Coal quality-improving method free of waste water discharge

A technology for improving coal quality without waste water, applied in special forms of dry distillation, petroleum industry, solid fuel, etc., can solve the problems of increasing waste water treatment measures, incomplete utilization of process gas, etc., and achieve the effect of process economical saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

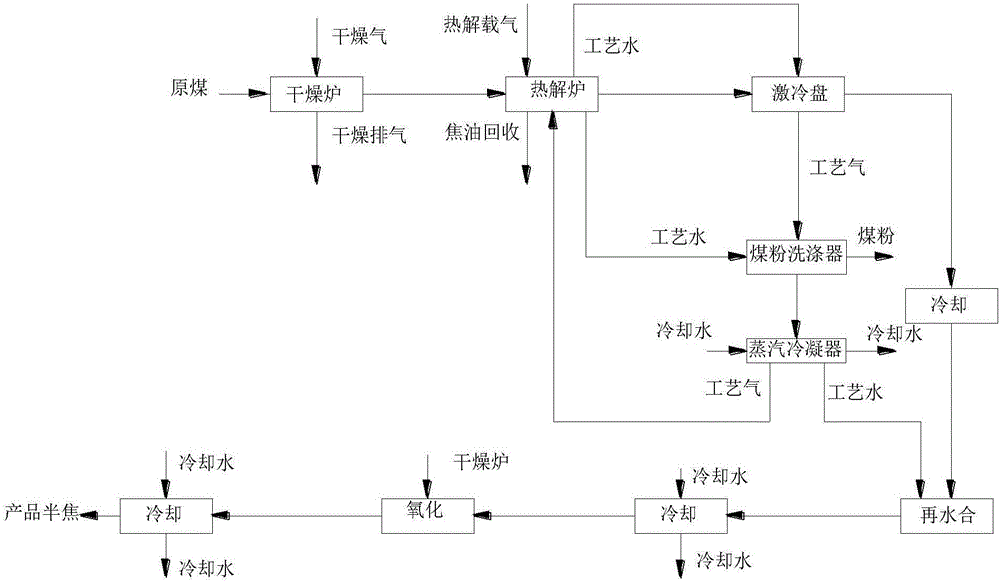

[0026] In order to better understand the purpose, structure and function of the present invention, a coal upgrading method without wastewater discharge of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, it shows the coal upgrading method without wastewater discharge of the present invention, which is used to dry and pyrolyze low-rank coal to remove moisture and hydrocarbons in low-rank coal, including the following steps: drying step, by The hot air in the drying furnace convectively heats and dries the raw coal, removes moisture, and obtains dry coal; the pyrolysis step enters the pyrolysis furnace to perform pyrolysis treatment on the dry coal to form high-temperature semi-coke, and collects the process water produced by pyrolysis In the quenching step, the process water collected in the pyrolysis step can be used to quench the semi-coke in the chilling plate, and the quenching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com