Conveying hose system for salt field

A technology for conveying hoses and salt fields. It is used in pipeline systems, hoses, hose connection devices, etc., and can solve the problems of hard pipes being difficult to bend, hard pipe joints being corroded, and labor intensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

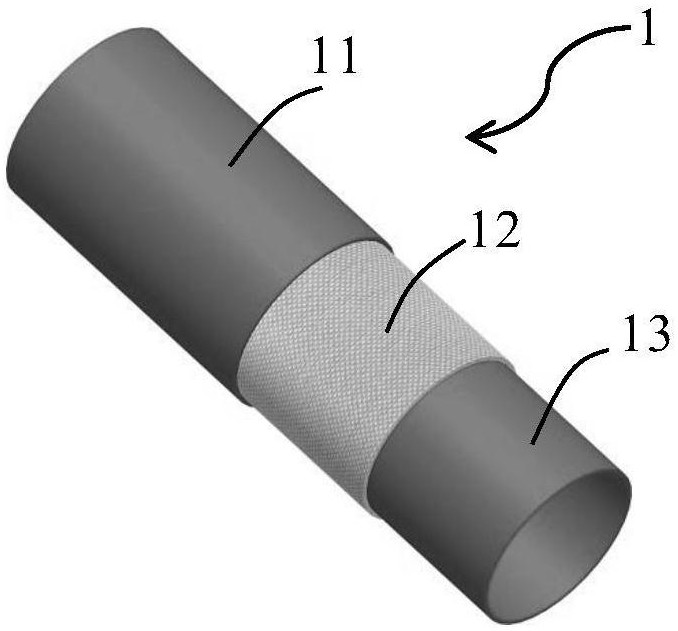

[0034] Such as figure 1 As shown, unlike the PE hard pipe in the prior art, the present invention uses a polyurethane material hose. In a preferred embodiment, this polyurethane hose 1 includes a three-layer structure: a polyurethane inner layer 1, a polyester braided reinforced middle Layer 2 and polyurethane outer layer.

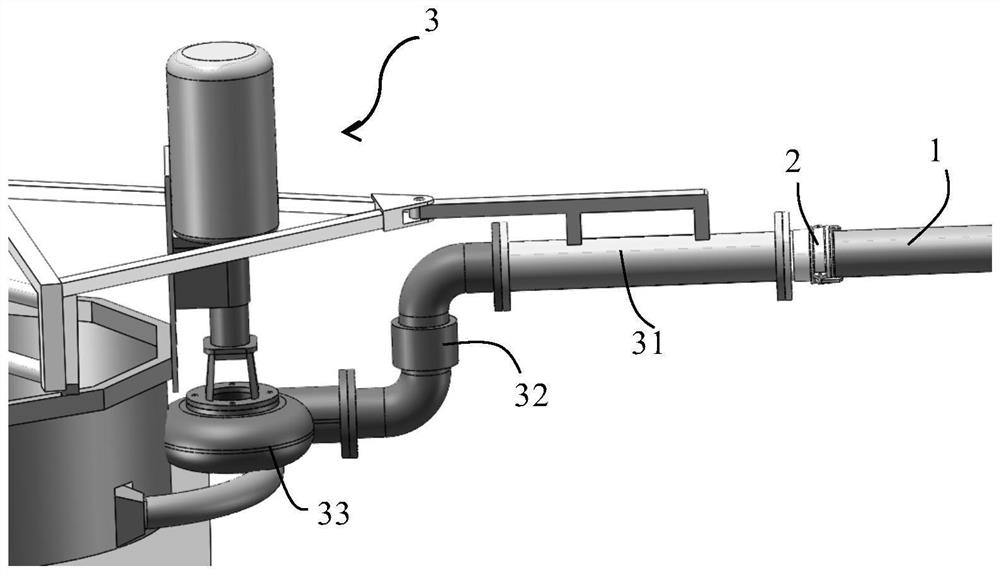

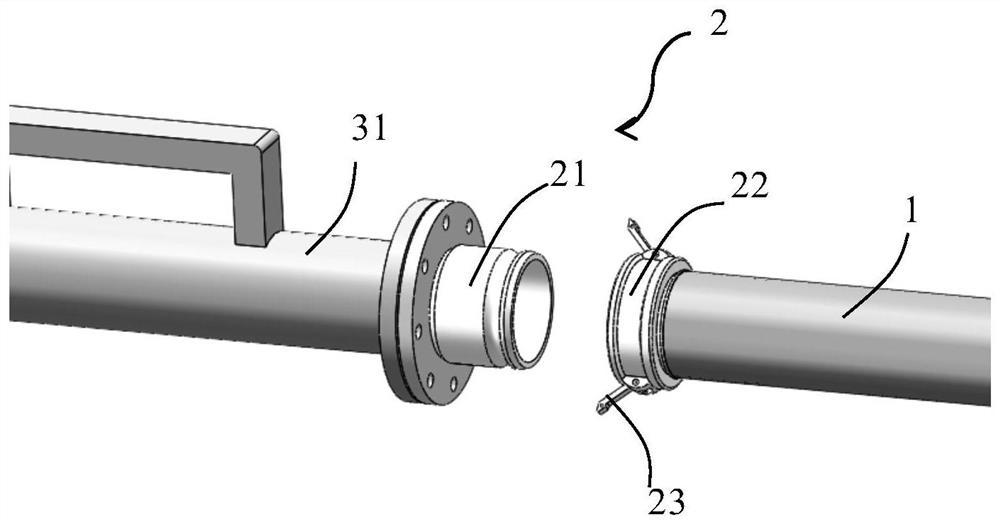

[0035] The connection between the hose 1 and the salt collecting truck 3 is as follows: figure 2 As shown, the pump 33 on the salt collection truck 3 is connected to the transition pipe 31 through the slewing bearing 32 , and the transition pipe 31 is connected to the hose 1 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com