Method for reducing acidity of acetate

A technology of acetate and acetic acid, which is applied in the field of acetate synthesis technology, can solve the problems of high cost, avoid costs, solve serious corrosion problems, and have simple processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

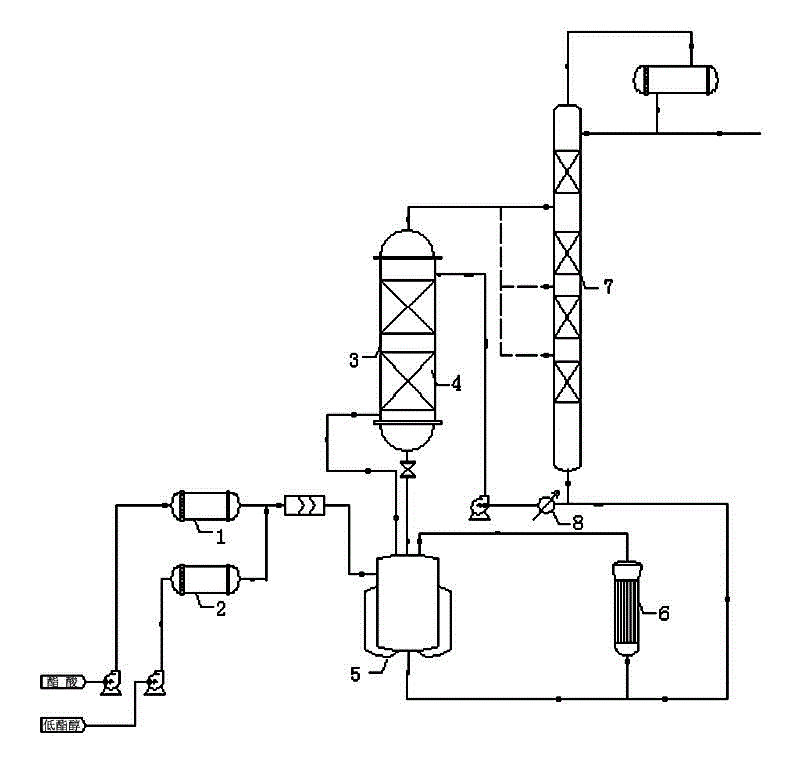

[0024] A method for reducing the acidity of n-butyl acetate, mainly using acetic acid and n-butanol as raw materials, continuously pumping them into the acetic acid preheater 1 and n-butanol preheater 2 respectively, and feeding them into the esterification kettle 5 after preheating and mixing , using concentrated sulfuric acid as a catalyst, carry out esterification reaction at a temperature of 120±5°C in a loop formed by esterification kettle 5 and reboiler 6, to prepare n-butyl acetate;

[0025] The n-butyl acetate formed by the esterification reaction in the loop forms an azeotrope with water and n-butanol. The boiling point of the azeotrope is 90.7°C. Entering the lower part of the acid trap 3 lined with polytetrafluoroethylene, the gaseous phase stream carries part of acetic acid and a small amount of sulfuric acid when entering the acid trap 3 .

[0026] The gaseous phase flows upward through the ceramic packing layer 4 in the acid trap 3 lined with polytetrafluoroethyl...

Embodiment 2

[0034] A method for reducing the acidity of ethyl acetate, mainly using acetic acid and alcohol (the main component is ethanol) as raw materials, continuously pumping them into the acetic acid preheater 1 and the ethanol preheater 2 respectively, and feeding the ester after preheating and mixing Reactor 5, using concentrated sulfuric acid as a catalyst, carries out esterification reaction in a loop formed by esterification kettle 5 and reboiler 6 to prepare ethyl acetate;

[0035] Ethyl acetate formed by the esterification reaction in the loop forms an azeotrope with water and ethanol. The boiling point of the azeotrope is 70.2°C. It is evaporated in the form of gas phase and enters the inner lining through the gas phase outlet at the top of the esterification kettle 5. At the lower part of the acid trap 3 of polytetrafluoroethylene, the gaseous phase flow carries part of acetic acid and a small amount of sulfuric acid when it enters the acid trap 3 .

[0036] The gas phase st...

Embodiment 3

[0047] A method for reducing the acidity of n-propyl acetate, mainly using acetic acid and n-propanol as raw materials, continuously pumping them into the acetic acid preheater 1 and n-propanol preheater 2 respectively, and passing them into the esterification kettle 5 after preheating and mixing , using concentrated sulfuric acid as a catalyst, carry out esterification reaction in a loop formed by esterification kettle 5 and reboiler 6, to prepare n-propyl acetate;

[0048] The n-propyl acetate formed by the esterification reaction in the loop forms an azeotrope with water and n-propanol. The boiling point of the azeotrope is 82.2°C. Entering the lower part of the acid trap 3 lined with polytetrafluoroethylene, the gaseous phase stream carries part of acetic acid and a small amount of sulfuric acid when entering the acid trap 3 .

[0049] The gas phase stream passes upwards through the ceramic packing layer 4 in the acid trap 3 lined with polytetrafluoroethylene, and carries ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com