Hard coating and its production method

A protective film, hard technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problem of not meeting the lubricity requirements of dry cutting conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1, comparative example 1

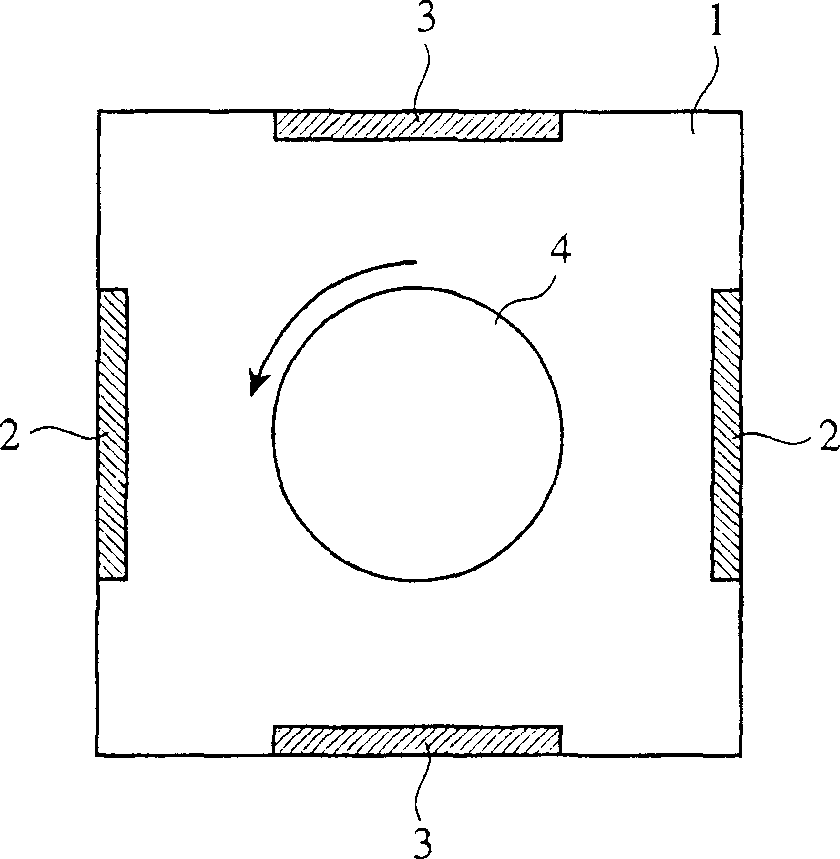

[0067] In Example 1, such as figure 1 As shown, a hard protective film was formed on a cemented carbide insert substrate mounted on a rotary table 4 using a small vacuum device 1 including an AIP target 2 and an MS target 3 as an evaporation source. Both AIP target 2 and MS target 3 use TiAl alloy. Use N 2 gas as a reactive gas. The pressure of the reaction gas was set to 3.0 Pa, and plasma was generated simultaneously by the AIP method and the MS method. The substrate temperature was set to 400°C, and the bias voltage was set to -40V to -150V. In addition, in Comparative Example 1, a hard film was formed on the insert under the same conditions as in Example 1 except that only the AIP method was used.

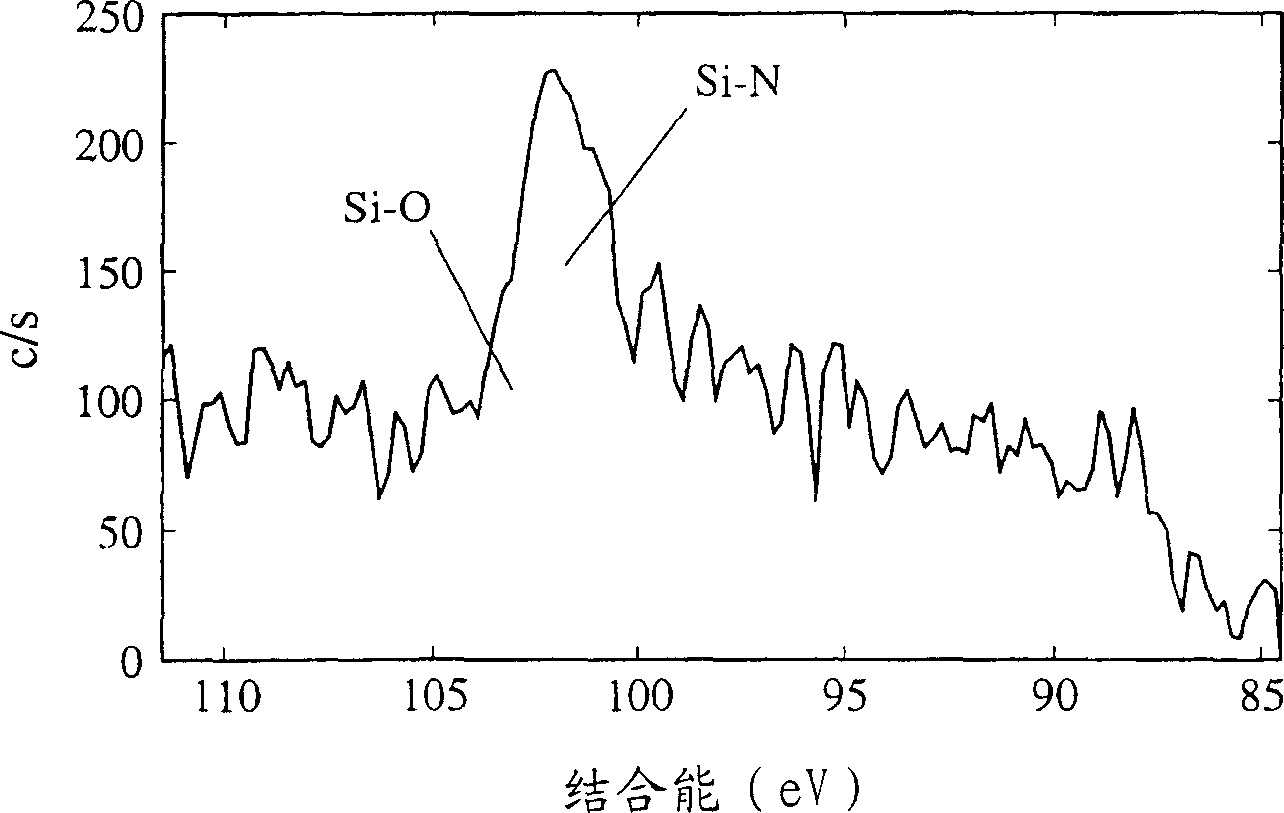

[0068] The (TiAl)N hard film obtained in Example 1 has high toughness, and also has a multilayer structure composed of layer 21 obtained by the AIP method and layer 22 obtained by the MS method. In this multilayer structure, cr...

Embodiment 2~15

[0069] Examples 2-15, Comparative Examples 2-14 and Conventional Examples 1-5

[0070] In Examples 2-15, such as figure 1 As shown, a hard protective film was formed on a cemented carbide insert substrate mounted on a rotary table 4 using a small vacuum device 1 including an AIP target 2 and an MS target 3 as an evaporation source. As shown in Table 1, the AIP target 2 is an alloy of various compositions, and the MS target 3 is a metal silicide. Reactive gas is used in an appropriate combination of N and N according to the composition of the target hard film. 2 Gas, CH 4 Gas and Ar / O 2 One or two or more of the mixed gases. In order to make the silicon content of the hard protective film change periodically and smoothly in the lamination direction, the pressure of the reaction gas is set to 3.0 Pa, and the plasma is generated simultaneously by two film-forming methods of the AIP method and the MS method. The discharge power of the MS target 3 in each Example and Comparati...

Embodiment 15

[0117] A hard protective film was formed on the insert in the same manner as in Example 14, except that oxygen was not added to the reaction gas. The structure of the obtained hard film was columnar, the lattice bands were continuous, and the average thickness of one layer was 33.6 nm. In addition, the Si content in the hard film is 6.3 atomic %, and Si A 10.7 at%, Si B 1.9 at%, with a difference in Si content, but no Si-O bond. Therefore, the cutting distance is 19.4m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com