Silicon-based thin film, solar cell and preparation method of silicon-based thin film

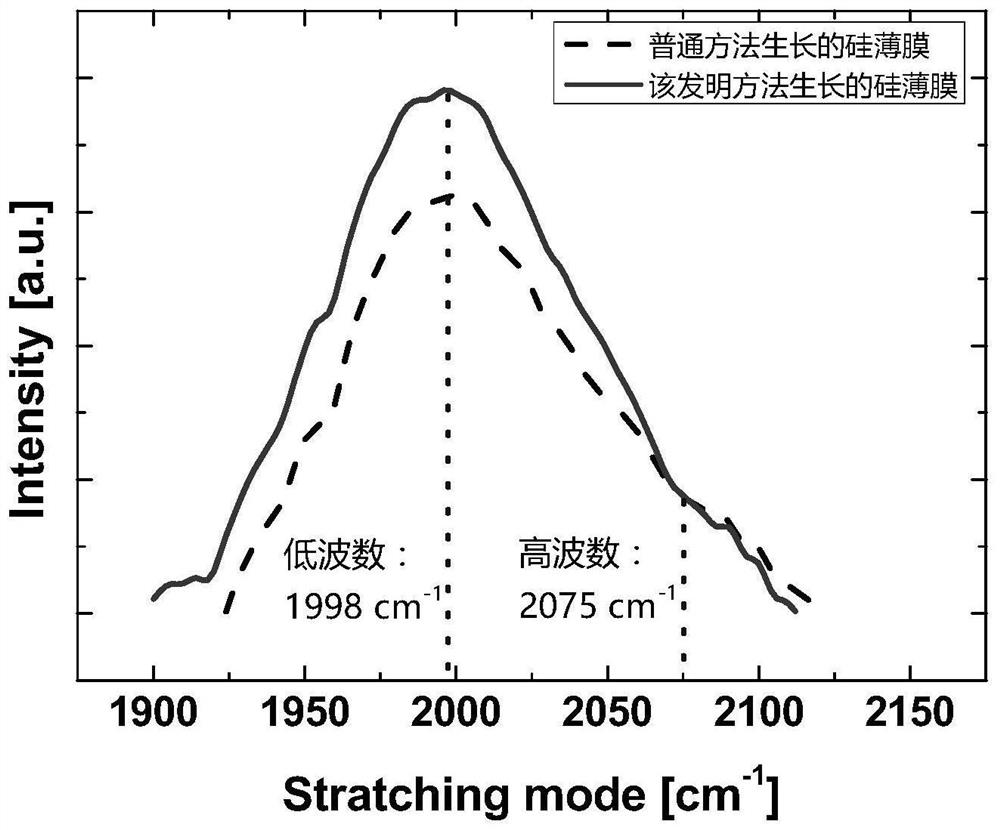

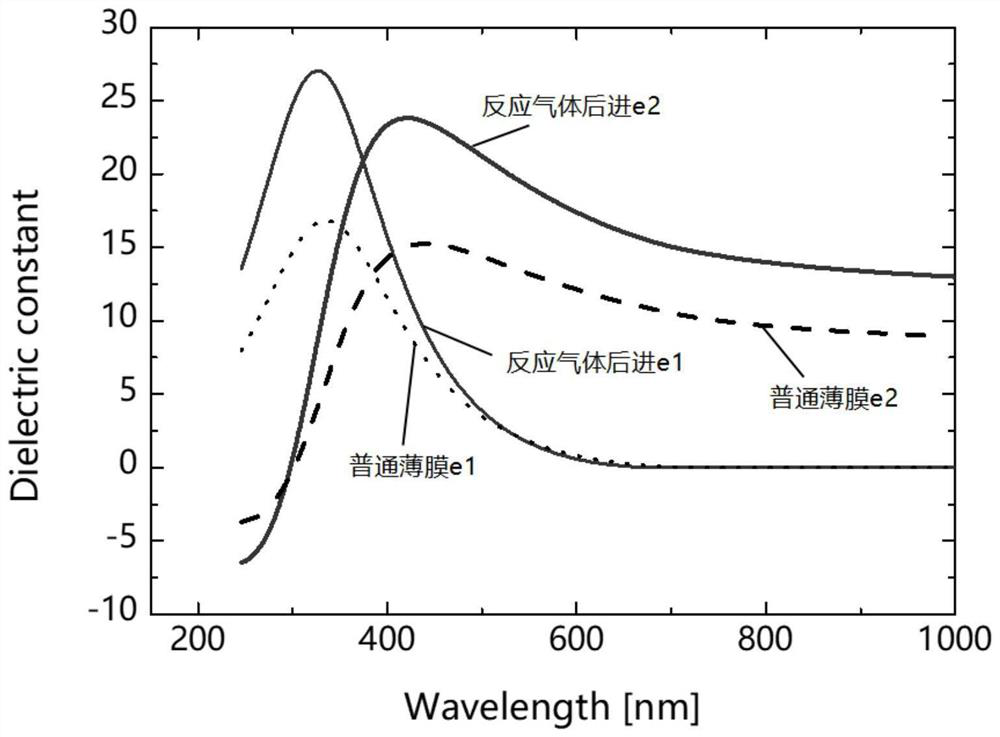

A silicon-based thin-film, solar cell technology, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of high cost pressure, low-efficiency gas utilization rate, and increase production cost of HJT solar cells. Bond density, enhanced molecular collisions, improved mass effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Some embodiments of the present invention provide a method for preparing a silicon-based thin film, including the following steps S100 and S200.

[0039] Step S100: Preheating the substrate.

[0040] Specifically, the substrate used is an n-type single crystal silicon substrate. The specific steps of preheating the substrate are as follows: first, placing the substrate in a vacuum preheating chamber, preheating the substrate, and filling the preheating chamber with hydrogen and inert gas during the preheating process.

[0041]In the traditional silicon-based thin film deposition method, the preheating time of the n-type single crystal silicon substrate is generally long, which leads to a long production tact time and affects the production efficiency. In the present invention, hydrogen and inert gas are filled into the preheating chamber during the preheating process of the substrate; the introduction of hydrogen can enhance the collision of gas molecules, thereby acce...

Embodiment 1

[0076] A method for preparing a heterojunction solar cell according to an embodiment of the present invention includes the following steps:

[0077] 1) Texturing and cleaning of n-type single crystal silicon substrate:

[0078] The n-type single crystal silicon substrate is textured with alkaline solutions such as KOH and NaOH, and the surface of the n-type single crystal silicon substrate is textured by the anisotropic etching characteristics of the alkaline solution; then the RCA1 and RCA2 solutions are used The n-type single crystal silicon substrate is cleaned to obtain an n-type single crystal silicon substrate with a clean surface.

[0079] 2) Deposition of silicon-based thin films:

[0080] Intrinsic silicon thin films and n-type doped silicon stacked thin films are sequentially deposited on the first surface of the n-type single crystal silicon substrate by PECVD; sequentially deposited on the second surface of the n-type single crystal silicon substrate opposite to t...

Embodiment 2

[0090] A method for preparing a silicon heterojunction solar cell according to an embodiment of the present invention includes the following steps:

[0091] 1) Texturing and cleaning of n-type single crystal silicon substrate:

[0092] The n-type single crystal silicon substrate is textured with alkaline solutions such as KOH and NaOH, and the surface of the n-type single crystal silicon substrate is textured by the anisotropic etching characteristics of the alkaline solution; The silicon substrate is cleaned to obtain an n-type single crystal silicon substrate with a clean surface, which is placed in an ultra-clean space so that a natural oxide layer of about 2 nm is formed on the surface of the single crystal silicon substrate.

[0093] 2) Deposition of silicon thin film passivation layer:

[0094] Intrinsic silicon thin films and n-type doped silicon stacked thin films are sequentially deposited on the first surface of the n-type single crystal silicon substrate by HWCVD t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com