A passivation method for boron emitter of n-type crystalline silicon cell

A crystalline silicon battery and emitter technology, which is applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of passivation performance decline, low utilization rate of chemical materials, low material utilization rate, etc., and achieve equipment cost and Low cost of consumables, ease of mass production, effects of economical process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

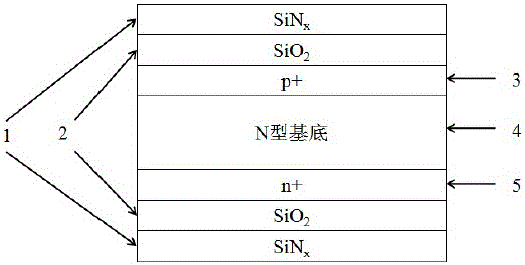

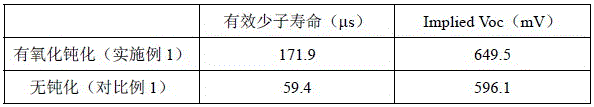

[0020] like figure 1 Shown, a kind of passivation method of boron emitter of N-type crystalline silicon battery comprises the following steps:

[0021] (1) Use N-type monocrystalline silicon wafers as the substrate, with a resistivity of 1-12 W cm and a thickness of 170-200 mm. The silicon wafers are cleaned to remove the damaged layer on the surface, and the silicon wafers are treated with alkaline solution. Texturing treatment;

[0022] (2) The boron emitter P+ layer is prepared by doping the silicon wafer with boron on one side of the silicon wafer through high-temperature boron diffusion;

[0023] (3) Remove the borosilicate glass on the surface and the diffusion diffraction layer on the back by wet etching, and prepare a phosphorus diffusion mask layer on the boron emitter P+ layer;

[0024] (4) Use a tube furnace to diffuse phosphorus on the other side of the silicon wafer to form an N+ layer, and use chemical etching to remove the surface phosphosilicate glass layer a...

Embodiment 2

[0028] like figure 1 Shown, a kind of passivation method of boron emitter of N-type crystalline silicon battery comprises the following steps:

[0029] (1) Use N-type monocrystalline silicon wafers as the substrate, with a resistivity of 1-12 W cm and a thickness of 170-200 mm. The silicon wafers are cleaned to remove the damaged layer on the surface, and the silicon wafers are treated with alkaline solution. Texturing treatment;

[0030] (2) The boron emitter P+ layer is prepared by doping the silicon wafer with boron on one side of the silicon wafer through high-temperature boron diffusion;

[0031] (3) Remove the borosilicate glass on the surface and the diffusion diffraction layer on the back by wet etching, perform phosphorus doping on the other side of the silicon wafer by implantation, and form a phosphorus-doped N+ layer after annealing;

[0032] (4) Put the silicon wafer in (3) into an oxidation furnace for oxidation passivation treatment in a high-purity oxygen atm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com