Trimetal layered double hydroxide and preparation method and application thereof

A double hydroxide and hydroxide technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of easy collapse of the structure, inability to adsorb at the same time, LDH can not be passivated at the same time, etc., to achieve stability Good performance, simple preparation method and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

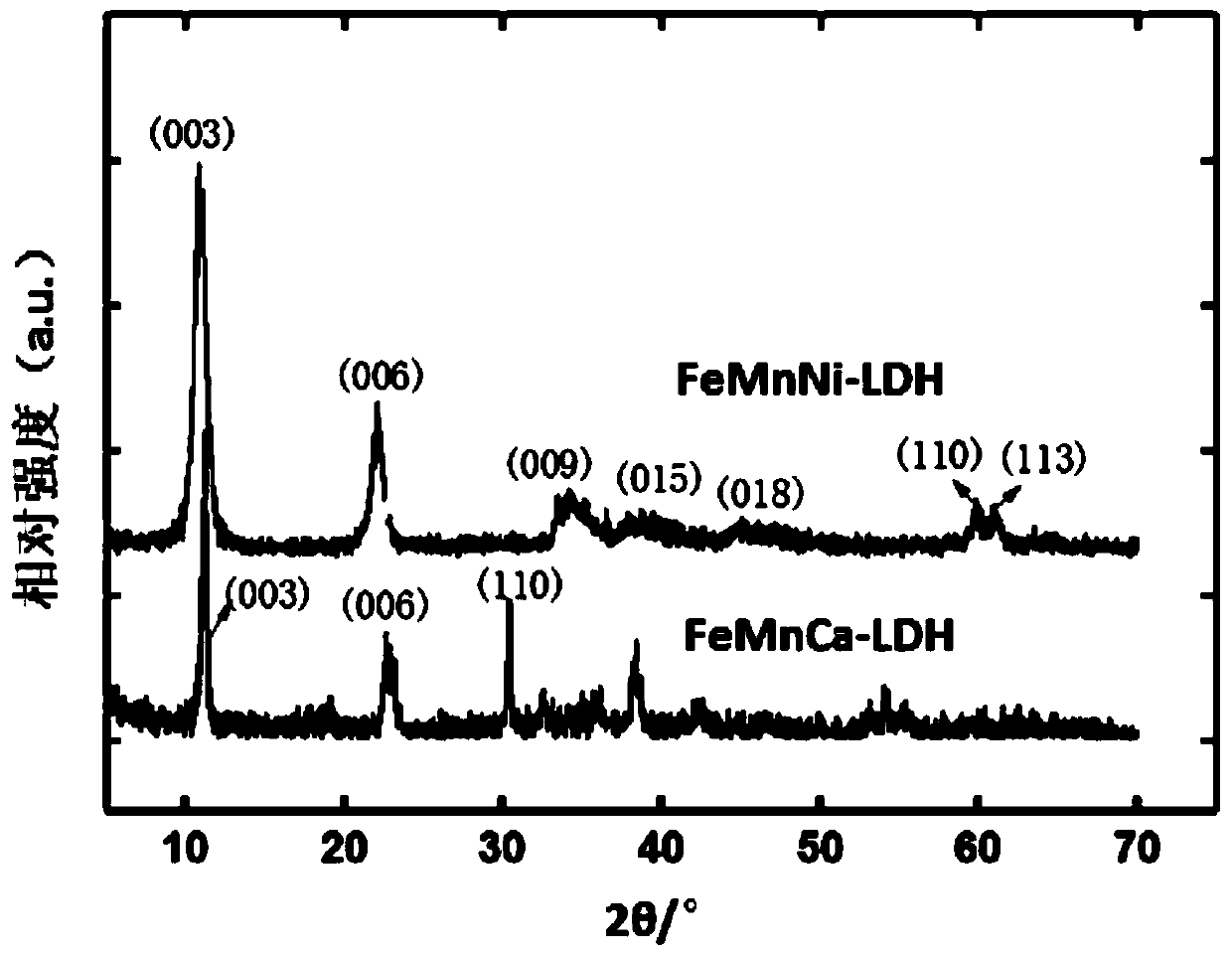

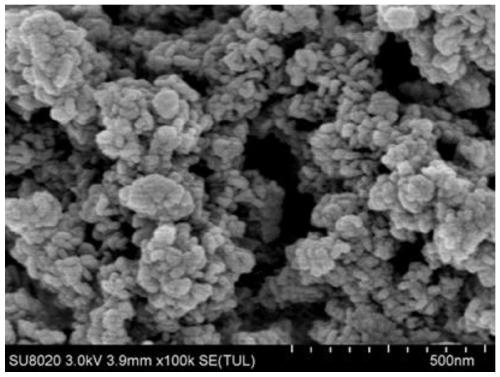

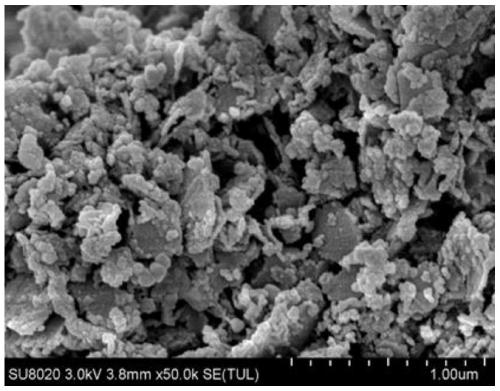

[0037] A kind of trimetal layered double hydroxide, has the nano-layered structure of double hydroxide, and general molecular formula is FeMnM-LDH, and wherein M is metal Ca or metal Ni, and wherein, the molar ratio of Fe, Mn and M is 1:1:2.

[0038] Preparation:

[0039] FeCl 3 ·6H 2 O, MnCl 2 4H 2 O and NiCl 2 ·6H 2 O according to Fe 3+ :Mn 2+ : Ni 2+ =1:1:2 was dissolved in 50mL of anaerobic water to prepare a metal ion salt mixed solution, wherein the total concentration of metal ions was 2mol / L; The pH was adjusted to 10 with NaOH. The entire apparatus was placed in a 60°C water bath. Under mechanical stirring and a nitrogen atmosphere, the metal ion salt mixed solution was added dropwise to the three-necked flask at a rate of 0.5 mL / min, and mechanical stirring was used to keep the pH of the solution at 10-13 throughout the process. After the dropwise addition was completed, continue to feed nitrogen into the forward three-necked flask, and continue stirring ...

Embodiment 2

[0050] Add 0.05g of FeMnNi-LDH and FeMnCa-LDH prepared in Example 1 into 50mL of 50mg / L Cd(II) solution respectively, the solution pH=5.5, shake at room temperature for 4h to reach adsorption equilibrium. The concentration of the solution was measured by ICP-OES, and the results showed that the concentration of Cd(II) decreased to 5.46mg / L after being adsorbed by FeMnNi-LDH, and the adsorption rate reached 89.08%; after being adsorbed by FeMnCa-LDH, the concentration of Cd(II) decreased to 0.78mg / L, the adsorption rate reaches 98.44%.

Embodiment 3

[0052] Add 0.05g of FeMnNi-LDH and FeMnCa-LDH prepared in Example 1 into 50mL of 50mg / L As(Ⅲ) solution respectively, the solution pH=5.5, shake at room temperature for 4h to reach adsorption equilibrium. The concentration of the solution was measured by ICP-OES, and the results showed that the concentration of As(Ⅲ) was reduced to 1.85 mg / L after being adsorbed by FeMnNi-LDH, and the adsorption rate was 96.3%; the concentration of As(Ⅲ) was reduced to 0.89mg / L, the adsorption rate reached 98.22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adsorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com