Carbon-ceramic heating tube and processing method

A carbon ceramic heating tube and heating tube technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of low electric-thermal conversion efficiency, short life, difficult to guarantee input power, etc., to reduce moisture absorption and improve conversion efficiency High, low thermal inertia effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

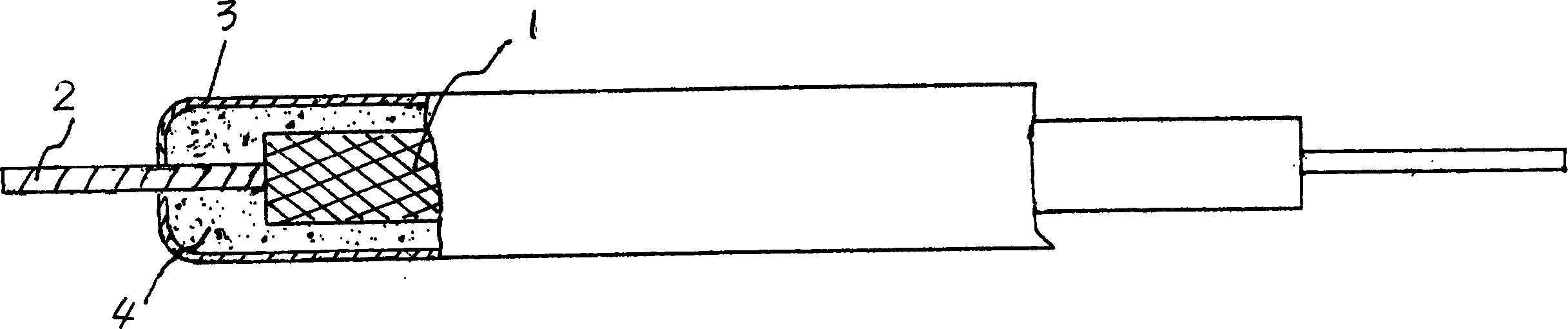

[0028] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 As shown: there is a carbon ceramic heating base 1, and electrode lead rods 2 are connected to both ends of the carbon ceramic heating base 1. The carbon ceramic heating base 1 is covered with a protective tube 3, and the space between the carbon ceramic heating base 1 and the protective tube 3 is filled. There are insulating and heat-conducting powder4.

[0029] The specific processing method is:

[0030] a. Mix carbon powder, non-oxide ceramic powder, alloy oxide, and infrared radiation powder in a volume ratio of 5-8:0.5-1.5:0.5-1.5:0.5-1.5, stir evenly, and process it into carbon ceramics by chemical curing The two ends of the heating substrate 1 should be fixed with the electrode lead-out rod 2 . The particle size of carbon powder, non-oxide ceramic powder, alloy oxide and infrared radiation powder should be less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com