Method for low-temperature smelting of regenerated lead

A technology of regenerated lead and low temperature, which is applied in the field of low temperature smelting of regenerated lead, can solve the problems of not being used in industry, etc., and achieve the effect of increasing service life, high lead recovery rate and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

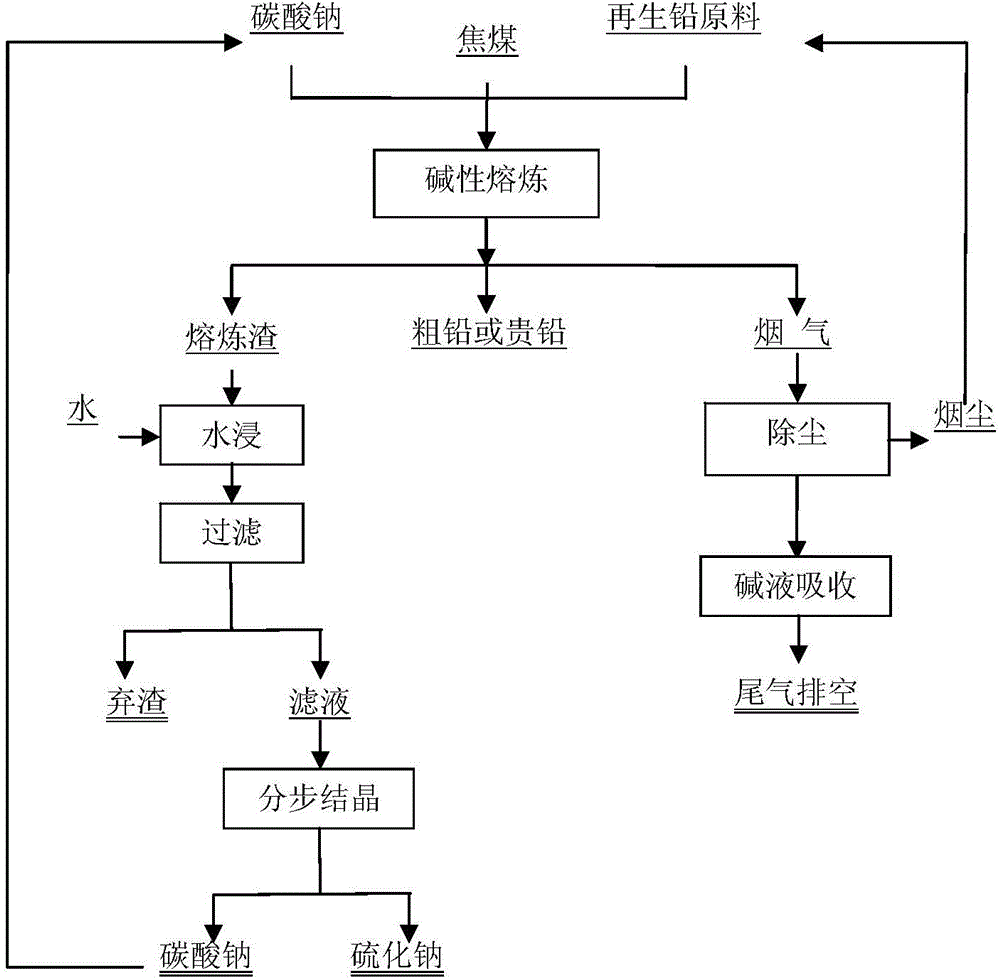

Method used

Image

Examples

Embodiment 1

[0040] Take the waste storage battery cement containing 68.76% lead and mix it with the broken grid containing 93.12% lead, the mixed material is 100kg, containing 76.31% lead. Continuously add the mixed lead material and reduced coal (15kg) into the sodium carbonate (200kg) melt at 900°C, the coke particle size is ≤10mm, and the stirring speed is 200 rpm. Obtain crude lead 72.89kg, lead recovery rate 94.31%, crude lead contains lead 98.74%. Take 50 kg of slag and soak it in 150 L of water at normal temperature, recover sodium carbonate and sodium sulfide step by step, concentrate and crystallize step by step to obtain 10 kg of sodium sulfide product, and the sulfur fixation rate exceeds 90%.

Embodiment 2

[0042] Take waste battery cement containing 68.76% lead and mix it with sulfide ore powder containing 20.14% lead and Au 4g / t. The mixed material is 100kg and contains 50.12% lead. Continuously add the mixed lead material and reduced coal (15kg) into the sodium carbonate (200kg) melt at 900°C, the coke particle size is ≤10mm, the stirring speed is 100 rpm, after adding the materials, keep it at 900°C for 0.5 hours, and the product is produced 47.08kg of crude lead was obtained, the lead recovery rate was 93.11%, the crude lead contained 99.12% lead, the crude lead contained Au 8.2g / t, and the direct gold recovery rate was 97.67%. Take 50 kg of slag and soak it in 150 L of water at normal temperature, recover sodium carbonate and sodium sulfide step by step, concentrate and crystallize step by step to obtain 18 kg of sodium sulfide product, and the sulfur fixation rate exceeds 90%.

Embodiment 3

[0044] Take the waste battery cement containing 68.76% lead and mix it with lead chloride slag containing 30.58% lead and Au 93.18g / t. The mixed material is 100kg, containing 60.48% lead and 12.14g / t gold. Continuously add the mixed lead material and reduced coal (15kg) into the sodium carbonate (200kg) melt at 900°C, the coke particle size is ≤10mm, the stirring speed is 100 rpm, after adding the materials, keep it at 900°C for 0.5 hours, and the product is produced 55.55kg of crude lead was obtained, the lead recovery rate was 90.21%, the crude lead contained 98.21% lead, the crude lead contained Au22.8g / t, and the direct gold recovery rate was 98.89%. Take 50kg of slag and soak it in 150L of water at normal temperature, recover sodium carbonate and sodium sulfide step by step, concentrate and crystallize step by step to obtain 13kg of sodium sulfide product, and the sulfur fixation rate exceeds 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com