Novel suspended type permanent magnetism velocity modulation electric engine structure

A technology of permanent magnet speed regulation and motor structure, applied in the electromechanical field, can solve the problems of belt winding safety hazards, reduced response speed, low transmission efficiency, etc., and achieve the effects of shortening the length of the main shaft, easy implementation, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

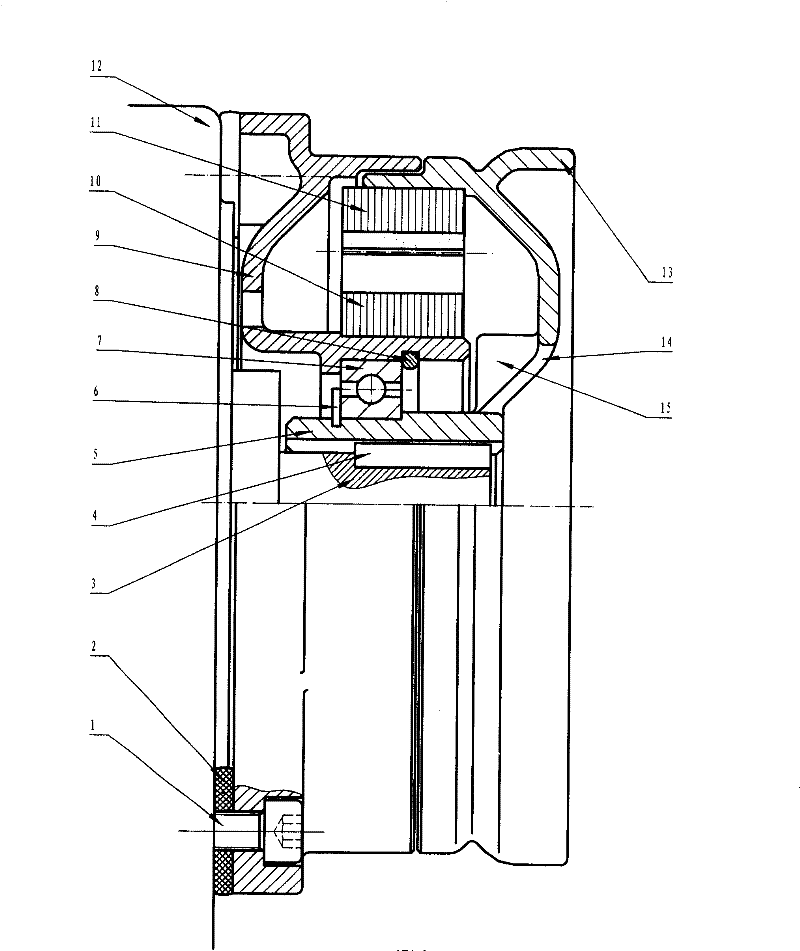

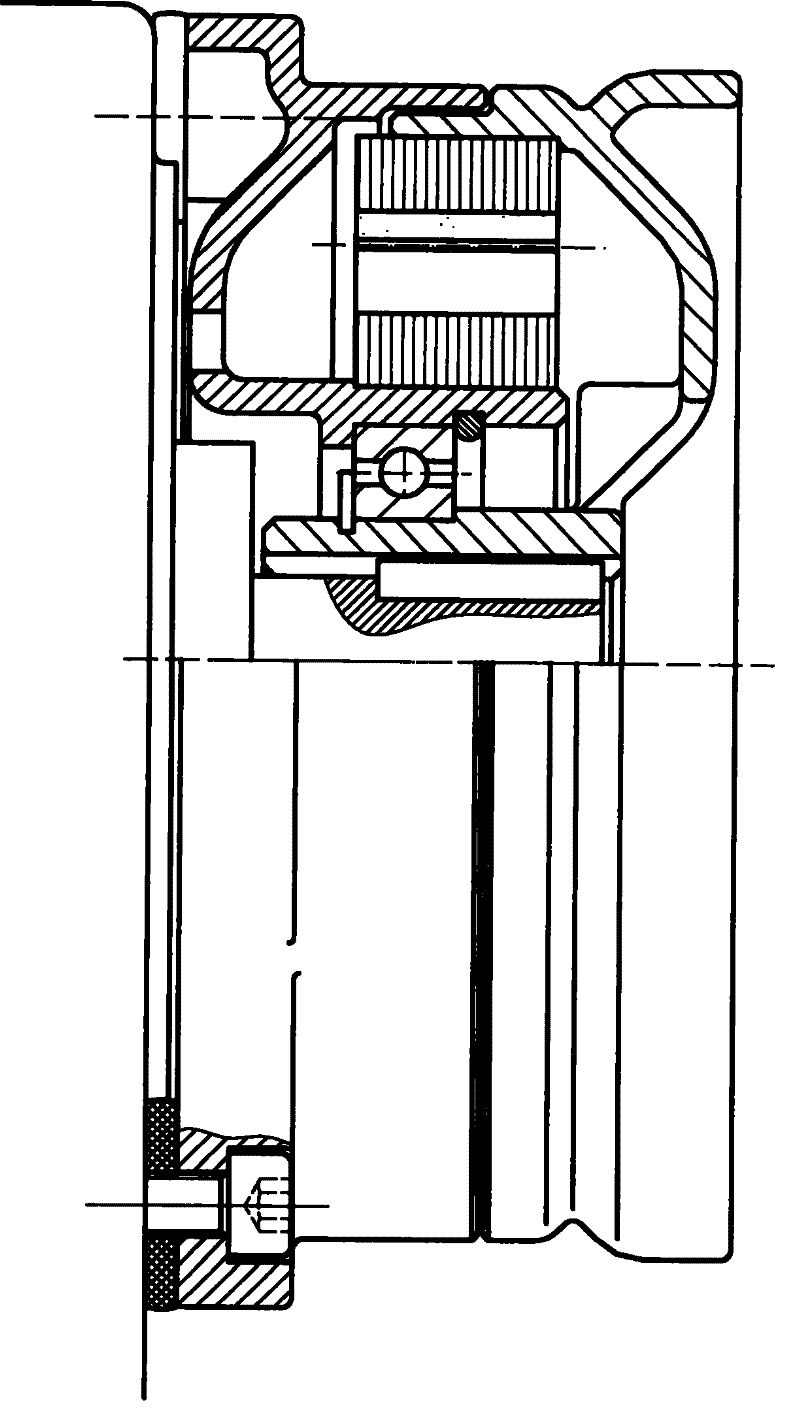

[0023] Example: A new suspension type electric sewing machine cup-shaped permanent magnet motor structure

[0024] refer to figure 1 , its basic structure is similar to that of an ordinary external rotor motor, consisting of a stator (9), a stator core (10), a rotor (5), a rotor core or a yoke (11), a permanent magnet, and a bearing (7). In terms of mechanical structure, the biggest difference from the traditional motor is: the rotor has no shaft, the shaft is borrowed from the sewing machine shaft (3), and there is only one bearing, which is also borrowed from the sewing machine, so the motor is not guaranteed to work well before it is installed on the sewing machine It may need a special tooling for motor debugging and testing.

[0025] The shape of the rotor (5) is special, and there is a sleeve part, which can be inserted into the sewing machine shaft (3), and the torque is transmitted by the key (4); Consider, rotor right inner side is also designed with ventilation hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com