Discharging robot with quality detection function and working method thereof

A robot and cutting technology, applied in manipulators, manufacturing tools, sorting and other directions, can solve the problems affecting the market competitiveness of enterprise products, insufficient product inspection, and the flow of defective products into the market, so as to avoid program confusion, good division of labor, Easy to track effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

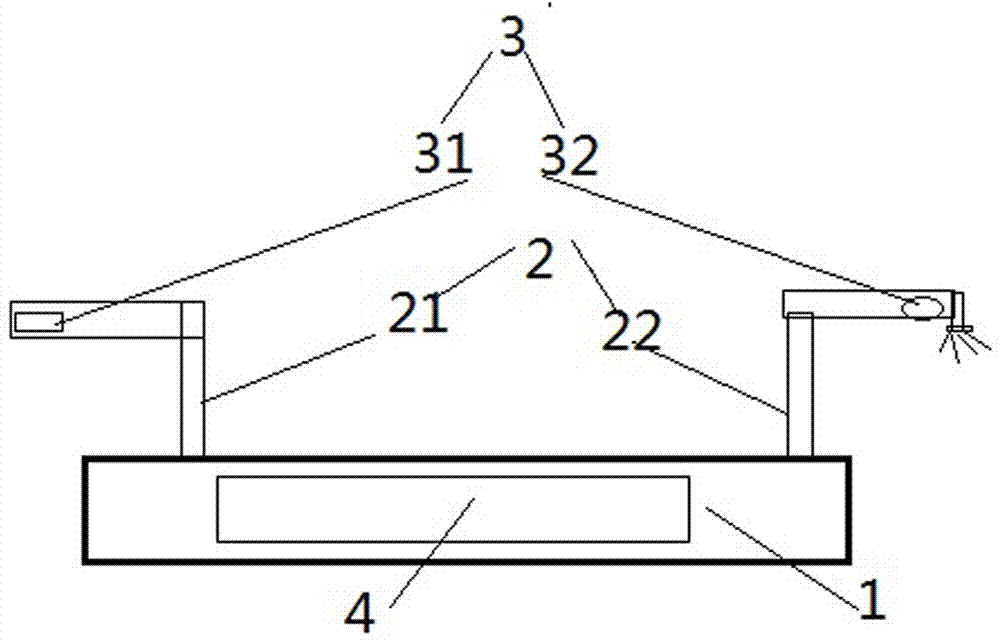

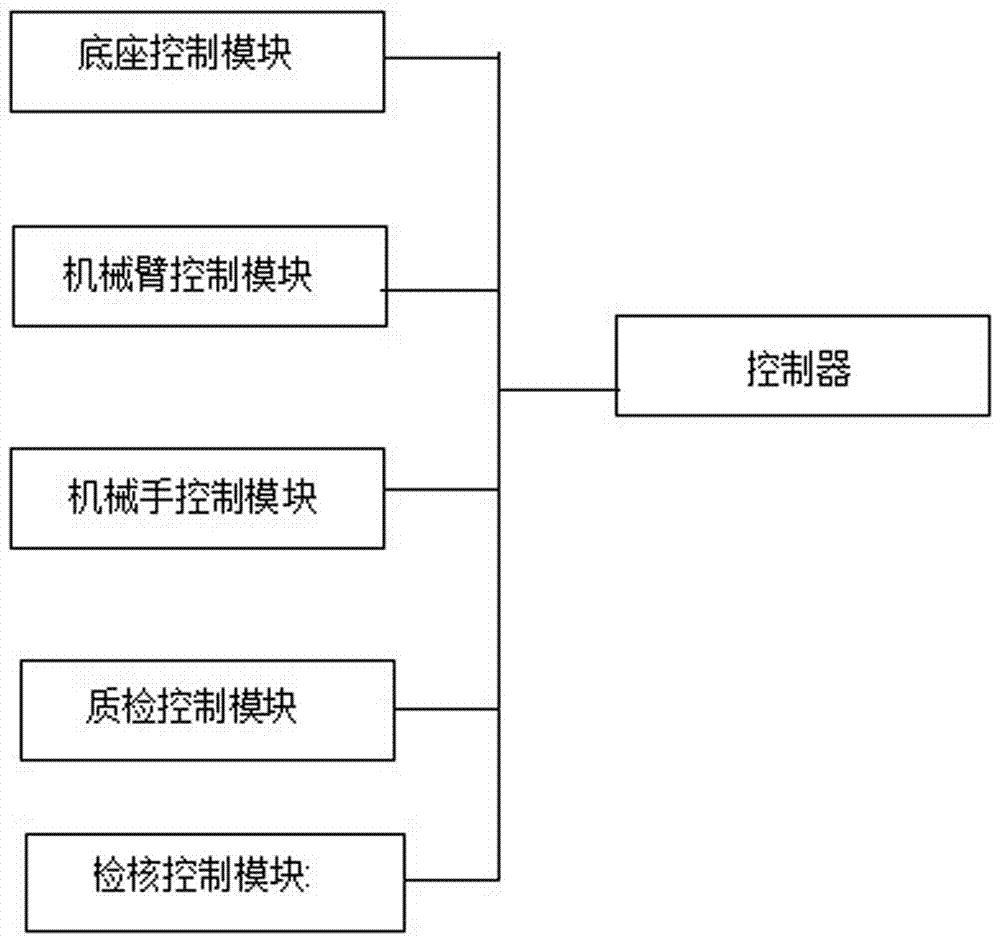

[0036] As shown in the figure, a cutting robot with quality inspection function includes: a base 1, a mechanical arm 2, a quality detection mechanism 3 and a control device 4, wherein the mechanical arm 2 is arranged on the base 1, and the quality The detection mechanism 3 is arranged at the end of the mechanical arm 2 , and the end of the mechanical arm 2 is provided with a feeding robot 5 , and both the quality detection mechanism 3 and the feeding robot 5 are connected to the control device 4 .

[0037] In this embodiment, the quality inspection mechanism 3 is provided with an appearance inspection device 31 and a performance analyzer 32 for inspecting the appearance of the product, and the appearance inspection device 31 and the performance analyzer 32 are both connected to the control device 4 .

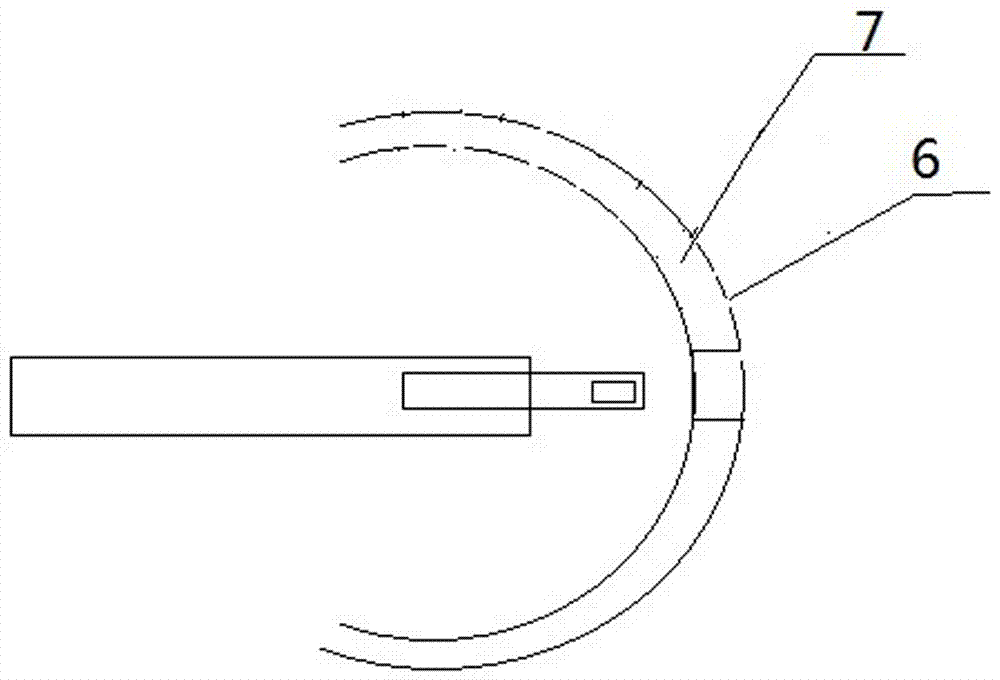

[0038] This embodiment also includes a workbench 6, which is in the form of a ring. A product placement area 7 is provided on the workbench 6. The product placement area 7 is div...

Embodiment 2

[0045] As shown in the figure, a cutting robot with quality inspection function includes: a base 1, a mechanical arm 2, a quality detection mechanism 3 and a control device 4, wherein the mechanical arm 2 is arranged on the base 1, and the quality The detection mechanism 3 is arranged at the end of the mechanical arm 2 , and the end of the mechanical arm 2 is provided with a feeding robot 5 , and both the quality detection mechanism 3 and the feeding robot 5 are connected to the control device 4 .

[0046] In this embodiment, the quality inspection mechanism 3 is provided with an appearance inspection device 31 and a performance analyzer 32 for inspecting the appearance of the product, and the appearance inspection device 31 and the performance analyzer 32 are both connected to the control device 4 .

[0047] This embodiment also includes a workbench 6, which is in the form of a ring. A product placement area 7 is provided on the workbench 6. The product placement area 7 is div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com