High-silicon high-aluminium ferrite stainless steel and its application in preparation of heat-resisting steel pipe

A high-alumina iron and stainless steel technology, applied to high-silicon, high-alumina ferritic stainless steel and its application in the preparation of heat-resistant steel pipes, ferritic stainless steel and its application in rolling heat-resistant steel pipes, can Solve the problems of surface peeling, poor stress corrosion resistance, difficult to process seamless steel pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

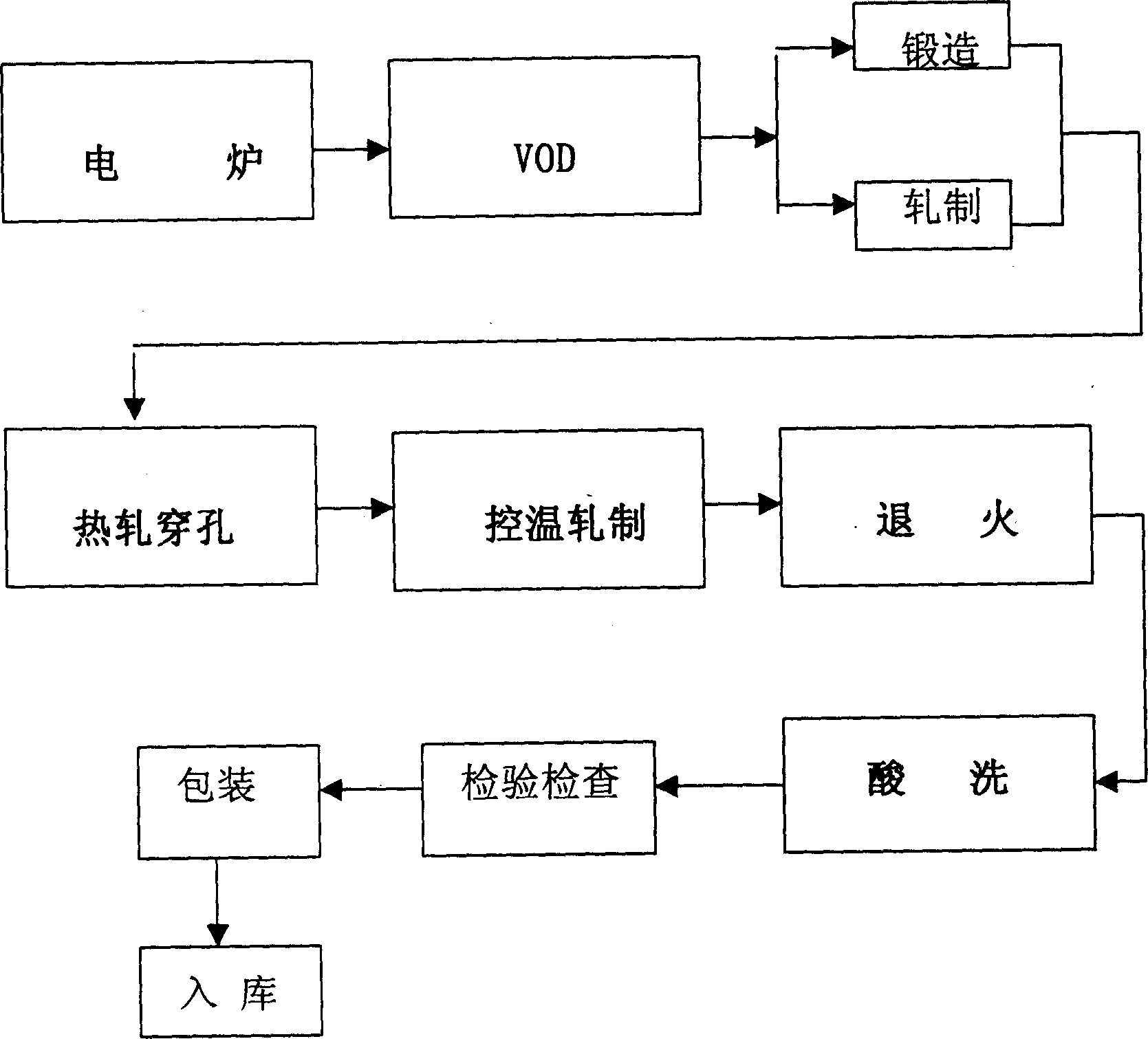

[0030] The invention is a ferritic stainless steel containing high silicon and high aluminum, which is processed into a seamless steel pipe by a temperature control method. High silicon and high aluminum elements are added to Cr18 ferritic stainless steel to improve the high temperature oxidation resistance of the steel, and it has good corrosion resistance in the environment of chloride ions, sulfur and hydrogen sulfide. The trace element titanium (niobium) is added to refine the grains of the steel. Due to the content of silicon and aluminum in the steel, it brings great difficulties to the tube-making process. In order to solve this problem, temperature-controlled processing without The method of sewing steel pipes. Compared with 18-8 type austenitic stainless steel pipe, this material has excellent resistance to stress corrosion cracking. At high temperature, it not only has superior oxidation resistance, but also has superior resistance to sulfur and hydrogen sulfide envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com