Patents

Literature

45results about How to "Solve serious corrosion problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical stripping solution and stripping method

InactiveCN103924245AEasy to recycleSolve serious corrosion problemsOrganic compoundHydrogen peroxide

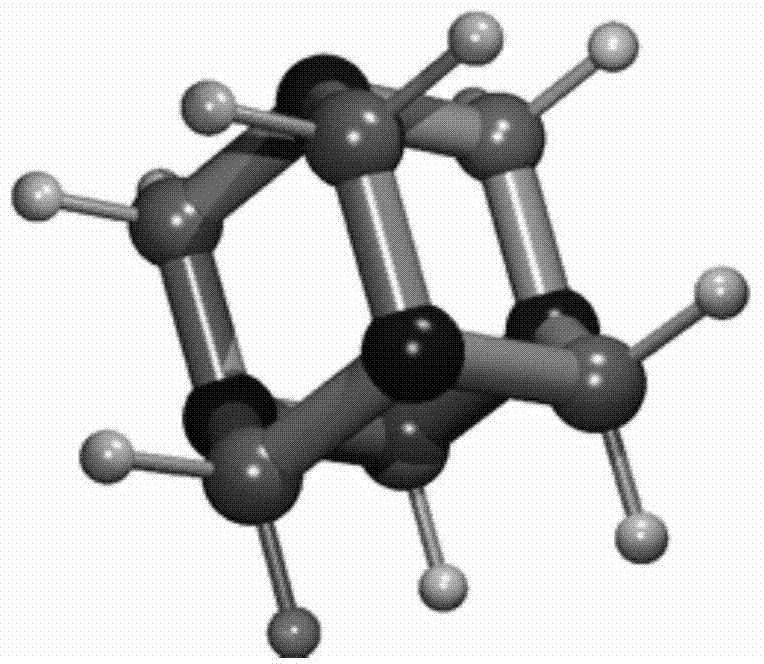

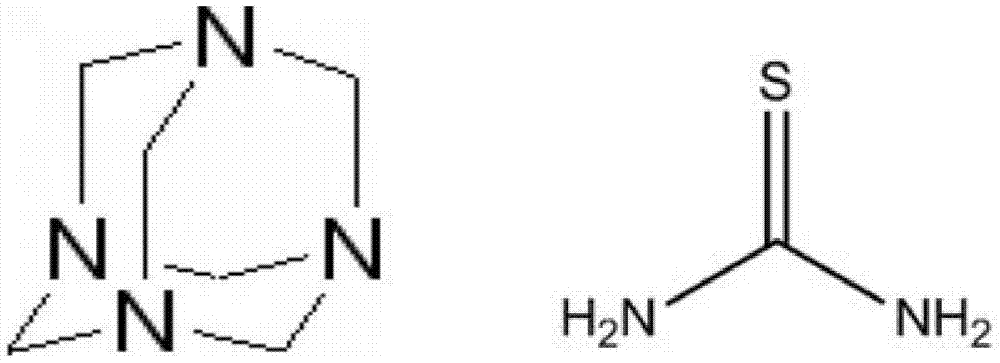

The invention provides a chemical stripping solution and a stripping method, belonging to the technical field of stripping. The chemical stripping solution comprises sulfuric acid, hydrogen peroxide and a water solution of corrosion inhibitors, wherein the corrosion inhibitors are organic matters containing nitrogen or sulfur and the like or are high-polarity organic compounds containing -COOR, -COOH, -CHO, triple bonds (Cis equivalent toC) or poly-hydroxy-OH and the like. The stripping solution has high stripping speed and can strip nickel and copper plated layers with thickness of 0.2mm within two minutes at an appropriate temperature.

Owner:BEIJING UNIV OF TECH

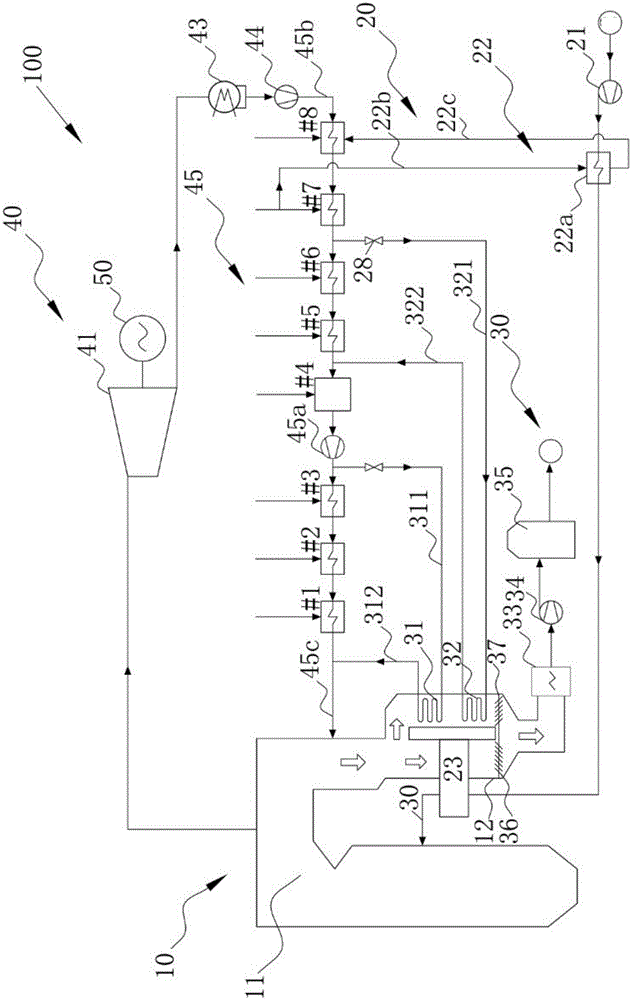

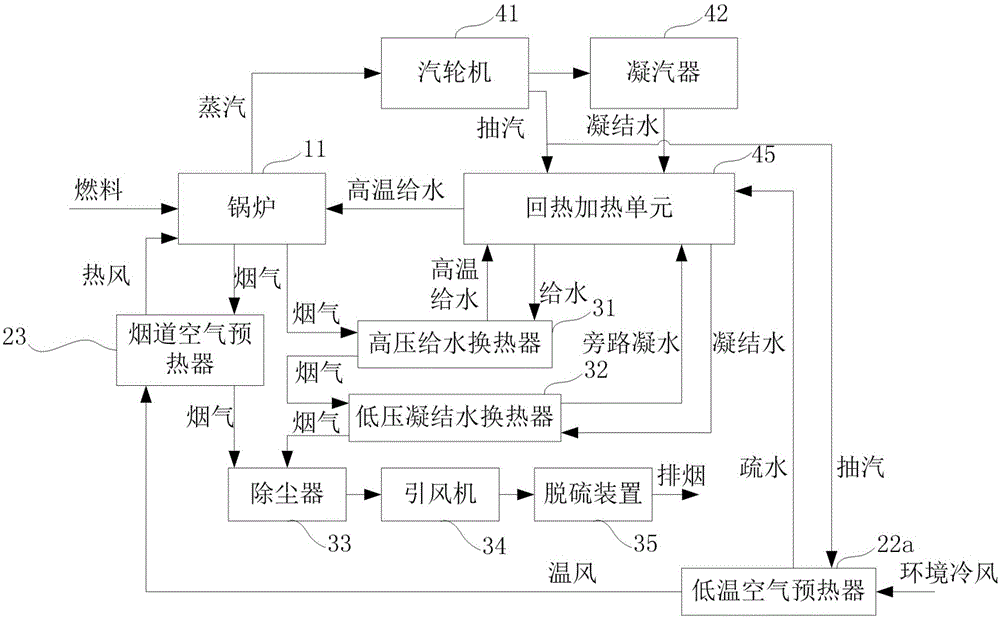

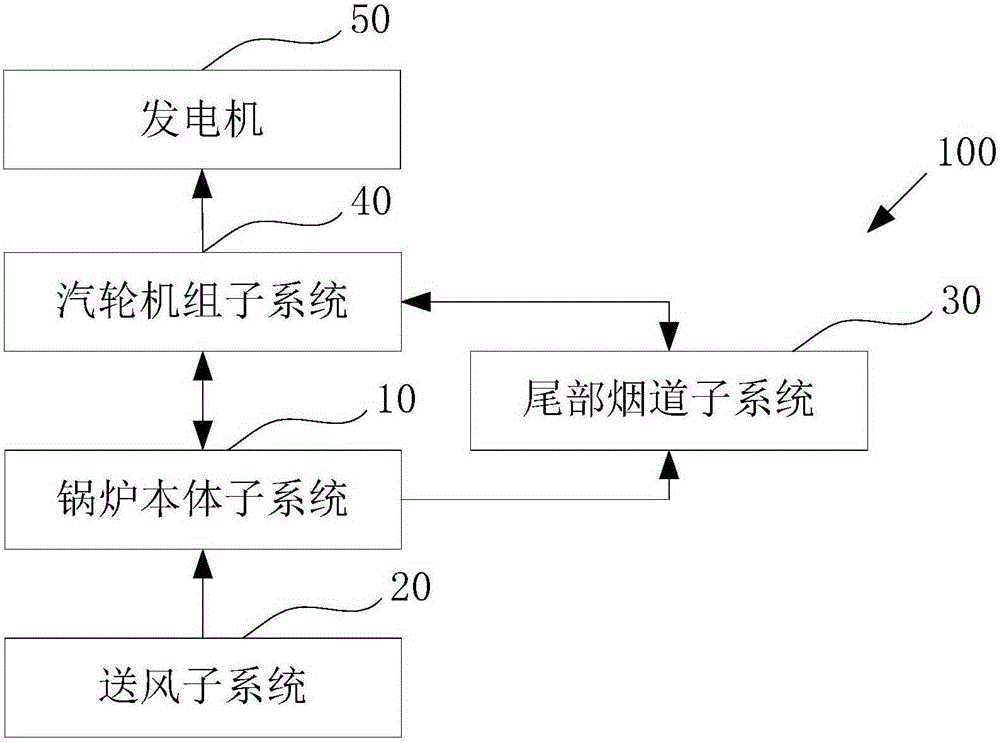

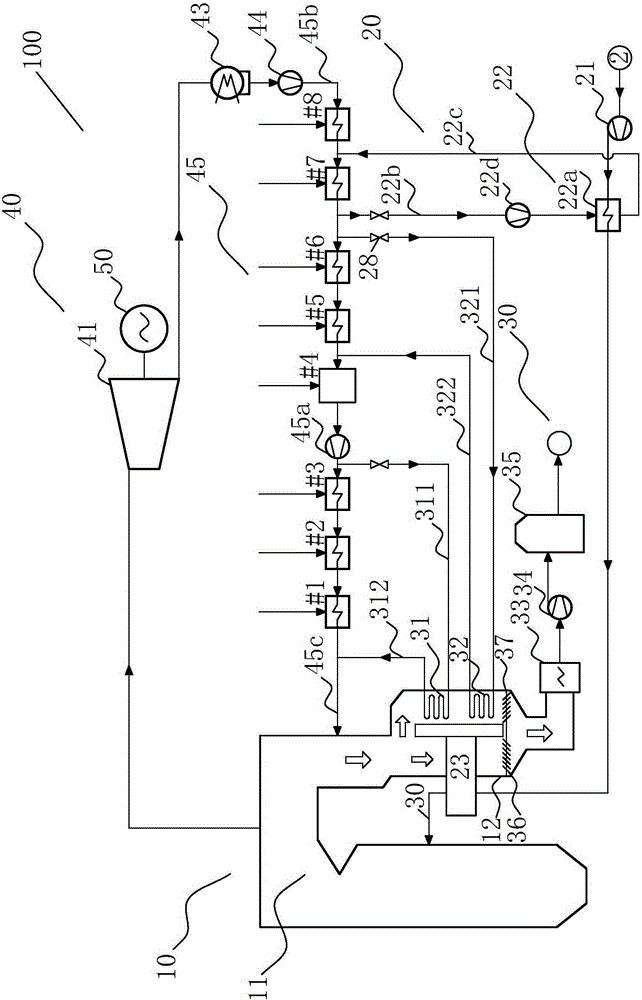

Coal-fired power generation system based on bypass flue at tail part of boiler

InactiveCN105157010ASolve the outstanding problem of severe low temperature corrosion on the heating surfaceImprove power supply efficiencySteam useFeed-water heatersAir preheaterCold air

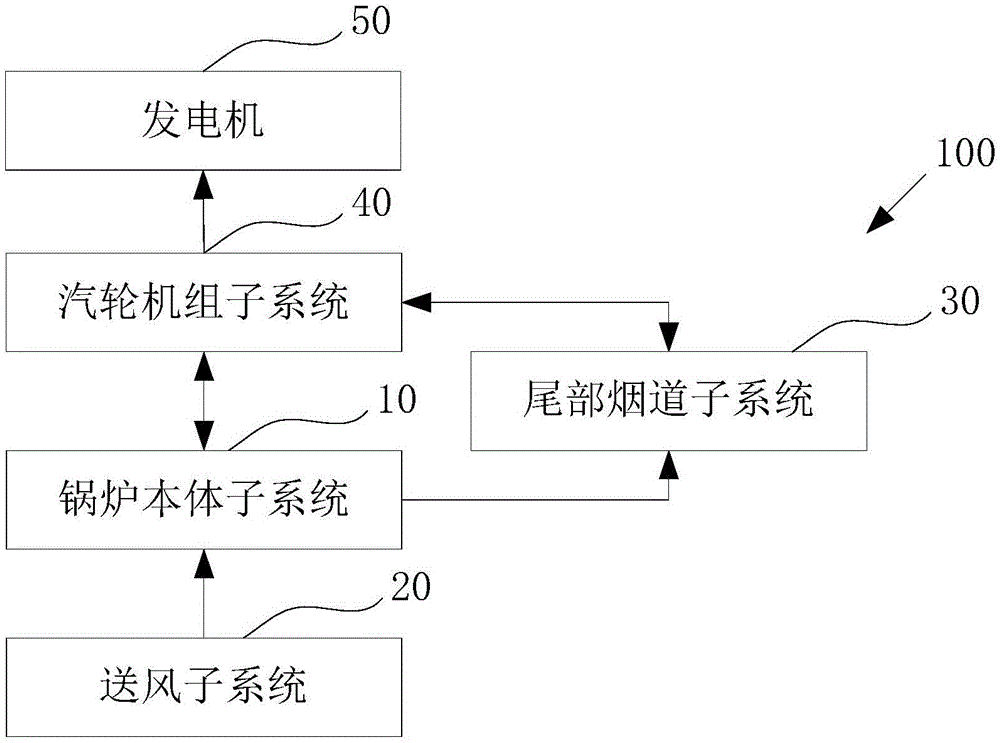

The invention provides a coal-fired power generation system based on a bypass flue at the tail part of a boiler as well as warm air obtained through steam extraction. The coal-fired power generation system adopts fuel to heat feed water so as to generate power, and is characterized by comprising a boiler body subsystem, an air supply subsystem, a tail flue subsystem, a turboset subsystem and a generator, wherein the boiler body subsystem comprises the boiler and a boiler flue, the boiler is provided with a hearth, and the boiler flue is connected with an outlet of the hearth and divided into a main flue and the bypass flue; the air supply subsystem comprises an air feeder, a front air preheater and a flue air preheater, the air feeder is used for supplying environment cold air, the front air preheater is connected with the air feeder and used for preheating the environment cold air to obtain warm air, and the flue air preheater is arranged in the main flue and used for heating the warm air; the tail flue subsystem comprises a high-pressure feed water heat exchanger and a low-pressure condensed water heat exchanger, the high-pressure feed water heat exchanger is arranged in the bypass flue and close to an inlet of the bypass flue, and the low-pressure condensed water heat exchanger is arranged in the bypass flue and close to an outlet of the bypass flue.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

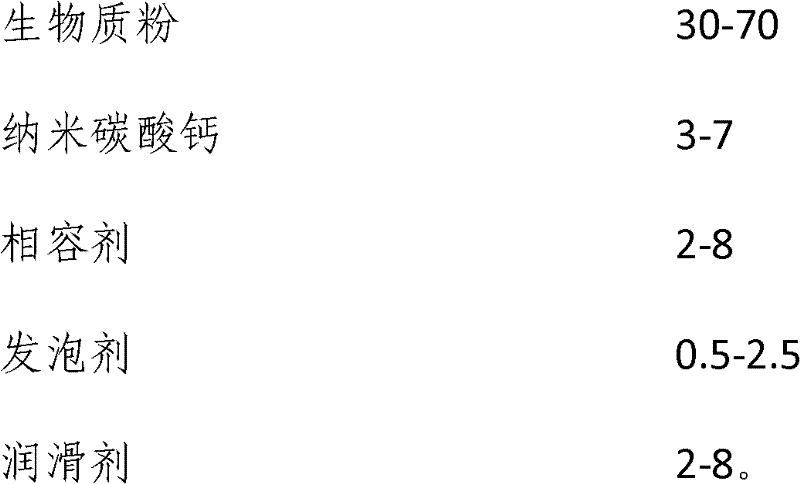

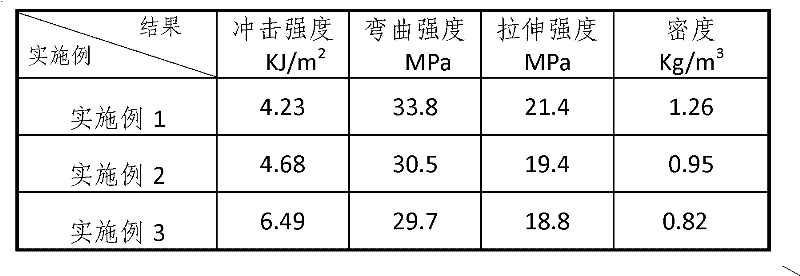

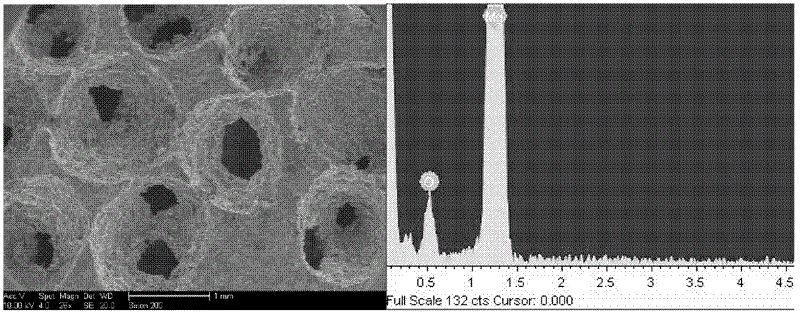

Polypropylene-based microcellular foaming wood-plastic composite material and production method thereof

ActiveCN102516666ASolve serious corrosion problemsLow densityLow-density polyethyleneProcedure Agents

The invention provides a polypropylene-based microcellular foaming wood-plastic composite material and a production method thereof, belonging to the technical field of a wood-plastic composite material. The polypropylene-based microcellular foaming wood-plastic composite material is characterized by being prepared from the following raw materials in parts by weight: 70 parts of polypropylene, 30 parts of low-density polyethylene, 30-70 parts of biomass powder, 3-7 parts of nanometer calcium carbonate, 2-8 parts of compatilizer, 0.5-2.5 parts of foaming agent and 2-8 parts of lubricant. The problem of severe corrosion of a material cylinder and a screw of an extruder can be effectively solved by adjusting the ingredient formula of the property components and the processing agents, so that the service life of the extruder is prolonged. Furthermore, the continuous and uniform microcellular foaming wood-plastic composite material is obtained, the material density is reduced, and the application range of the material is enlarged. Therefore, the biomass powder is widely recycled, the waste material is recycled, and the environment is protected.

Owner:SHANDONG UNIV OF TECH

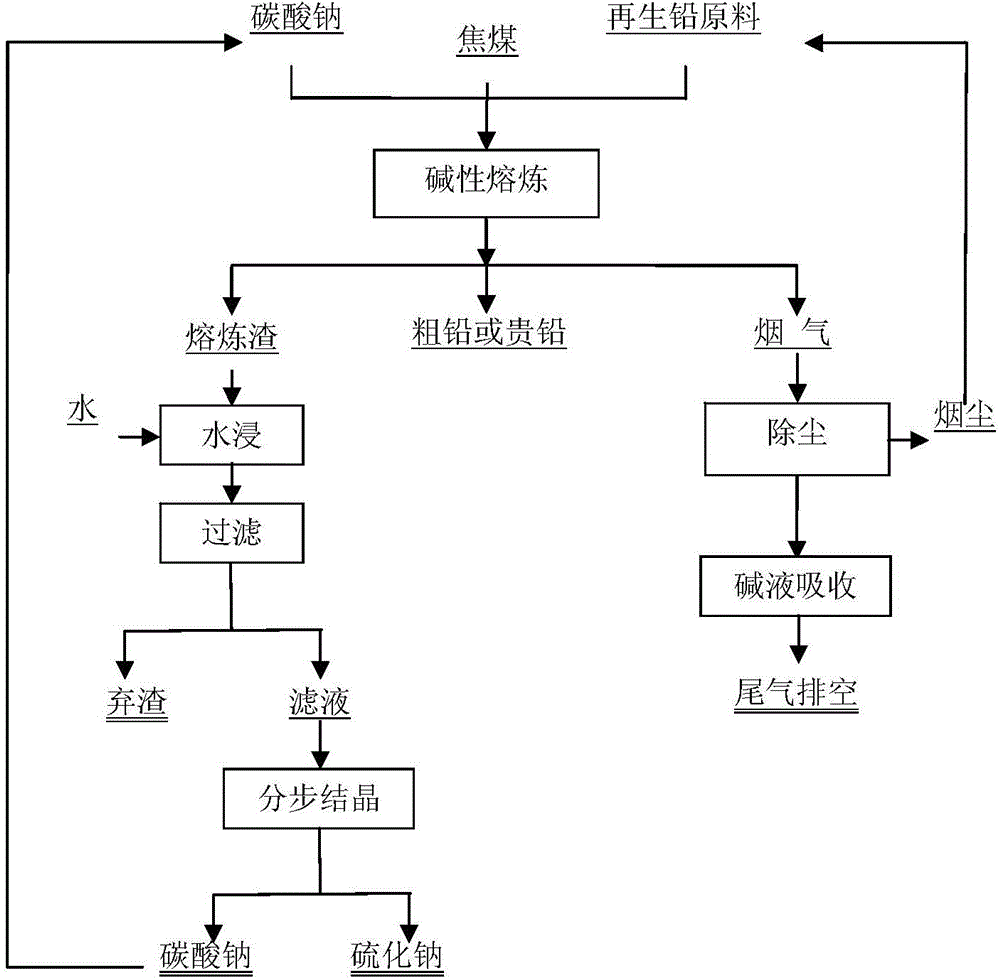

Method for low-temperature smelting of regenerated lead

InactiveCN104451161ASolve serious corrosion problemsExtended service lifeProcess efficiency improvementSlagMaterials science

The invention relates to a method for low-temperature smelting of regenerated lead and belongs to the technical field of preparation of regenerated lead. According to the method provided by the invention, an alkaline environment is provided by sodium carbonate, regenerated lead raw material and / or lead ore powder are / is taken as a lead source, carbon is taken as a reducing agent, alkaline smelting is performed at the temperature of 800-1100 DEG C, three products, namely crude lead or precious lead, smelting slag and smoke gas are produced, most of gold, silver and other precious metals enter crude lead or precious lead, crude lead produced by smelting is settled to the bottom for discharge, sulfur enters the smelting slag in the form of sodium sulfide, after water leaching of the smelting slag, filtrate is concentrated and crystallized in steps to obtain sodium carbonate and sodium sulfide products, and after dedusting of the smoke gas, smoke dust returns into the raw material, and waste gas can be directly discharged after being absorbed by lye. The technical scheme provided by the invention has the advantages of low energy consumption, low cost, environmental friendliness and the like, and further has significant economic benefits and social benefits.

Owner:CENT SOUTH UNIV +1

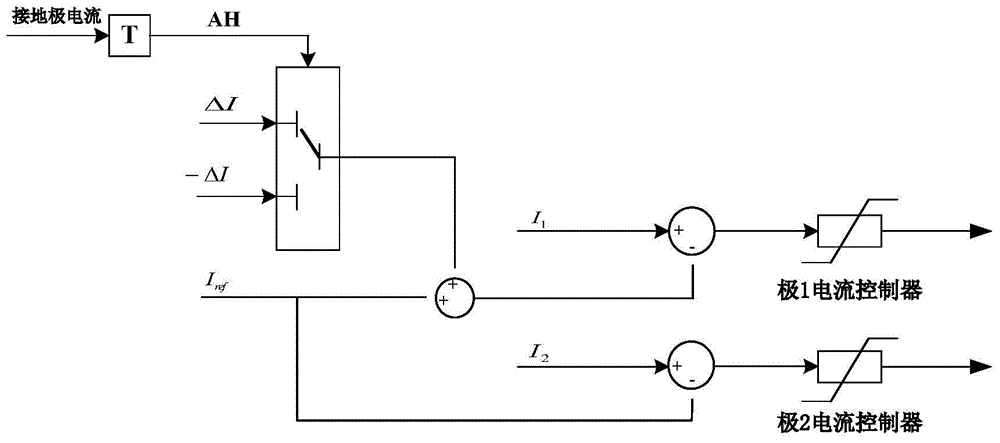

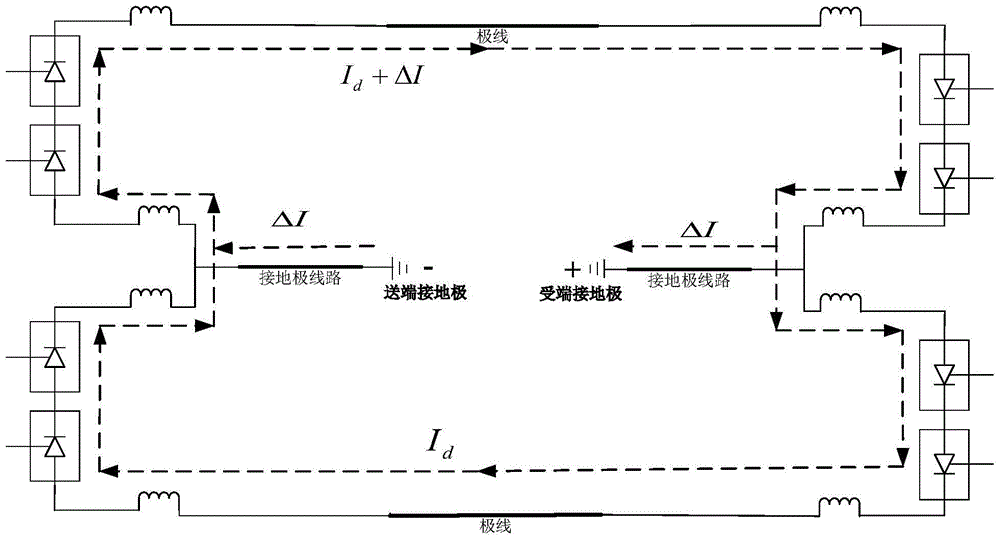

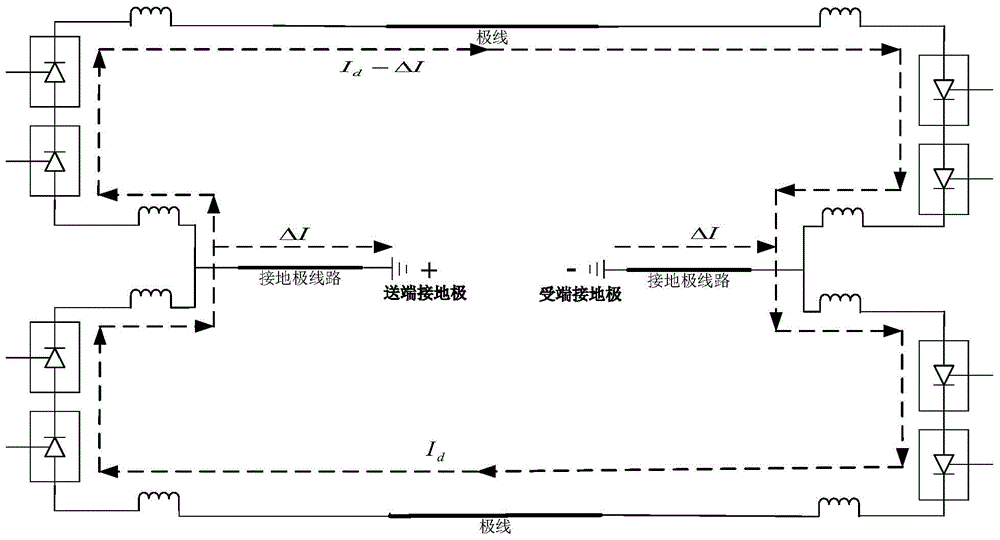

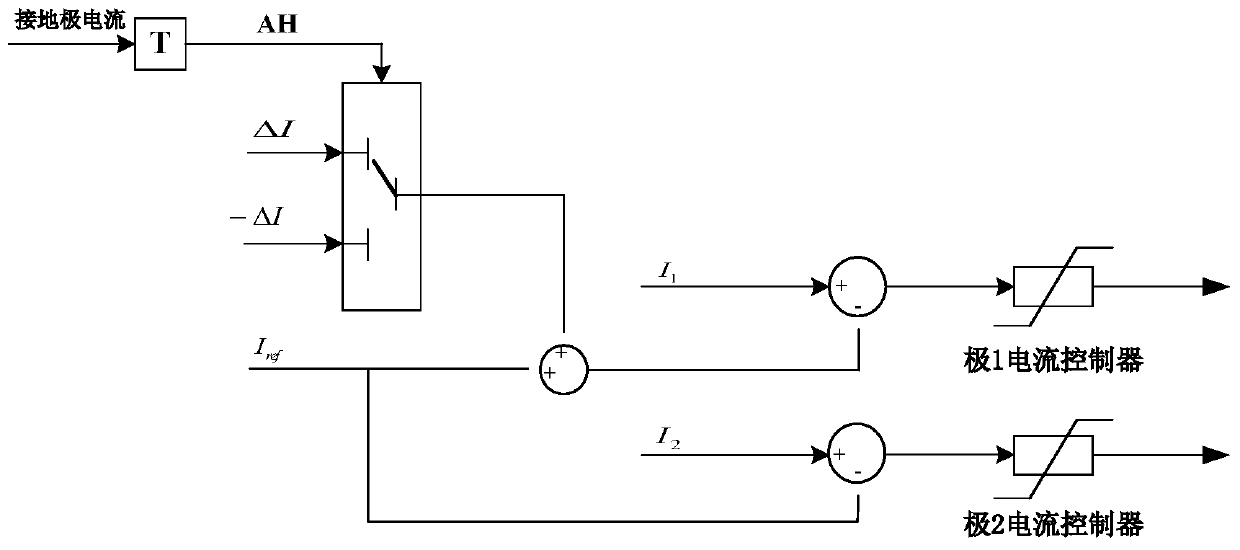

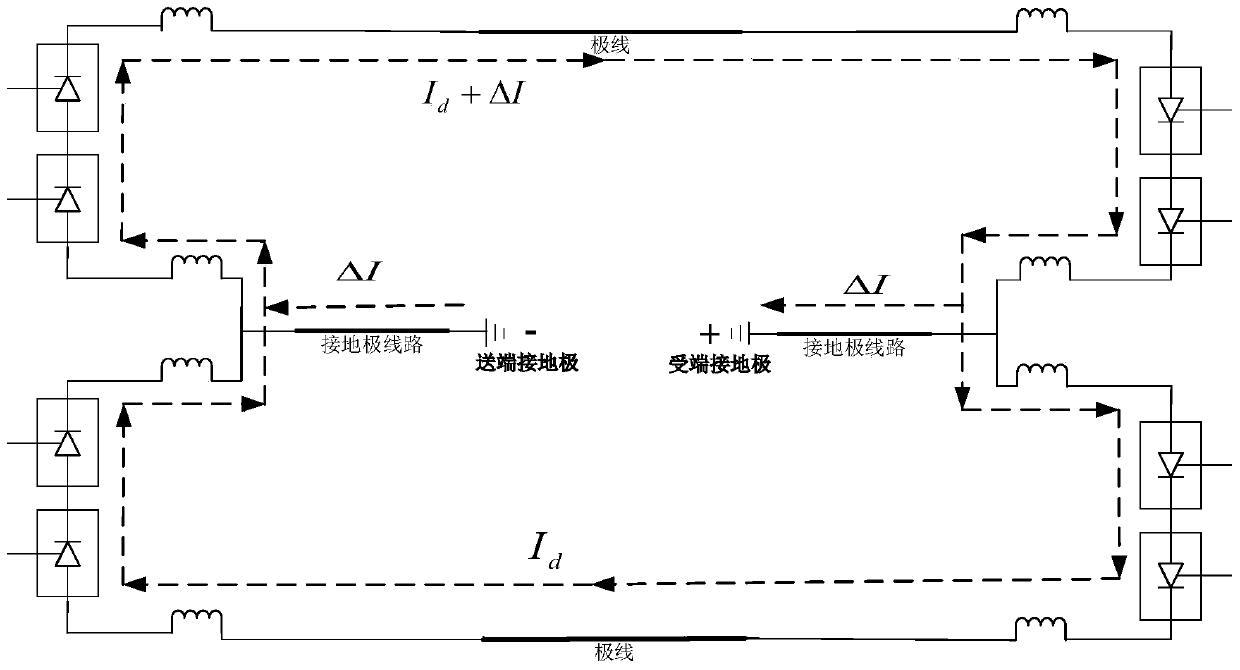

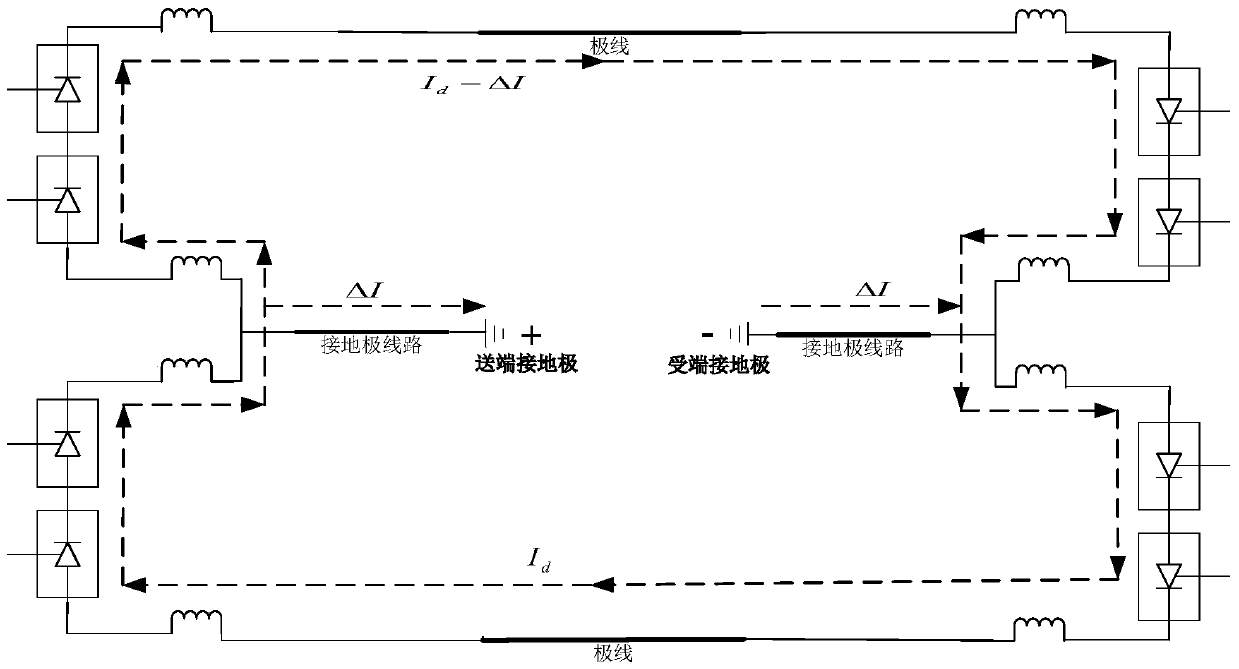

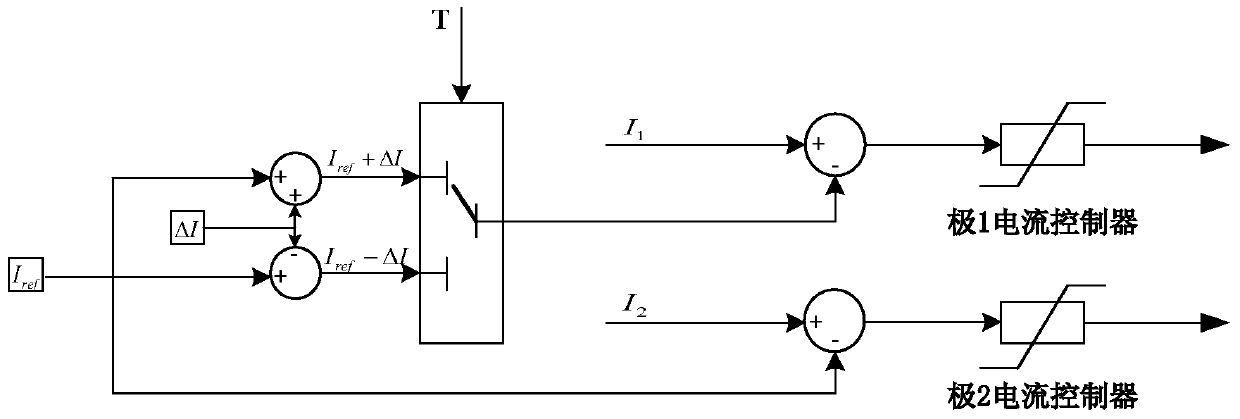

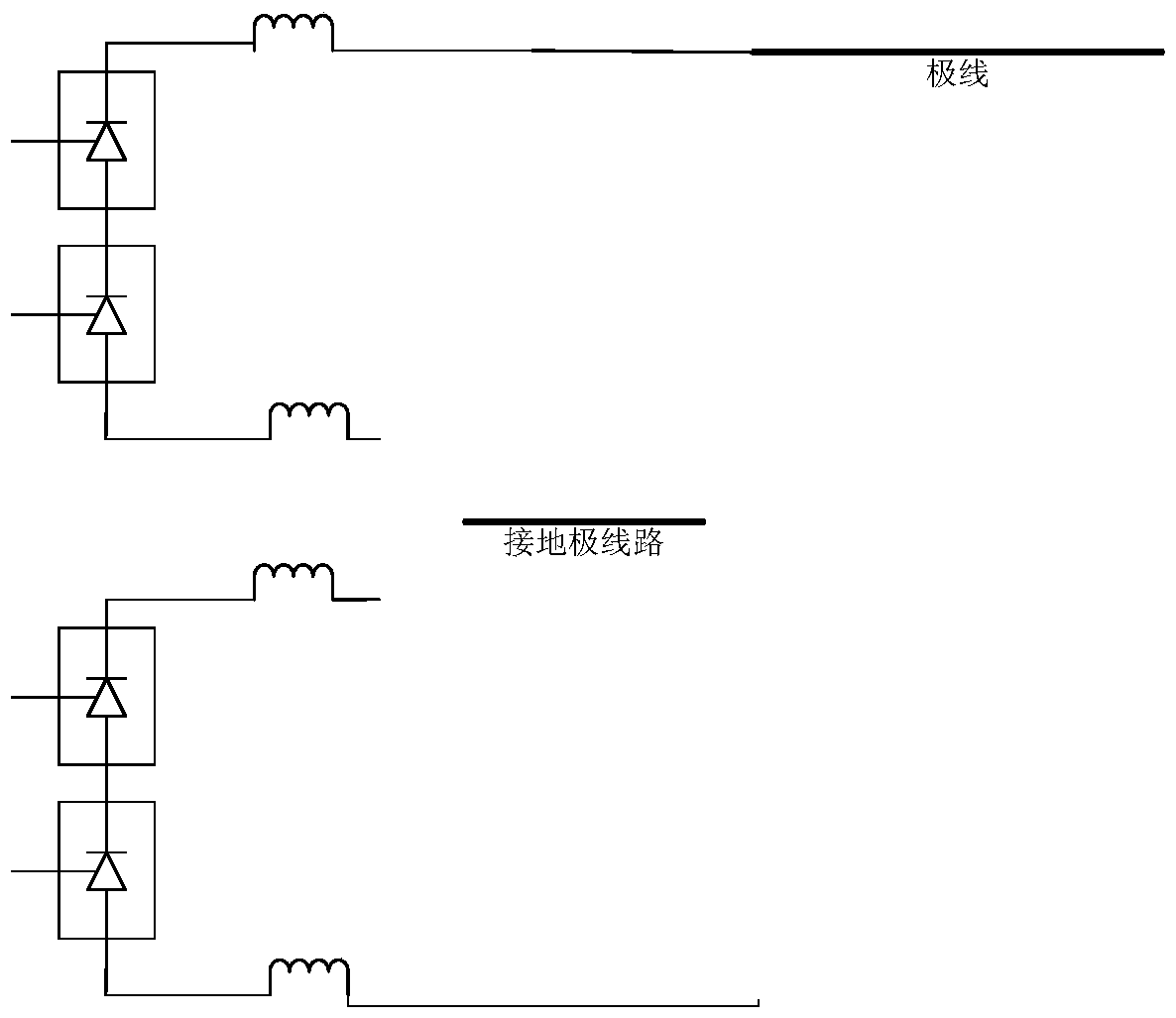

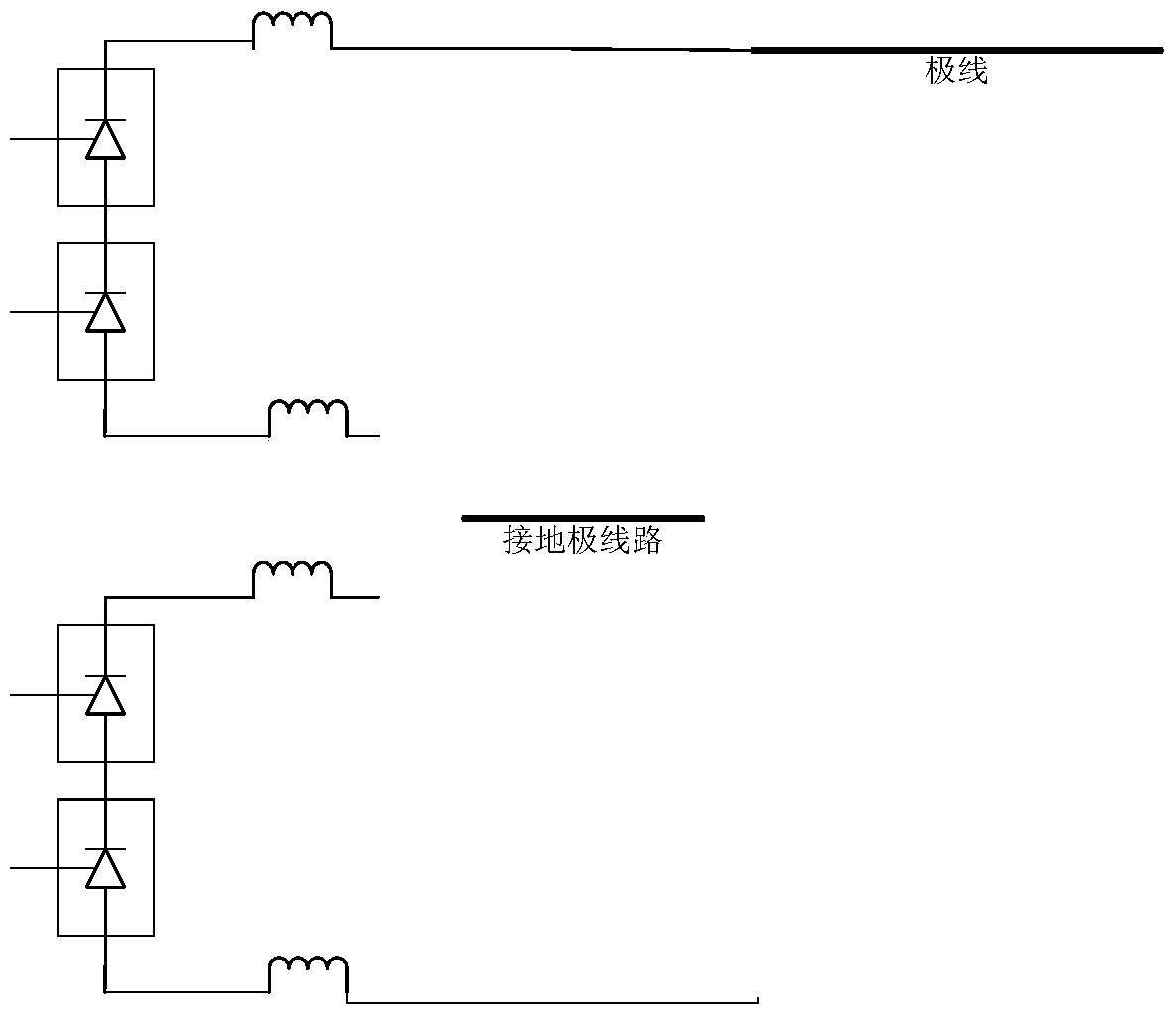

Control method for cathode protection of high-voltage direct-current transmission grounding electrodes

The invention discloses a control method for cathode protection of high-voltage direct-current transmission grounding electrodes. Improvement is performed on the basis of a direct-current transmission project constant current control manner, according to forward current detection results of the grounding electrodes, first-electrode current value deviation changes to be positive and negative alternately, alternate cathode protection of the sending end and receiving end grounding electrodes is achieved, corrosion losses of the grounding electrodes are reduced, the service life of the grounding electrodes is greatly prolonged, and the problem that the grounding electrodes are seriously corroded due to unbalanced current and the like is solved. The existing high-voltage direct-current transmission project constant current control manner is used, the manner is finely adjusted, the investment cost of a control protection system is not increased, the corrosion losses of the grounding electrodes can be greatly reduced, the service life of the grounding electrodes is prolonged, and the control method can be applied to a practical high-voltage direct-current transmission project.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

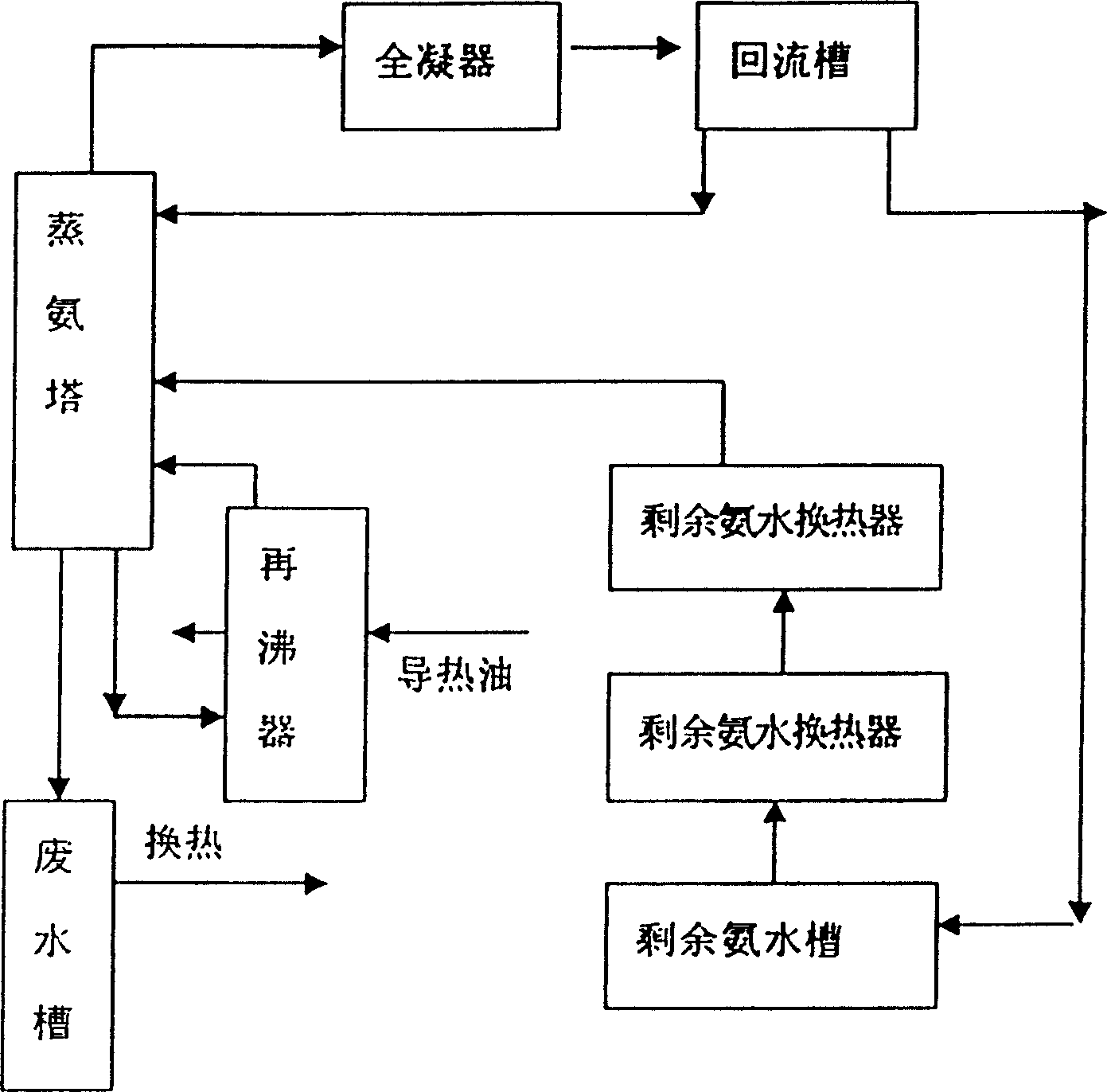

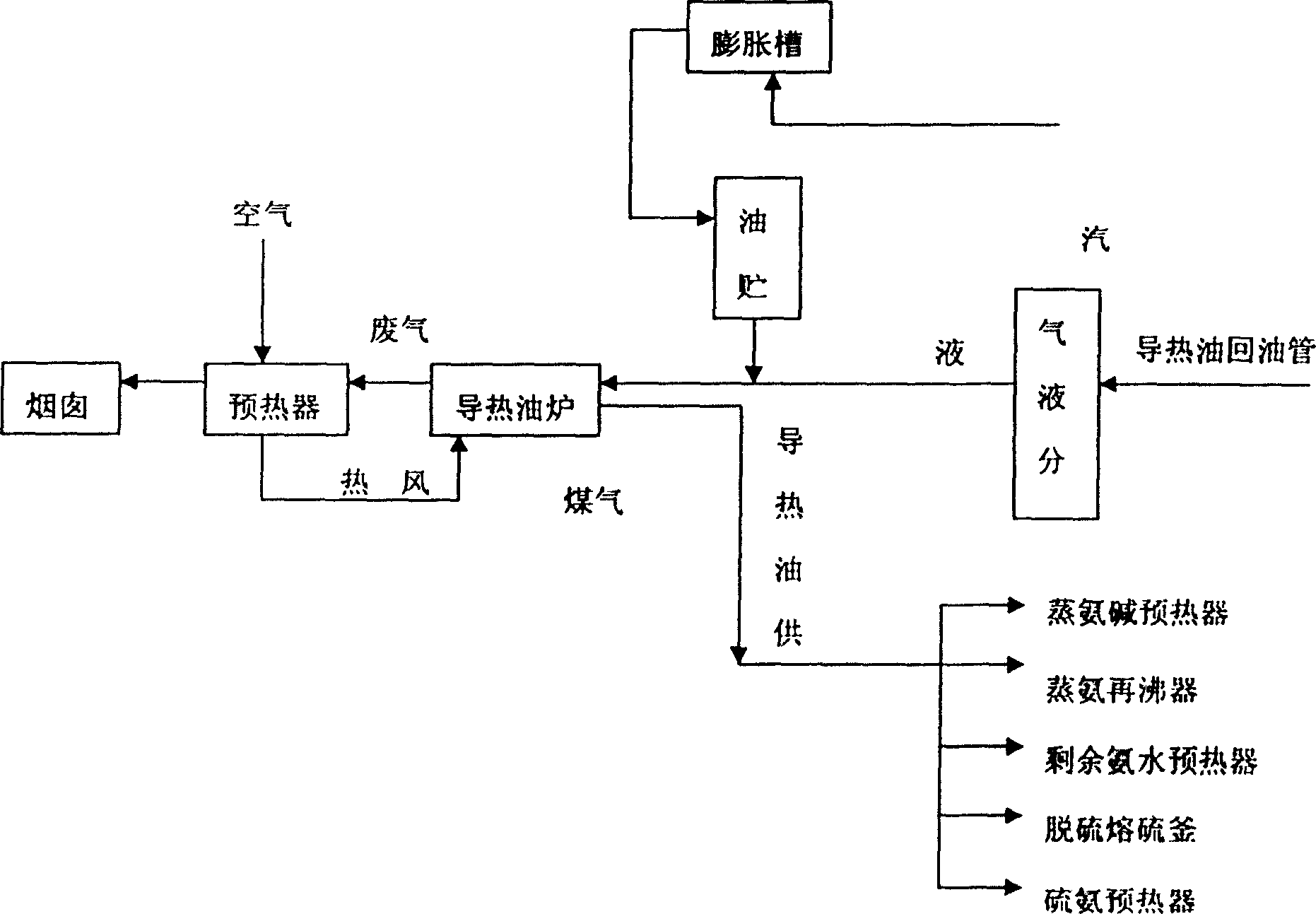

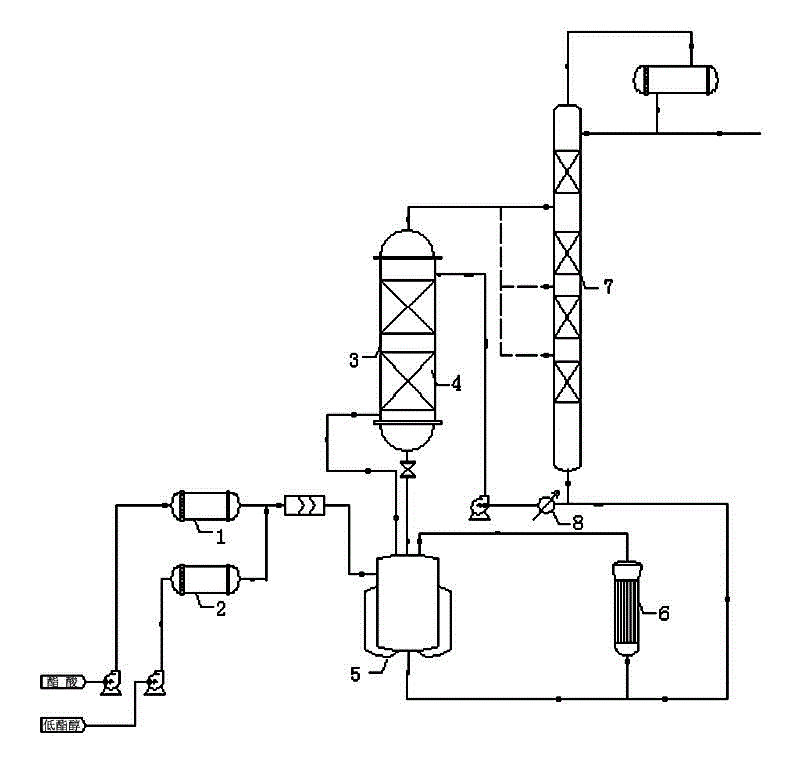

Process for treating residual ammonia water of coking

InactiveCN1631810ASolve puzzlesSolve pollutionFatty/oily/floating substances removal devicesWater/sewage treatment by heatingHeat conductingReboiler

The invention has supplied a processing technique for remained ammonia water, the remained ammonia water enters into ammonia still after heat exchange in heat exchanger, the ammonia gas enters into the condenser on the top of the tower to be cooled and flows back, its characteristics are: use the world-famous software package to do simulating optimal design, the ammonia still has multi-channel compound plate with declined holes, the hot waste water at the bottom enters into the reboiling device, the steam comes back from which to the ammonia still after being heated by heat conducting oil, for supplying heat to ammonia. The invention has advanced the conventional technique direct steam distillation technology for processing remained has stable operation, remarkable effect of energy-saving, decreasing the cost, increasing the products quality as well as the economic income, more importantly, the environmental pollution is reduced greatly by eliminating the direct steam and reducing the quantity of waste water generated.

Owner:JIGANG GRP

Anticorrosion method for slush mold

ActiveCN101294267AImprove corrosion resistanceSolve serious corrosion problemsMolten spray coatingSand blastingHot Temperature

The invention discloses a slush-molding die corrosion prevention method, which comprises the following steps: a sand-blasting technology is adopted to perform the sand-blasting cleaning treatment on the outer surface of a slush-molding die; the die is processed through preheating treatment, and the preheating temperature is between 80 DEG C and 120 DEG C; an air gun is utilized to perform the silver spraying treatment on the bottom of the die; powders which are made of the materials with high-temperature oxidation resistance and acid and base resistance performances are sprayed on the slush-molding die through a high-speed flame plating technology; the surface-sealing is performed through the silver spraying; the aging treatment is performed. An anticorrosion coating of the slush-molding die manufactured according to the slush-molding die corrosion prevention method plays a good anticorrosion role to the online production of the slush-molding die without any negative influences on the productive tempo. That the technology is applied to the slush-molding die is a first case at home and abroad, which solves the serious corrosion problem when in the online production of the slush-molding die, and greatly prolongs the service life of the slush-molding die without influencing the production technology and the tempo.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

Preparation method for environment-friendly chemical deplating agent applied to copper plating and nickel plating

The invention provides a preparation method for an environment-friendly chemical deplating agent applied to copper plating and nickel plating. The environment-friendly chemical deplating agent is an aqueous solution comprising sulfuric acid, hydrogen peroxide and corrosion inhibitor, wherein the corrosion inhibitor is organic matter containing nitrogen or sulfur and the like or a high-polarity organic compound containing -COOR, -COOH, -CHO, triple bonds (C is equivalent to C) or multiple hydroxyl -OH and the like. In addition, potential differences exist between a cathode and an anode, the potential differences can be eliminated or reduced through the action of an electron-poor group and an electron-rich group of the organic matter, and therefore corrosion can be reduced or corrosion can be temporarily stopped. The deplating liquid is high in deplating speed, at the appropriate temperature, a 0.2 mm-thick nickel coating and a 0.2 mm-thick copper coating can be deplated within 2 minutes, and the waste deplating liquid obtained after deplating is completed facilities recovering of metal copper and nickel.

Owner:繁昌县晶鑫贸易有限公司

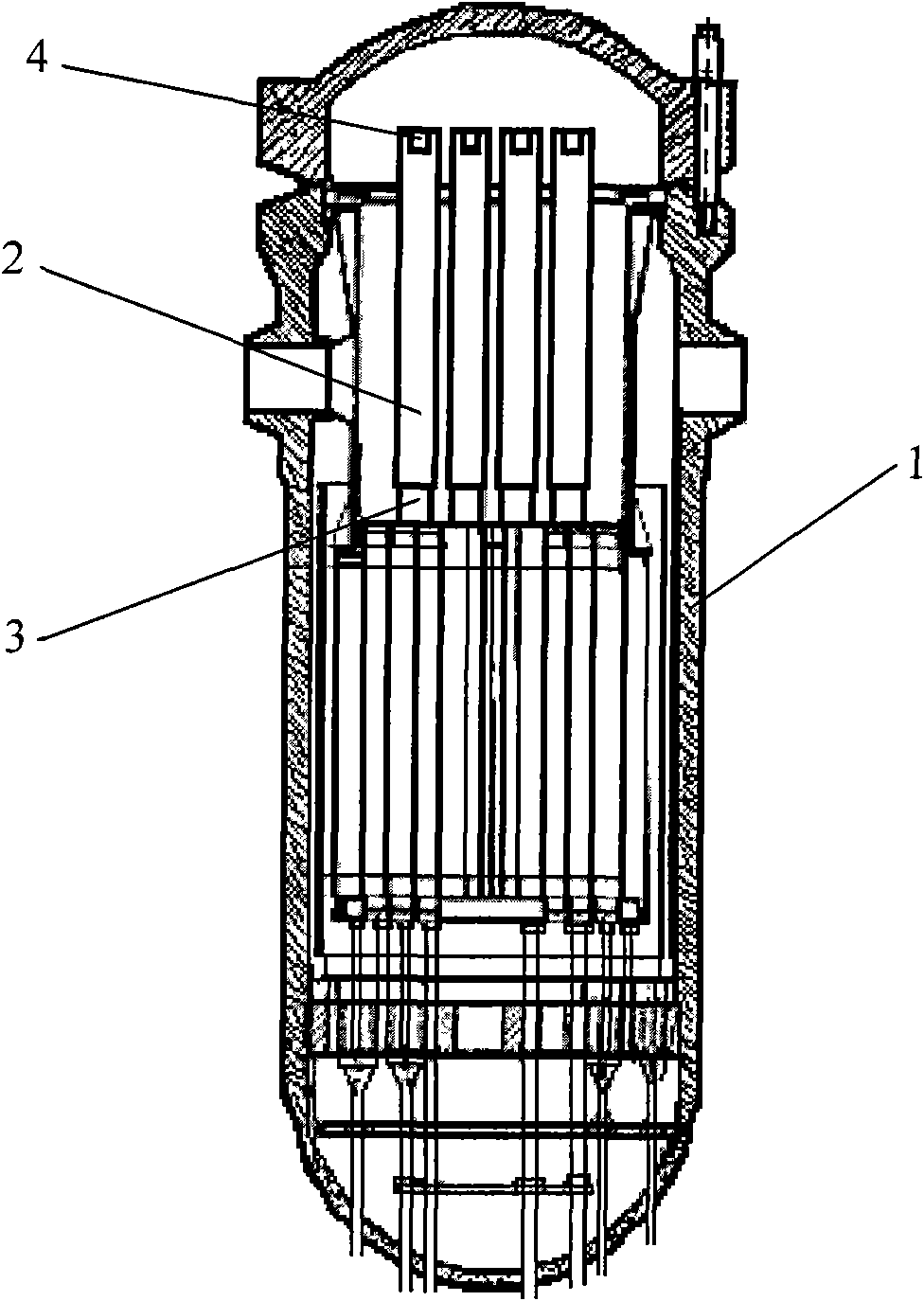

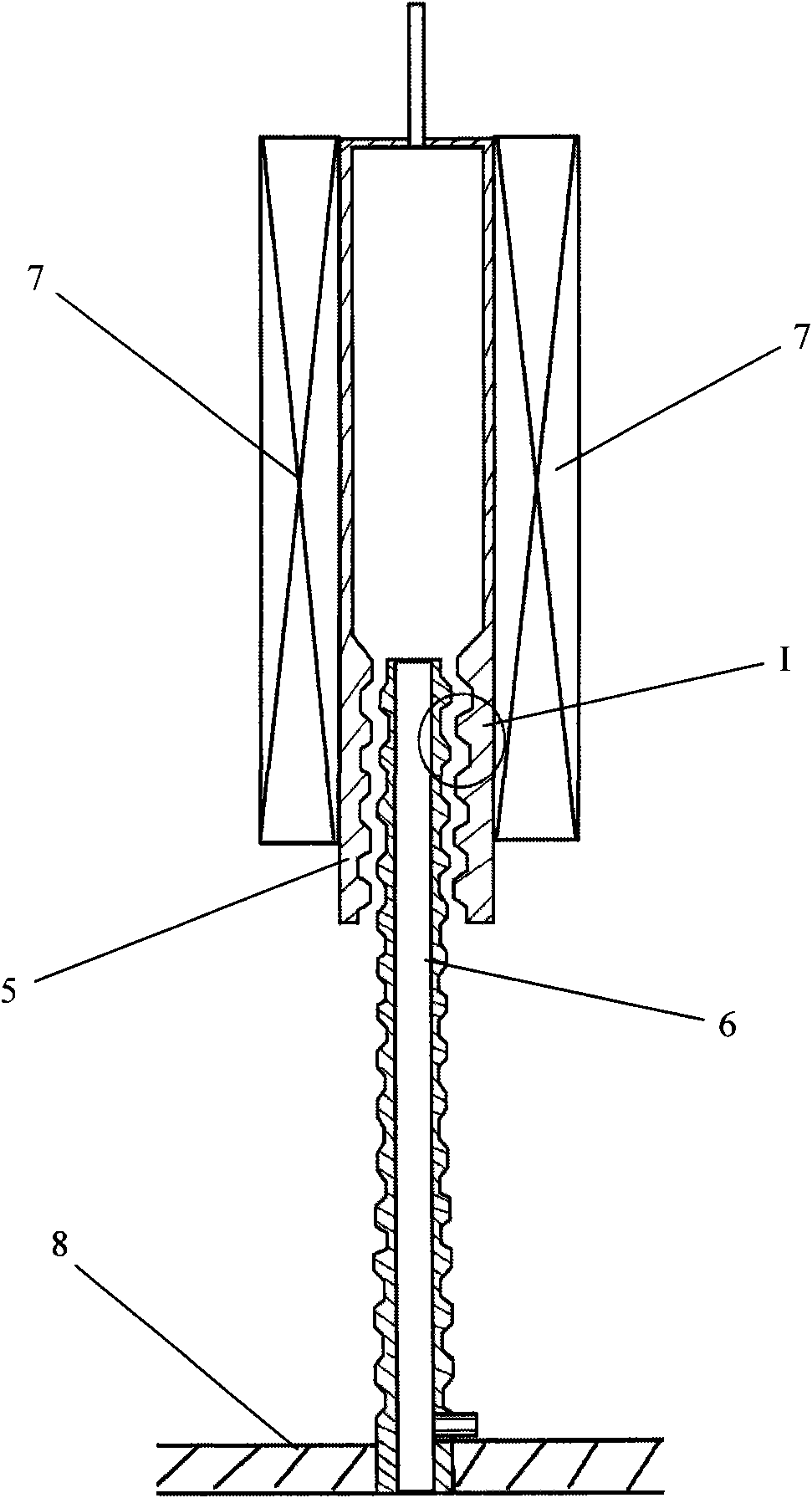

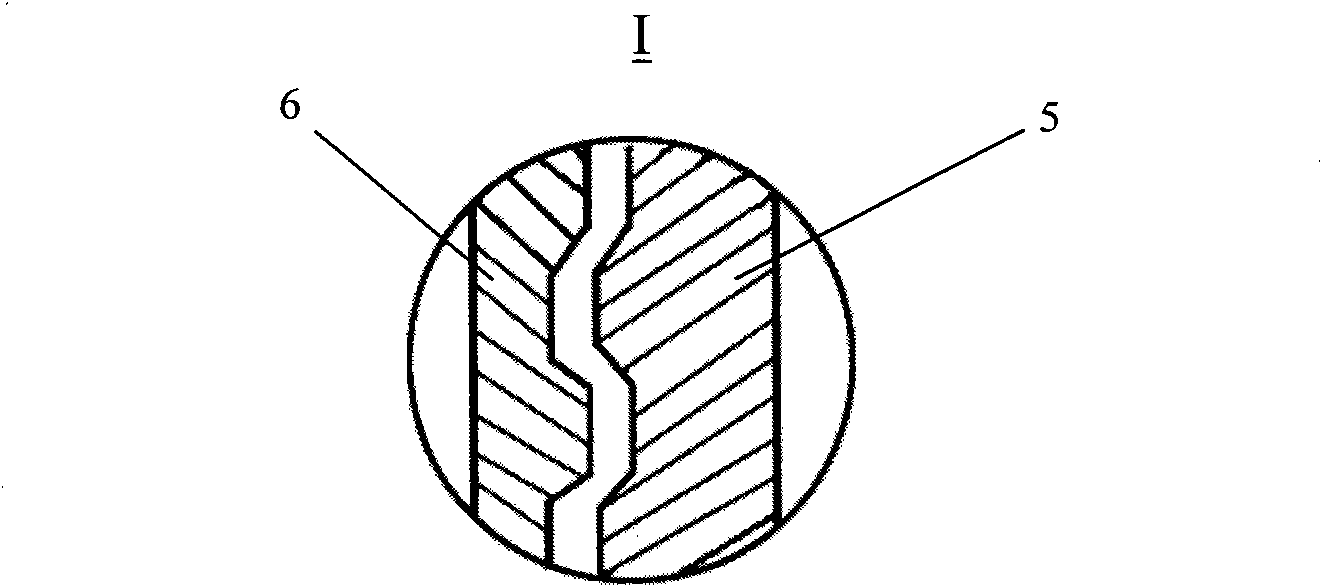

Follower component driven by driving mechanism in pressure shell and water reactor adopting same

InactiveCN101656112APrevent penetrationReduce cycle costsNuclear energy generationContainmentFuel reprocessingNatural uranium

The invention belongs to the field of nuclear reactor engineering, in particular to a follower component driven by a driving mechanism in a pressure shell and a water reactor adopting the same. The invention realizes the spectral shift control of a reactor and compansates the decrease of reactivity in a burn-up process by a depleted uranium (or thorium) compound follower, and adopts a dense weir and residential uranium compound fuel postprocessed by partially utilizing natural uranium and spent fuel, thereby greatly saving nuclear fuel and decreasing fuel cycle cost. A driving mechanisms driving a great amount of follower components are arranged in the pressure shell, so as to prevent the joint sections of the driving mechanism from penetrating through the upper sealing head of the pressure shell, carry out the spectral shift control under the condition without influencing the reliability of the pressure shell, lower the boron concentration of the water reactor in water in an operation process, avoid the occurrence of the problem of serious corrosion of the joint sections and the upper sealing head of the driving mechanism due to the penetration of boric acid through the upper sealing head of the pressure shell, reduce the possibility of elastic rod accidents and improve the safety.

Owner:张育曼 +2

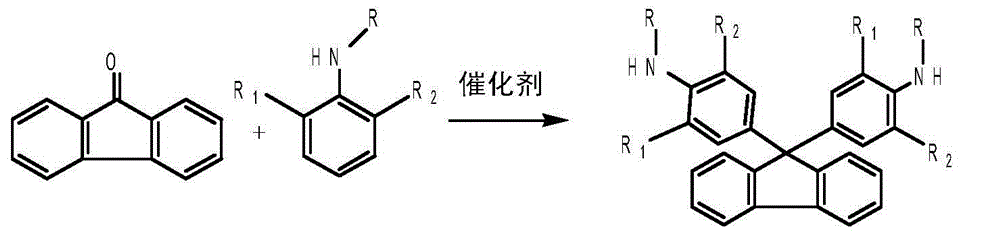

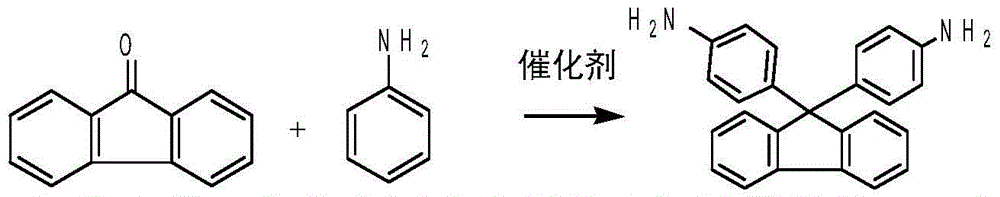

Method for clean preparation of alkyl substituted diamine fluorene compound

InactiveCN104892430ASolve serious corrosion problemsAvoid serious wasteOrganic compound preparationAmino compound preparationHigh energyCleaning methods

The invention belongs to the field of fine chemical engineering, and in particular relates to a method for clean preparation of an alkyl substituted diamine fluorene compound. The alkyl substituted diamine fluorene compound is prepared by taking 9-fluorenone and alkyl substituted aniline as raw materials and zirconium solid super acid as a catalyst for catalysis. The alkyl substituted diamine fluorene compound prepared by adopting the method provided by the invention has a yield of 85% and purity of 98.5-99.5%, a solvent after using can be recycled without further treatment, and the catalyst can be reused for more than 5 times. The method disclosed by the invention is mild in reaction condition, simple and convenient to operate, high in yield and low in cost, the three-waste quantity is greatly reduced compared with that of the conventional inorganic acid and organic acid methods, the environmental pollution is small, and meanwhile, and the problems of high energy consumption and low yield of other types of solid acid such as a multi-fluorine sulfonic acid polymer loaded aluminum oxide catalyst, ferric solid super acid, titanium solid super acid and tungsten solid super acid are solved, so that the method is a clean method suitable for large-scale industrial production.

Owner:SHENYANG RES INST OF CHEM IND

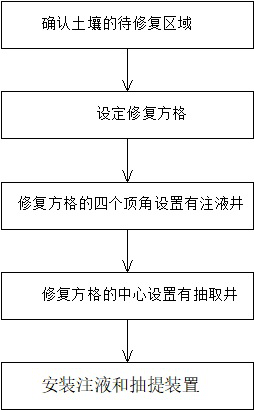

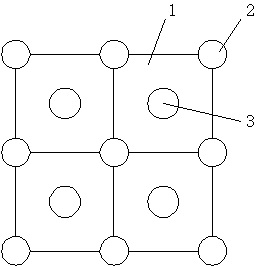

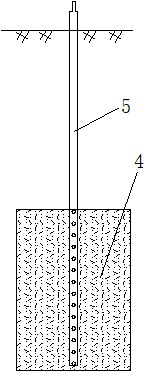

High-pressure splitting extrusion powder-mixing permeation-assisting in-situ remediation method for low-permeability polluted soil

PendingCN113020243AImprove permeabilityExpand the scope of repairContaminated soil reclamationSoil scienceIn situ remediation

The invention relates to a high-pressure splitting extrusion powder-mixing permeation-assisting in-situ remediation method for low-permeability polluted soil. The remediation method comprises the following steps: confirming a to-be-remedied area of soil; setting one or more remediation grids according to the size of the to-be-remedied area of the soil; arranging liquid injection wells at the four top corners of the repairing square grids; arranging an extraction well in the center of the repair grid; and mounting aliquid injection device at the liquid injection well, and mounting a negative pressure extraction device at the extraction well for liquid injection and extraction. Water and gas are injected into the polluted soil body through high-pressure jet grouting under high pressure, the original structure of the polluted soil body is destroyed, and a mud cake-shaped structure is formed, so that plant ash and sand are injected to be evenly mixed into the polluted soil body, the grain composition of the soil body is changed, and the permeability coefficient of the soil body is increased; and the chemical agent permeation rate is increased, the reaction rate and the permeation range are increased, the remediation range is increased, the remediation period is greatly shortened, the chemical agent dosage, the permeation path and the permeation range can be controlled, and secondary pollution is avoided.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +1

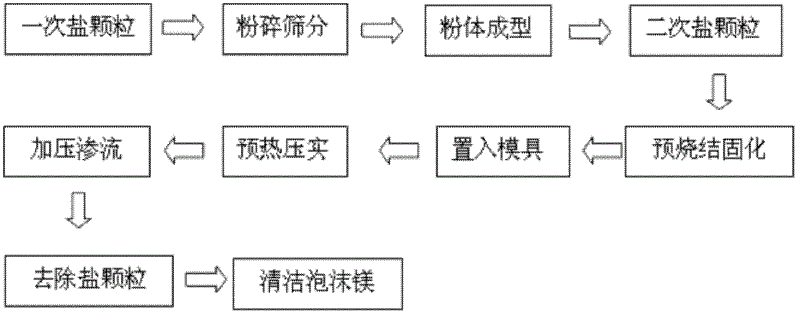

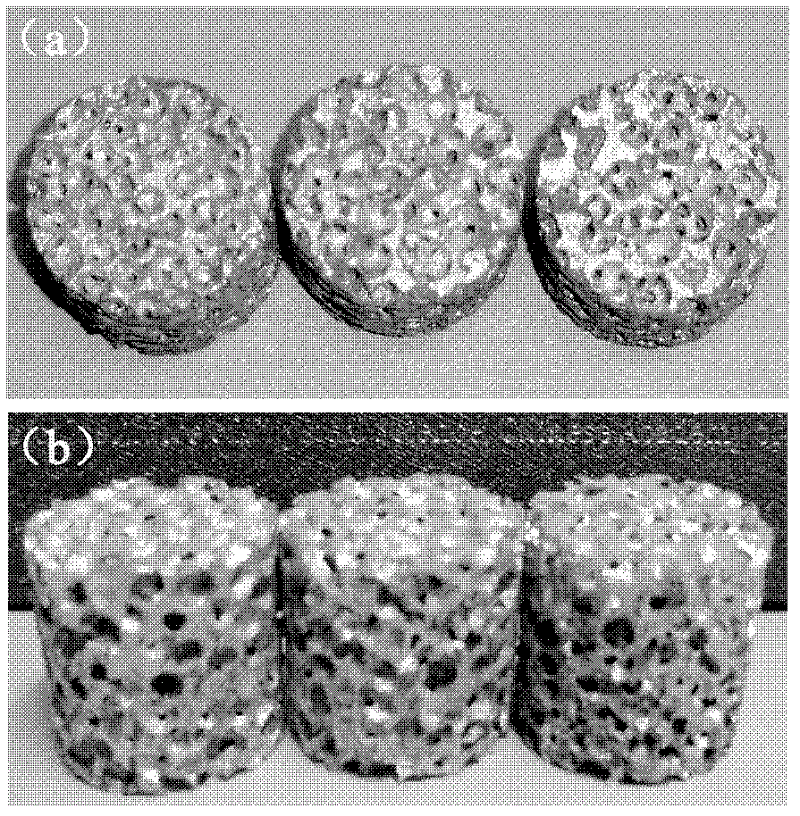

Preparation method for clean foam magnesium in bionic field

The invention discloses a preparation method for clean foam magnesium in the bionic field, which comprises first drying primary NaC1 particles, and performing ball-milling to obtain a power body, then preparing secondary particles by performing a granulation step on the NaC1 power body, and screening the particles to be different particle sizes through a screen; performing presintering on the NaC1 particles, lastly melting metal magnesium, paving a SY-LF1 covering agent above metal liquid, performing pressurizing seepage through inert gas to enable the metal magnesium liquid to seep into gaps of prefabricated block particles, removing NaC1 after cooling, and obtaining the foam magnesium. Compared with a powder metallurgic method and a traditional particle seepage flow method, the preparation method has the advantages that the seepage flow particles are the secondary particles which have optimized dissolubility compared with the primary particles, and the secondary particles are extremely easy to remove after seepage flow, can not cause corrosion and damage to a magnesium foam substrate, and the method has great application prospects in the bionic field.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

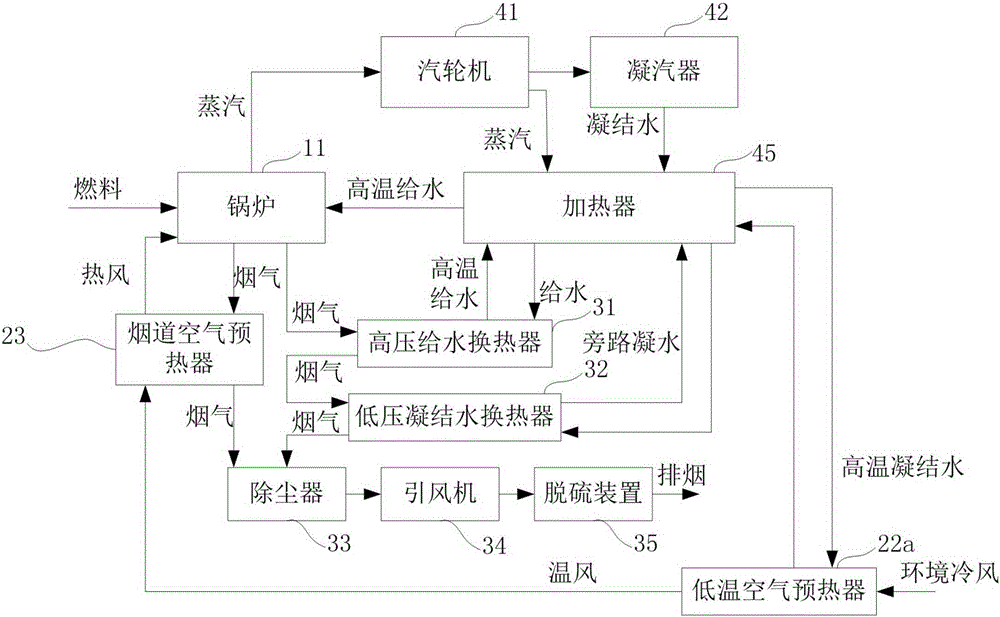

Thermal power generation system based on boiler tail bypass flue

The invention provides a thermal power generation system based on a boiler tail bypass flue. The thermal power generation system comprises a boiler body subsystem, an air supply subsystem, a tail flue subsystem, a turboset subsystem and an electric generator, wherein the boiler body subsystem comprises a boiler and a boiler flue; the air supply subsystem comprises an air feeder, a front air preheater and a flue air preheater; the tail flue subsystem comprises a high-pressure water feeding heat exchanger and a low-pressure water condensation heat exchanger; the turboset subsystem comprises a turbine, a condenser and a plurality of heaters; all the heaters sequentially use steam extraction with incremental pressure in the turbine correspondingly to heat condensation water, high-temperature condensation water is obtained, a water inlet of the front air preheater is connected with a water outlet of the second heater, and the high-temperature condensation water is used for heat exchange with environmental cold air to obtain warm air; and the multiple heaters comprises the low-pressure heaters and the high-pressure heaters.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for reducing acidity of acetate

ActiveCN103467285AHigh boiling pointLow costOrganic compound preparationCarboxylic acid esters separation/purificationReboilerGas phase

The invention relates to a method for reducing the acidity of acetate. The method comprises the following steps: carrying out an esterification reaction of raw materials comprising acetic acid and lower fatty alcohol in a loop composed of an esterification kettle and a reboiler by treating concentrated sulfuric acid as a catalyst; allowing a gas phase material steamed after the esterification reaction to go through an acid trap having a polytetrafluoroethylene inner liner, carrying out mass transfer exchange of the obtained gas phase material and a tower bottom liquid from the bottom of an esterification tower in a ceramic filler layer for washing off most acetic acid and most sulfuric acid entrained by a gas phase material flow; connecting different gas phase material flows discharged from the upper portion of the acid trap to feeding ports at different positions of the esterification tower through the valve combination, and carrying out separation and subsequent refining in the esterification tower to reduce the acidity of the acetate. The acetate obtained through adopting the method accords with product acidity requirements of corresponding product standards.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

Catalyst used for preparing amino acid salt through low-temperature oxidative dehydrogenation by using amino alcohol

InactiveCN101683618ASimple preparation conditionsGood activity at low temperatureOrganic compound preparationAmino-carboxyl compound preparationAlkali hydroxideAmino acid

The invention provides a catalyst used for preparing amino acid salt through low-temperature oxidative dehydrogenation by using amino alcohol, which uses Cu / ZrO2 as a main catalyst and Pd as a cocatalyst. The catalyst has good low temperature activity, high selectivity and stability and simple preparation conditions and can be used in industrial production of amino acid salt preparation. The aminoalcohol and alkali metal hydroxides are used as the raw materials to generate the amino acid salt through reaction in the presence of the catalyst under the conditions of low reaction temperature of140-180 DEG C and reaction pressure of 0.5-1.0MPa. The technical scheme adopted by the invention better solves the problem that the production equipment is severely corroded under the high temperatureand strong alkali reaction conditions.

Owner:EAST CHINA UNIV OF SCI & TECH

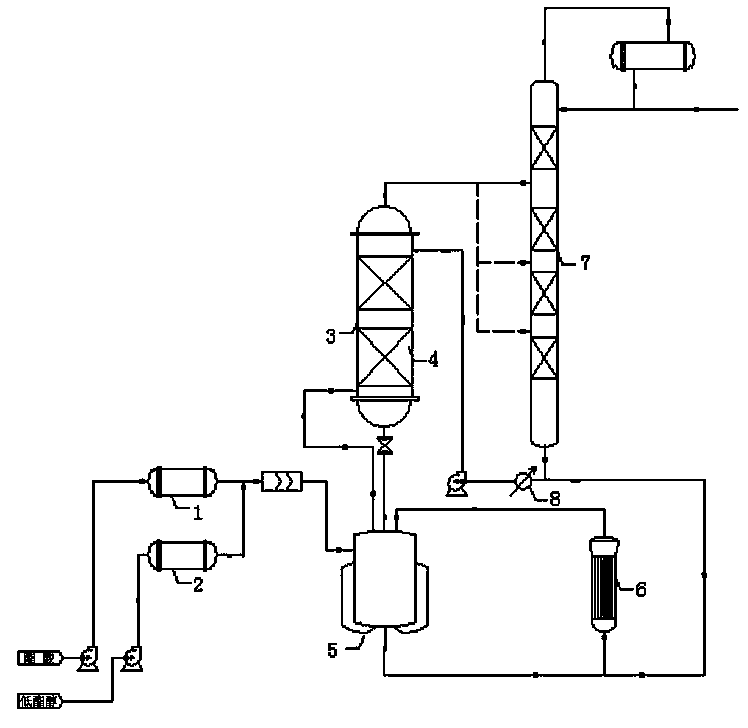

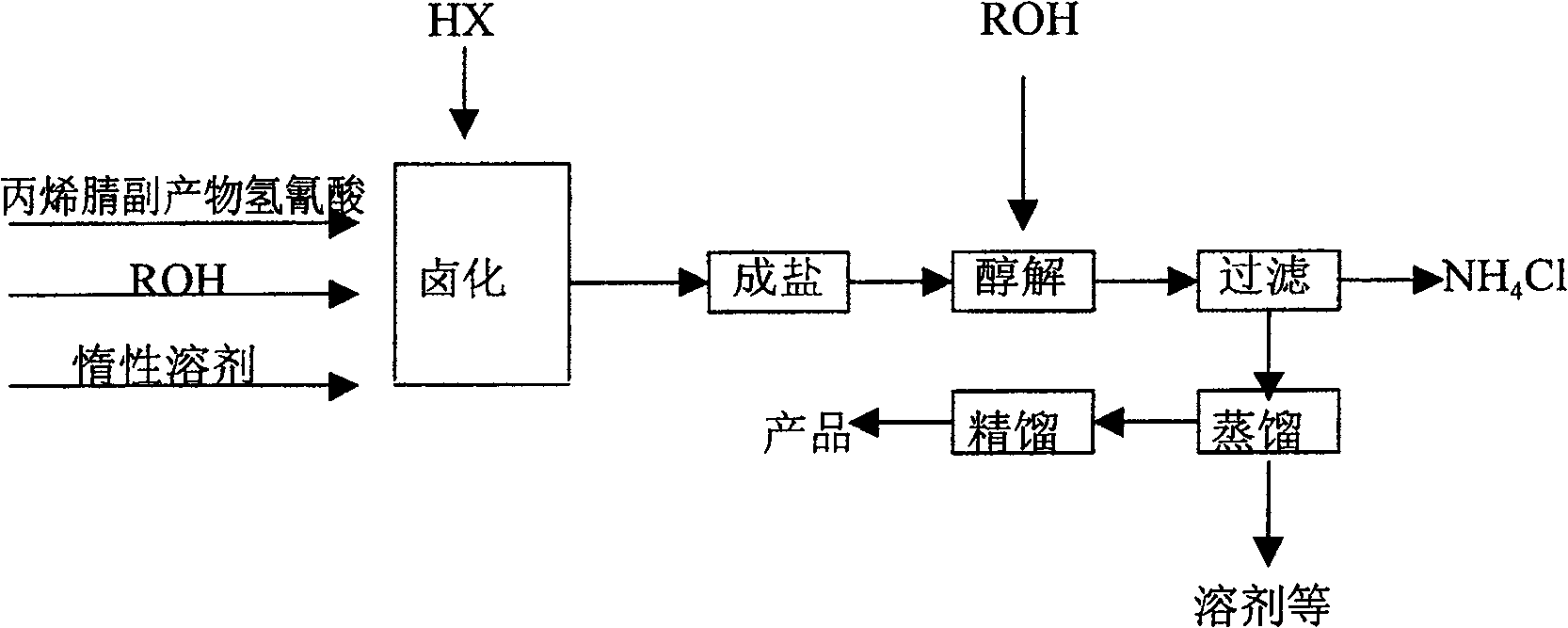

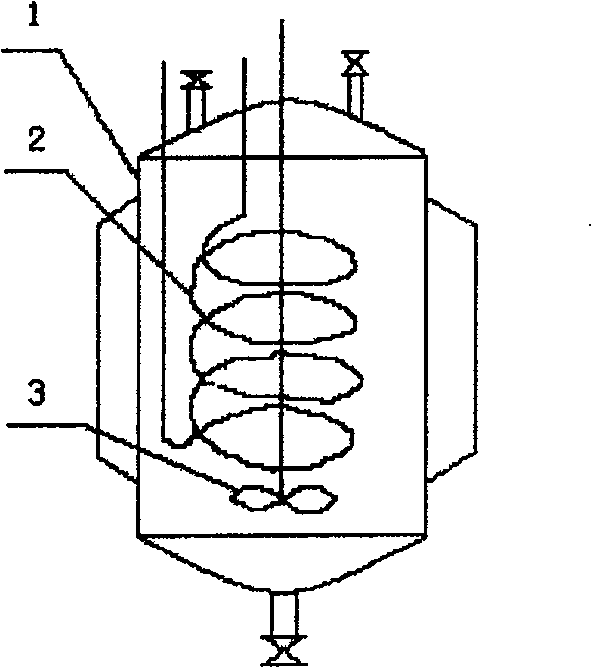

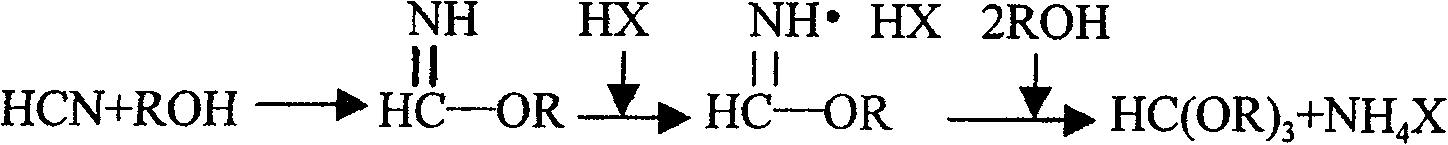

Process and device for preparing orthoformate by using byproduct hydrocyanic acid from acrylonitrile production

ActiveCN100457704CStable reaction temperatureFewer reaction by-productsEther preparationSolventChemistry

The present invention relates to a process for preparing orthoformate by taking advantage of hydrocyanic acid, as by-product in production of acrylic nitrile, and apparatus therefore. The hydrocyanic acid, as by-product in production of acrylic nitrile, is adopted as a starting raw material and, together with alkyl alcohol and halogen hydride, is dissolved in an indifferent solvent; then after halogenation, salt forming and alcoholysis reactions, crystal separation and distillation rectification, the orthoformate is obtained. By adopting a reactor equipped with stirring, built-in plastics bundled tubes or metal dish tube heat interchanger to resolve the heat exchange problem existing in the aggregation exothermic halogenation and salt forming reactions, the present invention prevents blasting boiling and exploding accident states from appearing during the course of reaction, facilitates placidity and controllability of the reaction temperature, and achieves the requirement for safe reactions.

Owner:YINGKOU YINGXIN CHEM TECH CO LTD

Electro-galvanizing brightening agent

InactiveCN106435659ASolve the problem of lightSolve serious corrosion problemsPyridiniumCholine chloride

An electro-galvanizing brightening agent is characterized by comprising, in weight percentage, 49%-51% of 1-benzyl pyridinium-3-carboxylate, 19%-21% of choline chloride, 14%-16% of urea and 14%-16% of 2.4-dichlorobenzaldehyde. The electro-galvanizing brightening agent solves the problem of poor brightness of an alkaline electro-galvanized coating, and accordingly solves the problem that equipment is seriously corroded by current acid electro-galvanizing.

Owner:JIANGSU MENGDE NEW MATERIALS TECH CO LTD

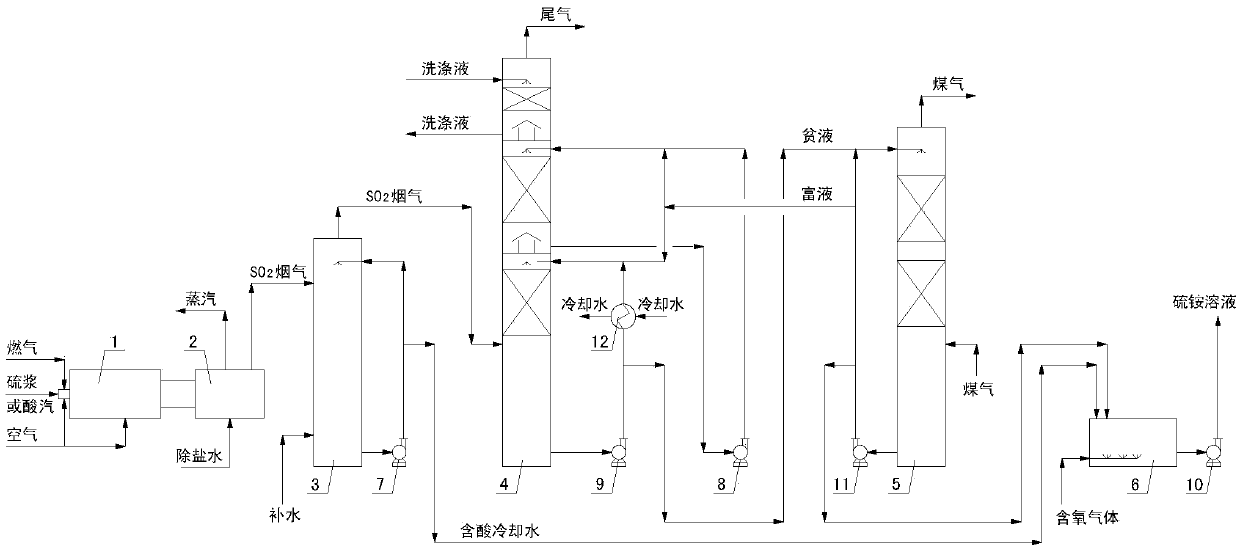

Process and system for producing ammonium sulfate by deaminizing coke oven gas with ammonium sulfite method

PendingCN109517630AProcess step scienceProcess steps are reasonableGas treatmentDispersed particle separationSulfurCoke oven

The invention provides a process and a system for producing ammonium sulfate by deaminizing coke oven gas with an ammonium sulfite method. The process for producing the ammonium sulfate by deaminizingthe coke oven gas with the ammonium sulfite method comprises the following steps of using ammonia in the coke oven gas and sulfur dioxide generated by sulfur paste, generated by the wet oxidative desulfurization on the gas with an ammonia method, or an acid gas, generated by desulfurization with an absorptive method, through incineration as raw materials, absorbing the ammonia in the coke oven gas by adopting an ammonium sulfite solution as a solvent, regenerating the ammonium sulfite solution through absorbing the sulfur dioxide in flue gas generated by the incineration of the sulfur paste or the acid gas, and converting ammonium sulfite generated by absorbing the ammonia and the sulfur dioxide into ammonium sulfate through oxidation. The problem that a device in a process of washing theammonium with sulfuric acid is seriously corroded is solved. According to the process, cooling water absorbs sulfur trioxide to generate the sulfuric acid which can be used for replacing sulfuric acid which is needed to be purchased when the ammonium sulfate is produced; and the resource is comprehensively utilized. The invention also discloses the system for producing the ammonium sulfate by deaminizing the coke oven gas with the ammonium sulfite method. The system has the advantages of being low in investment, low in energy consumption and easy to popularize.

Owner:DALIAN HAOTONG ENVIRONMENTAL PROTECTION ENGINEERING TECHNOLOGY CO LTD

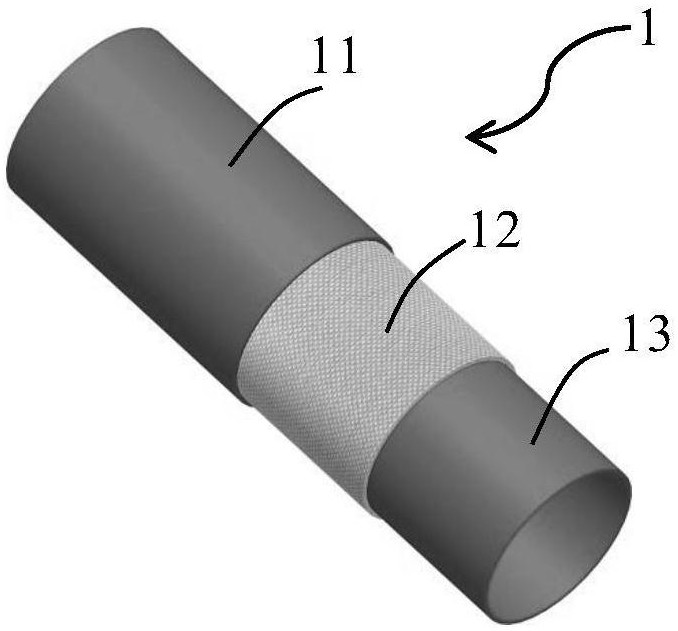

Flue gas pipeline, preparation method thereof and waste incineration flue gas recovery device

ActiveCN109680313ASolve serious corrosion problemsImprove anti-corrosion performanceElectrolytic coatingsNanotechnologyFlue gasProcess engineering

The invention provides a flue gas pipeline, a preparation method of the flue gas pipeline and a waste incineration flue gas recovery device. The flue gas pipeline comprises a pipeline body and a Ni-Crnano coating, and the Ni-Cr nano coating is arranged on the inner surface of the pipeline body. The anti-corrosion performance of the surface of the waste incineration flue gas pipeline can be effectively improved through the Ni-Cr nano coating, therefore the problem that flue gas generated by waste incineration has serious corrosion to the flue gas pipeline is solved, and the stability and service life of flue gas recovery and purification device are increased.

Owner:CHINA ENFI ENGINEERING CORPORATION

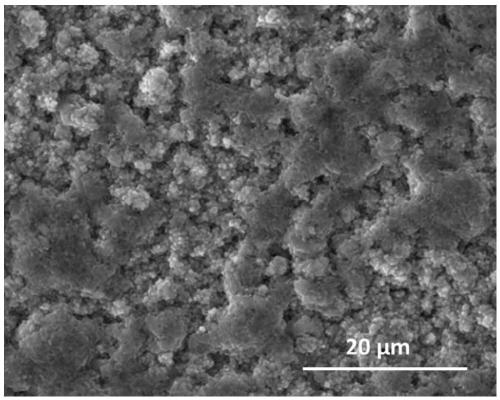

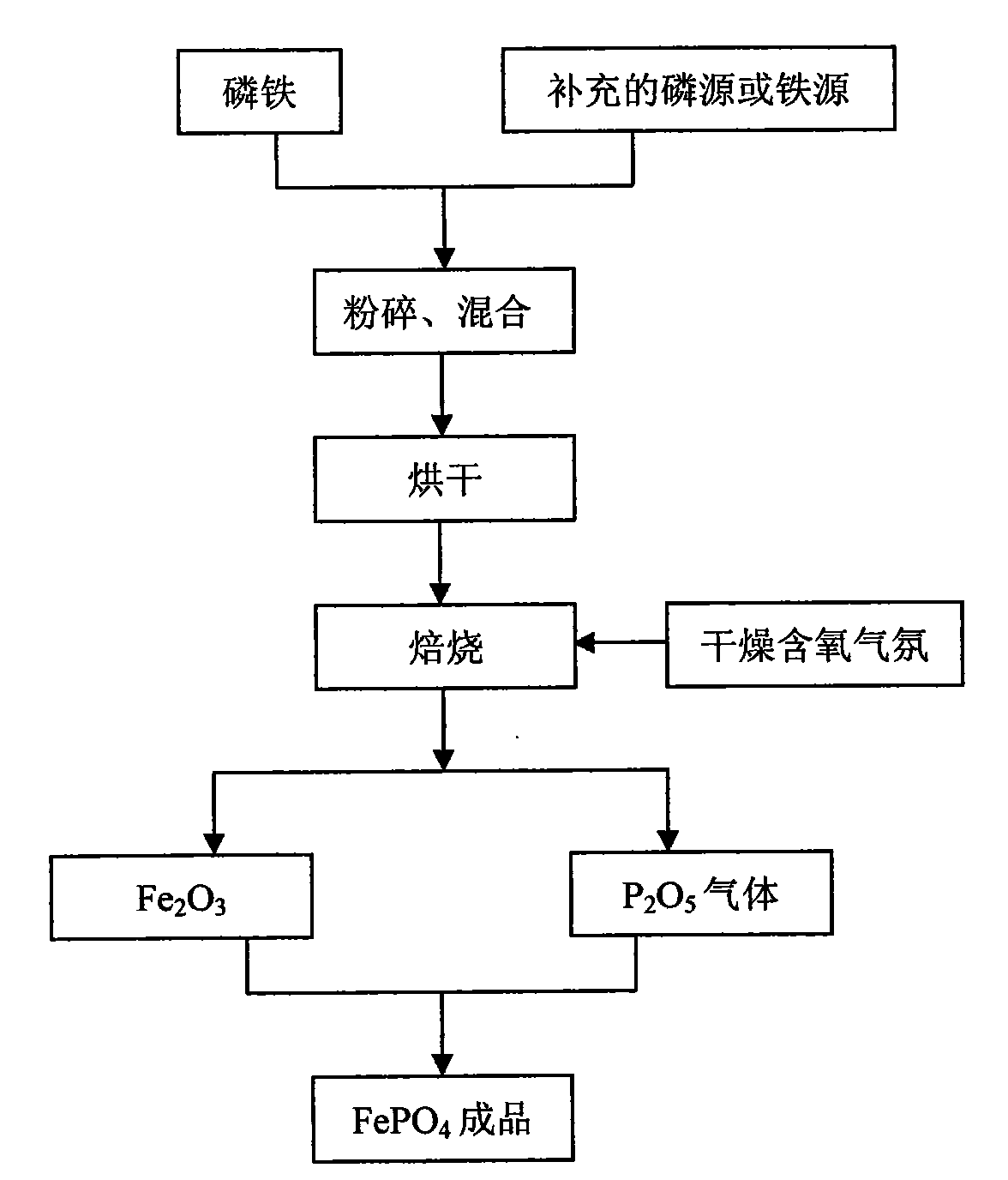

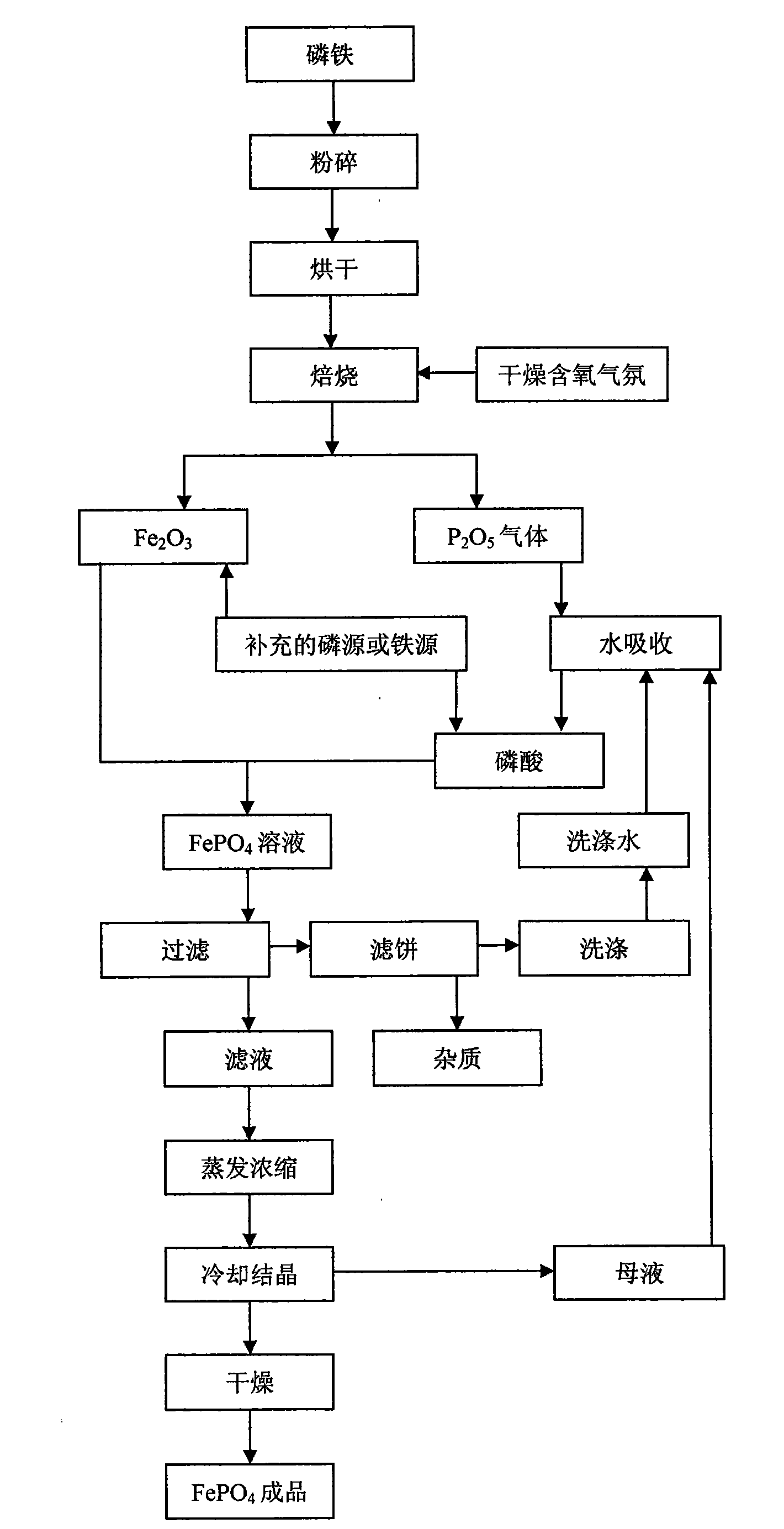

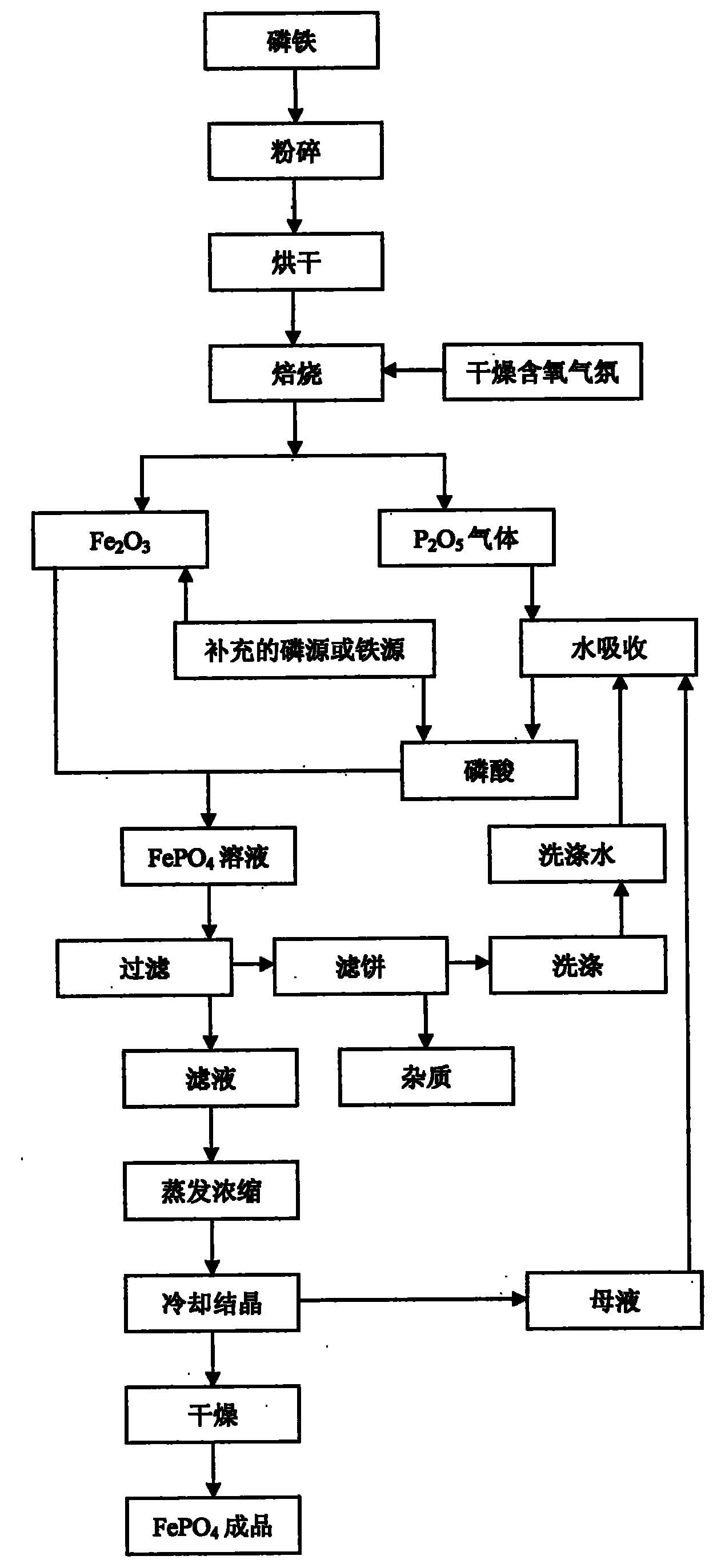

Method for preparing iron phosphate from ferrophosphorus

InactiveCN101659406BOvercome the problem of difficult ratioWide variety of sourcesPhosphorus compoundsResource utilizationLow demand

The invention relates to a method for preparing iron phosphate from ferrophosphorus. The ferrophosphorus is used as a part or the whole of a phosphorus source and an iron source for preparing the iron phosphate. The phosphorus source or the iron source is supplemented according to a mol ratio of (0.8-1.2):1.0 between total phosphorus elements and total iron elements. The ferrophosphorus is roasted in a dry and oxygen-containing atmosphere. The iron phosphate product is obtained by means of dry or wet oxidation product reaction. The method adopts the ferrophosphorus as the raw material for preparing the iron phosphate, makes full use of elements in the ferrophosphorus and creates a novel preparing process of iron phosphate. In addition, as the reaction process can be used for weakening or eliminating the influence of impurity elements in the ferrophosphorus on the iron phosphate product, the method indirectly purifies the ferrophosphorus and eliminates the influence of the impurities in the ferrophosphorus and the problem of severe corrosion caused by the existence of water during the roasting of ferrophosphorus. The reaction process has relatively low demand on apparatuses. The preparing method has simple process, short production flow and low production cost, is clean and environment-friendly, realizes high resource utilization rate, low investment and good benefit and is suitable for large-scale, industrial, low-cost and clean preparation of iron phosphate.

Owner:SICHUAN UNIV

Method for preparing glyceryl triacetate

InactiveCN106588646ASolve serious corrosion problemsSimple processPreparation by ester-hydroxy reactionOrganic compound preparationPollutant emissionsGlycerol

The invention provides a method for preparing glyceryl triacetate. The method includes the following steps that firstly, glycerol and an excessive amount of methyl acetate are added into a reaction kettle with a reflux device, and alkali is added to serve as a catalyst to be reacted for 1-2.5 h; secondly, the mixture obtained in the first step is distilled at 70-80 DEG C; thirdly, the mixture composed of glyceryl triacetate, glycerol and the alkaline catalyst and obtained in the second step is extracted by means of an extraction agent; fourthly, the mixture composed of glyceryl triacetate and the extraction agent and obtained in the third step is distilled at 80-90 DEG C, the extraction agent is separated out, and the finally product, namely glyceryl triacetate, is obtained. Glycerol and methyl acetate react to generate glyceryl triacetate, the process is free of pollutant emission, the problem that equipment is severely corroded by using sulfuric acid as a catalyst is solved, the process is simple, operation conditions are simple, and the method is easy to control.

Owner:田璐

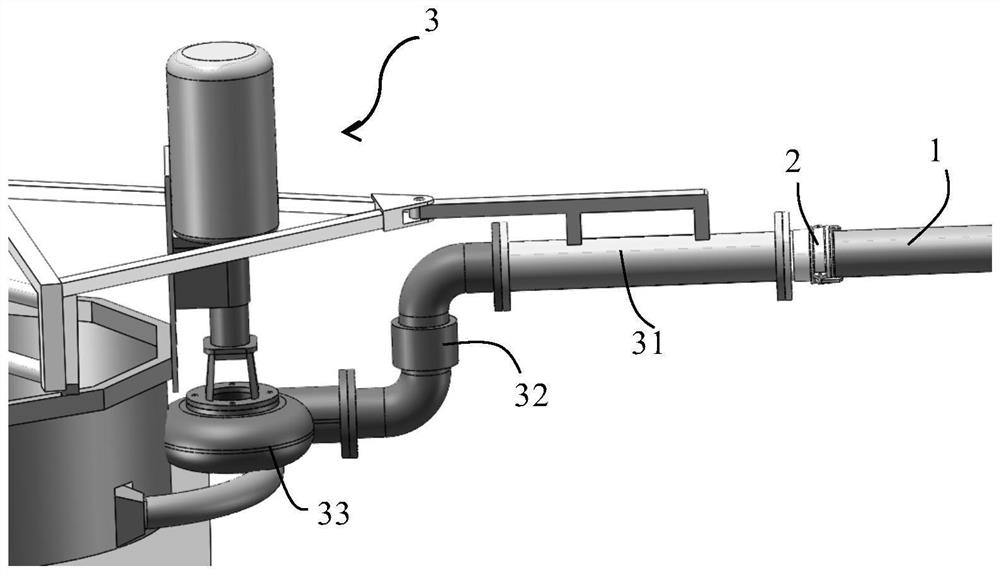

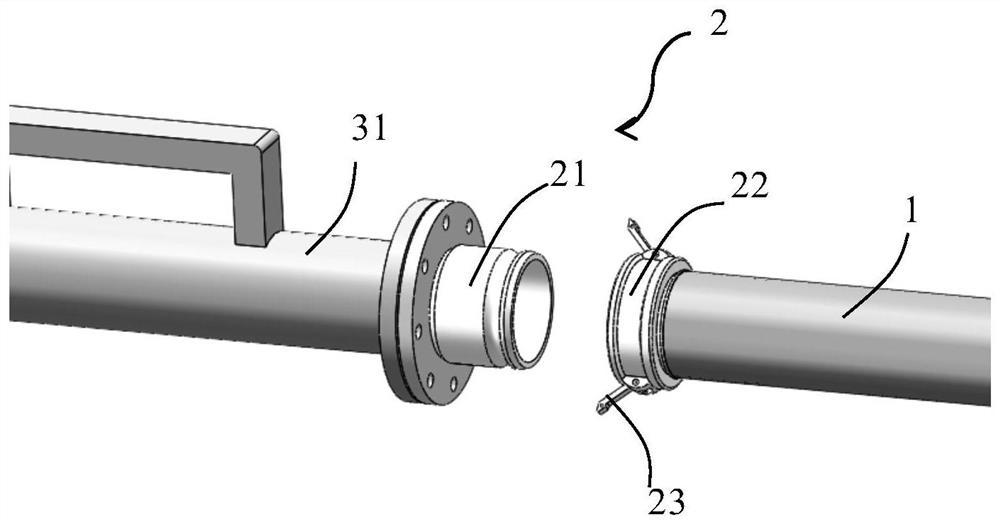

Conveying hose system for salt field

PendingCN113357459AImprove wear resistanceImprove corrosion resistancePipe supportsAdjustable jointsClassical mechanicsStructural engineering

The invention discloses a conveying hose system for a salt field. Conveying hoses are polyurethane hoses and are connected with a salt collecting vehicle, a pump on the salt collecting vehicle is connected with a transition pipe through a slewing bearing, the transition pipe is connected with the conveying hoses through a quick connector, and the two conveying hoses are also connected through a quick connector.

Owner:JIANGSU ASOE NEW MATERIAL TECH

Method for preparing p-nitrobenzoic acid through polystyrene foam

InactiveCN106008220ALow costHigh purityOrganic compound preparationNitro compound preparationP-nitrobenzoic acidCatalytic oxidation

The invention discloses a method for preparing p-nitrobenzoic acid by using polystyrene foam, which comprises the following steps: (1) defoaming treatment; (2) microwave digestion; (3) catalytic oxidation; (4) product separation and purification. The present invention utilizes polystyrene foam to prepare the method for p-nitrobenzoic acid, which is simple and convenient to operate and easy to realize. It takes waste polystyrene foam as raw material and utilizes the method of nitric acid digestion and oxygen oxidation to turn waste into wealth on the one hand, The cost of raw materials is reduced, and on the other hand, the problem of severe corrosion caused by the direct use of nitric acid oxidation is effectively solved, and the product has high purity, high yield, and easy separation and treatment of the product.

Owner:诚和环境科技(苏州)有限公司

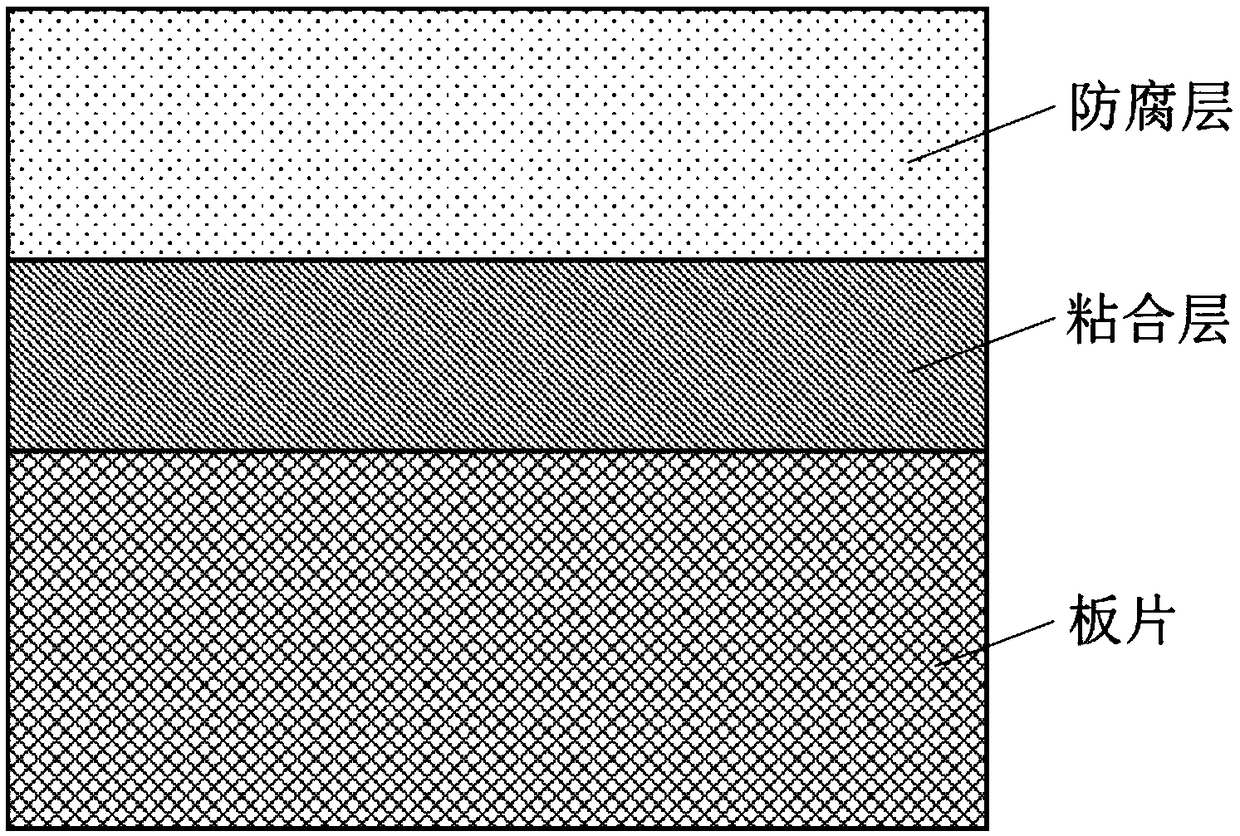

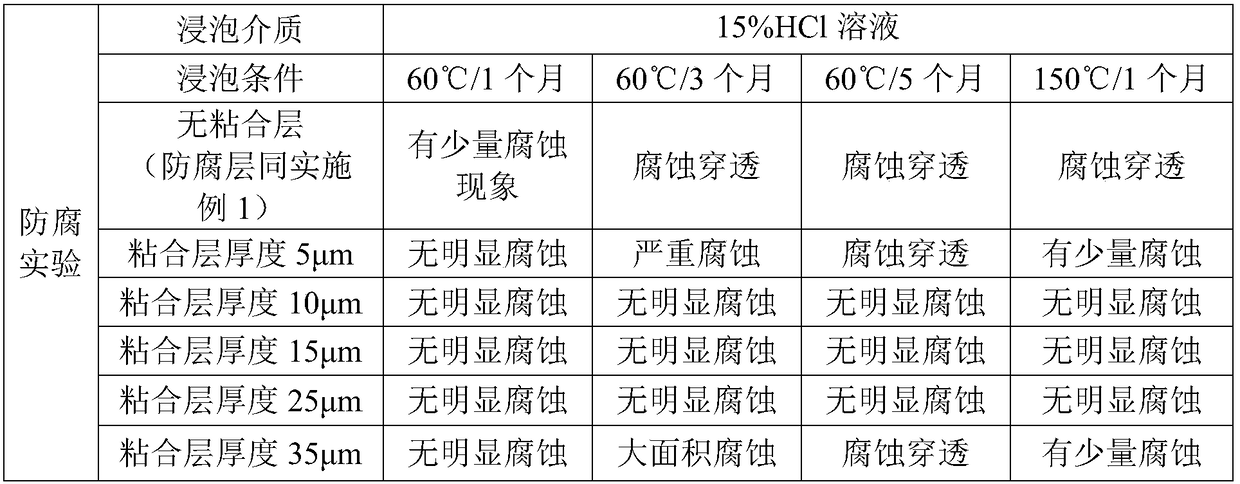

Plate of corrosion-resistant plate heat exchanger and corrosion-resistant treatment method of plate

ActiveCN109489471AEasy to useImprove erosion resistanceCoatingsLaminated elementsPlate heat exchangerPolyvinyl alcohol

The invention belongs to the technical field of corrosion resistance of plate heat exchangers, and provides a plate of a corrosion-resistant plate heat exchanger and a corrosion-resistant treatment method of the plate. A binding layer and a corrosion-resistant layer are sequentially sprayed on the surface of the plate; the binding layer is prepared from polyvinyl alcohol, xylene and talcum powder,wherein the mass ratio of the polyvinyl alcohol to the xylene to the talcum powder is 30:(5 to 10):(10 to 15). According to the corrosion-resistant plate heat exchanger, the surface of the plate andthe surface corrosion-resistant layer are tightly bound by the binding layer, so that the plate has the excellent property of acid-alkali corrosion resistance. The corrosion-resistant treatment methodhas the characteristics that the material price is low, manufacturing is easy and the property is stable.

Owner:HEIMDALLR SHANGHAI ENERGY SAVING TECH

Method for producing triacetin

ActiveCN101450897BWide range of usesReduce usagePreparation by transesterificationMethyl acetateSide reaction

The invention provides a method for preparing acetin. The method comprises that: in the presence of alkali catalyst, grease reacts with acetate, and acetin and fatty acid ester are collected. The method has the advantages of: (1), producing the acetin directly by using the grease and the acetate, generating little side reaction, achieving high product quality and widely used by products; 2, avoiding using acetic acid and acid catalyst, solving the problem of serious corrosion existing in the conventional process and lowering requirements on equipment material and operation and maintenance costs; and 3, enlarging the application range of methyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for concentrating phosphoric acid or other inorganic acids prepared by wet process

InactiveCN1314583CPrevents serious corrosion problemsSolve serious corrosion problemsEvaporationPhosphorus compoundsPhosphoric acidKerosene

A process for concentrating the wet-method phosphoric acid and other inorganic acids by vacuum (or ordinary-pressure) evaporation is disclosed. A certain quantity of kerosene or xylene is added to the concentrating tower while a certain temp is held. The diluted acid is dropped in the kerosene. In the falling procedure of acid drops, they suck heat from kerosene and evaporate along with the light component of kerosene. After condensed, the oil and water are naturally separated as the phosphoric acid is not soluble to kerosene. Said separated oil can be cyclically used.

Owner:WUHAN CHEM COLLEGE

A control method for cathodic protection of ground electrode in HVDC transmission

The invention discloses a control method for realizing the cathodic protection of the ground electrode of high-voltage direct current transmission, which is improved on the basis of the constant current control mode of the direct current transmission project, and according to the detection result of the positive current of the ground electrode, the deviation of the current value of one pole is positive or negative. Alternate change, realizes alternate cathodic protection of the sending end and the receiving end grounding electrode, reduces the corrosion loss of the grounding electrode, greatly prolongs the service life of the grounding electrode, and solves the problem of serious corrosion of the grounding electrode caused by unbalanced current and other problems . The present invention utilizes the existing high-voltage direct current transmission constant current control mode, and makes small adjustments in this mode, which does not increase the investment cost of the control and protection system, and can greatly reduce the corrosion loss of the ground electrode, prolong the service life of the ground electrode, and can be applied to HVDC transmission in practical engineering.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

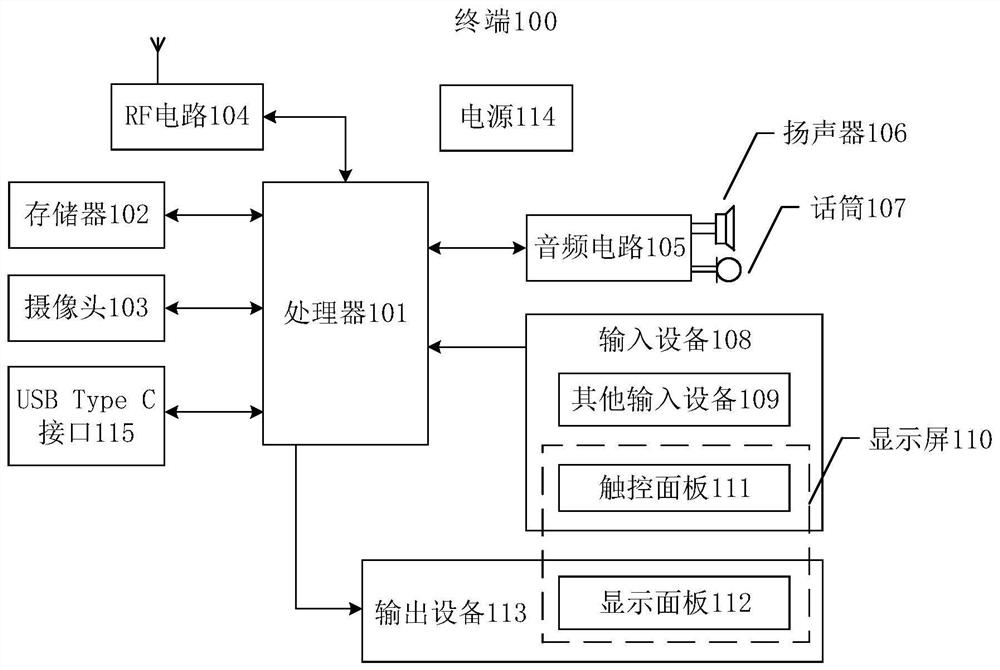

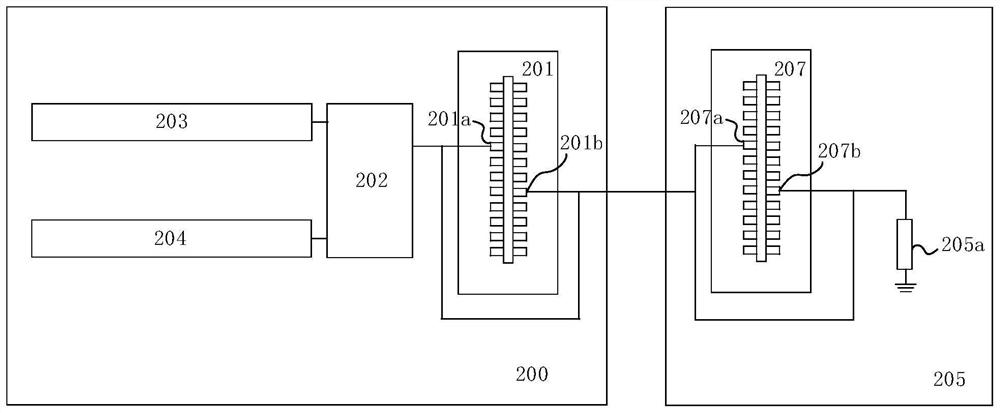

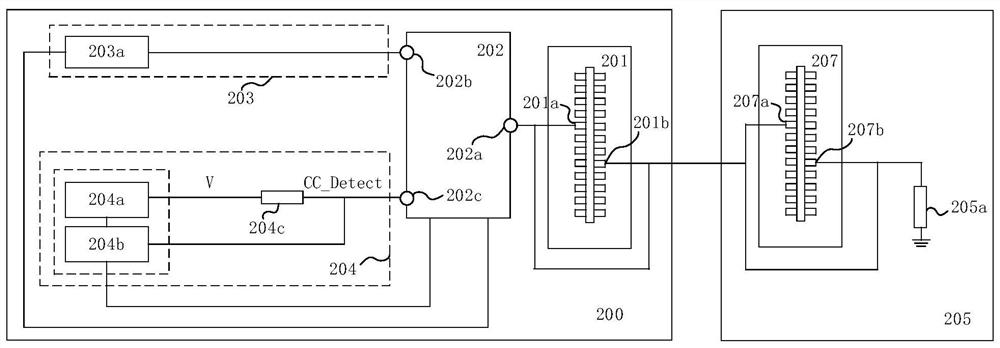

An electronic device with a usb Type C interface, a control method, and a readable storage medium

ActiveCN110520854BReduce voltageReduce corrosionPower supply for data processingEngineeringElectric devices

An electronic device (200) and a control method of a USB Type C interface (201), which can solve the problem of severe corrosion of the USB Type C interface (201) in a standby state. The electronic device (200) includes a USB Type C interface (201), a switch assembly (202), a first signal path (203) and a second signal path (204); wherein, the USB Type C interface (201) is used to connect the USB Type C equipment (205); the switch assembly (202) is connected to the USB Type C interface (201); the switch assembly (202) is connected to the first signal path (203); the switch assembly (202) is connected to the second signal path (204); when the USB When the Type C interface (201) is connected to the USB Type C device (205), the first signal path (203) is connected to the USB Type C interface (201) through the switch assembly (202), and the first tube of the USB Type C interface (201) The level of the pin (201a) is the first level; when the USB Type C interface (201) was disconnected from the USB Type C device (205), the second signal path (204) was connected to the USB Type C device through the switch assembly (202). C interface (201), the level of the first pin (201a) of the USB Type C interface (201) is the second level; the first level is greater than the second level.

Owner:HUAWEI TECH CO LTD

Method for reducing acidity of acetate

ActiveCN103467285BHigh boiling pointLow costOrganic compound preparationCarboxylic acid esters separation/purificationReboilerGas phase

The invention relates to a method for reducing the acidity of acetate. The method comprises the following steps: carrying out an esterification reaction of raw materials comprising acetic acid and lower fatty alcohol in a loop composed of an esterification kettle and a reboiler by treating concentrated sulfuric acid as a catalyst; allowing a gas phase material steamed after the esterification reaction to go through an acid trap having a polytetrafluoroethylene inner liner, carrying out mass transfer exchange of the obtained gas phase material and a tower bottom liquid from the bottom of an esterification tower in a ceramic filler layer for washing off most acetic acid and most sulfuric acid entrained by a gas phase material flow; connecting different gas phase material flows discharged from the upper portion of the acid trap to feeding ports at different positions of the esterification tower through the valve combination, and carrying out separation and subsequent refining in the esterification tower to reduce the acidity of the acetate. The acetate obtained through adopting the method accords with product acidity requirements of corresponding product standards.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

A Control Method for Alternating Cathodic Protection of Grounding Electrodes in DC Transmission

The invention relates to a control method for realizing the cathodic protection of the DC transmission ground electrode, which is improved on the basis of the constant current control mode of the DC transmission project, and adopts the mode of alternately changing the slight deviation of the current value of one pole to realize the sending end and the receiving end The alternate cathodic protection of the ground electrode reduces the corrosion loss of the ground electrode, greatly prolongs the service life of the ground electrode, and solves the problem of serious corrosion of the ground electrode caused by unbalanced current and other problems.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com