Method for producing fluorinated organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0041]The following prophetic example is a preferred embodiment that is provided to further illustrate certain aspect of the invention.

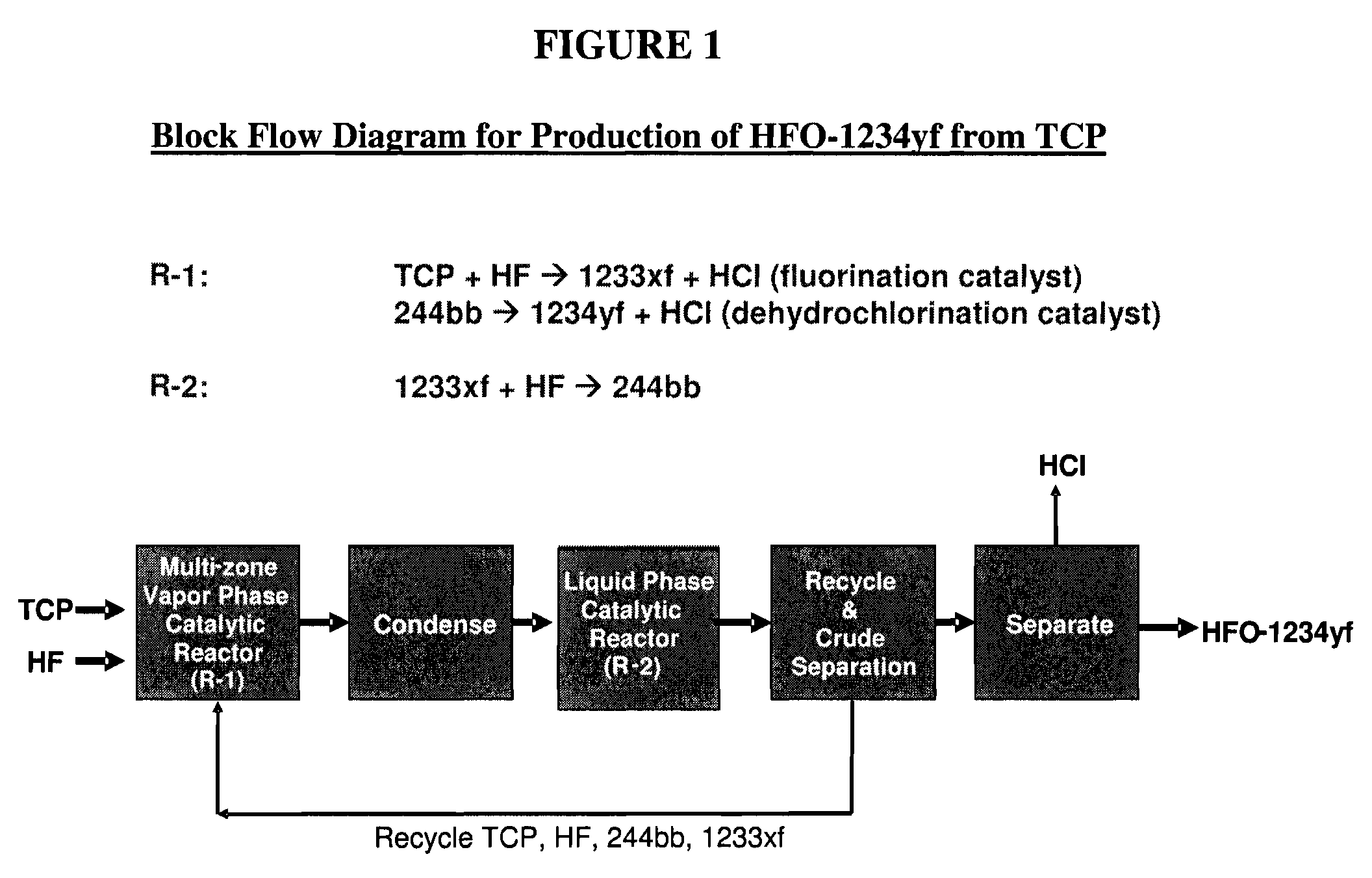

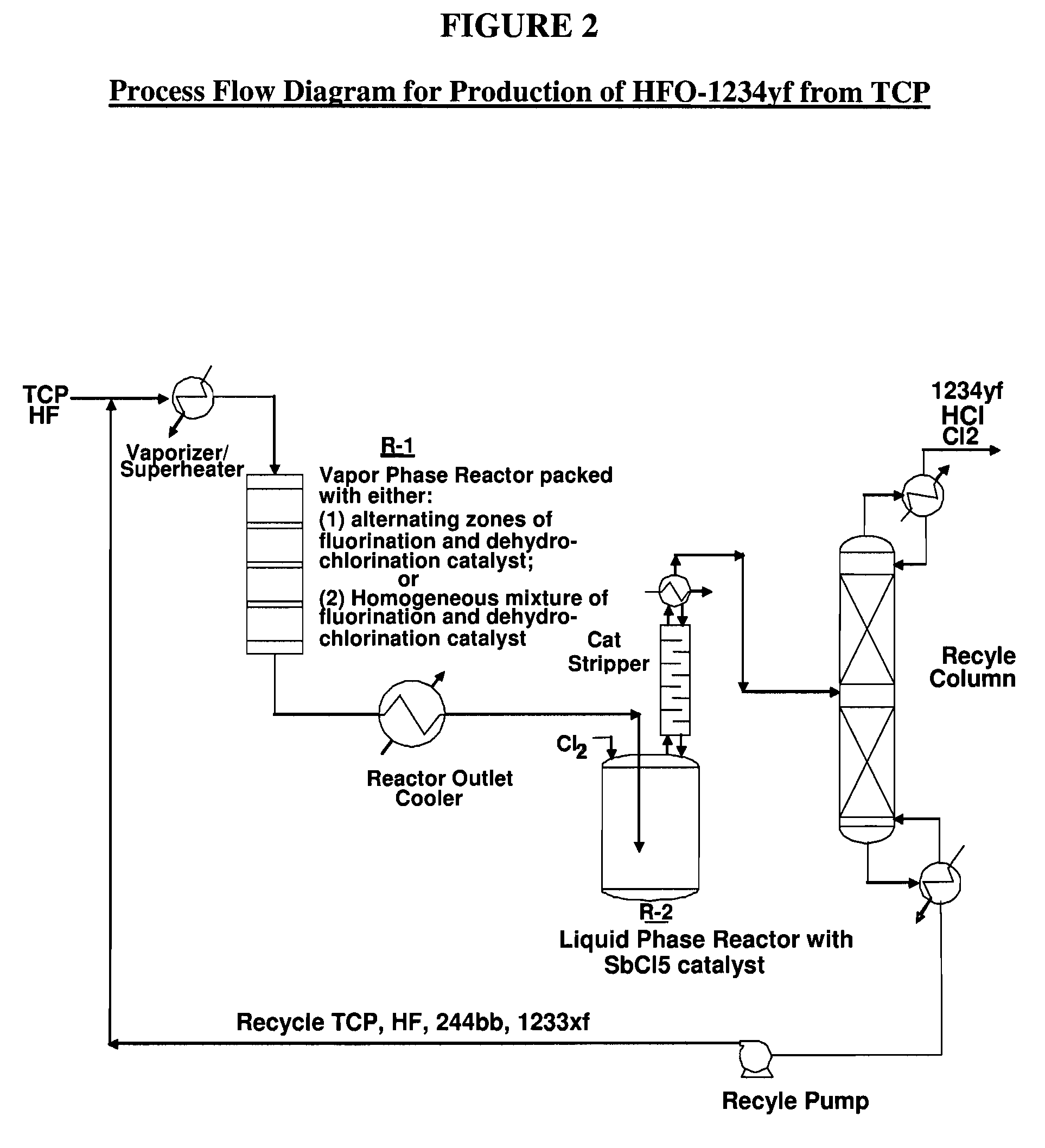

[0042]With reference to FIGS. 1 and 2, shown is an integrated process for the production of HFO-1234yf from tetrachloropropene (TCP) in three reaction steps where the first (exothermic) and third (endothermic) reactions are carried out in a single reactor or reaction zone. The process is summarized as follows:

Step 1: Hydrofluorination of TCP to HCFO-1233xf and dehydrochlorination of intermediate HCFC-244bb (formed in a separate reactor as described below) occur in a single reactor system using a series of reactors or multi-stage reactor, or combination of reactor design, as illustrated on the attached process flowsheet. The reactor is either segregated into alternating beds of fluorination / dehydrochlorination zones or a homogeneous mixture of fluorination catalyst and dehydrochlorination catalyst. The exotherm of the hydrofluorination reaction is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com