A multi-drill bit exchange device and method on a drilling shearer

A shearer and multi-bit technology, which is applied to drilling equipment and methods, mechanical equipment, drilling equipment, etc., can solve the problems of wasting time, that drilling shearers cannot fully adapt to mining, and work efficiency is low, so as to improve The effects of mining efficiency, enhanced product development efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

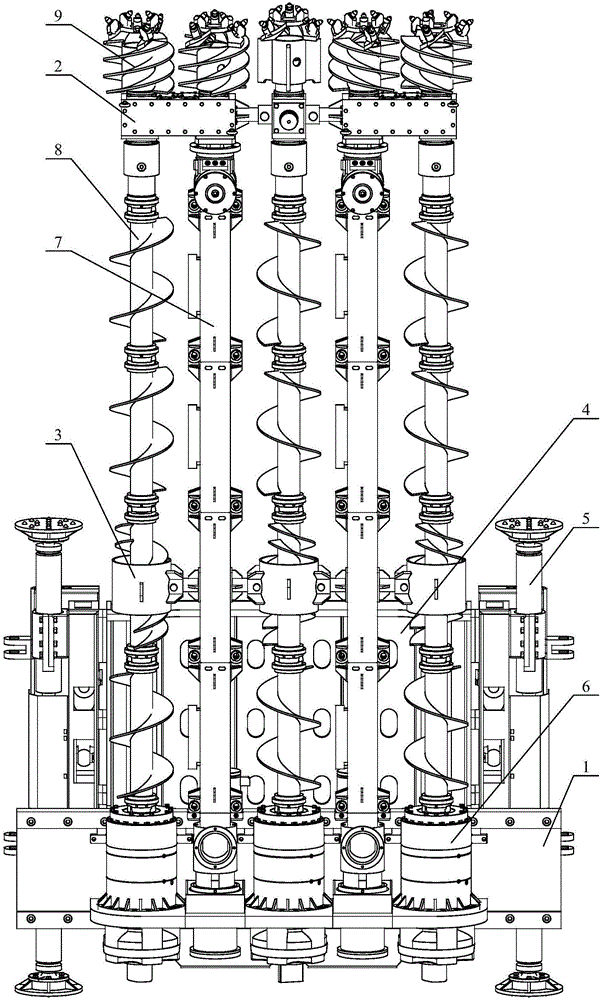

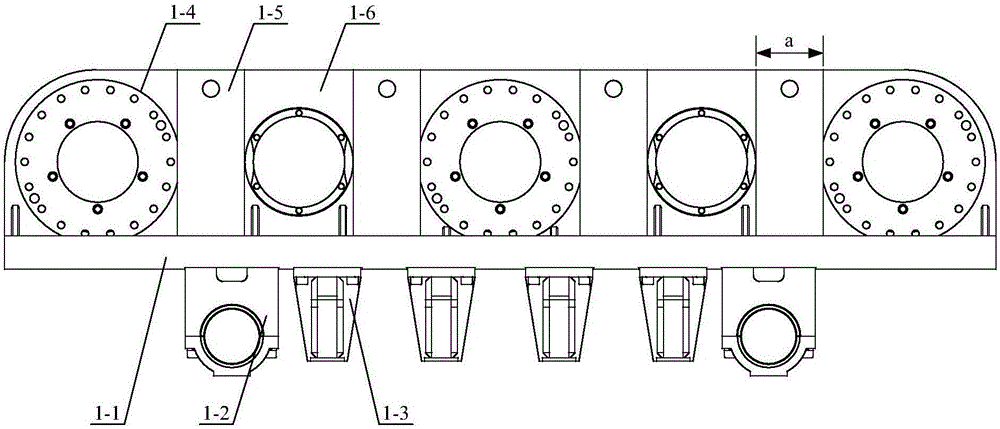

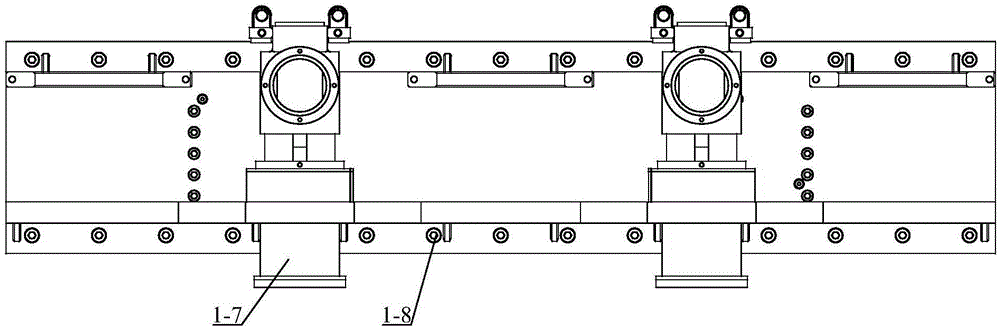

[0027] like figure 1 As shown, the multi-bit exchange equipment on the drilling shearer of the present invention mainly consists of a drive frame 1, an interchangeable transmission box 2, an interchangeable stabilizer 3, a bottom bracket 4, a side frame 5, and a hydraulic motor 6 , air duct 7, auger rod 8, and auger bit 9. The two sides of the bottom bracket 4 are connected to the side frame 5 by screws, and the guide frame 1 is connected to the bottom bracket 4 through the guide bushing 1-2. The guide shaft 4-1 on the top is connected, the cylinder base 1-3 is connected with the propulsion cylinder 4-2 on the bottom bracket 4, the interchangeable guide frame 1 is connected with the blower 7 through the blower interface 1-7, and the hydraulic motor 6 passes through The motor front support 1-4 and the motor rear support 1-9 are fixed on the interchangeable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com