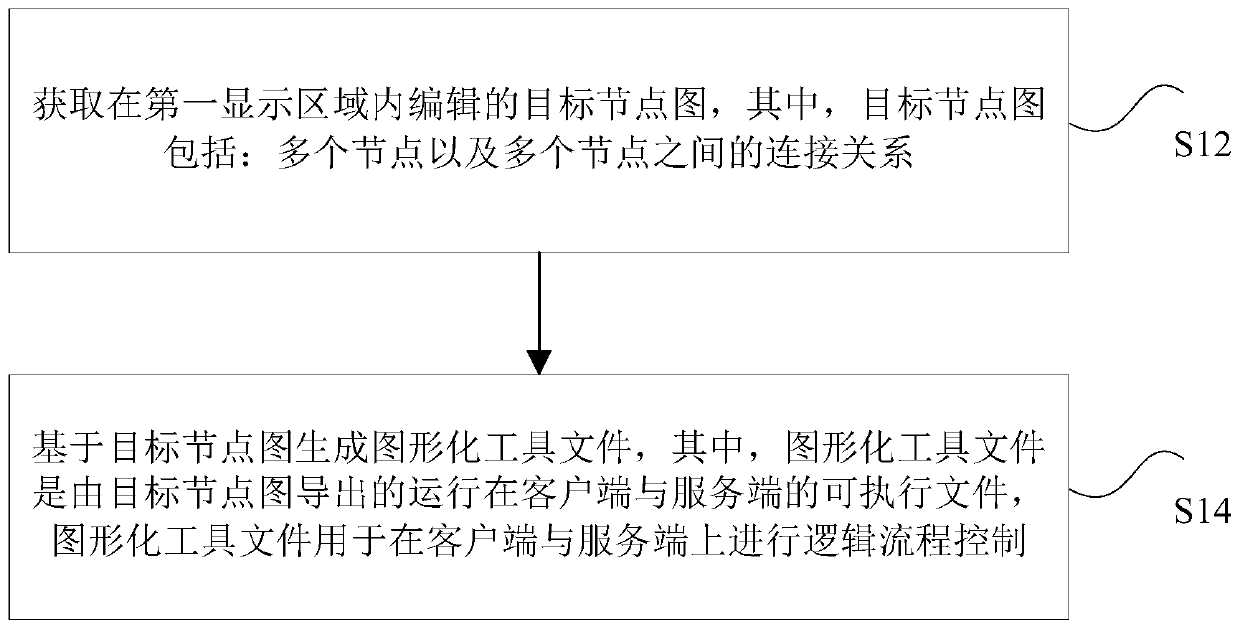

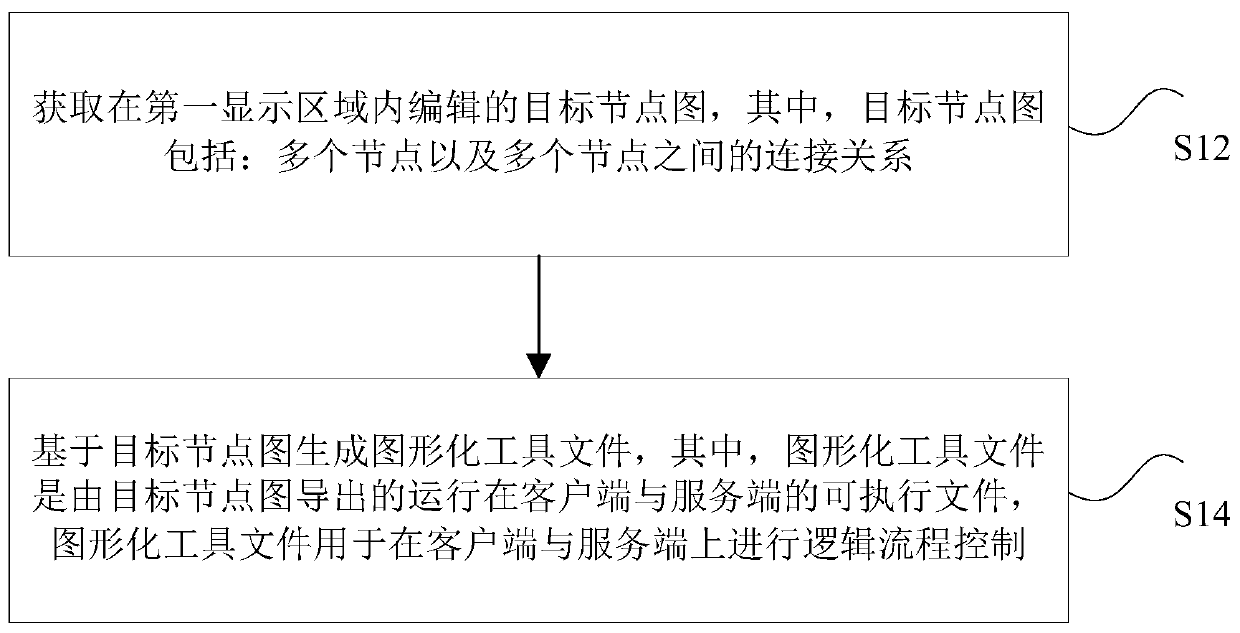

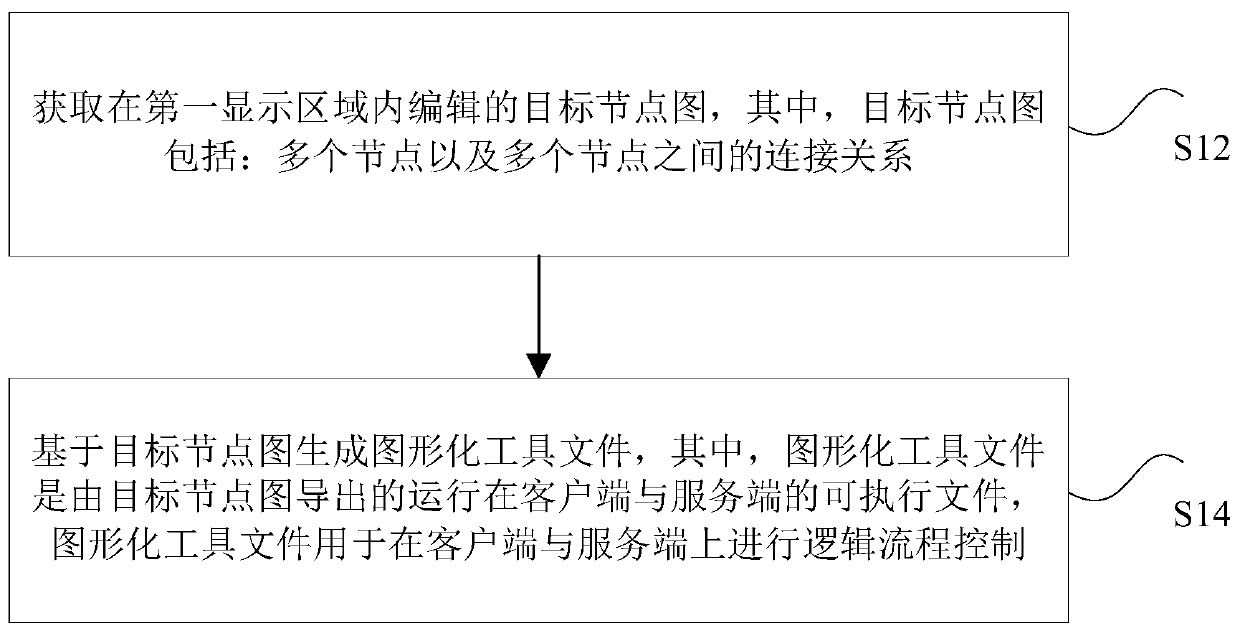

File processing method and device, storage medium, processor and electronic device

PendingCN111581112AEasy division of labor and collaborationReduce work stressSoftware engineeringInterprogram communicationGoal nodeDocument processing

The invention discloses a file processing method and device, a storage medium, a processor and an electronic device. The method comprises the following steps: receiving a graphical tool file and a first custom event sent by a graphical tool, wherein the graphical tool file is an executable file derived from a target node graph on the graphical tool, the target node graph comprises a plurality of nodes and a connection relationship among the plurality of nodes, and the first custom event is used for triggering the client to execute a graphical tool process corresponding to the executable file;and executing the graphical tool process based on the first custom event, and feeding back an execution result in real time. The technical problem that logic process control cannot be performed on theclient model and the server model through a visual graphical tool in related technologies is solved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

An intelligent robot with sorting function and its working method

The invention discloses an intelligent robot with a sorting function. The intelligent robot with the sorting function comprises a base, mechanical arms, a quality detection mechanism and a control device, wherein the mechanical arms are arranged on the base; the quality detection mechanism is arranged at the ends of the mechanical arms; discharging mechanical hands are arranged at the ends of the mechanical arms; a product grade database is arranged in the quality detection mechanism; and the quality detection mechanism and the discharging mechanical hands are connected to the control device. The intelligent robot with the sorting function has the beneficial effects that products are detected by the quality detection mechanism in a working process, firstly the appearances of the products are detected, and then the performance indexes of the products are detected; the products are sorted by the control device according to the detection results of the products, and then the discharging mechanical hands are used for grabbing different grades of products to appointed positions, so that automation and intellectualization are realized in the whole discharging process; meanwhile, the follow-up quality detection working is also omitted; and the production efficiency of the intelligent robot with the sorting function is greatly improved.

Owner:JIANGSU FANGSHIYUANLVE SCI & TECH CONSULTING CO LTD +1

A dual-motor control system and control method for a dual-motor combined drive system

ActiveCN113442737BReduced responsiveness variesSave resourcesAC motor controlVector control systemsControl systemControl engineering

The invention discloses a dual-motor control system and a control method of a dual-motor joint drive system. The dual-motor control system adopts a multi-core single processor to control the operation of two motors with different characteristics, saving communication, storage, peripheral circuits, etc. resources, reduce the influence of different motor response speeds that may be caused by communication time differences, and the impact of ineffective coordination and cooperation, and at the same time achieve lightweight, low cost, and high reliability. And the three cores perform different tasks according to the nature of the task to optimize the division of labor and improve operating efficiency. Kernel 1 receives the demanded torque command of the vehicle, optimizes the torque distribution in real time according to the different characteristics and data of the two motors, and performs vector control on the two motors by Kernel 2 and Kernel 3 to output the corresponding torque, and dynamically adjusts the coordinating torque according to the road conditions. The state variables are applicable to various road conditions, optimize the torque distribution in real time, and minimize the loss of the controller and the dual-motor coupling drive system to achieve efficient operation.

Owner:SINO TRUK JINAN POWER

System and method for implementing PC / SC interface of HID / SCSI apparatus

ActiveCN101329661BEasy to modifyEasy maintenanceElectric digital data processingCommunications securitySCSI

Owner:FEITIAN TECHNOLOGIES

Design system and method for a visual script editor

ActiveCN107357567BFacilitate division of labor and cooperationSimple processIntelligent editorsVisual/graphical programmingComputer graphics (images)Reusability

A method for implementing a visualization script editor is provided. The method comprises following steps: A. creating flow nodes and building graphical identifications corresponding to the flow nodes; B. connecting the flow nodes into a visualization script and executing the flow; C. performing serial storage on the visualization script data. The invention also discloses a design system corresponding to the visualization script editor. The method and system of the invention facilitate planning personnel and artists to take part in game development so that they can better share out the work and cooperate with one another; the flow is optimized; the development period is shortened; specific requirements of visual understanding of games are facilitated; reusability and scalability of codes are enhanced.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

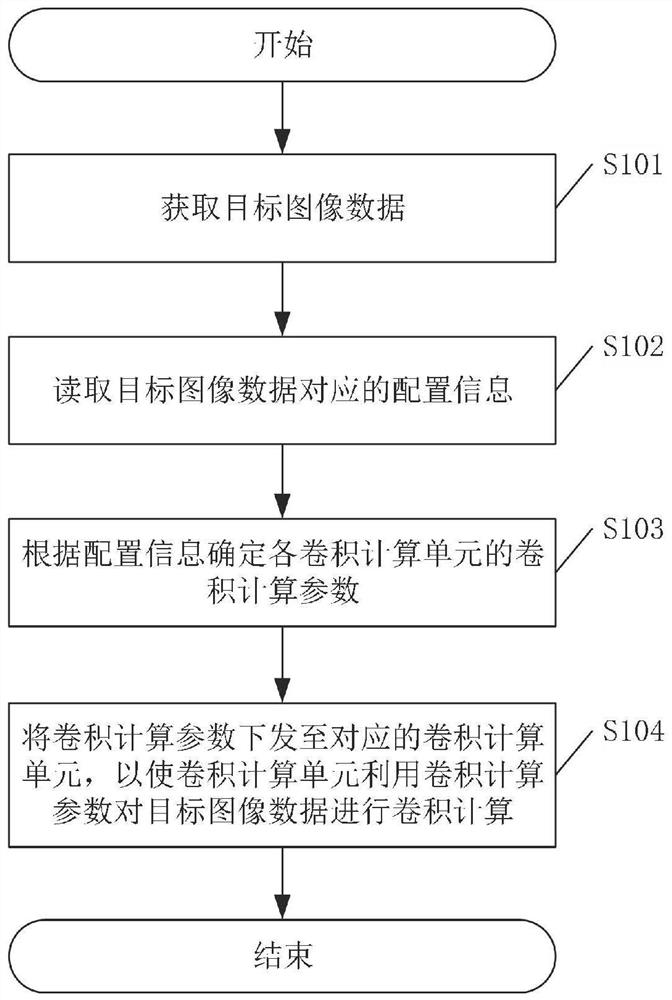

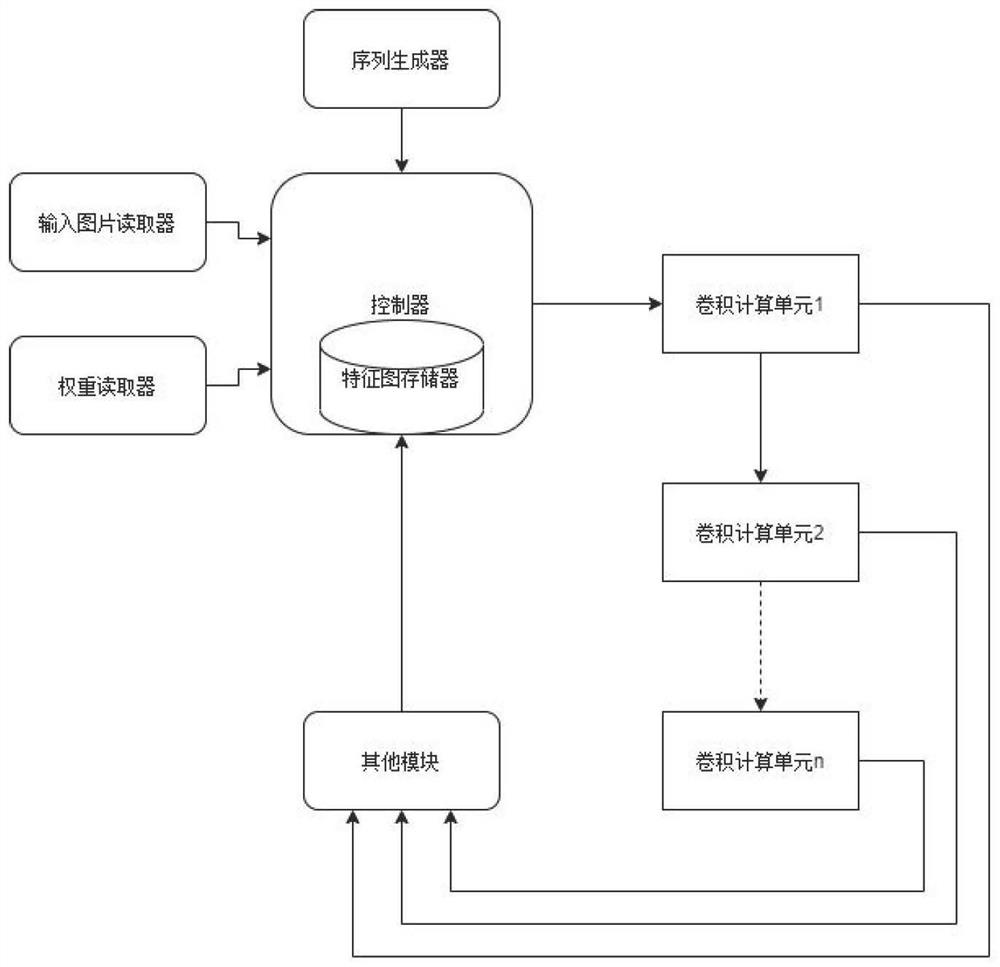

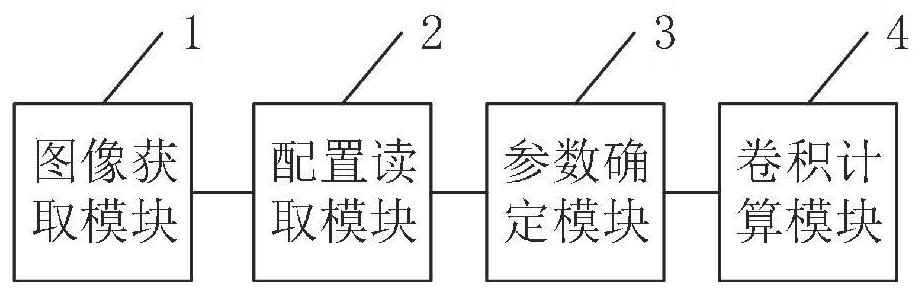

Image processing method and device based on convolutional neural network, and related equipment

PendingCN114004731APromote division of laborReduce resource consumptionProcessor architectures/configurationProgram loading/initiatingImaging processingAlgorithm

The invention discloses an image processing method based on a convolutional neural network, and the method is applied to a convolution calculation unit controller, and comprises the steps: obtaining target image data; reading configuration information corresponding to the target image data; determining convolution calculation parameters of each convolution calculation unit according to the configuration information; and issuing the convolution calculation parameters to the corresponding convolution calculation unit, so that the convolution calculation unit performs convolution calculation on the target image data by using the convolution calculation parameters. The image processing method based on the convolutional neural network can be used to effectively reduce resource consumption in a convolutional neural network processing process. The invention also discloses an image processing device based on the convolutional neural network, the convolution calculation unit controller and a computer readable storage medium, which all have the above beneficial effects.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

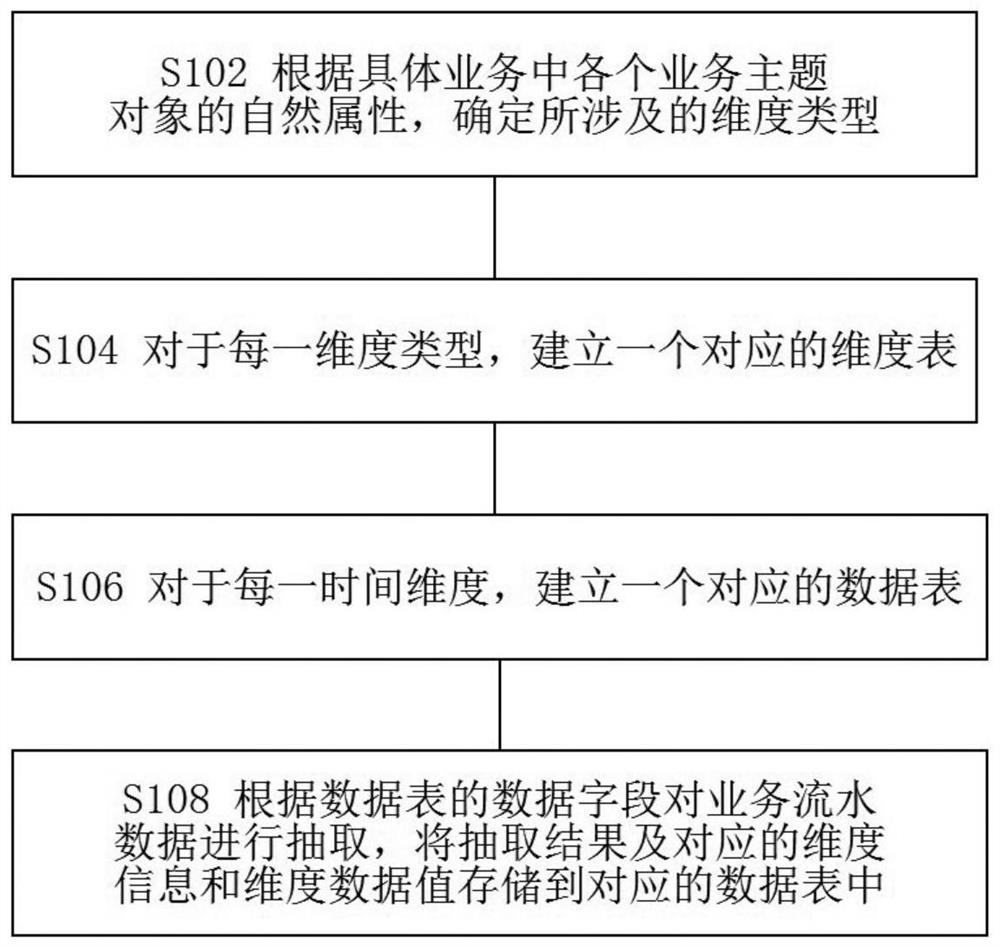

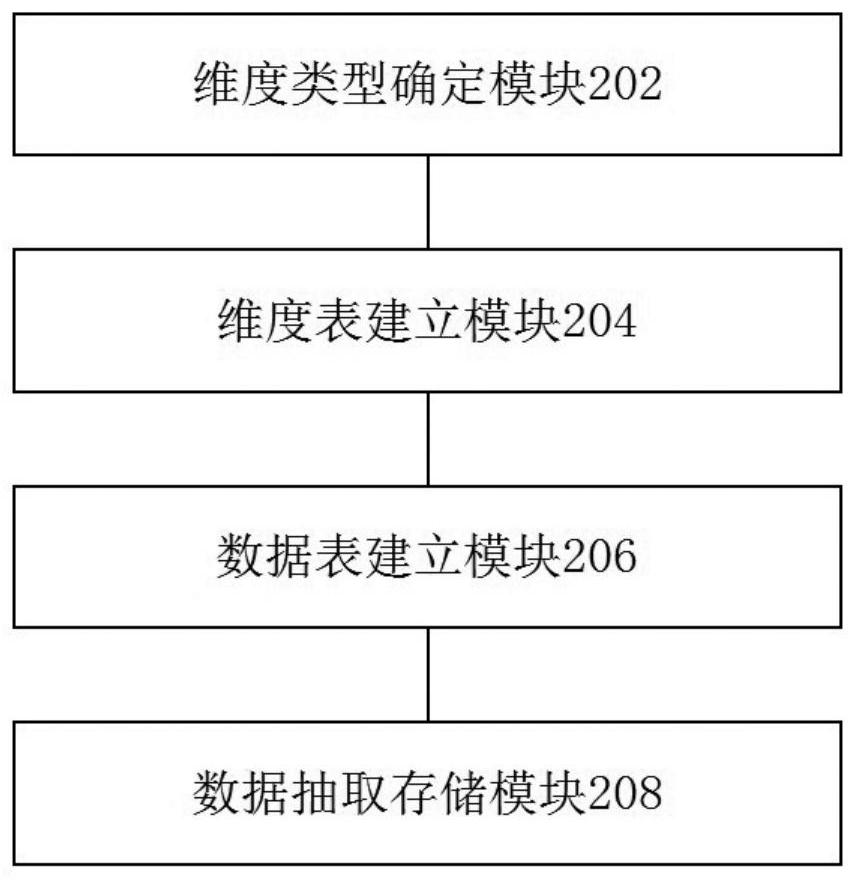

Chart information data storage method and system, corresponding equipment and storage medium

PendingCN112732712AImprove scalabilityImprove efficiencyDatabase management systemsSpecial data processing applicationsDatasheetData field

The invention discloses a chart information data storage method and system, corresponding equipment and a storage medium. The method comprises the following steps: determining an involved dimension type according to business flow data; establishing a dimension table for each dimension type, wherein the dimension table comprises dimension fields and dimension names; establishing a data table for each time dimension, wherein the data table comprises a dimension value field and a data field; and extracting the business flow data according to the data fields of the data table, storing an extraction result into a corresponding data table, and storing dimension information and dimension data values corresponding to the data into the corresponding data table, the data table storing the data being used for responding to chart information display, and the data table storing the data being used for displaying the chart information, according to the dimension of the chart information, directly obtaining a corresponding numerical value from the corresponding data table. According to the method and the system, the data loading speed during chart information display can be improved.

Owner:望海康信(北京)科技股份公司

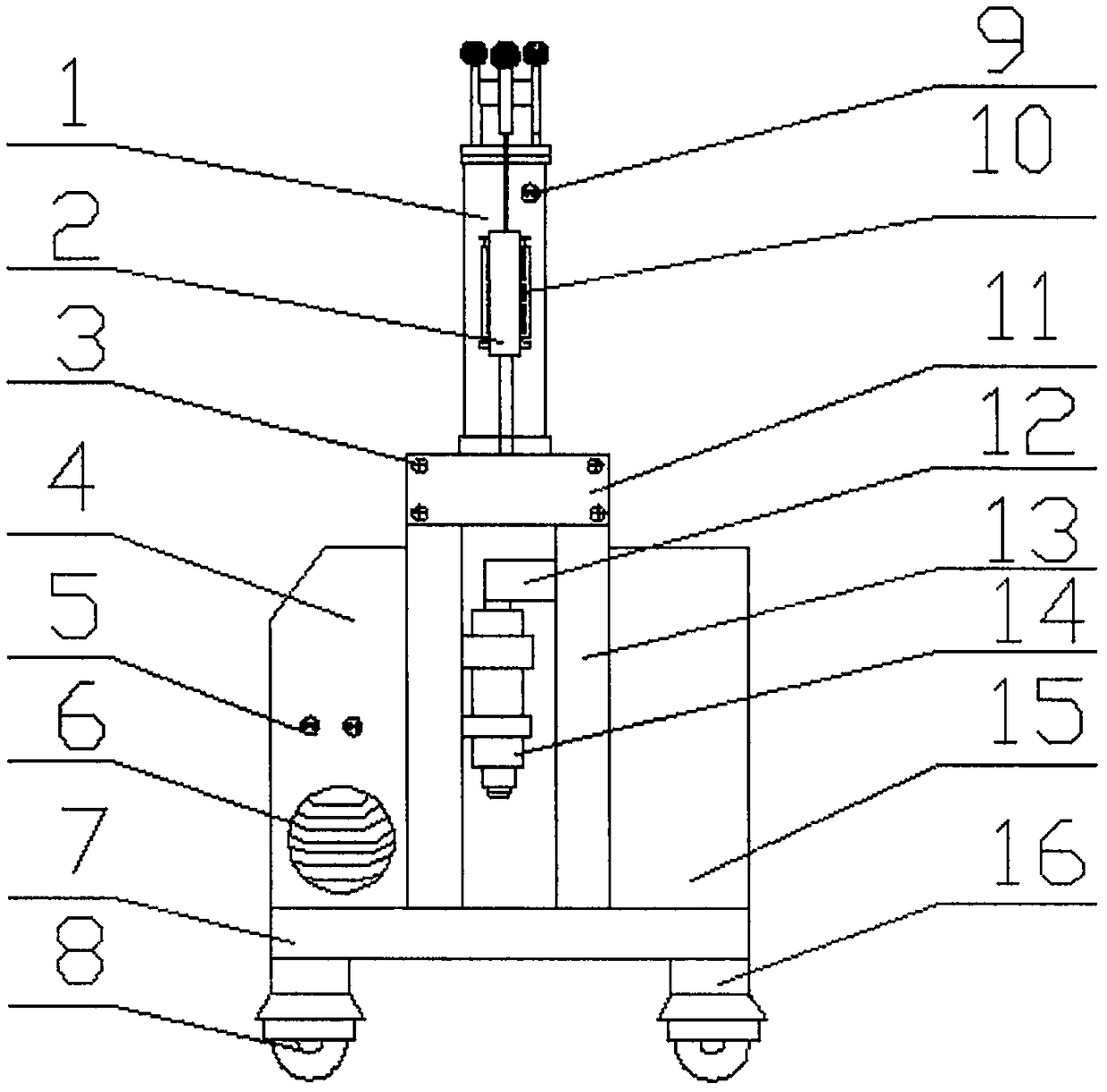

Light and convenient drilling machine

The invention discloses a light and convenient drilling machine. The light and convenient drilling machine comprises an upper part box body, a drilling tool and a base. The upper part box body is arranged between an oiler and the drilling tool. A motor, an oil pipe and an oil storage tank are arranged in the upper part box body. The upper part box body is arranged above a drilling frame, and the drilling tool is arranged below the drilling frame. The light and convenient drilling machine is simple in structure and convenient to use, and equipped with the lifting motor, up-down repeated pressing and drilling work is conducted by cooperating with the drilling tool, meanwhile, worm and gear decelerator cooperates with the drilling tool to rotate to drill, the operation efficiency is effectively improved through design of a fractional motor, labor division and synchronous working are facilitated, work delay due to usage delay caused by hybrid using cannot occur, double clamping devices arearranged at the same time, the drilling tool can be stably clamped in the up-down pressing and drilling process, and the light and convenient drilling machine is suitable for being applied and popularized.

Owner:朱立国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com